A combined multi-stage mud debris drill bit

A combined type, drill bit technology, applied in construction and other directions, can solve the problems of difficult formation of debris, high viscosity, difficult ideal particle size, etc., to achieve the effect of facilitating discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

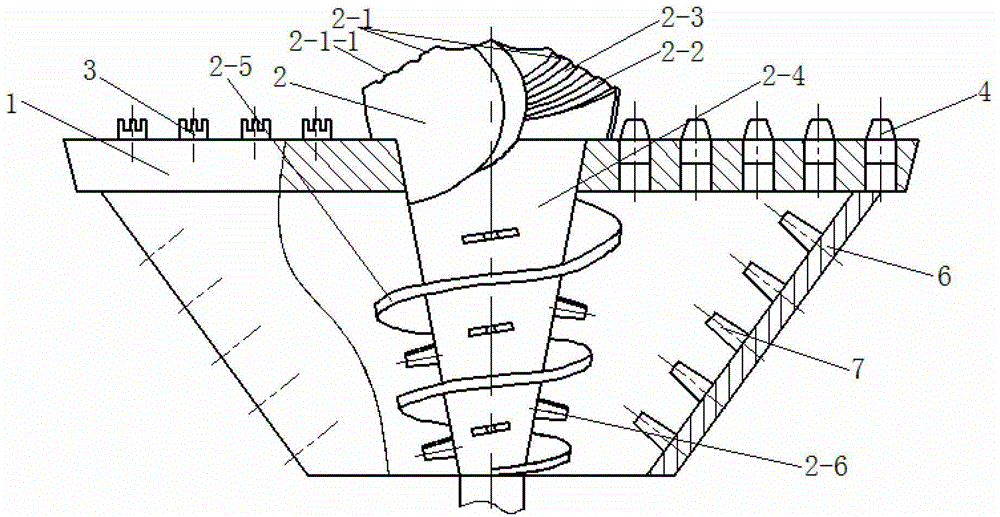

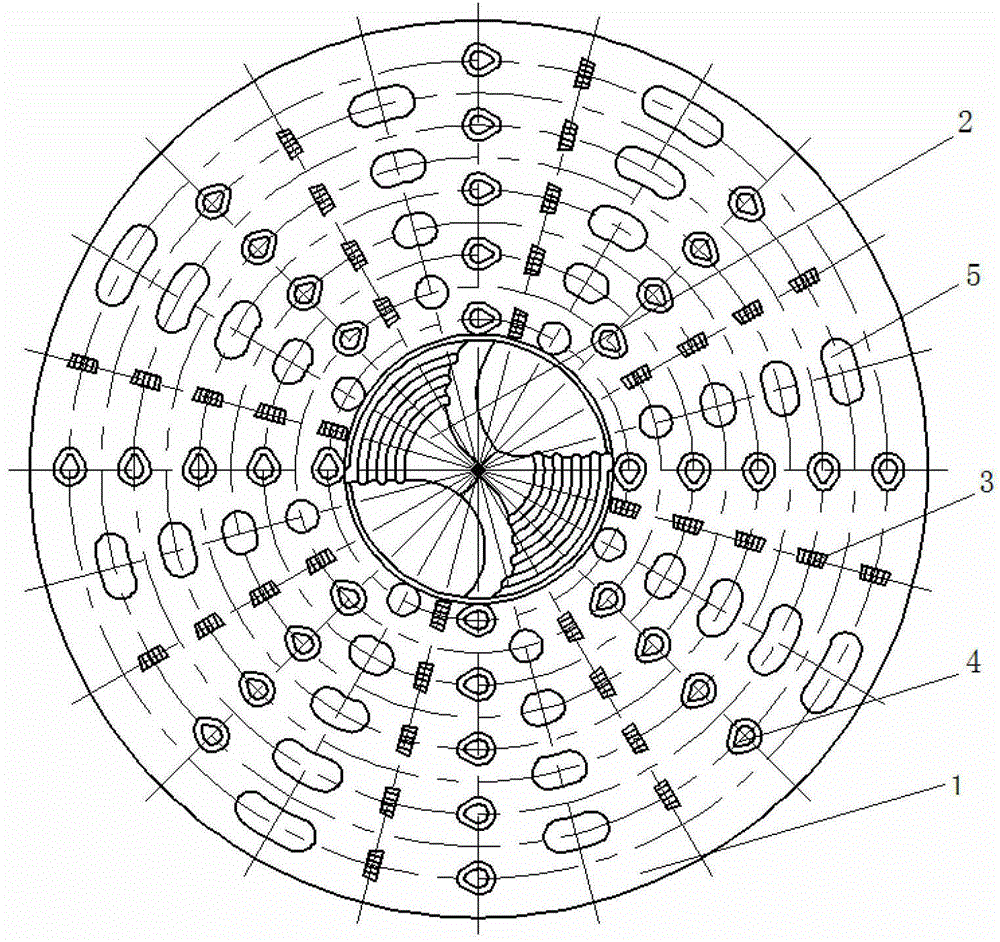

[0029] See figure 1 and figure 2 , a combined multi-stage debris drill bit in this embodiment includes an upper cutter head 1, a centering drill bit 2, 36 blades 3, 36 crushing teeth 4, 36 chip removal holes 5, a conical disc 6 and Five cutting teeth7.

[0030]The centering drill bit 2 is loaded into the tapered hole in the middle of the upper cutter head 1, and the contact circumference is welded. The two main edges 21 of the centering bit 2 are left-right symmetrical arc edges; Asymmetrically provided with a plurality of variable-pitch helical chipbreakers 2-3 on the connected flank 2-2; each main edge 2-1 of the centering drill bit 2 is composed of a plurality of short sections with a length not exceeding 30mm. Edge 2-1-1; chip breaker 2-3 is arranged between two sections of short edges 2-1-1, and the groove width of each chip breaker 2-3 is no more than 30mm. The centering drill bit 2 is located at the lower part of the upper cutter head 1 and is a cone rod 2-4, and th...

