Inner-cooling composite rotating direction dry type cutting milling cutter

A dry cutting and milling cutter technology, applied in the direction of milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of poor surface finish, low processing efficiency, and poor heat dissipation effect of the processed workpiece, so as to suppress the generation of built-up edge and eliminate Chips are smooth and easy to dissipate heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

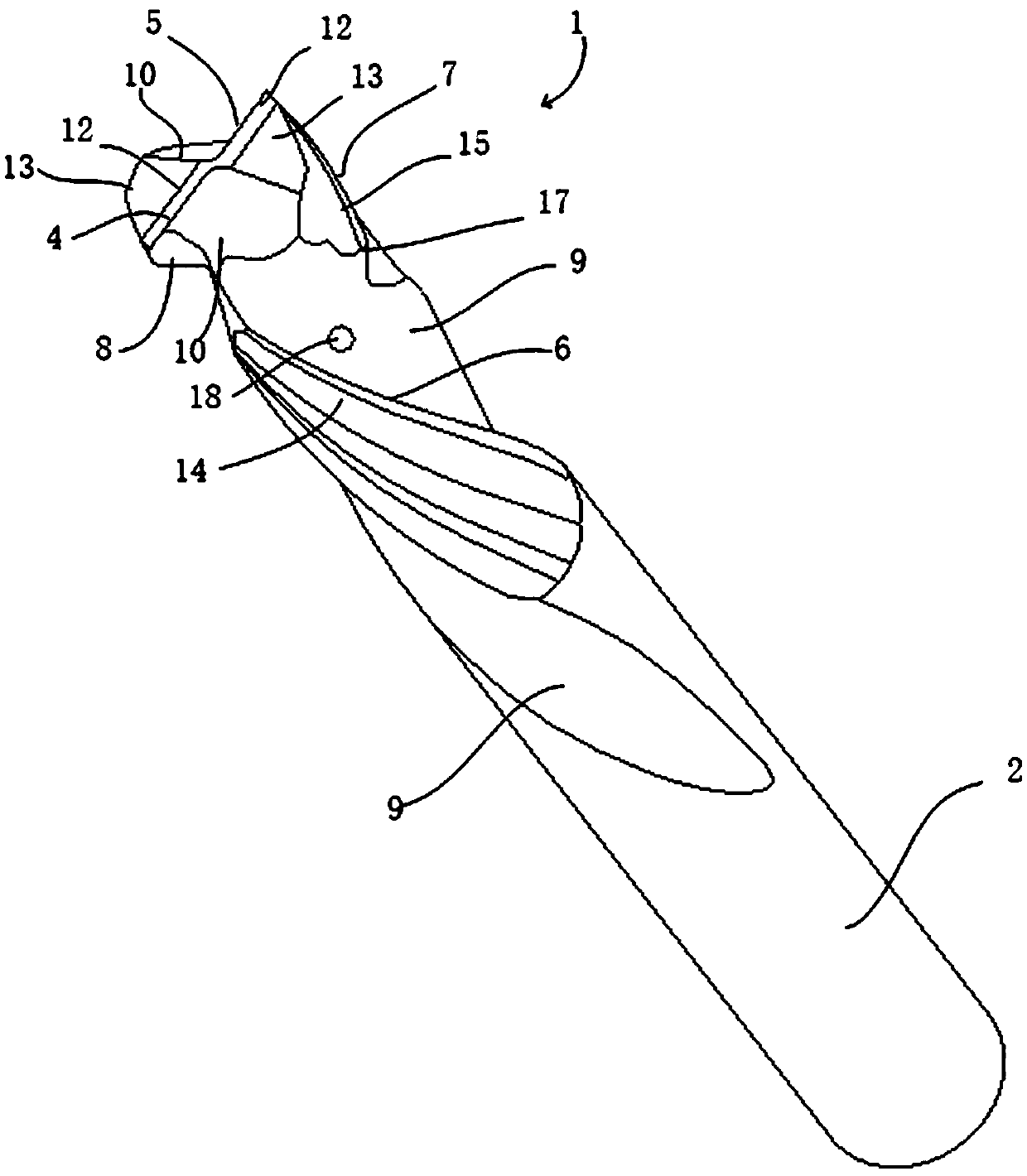

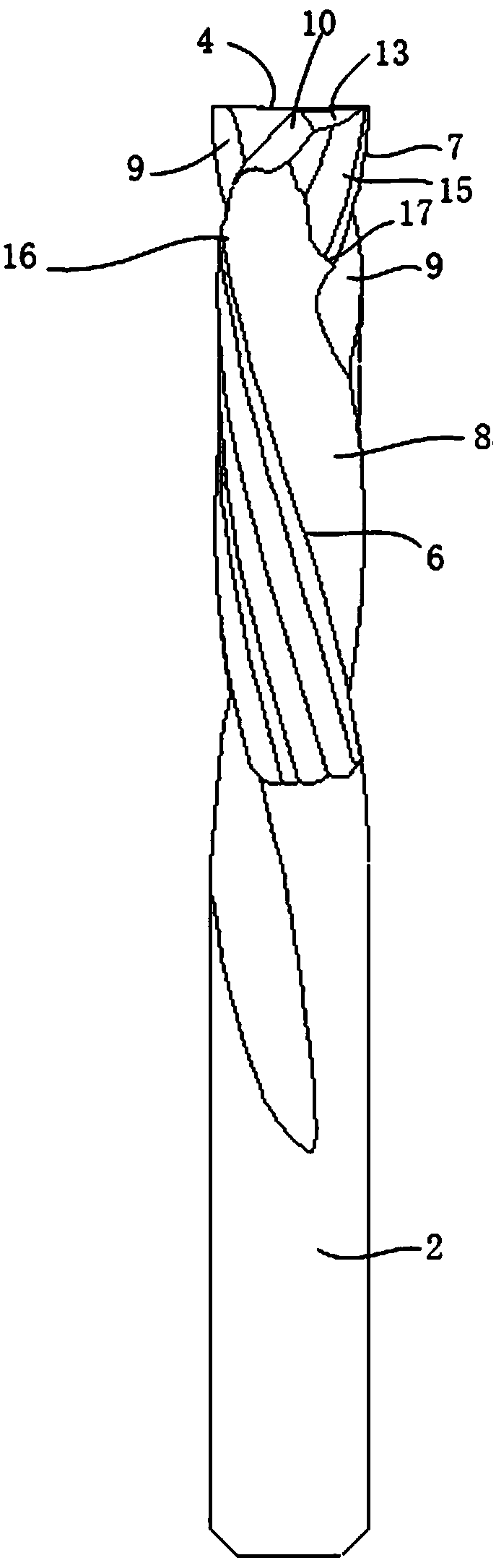

[0030] Example 1, such as Figure 1-3 As shown, a kind of internal cooling composite rotary dry cutting milling cutter is used for processing flat bottom grooves, including a cutter head 1 and a handle 2 made of hard alloy, the diameter of the handle 2 is 6mm, and the cutter head 1 is composed of two Each cutting seat 3 consists of an end edge, a right-handed right cutting edge 7 and a left-handed right edge 6. The end edge is a straight edge with a blade inclination angle of 2°, which is used for cutting the bottom of a plane hole, and the end edge There is an end tooth chip pocket 10 in front of the edge for chip removal at the end, and two end edge flanks are arranged behind the end edge, including an end edge flank 12 and an end edge rear flank arranged in sequence behind the end edge. Cutter face two 13, the relief angle of end edge flank one 12 is 12°, and the relief angle of end edge flank two 13 is 22°; The front of the right-handed cutting edge 7 is provided with a r...

