Patents

Literature

48results about How to "Effective control of production costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

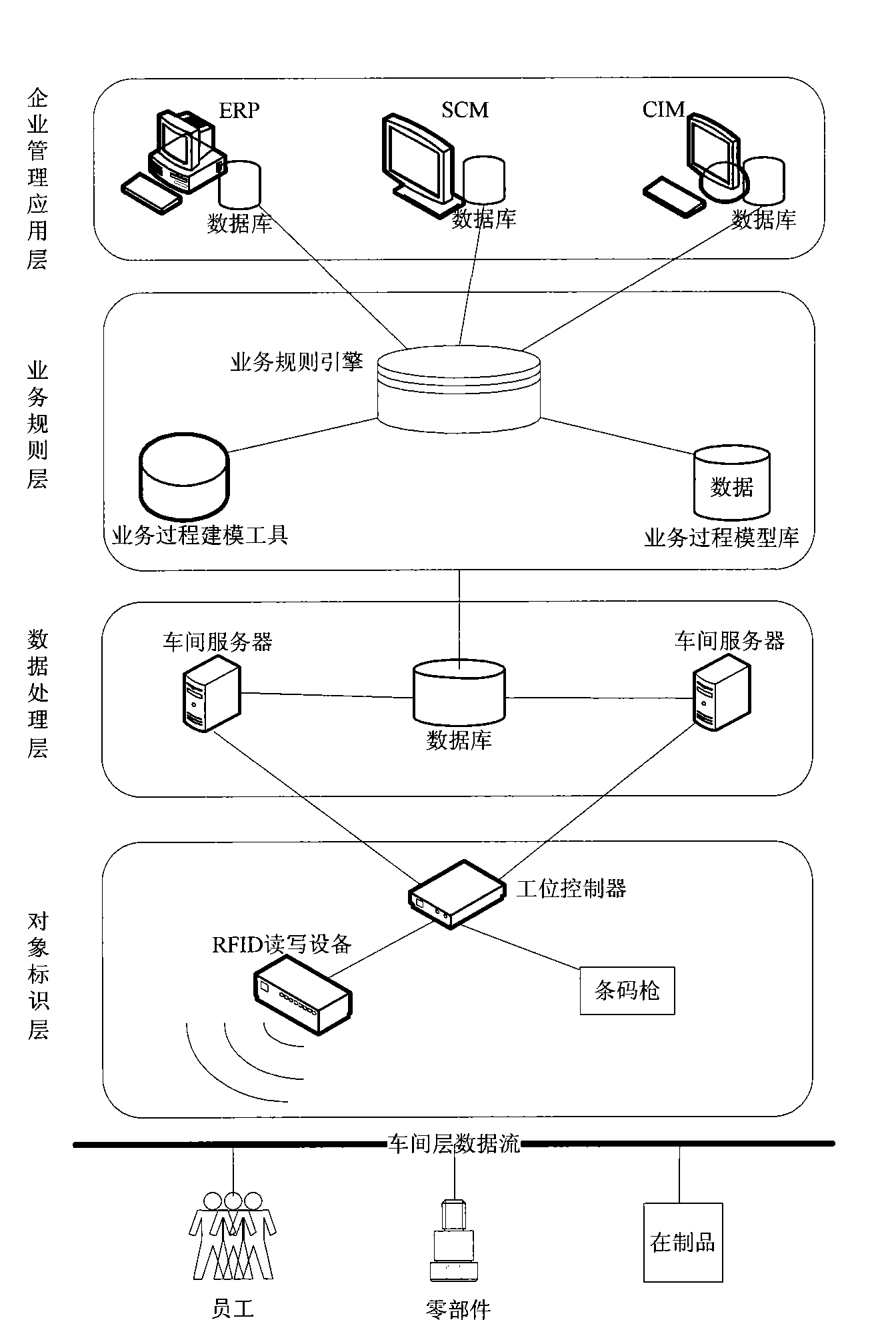

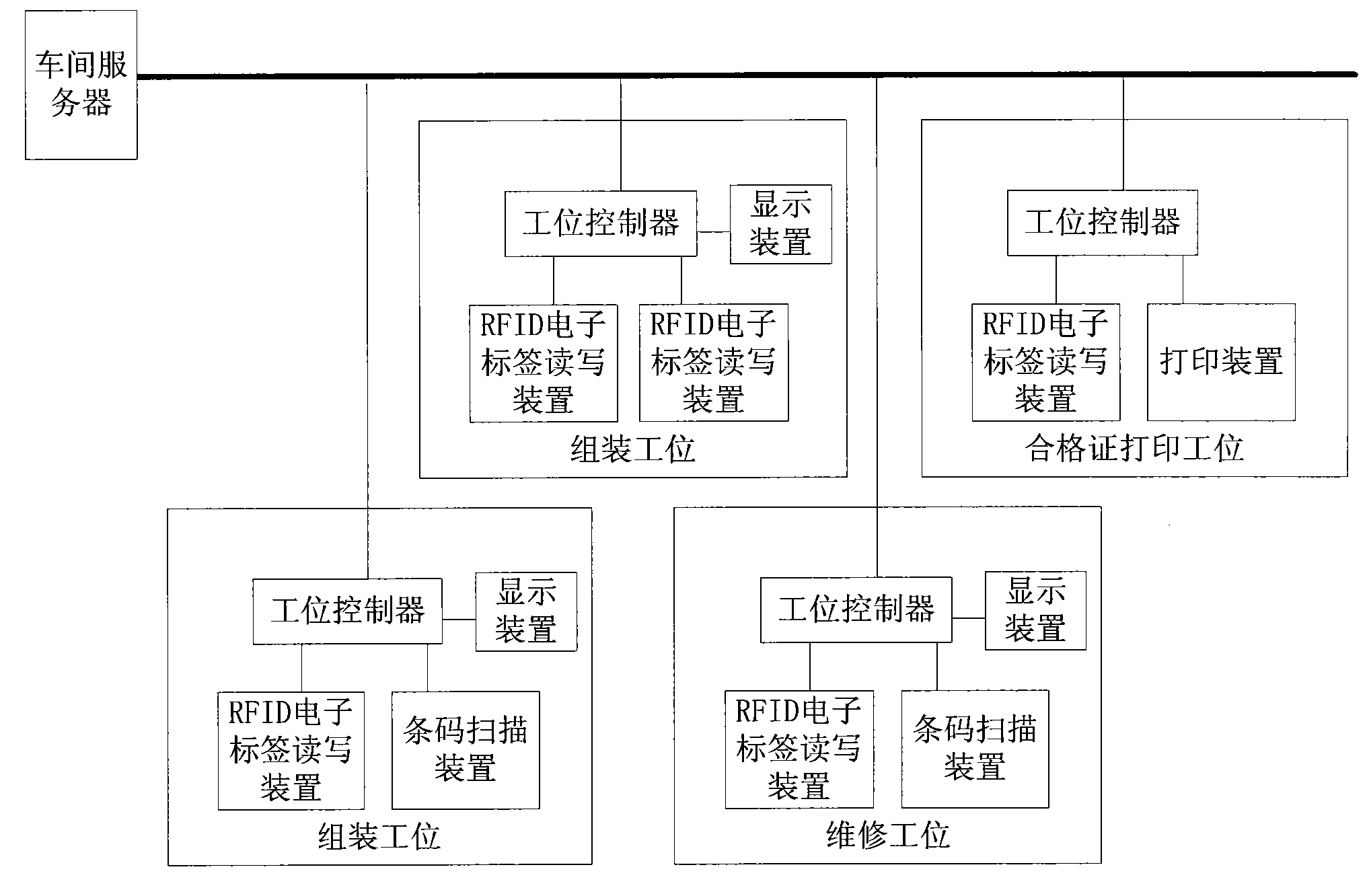

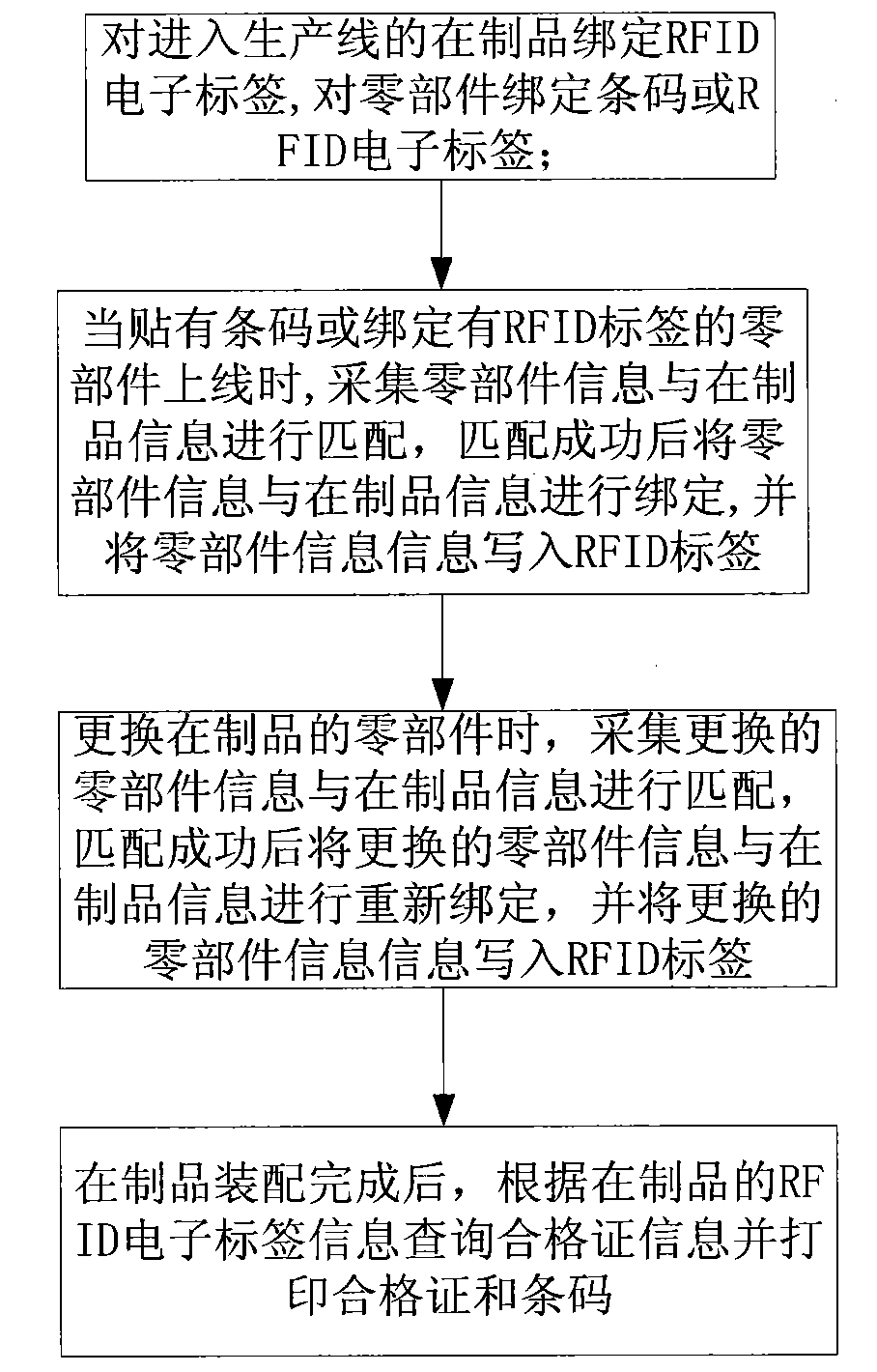

Refinement production system and production method based on RFID and bar code fusion

InactiveCN101655918AEffective cost controlLow costCo-operative working arrangementsRecord carriers used with machinesProduction lineMethods of production

The invention provides a refinement production system and a production method based on RFID and bar code fusion, wherein an RFID electronic tag is bound on the goods in process, the RFID electronic tag or a bar code can be selected randomly to be bound on the components and parts, thus being capable of effectively controlling production cost, being beneficial to carry out real time and effective collection on the information of goods in process and components and parts simultaneously, realizing accurate synchronization of material flow and information flow, and providing a possibility for therealization of refinement production for enterprises. The production method in the invention comprises the following steps: 1) binding the RFID electronic tags on the goods in process which enter a production line, and binding the bar codes or the RFID electronic tags on the components and parts; 2) when the components and parts which are pasted with bar codes or bound with the RFID electronic tags are on the production line, collecting the information of the components