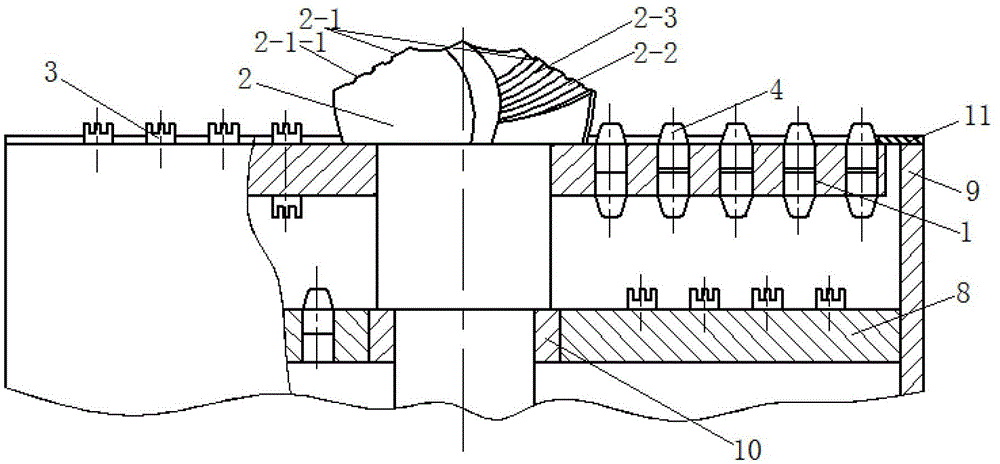

Embodiment 2)

[0038] The difference between the combined multi-stage debris drill bit in this embodiment and the embodiment 1 lies in the secondary crushing chamber, which is composed of the lower cutter head 8 , the outer sleeve 9 and the upper cutter head 2 . A sliding bearing 10 is installed between the centering drill bit 2 and the lower cutter head 8; the inner hole of the sliding bearing 10 and the centering drill bit 2 are clearance fit, and the outer circle and the lower cutter head 8 are an interference connection. The upper cutterhead 1 and the lower cutterhead 8 are connected by an outer sleeve 9; the bottom surface of the upper cutterhead 1 is provided with 36 blades 3, 36 crushing teeth 4 and 36 corresponding to the upper surface of the upper cutterhead 1. Chip removal holes 5; the upper surface of the lower cutter head 8 is provided with 36 blades 3, 36 crushing teeth 4 and 36 chip removal holes 5 according to the same rule on the bottom surface of the upper cutter head 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com