Copper-based alloy tube containing silicon and aluminium and preparation method thereof

A technology of copper-based alloy and alloy tube, which is applied in the field of copper-based alloy tube and its preparation, can solve the problems of endangering human health, affecting the environment, lead intrusion or protruding out, etc., and achieve the effect of improving cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

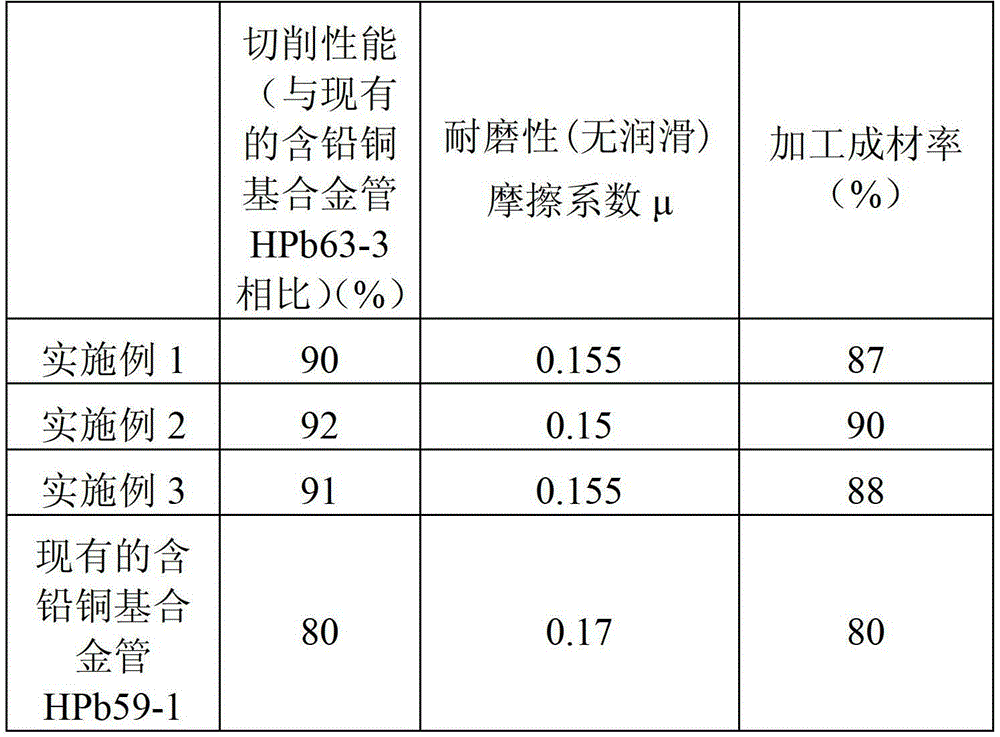

Examples

Embodiment 1

[0027] A copper-based alloy tube containing silicon and aluminum, consisting of the following components: copper accounting for 60% of the total weight of the alloy tube, silicon accounting for 4% of the total weight of the alloy tube, aluminum accounting for 4% of the total weight of the alloy tube, and the balance for zinc.

[0028] Place electrolytic copper, silicon, aluminum, and zinc in a power frequency electric furnace according to the above ratio, heat to 1150-1200 degrees, and keep warm to 1100 degrees after completely melting; after fully stirring the completely melted alloy liquid with a graphite rod, It is covered with high-purity scaly graphite powder to prevent its oxidation, and its thickness is about 10-15cm; after 1-1.5 hours of heat preservation, the samples taken out of the furnace are inspected 3-6 times with a German imported Spike direct-reading spectrometer , to determine that the alloy composition is within the specified range; after further heat preser...

Embodiment 2

[0031] A copper-based alloy tube containing silicon and aluminum, consisting of the following components: copper accounting for 65% of the total weight of the alloy tube, silicon accounting for 7% of the total weight of the alloy tube, aluminum accounting for 8% of the total weight of the alloy tube, and the balance for zinc.

[0032] Place electrolytic copper, silicon, aluminum, and zinc in a power frequency electric furnace according to the above ratio, heat to 1150-1200 degrees, and keep warm to 1100 degrees after completely melting; after fully stirring the completely melted alloy liquid with a graphite rod, It is covered with high-purity scaly graphite powder to prevent its oxidation, and its thickness is about 10-15cm; after 1-1.5 hours of heat preservation, the samples taken out of the furnace are inspected 3-6 times with a German imported Spike direct-reading spectrometer , to determine that the alloy composition is within the specified range; after further heat preser...

Embodiment 3

[0035] A copper-based alloy tube containing silicon and aluminum, consisting of the following components: copper accounting for 62.5% of the total weight of the alloy tube, silicon accounting for 5.5% of the total weight of the alloy tube, aluminum accounting for 6% of the total weight of the alloy tube, and the balance for zinc.

[0036] Place electrolytic copper, silicon, aluminum, and zinc in a power frequency electric furnace according to the above ratio, heat to 1150-1200 degrees, and keep warm to 1100 degrees after completely melting; after fully stirring the completely melted alloy liquid with a graphite rod, It is covered with high-purity scaly graphite powder to prevent its oxidation, and its thickness is about 10-15cm; after 1-1.5 hours of heat preservation, the samples taken out of the furnace are inspected 3-6 times with a German imported Spike direct-reading spectrometer , to determine that the alloy composition is within the specified range; after further heat pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com