and parts to match with the information of the goods in process, and binding the information of components and parts with theinformation of the goods in process after matching successively; and 3) when the products are finally off the line, collecting the RFID electronic tag information which is bound on the goods in process and printing manufacturer certificates and bar codes.

Owner:CHONGQING UNIV

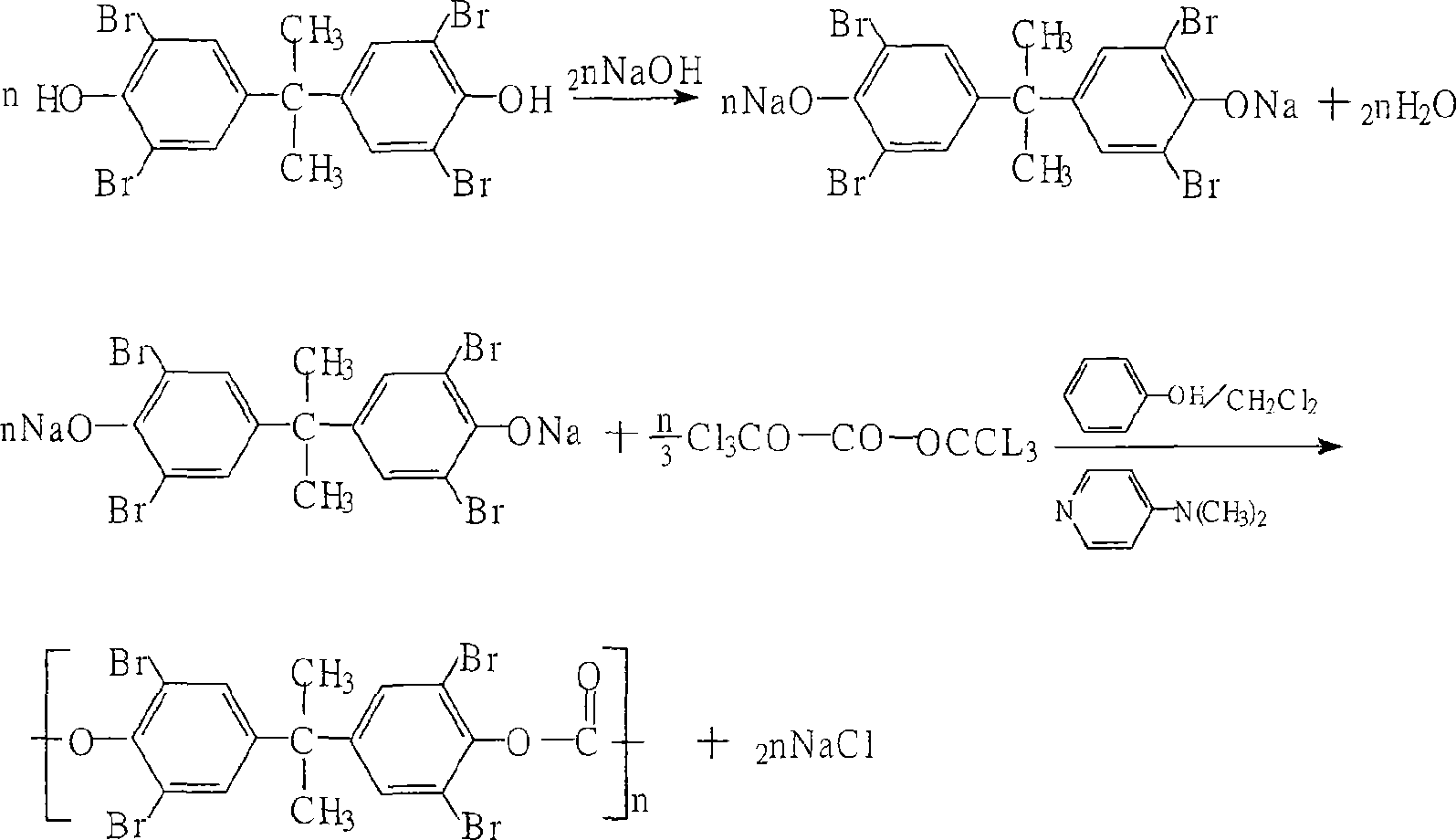

Method for preparing tetrabromo-bisphenol A polycarbonate

The invention relates to a method for preparing molecular tetrabromobisphenol-A polycarbonate. Its character shows as follow: a. it dissolves the tetrabromobisphenol-A and inhibitor in the natrium hydroxydatum, filtering. Then, it dissolves triphosgene in the halogenated alkane, filtring. b. it adds the filtered triphosgene solution to the filtered tetrabromobisphenol-A and inhibitor solution, and then it adds natrium hydroxydatum at room temperature under normal pressure, and maintains the system to be pH9-12, then it stirs the solution for 0.5-1 hours. c. it adds 10%-20% of the natrium hydroxydatum at room temperature under normal pressure, and maintains the system to be pH8-10, then it stirs the solution for 0.5-1 hours. d. it regulates the solution with acid to be neutral and takes out from the organic layer, then it washes the material with deionized water and adds fatty alcohol to precipitate white powder, then it achieves the molecular weight range of 150,000 ~ 250,000 molecular of tetrabromobisphenol-A polycarbonate through filtration and drying.