Embodiment 2

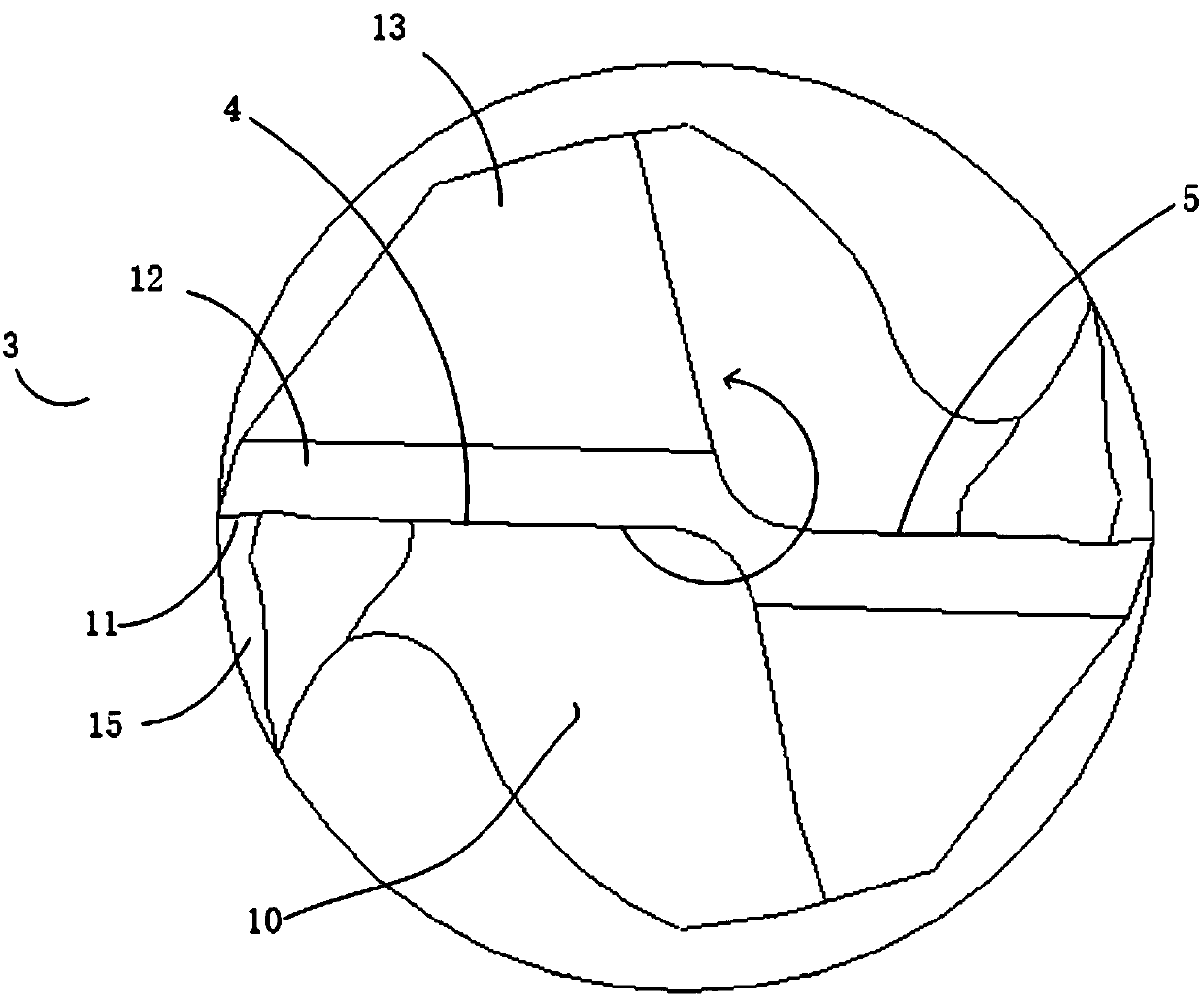

[0032] Embodiment 2, since the cutter head 1 is provided with two end edges, in order to avoid chip accumulation in the center of the hole bottom surface, such as image 3 As shown, on the basis of Embodiment 1, the lengths of the end edges of the two cutting seats 3 in this embodiment are different, which are respectively the long end edge 4 and the short end edge 5, and the long end edge 4 and the short end edge 5 along the cutting edge The end face of 1 is radially arranged in parallel, and the end point of the long end edge 4 passes through the center of the end face of the cutter head 1, so that the cutting plane of the long end edge 4 and the short end edge 5 can cover the entire hole bottom surface, and the long end edge 4 and the short end edge The end edges 5 do not intersect, so that the chip removal of the two end edges is broken. Specifically, the length of the end point of the long end edge 4 through the center of the end face of the cutter head 1 is 0.2 mm.

Embodiment 3

[0033] Embodiment 3, because the stress at the starting point of cutting is relatively large, in order to increase the sharpness of the cutting edge, such as image 3As shown, in this embodiment, on the basis of embodiment 1 or embodiment 2, the right-handed chip flute 9 intersects with the end edge to form a crescent secondary edge 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com