Method for manufacturing electromagnetic wire

A production method and technology of electromagnetic wire, applied in the direction of conductor/cable insulation, etc., can solve the problems of large difference in coating film thickness, unevenness, water pollution, etc., to improve the appearance and leveling of the coating film, and improve the electrical insulation performance , The effect of uniform spraying thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

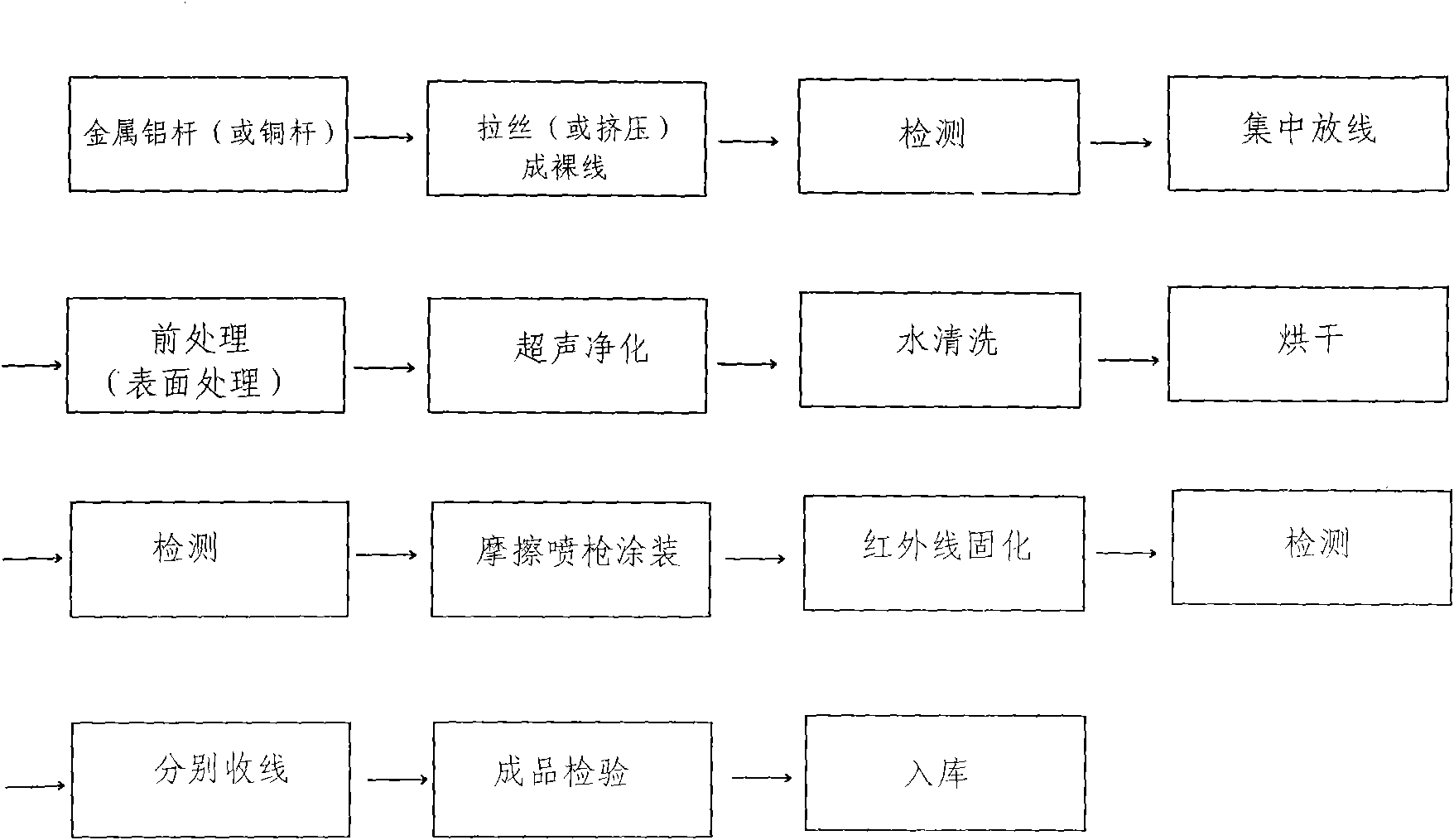

Method used

Image

Examples

Embodiment 1

[0030] Take 20-40 copper-aluminum bare wires that have been drawn or extruded and pre-treated, and arrange them in parallel at a certain interval. Use a triboelectric charge spray gun to spray a polymeric polymer coating with a special formula. 2-4 minutes of leveling, cross-linking and curing to obtain a relatively uniform thickness of the coating film (50-80 microns), good mechanical properties, chemical resistance and electrical insulation properties of the coating film (breakdown voltage greater than 3 kV), can completely replace enameled wire Electrically insulating coatings for electromagnetic wires such as silk-covered wires.

Embodiment 2

[0032] Take 20-40 copper and aluminum bare wires that have been drawn or extruded and pre-treated, and arrange them in parallel at a certain interval. Use a triboelectric charge spray gun to spray a polyester resin powder coating with a special formula. ℃ / 2~4min leveling, cross-linking and curing to obtain a relatively uniform thickness of the coating film (50-80 microns), good mechanical properties, chemical resistance and electrical insulation properties of the coating film (breakdown voltage greater than 3 kV), it is completely ok Substitutes electrical insulating coatings for various magnet wires and enameled wires.

Embodiment 3

[0034] Take 20-40 copper and aluminum bare wires that have been drawn or extruded and pre-treated, arrange them at a certain interval, spray polyurethane powder coating with a special formula with a triboelectric charge spray gun, and bake them at 200 ° C for 3 ~6min leveling, cross-linking and curing to obtain a relatively uniform coating film thickness (50-80 microns), good mechanical properties, chemical resistance and electrical insulation properties of the coating film (breakdown voltage greater than 3 kV), and can completely replace various Electrically insulating coatings for magnet and enamelled wires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com