Owner:TAIZHOU UNIV

Modified zeolite-based soil amendment for saline-alkali land and preparation method thereof

InactiveCN106380288APrevent compactionReduced nutrient release rateCalcareous fertilisersBio-organic fraction processingAlkali soilPhosphate

The invention discloses a modified zeolite-based soil amendment for saline-alkali land. Raw materials of the soil amendment comprise, by weight, 1000-1500 parts of modified zeolite, 1000-1300 parts of polyacrylamide, 1000-1500 parts of chitosan, 800-1200 parts of powdered rock phosphate, 1200-1800 parts of nano-calcium carbonate, 35-50 parts of peat, 10-20 parts of calcium humate, 50-80 parts of magnesium sulfate, 60-90 parts of a compound enzyme preparation and 30-60 parts of ferment bacteria. By the use of the soil amendment for saline-alkali land with modified zeolite as a carrier, nutrient release speed of a fertilizer in soil can be effectively reduced, fertilizer efficiency period is long, and pollution to the environment and water body is reduced. In addition, the product has good functions of holding moisture, loosening soil and preventing soil hardening, etc.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

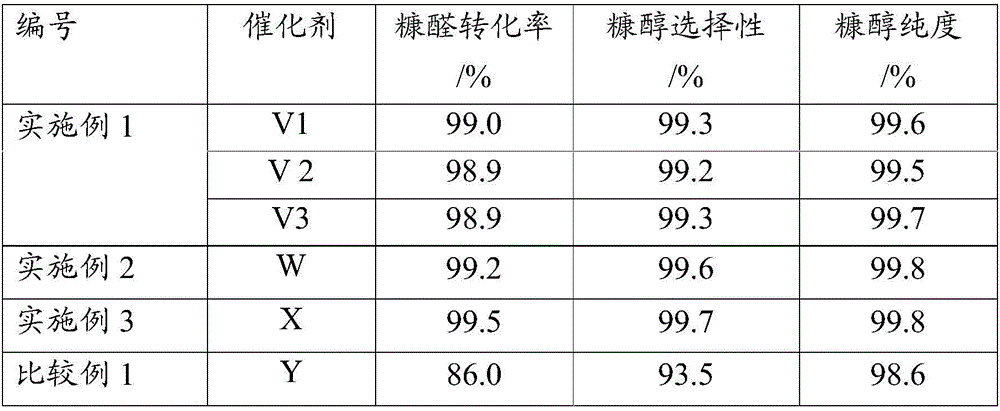

Method for preparing electrical insulating papers containing broadleaf wood fibers

InactiveCN104863022AEasy to operateLow pricePlastic/resin/waxes insulatorsTextiles and paperFiberElectrical performance

The invention relates to a method for preparing electrical insulating papers containing broadleaf wood fibers, which belongs to the technical field of electrical insulating papers, wherein needle-point leaf wood pulp dry pulp boards and broadleaf wood pulp dry pulp boards are immersed in deionized water to soak firstly, and are respectively or commonly defibered and beaten by utilizing a beating machine after being soak, and then two kinds of pulps are mixed and uniformly stirred to obtain paper pulp suspension liquid. The paper pulp suspension liquid is put into a paper page forming device to dehydrate and form, and obtains electrical insulating papers. Wet insulating paper pages are autoclaved to obtain finished electrical insulating papers after being autoclaved and dried. The finished electrical insulating papers are placed in constant temperature and constant humidity environment to store and reserve, the temperature of the constant temperature and constant humidity environment is 25 EDG C, and the relative humidity of the constant temperature and constant humidity environment is 50%. The method for preparing the electrical insulating papers containing the broadleaf wood fibers adds certain proportion of broadleaf wood fibers into needle-point leaf wood insulating papers, is simple in process and easy to operate, has lower price compared with needle-point leaf wood pulps, is obvious in economic advantages, and can effectively reduce production cost under the premise that electrical performance of insulating papers is guaranteed.

Owner:TSINGHUA UNIV

Crystalline glaze for sanitary ceramic sanitary ware and preparation process thereof

The invention discloses crystalline glaze for sanitary ceramic sanitary ware and a preparation process thereof. Proceeded from a process formula, the invention provides novel crystal glaze which meets the requirements of modern ceramic sanitary ware. The crystal glaze is few in type of raw materials required and wide in source and is beneficial for effectively controlling the production cost. The crystalline glaze for sanitary ceramic sanitary ware disclosed by the invention is simple in preparation process. The sintering temperature of the crystalline glaze is controlled at 1170-1230 DEG C, the sintering period is 13-15 hours, the complex process and unique sintering system of crystalline glaze are broken through, and the crystalline glaze for sanitary ceramic sanitary ware is sintered at one time. The crystalline glaze for sanitary ceramic sanitary war is strong in operability and beneficial for energy conservation and environmental protection, and the sintering cost is lowered.

Owner:GUANGDONG DOWSTONE TECH

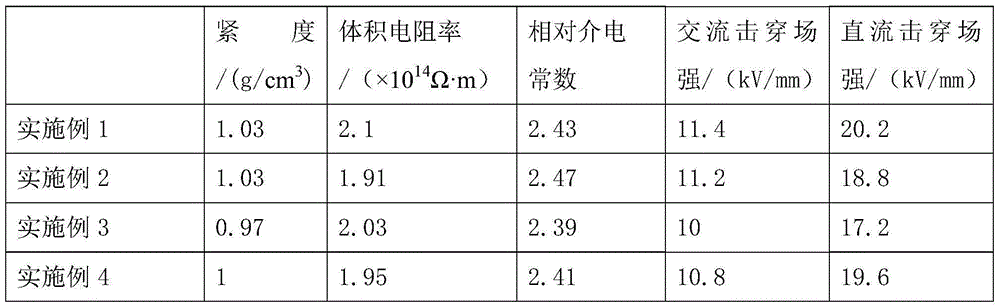

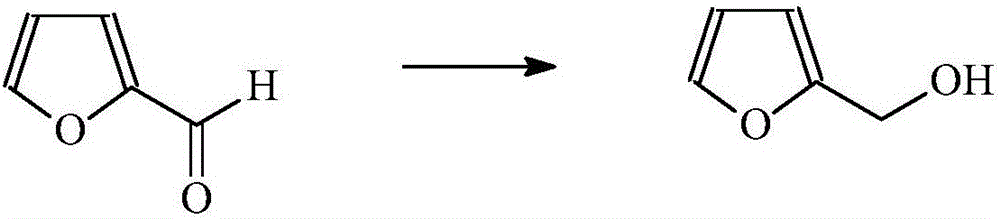

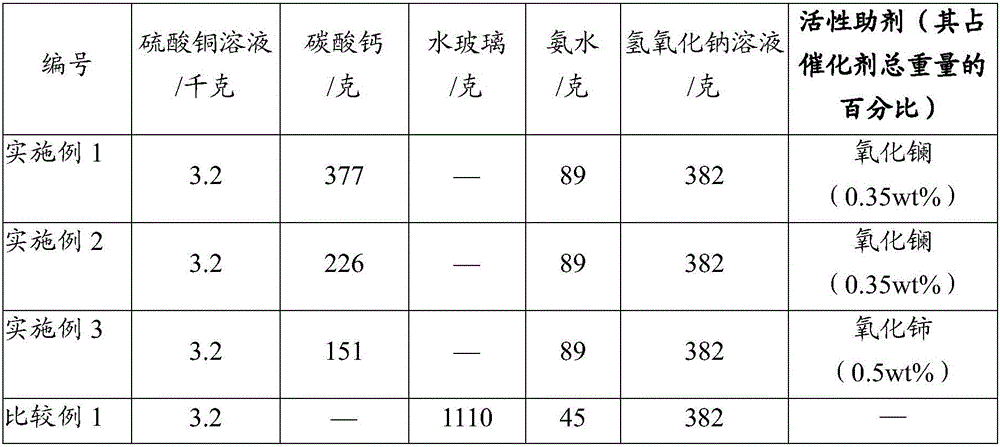

Furfural hydrogenation catalyst containing rare earth elements and preparation method thereof

ActiveCN106732706AAdjust DispersionAdjust granularityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementActive component

The invention discloses a furfural hydrogenation catalyst containing rare earth elements and a preparation method thereof. The catalyst takes calcium carbonate as a carrier, takes copper oxide as an active component and takes a rare earth compound as an active aid; the weight of copper oxide is 28-75wt% of the total weight of the catalyst; the weight of the rear earth compound is 0.1-5wt% of the total weight of the catalyst. According to the furfural hydrogenation catalyst containing rare earth elements and the preparation method thereof, the production cost of the furfural hydrogenation catalyst is effectively controlled; and the furfural hydrogenation catalyst is extremely high in furfural conversion rate and hydrogenation selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +2

