Brass alloy rod using silicon and aluminum elements to inhibit lead release and preparation method thereof

A technology of brass alloys and elements, applied in the field of alloy rods, can solve the problems of difficult processing, pollution of lead-containing alloy rods, and inability to meet the needs of environmental protection, etc., to achieve the effect of inhibiting lead dissolution and improving cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

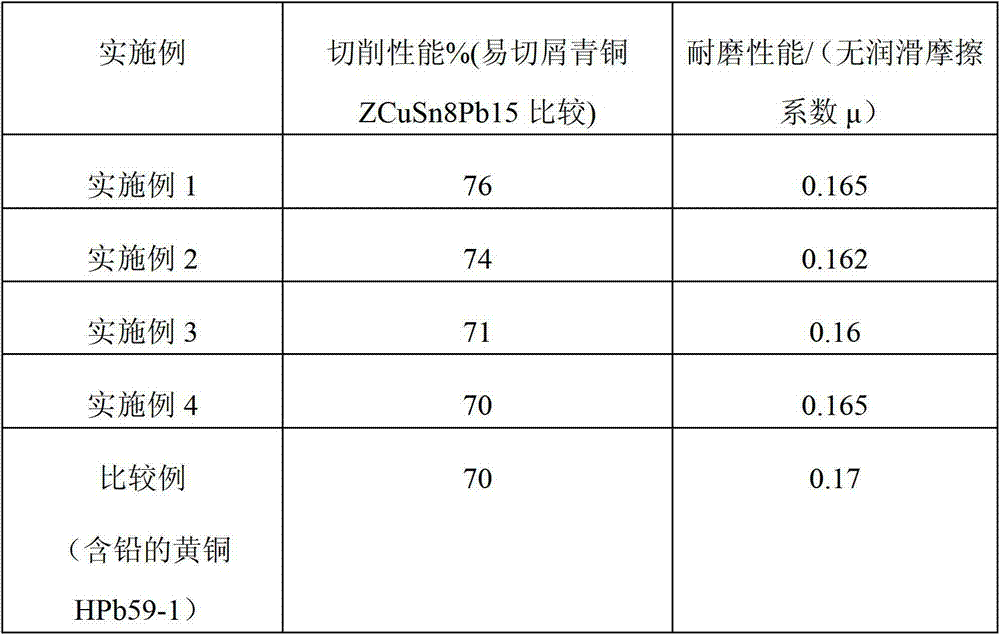

Examples

Embodiment 1

[0021] A brass alloy rod using silicon-aluminum elements to suppress lead dissolution, comprising the following components in weight percentages: 60%-65% copper, 4%-7% silicon, 4-8% aluminum, and the balance zinc. The preparation method is as follows: according to the above ratio, put each component in a power frequency electric furnace, heat it to 1150-1220 degrees and completely melt it, then keep it warm to 1100-1150 degrees; use a graphite rod to fully stir the completely melted alloy liquid , covered with high-purity flaky graphite powder to prevent its oxidation, the thickness is about 10-15cm; after the holding time of 1-2h, use the German imported Spike direct reading spectrometer to test the sample taken out of the furnace 3-6 times Sub-component inspection to ensure that the alloy composition is within the specified range; after further heat preservation for 50-60 minutes, the temperature is raised to 1200 degrees again, and the vibration device of the power frequency...

Embodiment 2

[0024] A brass alloy rod using silicon and aluminum elements to suppress the dissolution of lead is composed of the following components in weight percentage: 62.3% copper, 5.4% silicon, 6.2% aluminum, and the balance zinc. The preparation method is as follows: according to the above ratio, put each component in a power frequency electric furnace, heat it to 1150-1220 degrees and completely melt it, then keep it warm to 1100-1150 degrees; use a graphite rod to fully stir the completely melted alloy liquid , covered with high-purity flaky graphite powder to prevent its oxidation, the thickness is about 10-15cm; after the holding time of 1-2h, use the German imported Spike direct reading spectrometer to test the sample taken out of the furnace 3-6 times Sub-component inspection to ensure that the alloy composition is within the specified range; after further heat preservation for 50-60 minutes, the temperature is raised to 1200 degrees again, and the vibration device of the power...

Embodiment 3

[0027] A brass alloy rod using silicon-aluminum elements to suppress lead dissolution, consisting of the following components in weight percentages: 60%-65% copper, 4%-7% silicon, 4-8% aluminum, 1-3% iron, Balance Zinc. The preparation method is as follows: put each component in a power frequency electric furnace according to the above ratio, heat it to 1150-1220 degrees and completely melt it, then keep it warm to 1100-1150 degrees; stir the completely melted alloy liquid with a graphite rod , covered with high-purity flaky graphite powder to prevent its oxidation, the thickness is about 10-15cm; after the holding time of 1-2h, use the German imported Spike direct reading spectrometer to test the sample taken out of the furnace 3-6 times Sub-component inspection to ensure that the alloy composition is within the specified range; after further heat preservation for 50-60 minutes, the temperature is raised to 1200 degrees again, and the vibration device of the power frequency e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com