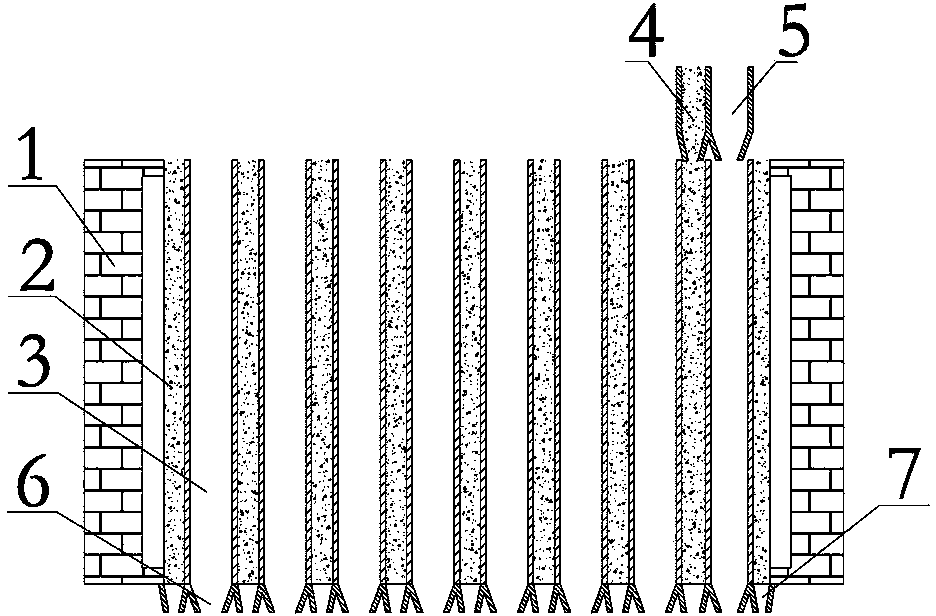

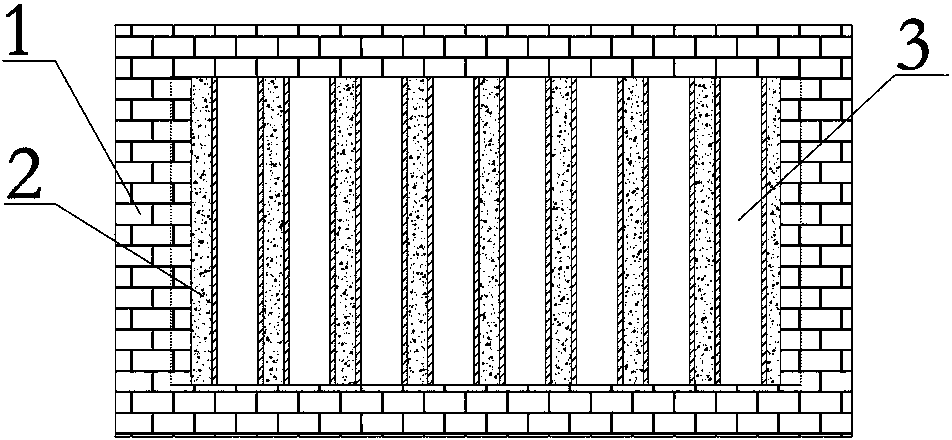

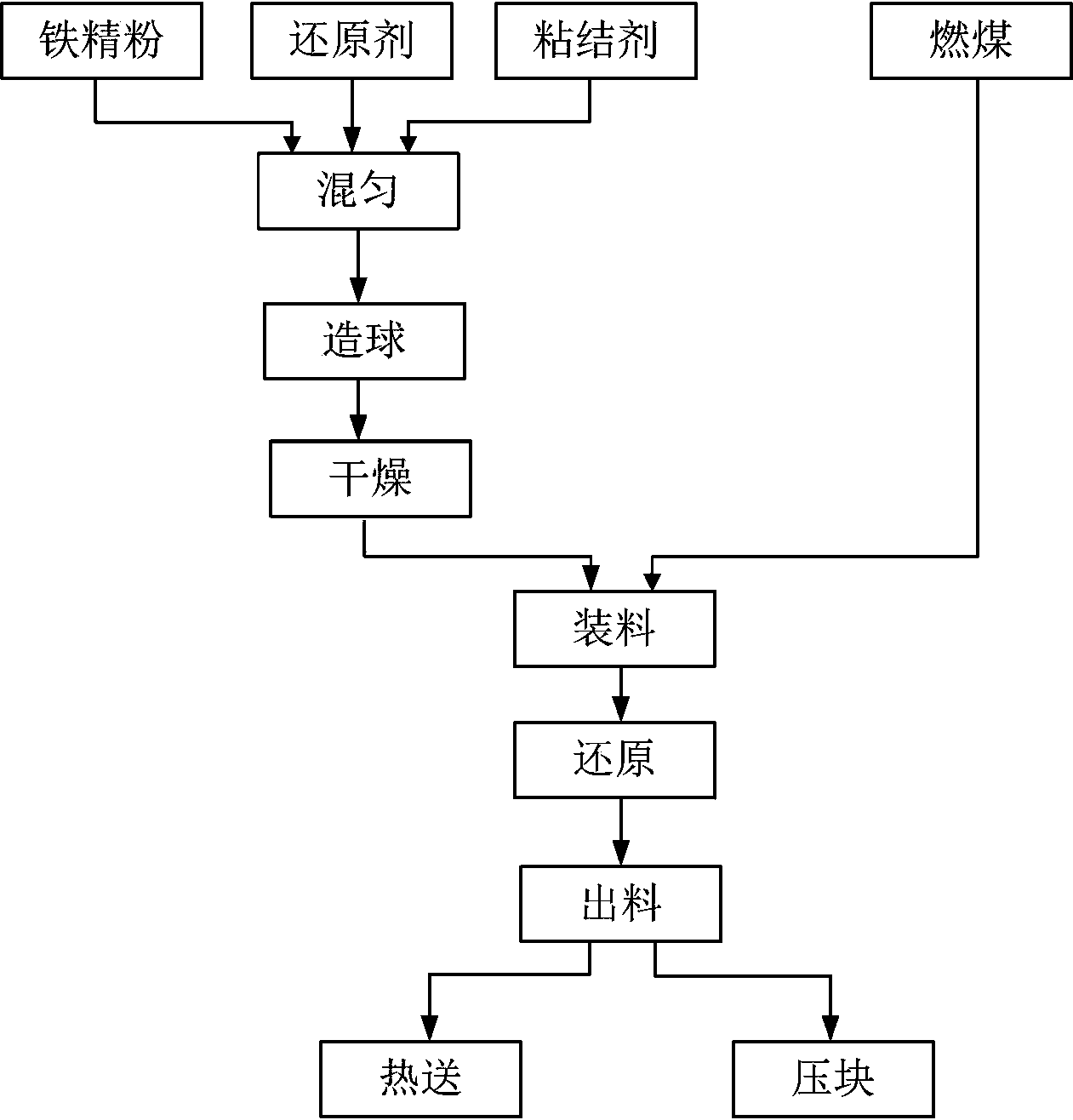

Reducing furnace, and technology for directly reducing coal-containing pellets through preheating outside coal base

InactiveCN103352097AAvoid the fatal flaw of small restoration capacityEvenly heatedFluidised-bed furnacesSteelmakingThermodynamics

The invention provides a reducing furnace. The reducing furnace comprises a furnace wall, at least one reducing tank and at least one combustion tank, and the at least one reducing tank and the at least one combustion tank are alternately arranged. The top of each reducing tank is connected with a raw material feeding device, and the bottom of each reducing tank is provided with a material outlet. The top of each combustion tank is connected with a fuel feeding device, and the bottom of each combustion tank is provided with an ash outlet. The invention also provides a technology for directly heating coal-containing pellets through preheating outside a coal base. The technology comprises the following steps: 1, mixing and pelletizing an iron-containing raw material, coal dust and a binder to obtain coal pellets; and 2, providing the reducing furnace, adding the pellets to the reducing tank(s) through the raw material feeding device(s), adding fire coal to the combustion tank(s) through the fuel feeding device(s), allowing the pellets and the fire coal to independently move from top to bottom, heating and reducing the pellets to form spongy iron, and discharging the spongy iron. The reducing furnace and the reducing technology have the advantages of high shaft furnace productivity, adoption of non-coking coal as a reducing agent in coal base reduction, adoption of cheap coal as a heat source, and production of the direct reduction iron for steel making.

Owner:WISDRI ENG & RES INC LTD

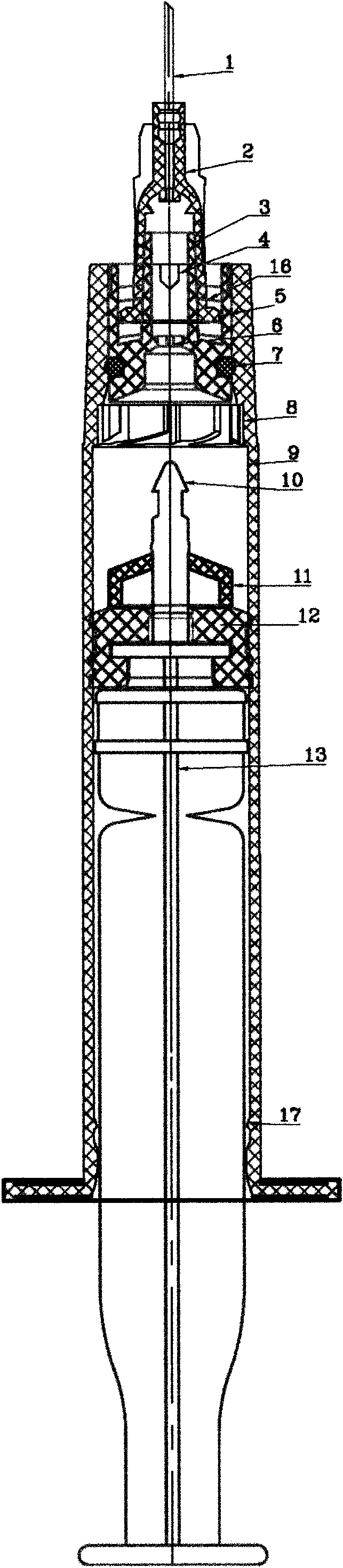

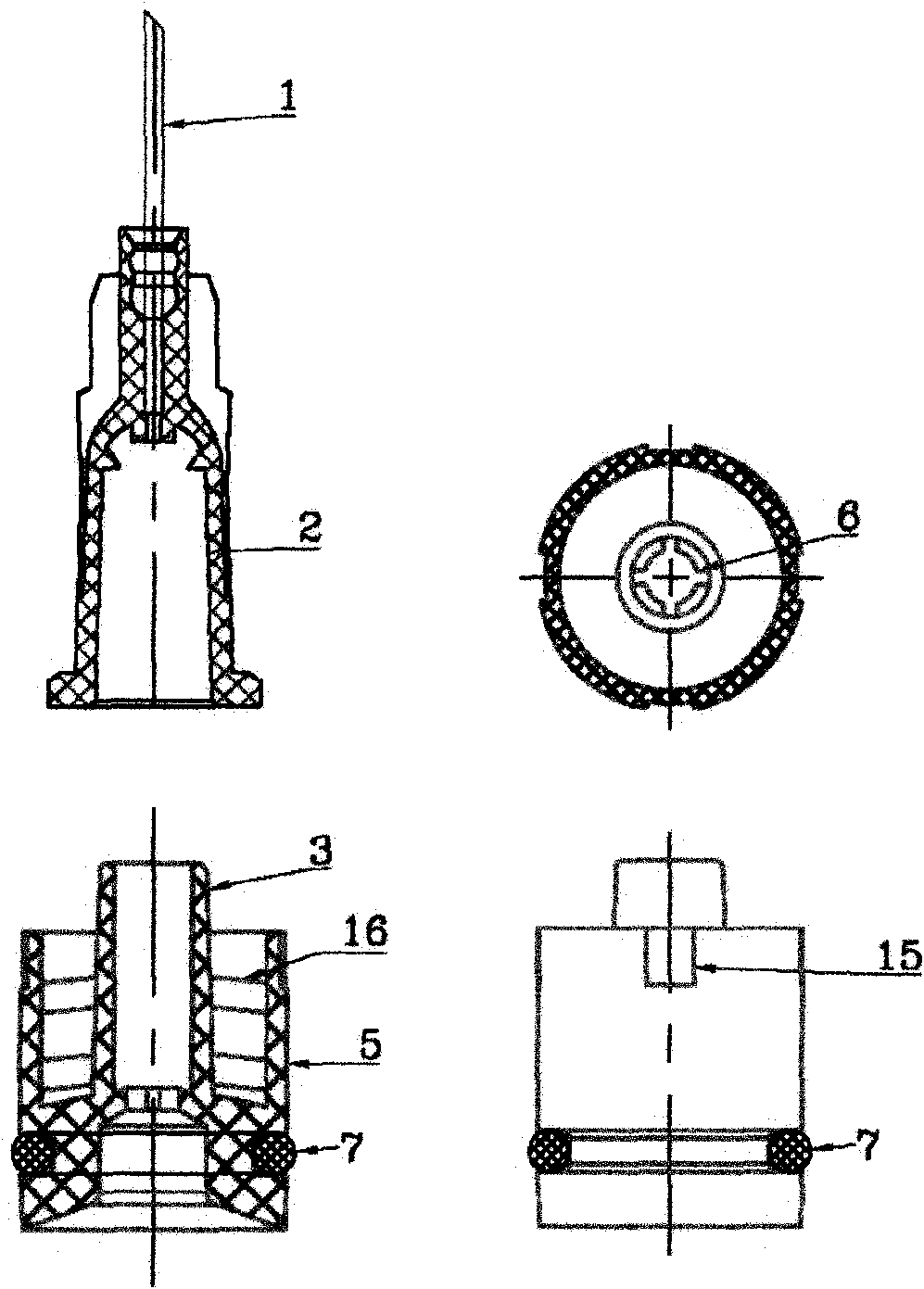

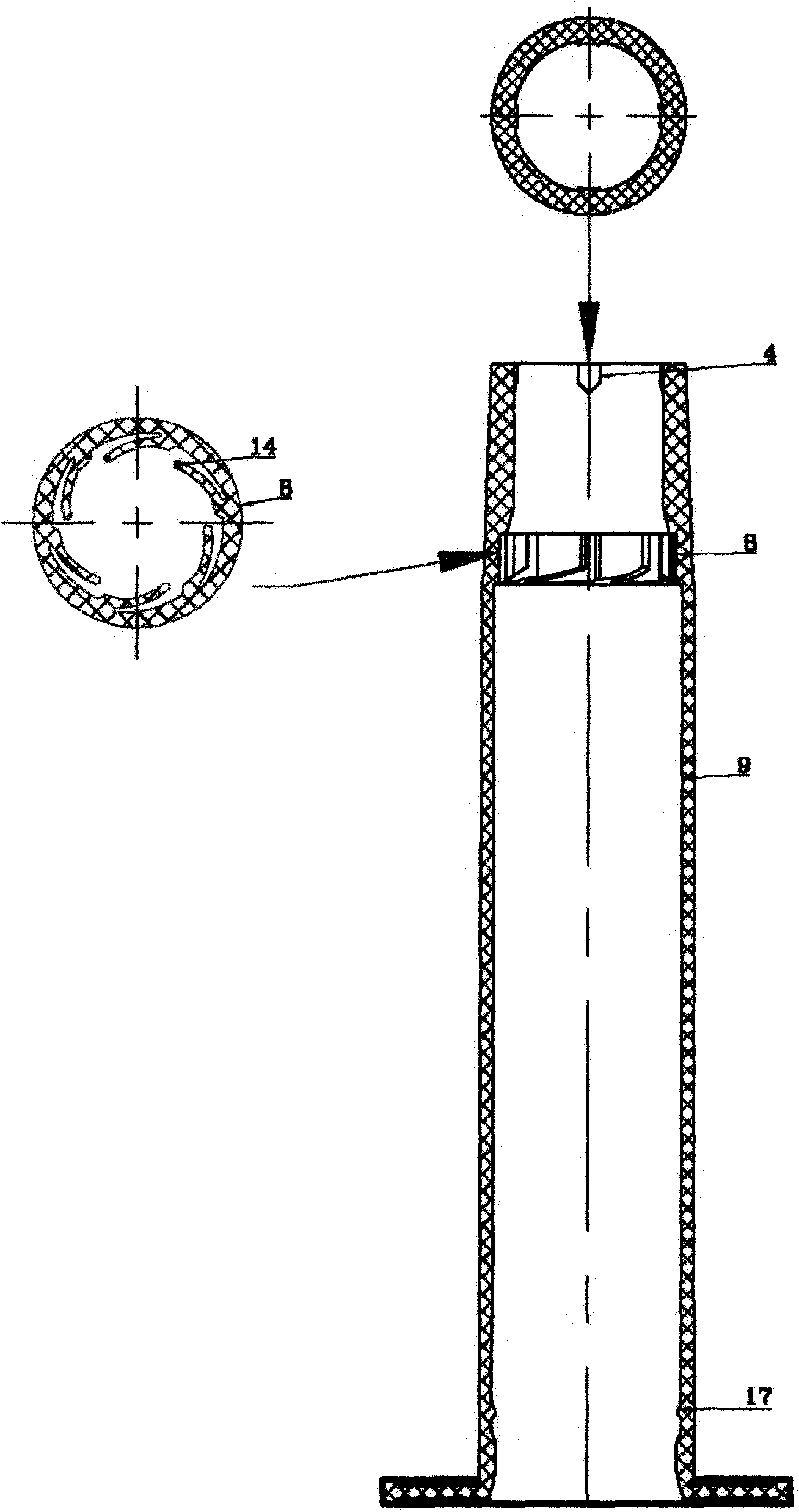

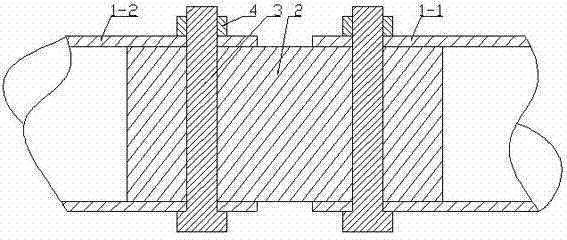

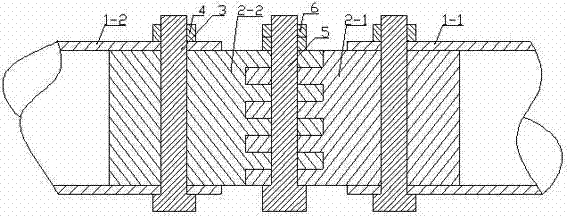

Safety self-destructive syringe

InactiveCN101810900AReduce the difficulty of production processReduce the difficulty of manufacturing processIntravenous devicesBiomedical engineeringCost savings

The invention discloses a safety self-destructive syringe, and the difference thereof from the prior art lies in: the syringe, an extension shrapnel on the neck of the inner syringe of the syringe, a core rod, a piston sleeved on the front end of the core rod, a piston fixing seat, a replaceable needle seat which is matched with the syringe body and can be pulled back, a seal ring, a needle seat and a needle. The replaceable needle seat is fixed and matched with the extension shrapnel on the neck of the inner syringe of the syringe body at the rear part. After injection is over, the piston fixing seat on the front end of the core rod pushes the extension shrapnel on the neck of the syringe outwards; and after the injection, a pull-back connection column on the front end of the core rod smoothly pulls the needle seat back into the syringe body, and a ring on the syringe body which prevents the core rod from being pushed back and being pulled out is used for locking the core rod, so that the core rod cannot move forwards or be pulled back. The safety self-destructive syringe breaks through the design philosophy of a traditional syringe, and has the advantages of reasonable structural design, high safety, low manufacturing process difficulty, few procedures, cost saving, easy production and easy popularization.

Owner:周明雄

Modified bamboo fiber reinforced composite high-density polyethylene resin based flame-retardant cupboard board and preparation method thereof

The invention discloses a modified bamboo fiber reinforced composite high-density polyethylene resin based flame-retardant cupboard board. The bamboo-plastic board is prepared from, by weight, 50-60 parts of modified bamboo fibers, 20-25 parts of high-density polyethylene, 10-15 parts of polyvinyl chloride resin, 3-5 parts of maleic anhydride grafted styrene, 1-2 parts of halloysite nanotubes, 0.1-0.2 part of a silane coupling agent, 3-5 parts of glycidyl methacrylate, 5-6 parts of ionic liquid, 1-2 parts of hydrogenated castor oil, 0.1-0.2 part of an antioxidant and 1-1.5 parts of zinc methacrylate.

Owner:ZBOM HOME COLLECTION CO LTD

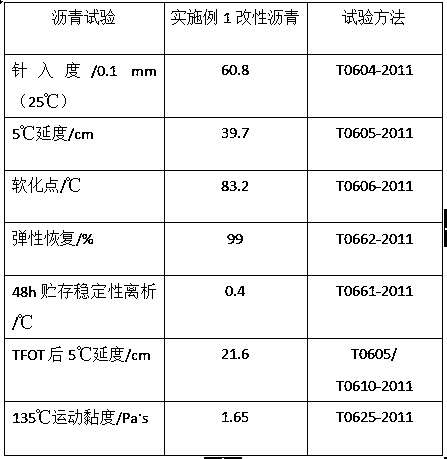

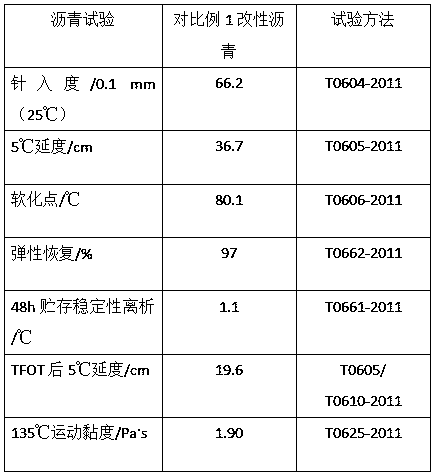

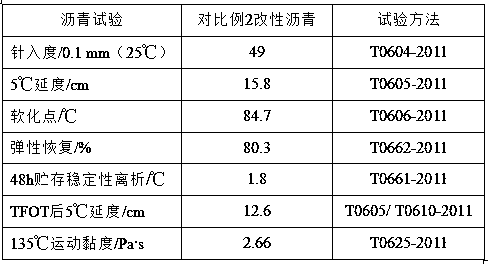

Modified asphalt composition with excellent high and low temperature performance and preparation method thereof

ActiveCN110951268AShort development timeEffective control of production costsBuilding insulationsPhysical chemistryAsphalt

The invention belongs to the technical field of modified asphalt, and particularly relates to a modified asphalt composition with excellent high and low temperature performance and a preparation method thereof. The modified asphalt composition with excellent high / low temperature performance is prepared from the following raw materials in parts by weight: 70-96 parts of asphalt, 3.0-7.0 parts of alinear or star-shaped SBS modifier, 0.1-1.0 part of a stabilizer, 0.15-4.3 parts of naphthenic oil, 0.05-4.0 parts of mineral oil, 0.1-6.0 parts of aromatic oil, 0.1 to 1.0 part of amorphous silica-alumina and 0.1 to 1.0 part of talcum powder. The prepared modified asphalt has the advantages of high ductility, high softening point, storage stability, high elasticity and the like, and can fully meet the use requirements of engineering construction of high-grade highways and the like in high-temperature areas in summer and low-temperature areas in winter.

Owner:SINOCHEM QUANZHOU ENERGY TECH CO LTD

Modified bamboo fiber enhanced polylactic acid bio-based cabinet panel and preparation method thereof

InactiveCN106118109AHigh strengthImprove strength defectsLaminationLamination apparatusMethacrylateAntioxidant

The invention discloses a modified bamboo fiber enhanced polylactic acid bio-based cabinet panel. The bamboo-plastic panel is prepared from the following raw materials in parts by weight: 50-60 parts of modified bamboo fiber, 20-30 parts of polylactic acid, 1-2 parts of magnesium stearate, 10-15 parts of high density polyethylene, 4-5 parts of silicone powder, 3-5 parts of maleic anhydride grafted polyethylene, 1-2 parts of hydrogenated castor oil, 0.1-0.2 part of an antioxidant, 0.4-0.5 part of sodium lignin sulfonate, 5-8 parts of ionic liquid and 1-2 parts of zinc methacrylate.

Owner:ZBOM HOME COLLECTION CO LTD

Carbon fiber composite material heating and curing process

InactiveCN105729828AImprove pass rateEffective control of production costsCarbon fiber compositePressure rise

The invention relates to a carbon fiber composite material heating and curing process, and belongs to the technical field of carbon fiber composite material forming processes. The carbon fiber composite material heating and curing process comprises the following steps: (1) vacuumizing: a carbon fiber composite material is put in a curing device for vacuumizing to reach a vacuum degree of below -0.8 bar and keeping by 2-10 min; (2) pressurization and heating: the environmental temperature in the curing device rises to 120-170 DEG C at a speed of 1.0-2.0 DEGC / min; and meanwhile, the pressure rises to 1.0-2.0 bar; (3) insulation and pressurization: under the pressure condition in the step (2), the pressure continuously rises to 3.0-4.0 bar, and is kept by 100-150 min; and (4) cooling and pressure reduction: the environmental temperature is slowly reduced according to the temperature gradient of 8-12 DEG C; each temperature gradient is kept by 5-15 min; and when the environmental temperature is lower than 80 DEG C, the pressure is slowly reduced. The carbon fiber composite material, obtained by the technical scheme, is higher in product pass percent compared with a traditional process; the production cost is effectively controlled; and the beneficial effects are prominent.

Owner:ANHUI JIALIQI AEROSPACE CARBON FIBER CO LTD

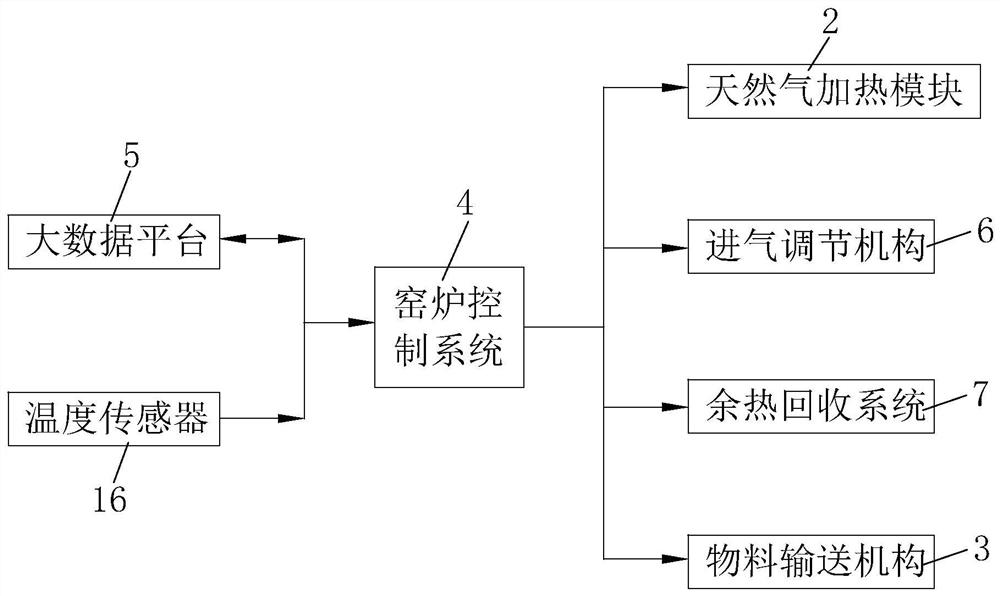

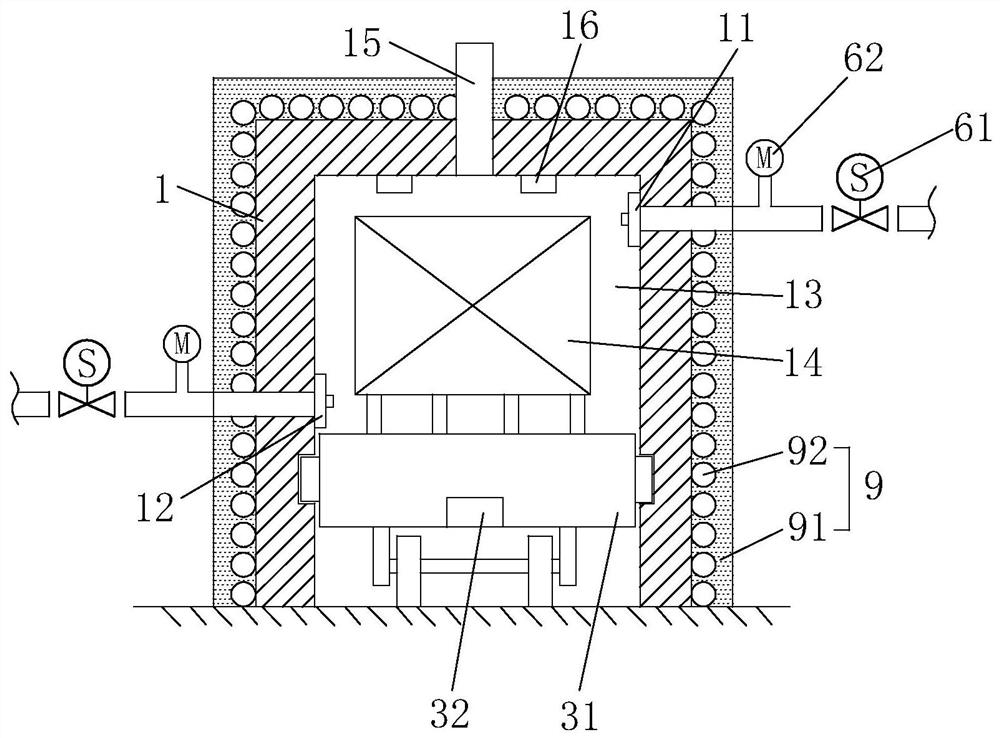

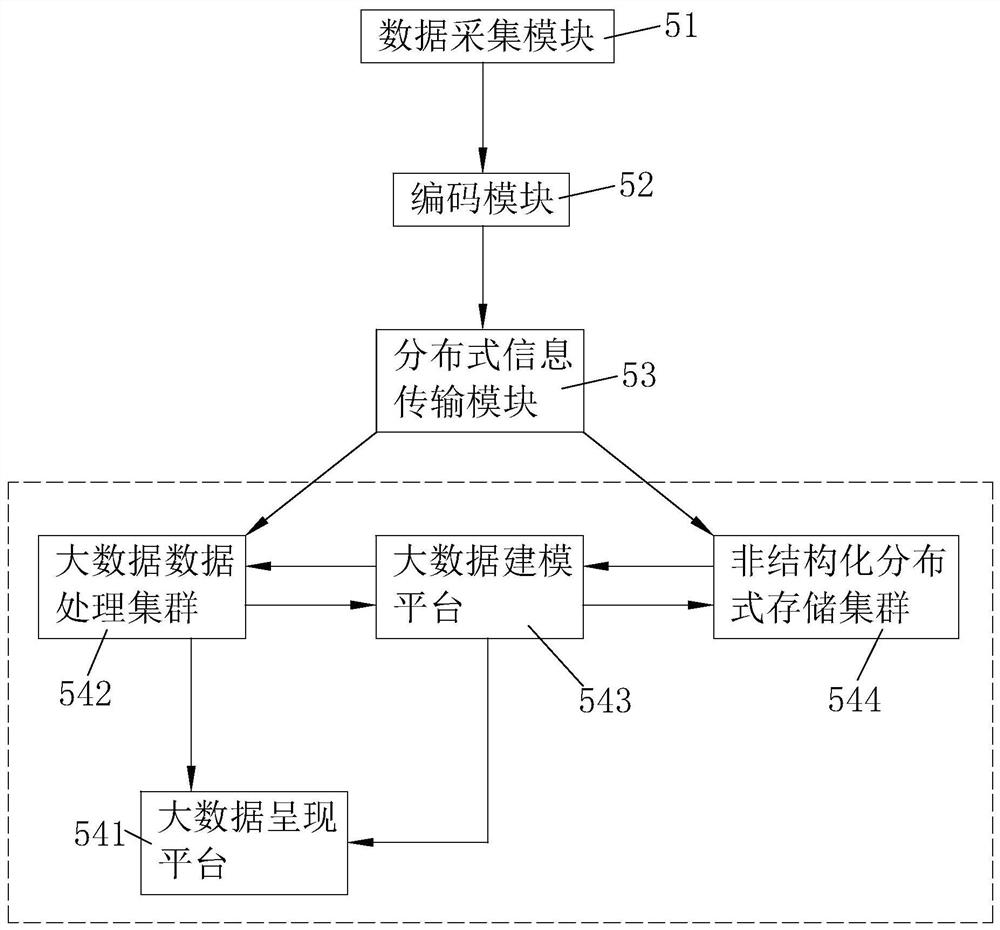

Building material kiln roasting system based on big data and process thereof

InactiveCN113390255AAvoid non-conformitiesImprove quality and efficiencyFurnace typesIncreasing energy efficiencyHeat conservationTime data

The invention relates to a building material kiln roasting system based on big data and a process thereof. The roasting system comprises a kiln body, a natural gas heating module, a material conveying mechanism and a kiln control system. The roasting system further comprises a big data platform, a gas inlet adjusting mechanism and a waste heat recovery system; and a plurality of temperature sensors are installed at the top in the kiln body. After the name of a produced building material is input into the kiln control system, the kiln control system automatically calls corresponding production parameters in the big data platform to control kiln equipment to perform producing and displays the standard temperature and heat preservation time of each section of kiln body on a display screen. Each temperature sensor is used for detecting the temperature in the kiln body and transmitting real-time data of the temperature to the kiln control system, and the kiln control system controls the air inlet adjusting mechanism, the waste heat recovery system and the material conveying mechanism to enable the kiln temperature to reach the preset standard temperature and heat preservation time after comparing and analyzing the real-time data and the standard temperature.

Owner:赣州科帕机电自动化有限公司

High-gloss low-haze external packaging film for cigarette packet

InactiveCN106928724AImprove sharpnessHigh glossSynthetic resin layered productsCellulosic plastic layered productsLinear low-density polyethyleneNitrocellulose

The invention discloses a high-gloss and low-haze cigarette package outer packaging film, which comprises a base film layer and functional layers arranged on the upper and lower sides of the base film layer. The functional layer is counted in parts by weight and its raw material formula As follows: 1,000-1,500 parts of hexahydrophthalic anhydride, 1,000-1,300 parts of vinyl silicone resin, 1,000-1,500 parts of nitrocellulose with a particle size of 5-15 μm, 800-1,200 parts of metallocene linear low-density polyethylene, vinegar 1200-1800 parts of acrylic emulsion, 35-50 parts of diisooctyl sulfonate sodium succinate, 10-20 parts of PVC resin, 50-80 parts of nano-aluminum oxide, 60-90 parts of dipentaerythritol, ethoxylated 30-60 parts of alkyl ammonium sulfate. The hexahydrophthalic anhydride in the formula of the present invention can improve the sharpness of image and gloss of the outer packaging film of high-gloss and low-haze cigarette packets, and at the same time, diisooctyl sodium succinate sulfonate can further solve the problem of foaming ;Using nano-alumina, it has the function of water-proof condensation and can eliminate the appearance defects of "water mist".

Owner:JIANGYIN ZHONGDA FLEXIBLE PLASTIC NEW MATERIALS CO LTD

Preparation method of precise casting wax mold repair wax

InactiveCN108788010AHigh hardnessStrong regulationFoundry moulding apparatusWaxVolumetric Mass Density

The invention discloses a preparation method of precise casting wax mold repair wax. The preparation method comprises the following steps that a, firstly, selected raw materials are processed; b, auxiliary materials are prepared after the step a is finished; c, after the step b is completed, and then heating and fusing are carried out by utilizing a stirrer; d, after the step c is finished, the preparation of the repair wax is carried out; and e, after the step d is completed, finally the repair wax is collected. According to the preparation method, in the process of manufacturing the repair wax, the auxiliary materials are added on the conventional raw materials, white vaseline, rosin, petrochemical engineering resin and stearic acid in the auxiliary materials are utilized, the overall hardness of the repair wax can be increased according to the proportioned proportion, and the adjusting degree is higher, and therefore, different repairing requirements can be met, and the production cost can be effectively controlled; and cooling equipment can be provided for gradually cooling when mechanical fusion is carried out, so that the formation of internal air holes is avoided on the premise that the adhesion performance is improved, the forming speed and the overall density are increased, and popularization and use are facilitated.

Owner:山东景阳岗金属设备有限公司

A kind of crystalline glaze for sanitary ceramic sanitary ware and its preparation process

Owner:GUANGDONG DOWSTONE TECH

Ferment-calcium humate organic fertilizer for secondary saline-alkali land and preparation method thereof

InactiveCN106380339ARelieve alkalinizationIncrease available nitrogen nutrientsCalcareous fertilisersBio-organic fraction processingCellulosePhosphate

The invention discloses a ferment-calcium humate organic fertilizer for secondary saline-alkali land. Raw material formula of the fertilizer comprises, by weight, 1000-1500 parts of blue algae, 1000-1300 parts of sodium alginate, 1000-1500 parts of tobacco waste, 800-1200 parts of ground phosphate rock, 1200-1800 parts of nano-calcium carbonate, 35-50 parts of potassium hydroxide, 10-20 parts of calcium humate, 50-80 parts of magnesium sulfate, 60-90 parts of a complex enzyme preparation and 30-60 parts of ferment bacteria. By adding calcium humate, sodium ions in soil can be removed, and humic acid neutralizes a certain alkalinity. After the fertilizer is applied into soil, soil alkalization is remarkably alleviated, and available nitrogen nutrient of soil is increased. Ferment bacteria is an ideal compost external inoculant, which can enhance the capability of decomposing organic matter and inorganic matter such as cellulose, indissolvable mineral matter, etc.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Production process of rubber diaphragm in automobile brake air chamber

InactiveCN105835283AImprove low temperature performanceImprove performanceRubber materialVulcanization

The invention relates to a production process of a rubber diaphragm in an automobile brake air chamber and belongs to the technical field of automobile brake systems. The production process comprises the steps of: 1) pre-vulcanizing an upper and a lower rubber layers; and 2) fusing the upper and a lower rubber layers. In the technical scheme, a secondary vulcanization process with the same rubber material formula and the equal vulcanization speed is provided, and by means of the process, the upper and the lower rubber layers of the diaphragm is produced through an extruder die, wherein through the vulcanization process in the equal time, vulcanization status in the upper and the lower rubber layers are completely same, so that the problem, which troubles people for a long time, of over-vulcanization of the lower rubber layer during the vulcanization shaping process can be solved, and the problems that rubber materials in different formula are complex and difficult to distinguish and fuse, which influences bonding strength, are solved. The rubber diaphragm is increased greatly in qualified rate, is effectively controlled in production cost, has excellent high-temperature and low-temperature performances, has excellent anti-aging and anti-fatigue performances, is greatly improved in total performance and service life, and has significant advantages.

Owner:DATWYLER SEALING TECH ANHUI

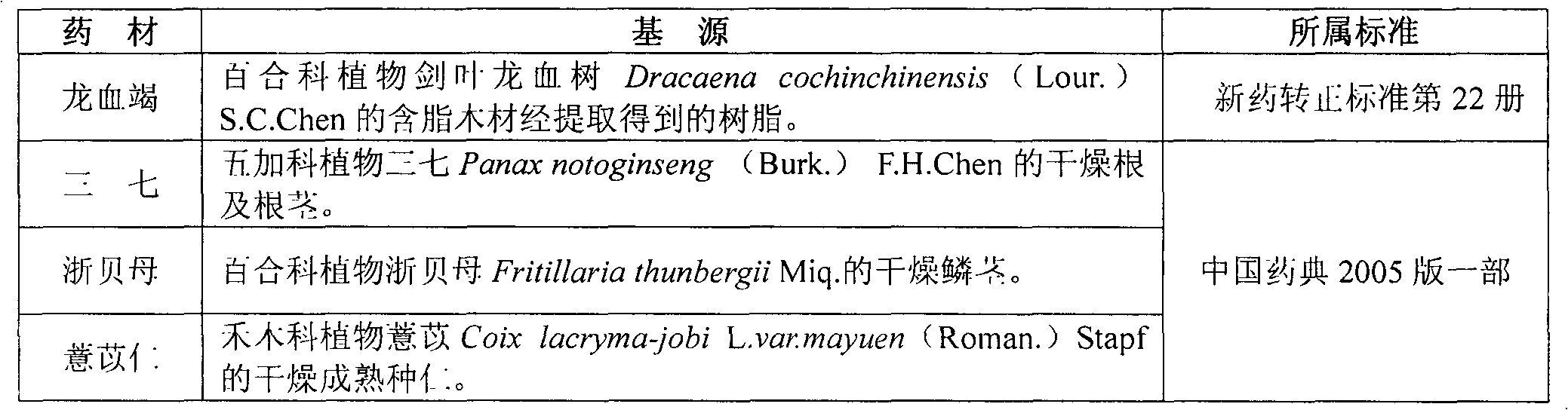

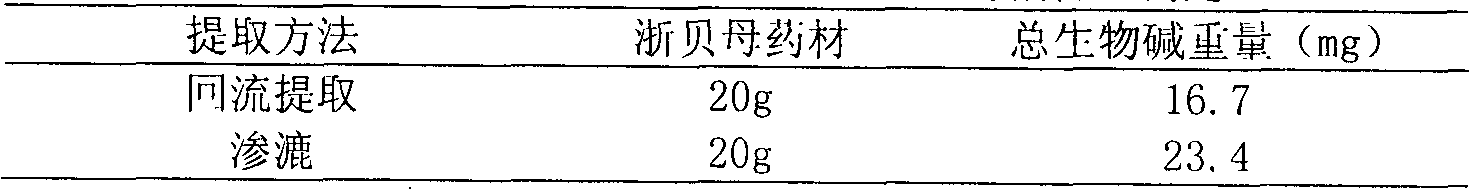

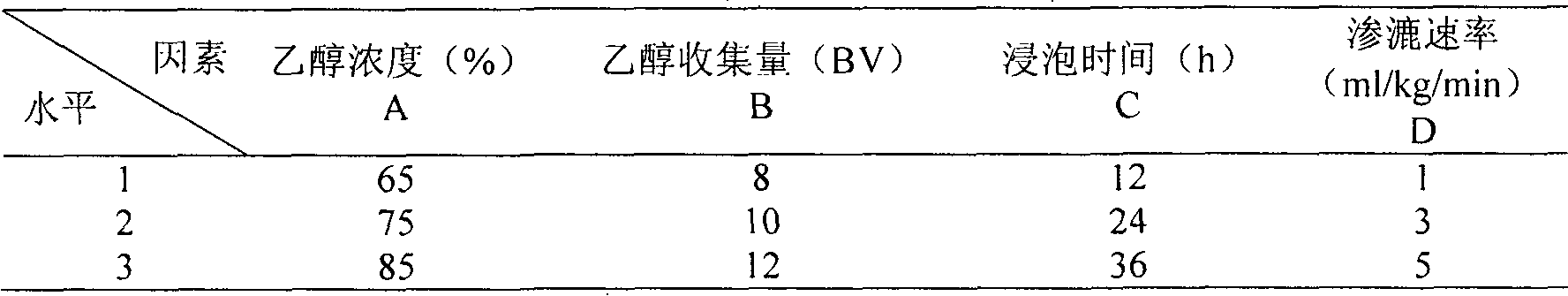

Traditional Chinese medicine composition for treating endometriosis and preparation method thereof

InactiveCN102688408ATake a small doseImprove complianceSexual disorderPlant ingredientsRefluxEndometriosis

The invention belongs to the traditional Chinese medicine field, and relates to a traditional Chinese medicine composition for treating endometriosis and a preparation method thereof; the traditional Chinese medicine composition is prepared by the following raw material drugs by weight: 40-85 parts of dragon blood, 40-85 parts of pseudo-ginseng, 80-120 parts of Zhejiang fritillaria bulb, and 140-210 parts of coix seeds; the preparation method comprises the following steps: directly pulverizing pseudo-ginseng and dragon blood into fine powder so as to be used as medicine; crushing Zhejiang fritillaria bulb medicinal materials into crude powder, adding 65-85% ethanol, soaking for 12-36 hours, percolating with 65-85% ethanol, collecting percolated liquid with an amount of 8-16 times to obtain a Zhejiang fritillaria bulb extract; crushing coix seeds medicinal materials into crude powder, performing reflux for 1-3 times with 85-95% ethanol with an amount of 10-30 times more than that the crude powder, 1-4 hours each time, combining the extracts, filtering to obtain a coix seed extract; recovering ethanol at a reduced pressure from the Zhejiang fritillaria bulb extract and the coix seed extract, concentrating into thick paste, mixing the thick paste with pseudo-ginseng fine powder and dragon blood fine powder, drying, crushing to obtain dry extract powder, preparing and shaping.

Owner:JIANGSU KANION PHARMA CO LTD

Modified-bamboo-fiber-reinforced polyvinyl-chloride-based high-compactness cupboard sheet material and preparation method thereof

InactiveCN106189313AHigh strengthEasily damagedFibre treatmentConjugated synthetic polymer artificial filamentsMethacrylatePolyvinyl chloride

The invention discloses a modified-bamboo-fiber-reinforced polyvinyl-chloride-based high-compactness cupboard sheet material. The bamboo-plastic sheet material is prepared from the following raw materials in parts by weight: 50-60 parts of modified bamboo fibers, 20-25 parts of polyvinyl chloride, 5-10 parts of ultrafine per-sulfurized powder butadiene-acrylonitrile rubber, 3-5 parts of maleic anhydride grafted polypropylene, 0.4-0.5 part of amino silane coupling agent, 2-3 parts of nano carbon black, 1-2 parts of hydrogenated castor oil, 0.1-0.2 part of antioxidant, 5-8 parts of ionic liquid and 1-2 parts of zinc methacrylate.

Owner:ZBOM HOME COLLECTION CO LTD

Detection method for preparing puerperal blood-stasis dispersing capsule

ActiveCN103983734ASensitive detection methodEffective control of production costsComponent separationMotherwortFerulic acid

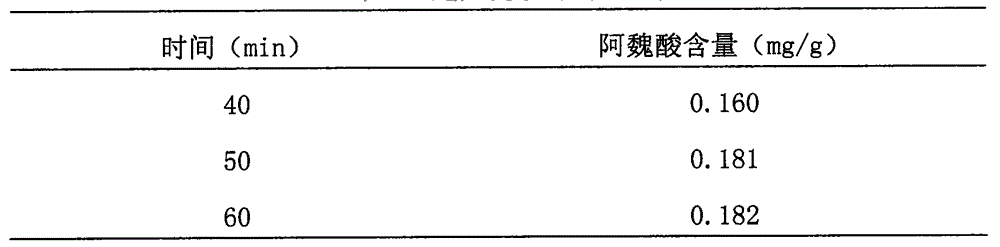

The invention relates to a detection method for preparing a puerperal blood-stasis dispersing capsule. The method comprises the steps of carrying out thin-layer chromatography identification on ligusticum wallichii, angelica and motherwort, and carrying out high performance liquid chromatography testing on the content and limit of ferulic acid.

Owner:JIANGXI MINJI MEDICINE

Roller coating conversion treatment agent for colored coated steel plate

InactiveCN104164662AMeet the requirements of rapid conversion treatment processEasy to useMetallic material coating processesPolyethylene glycolPhosphoric acid

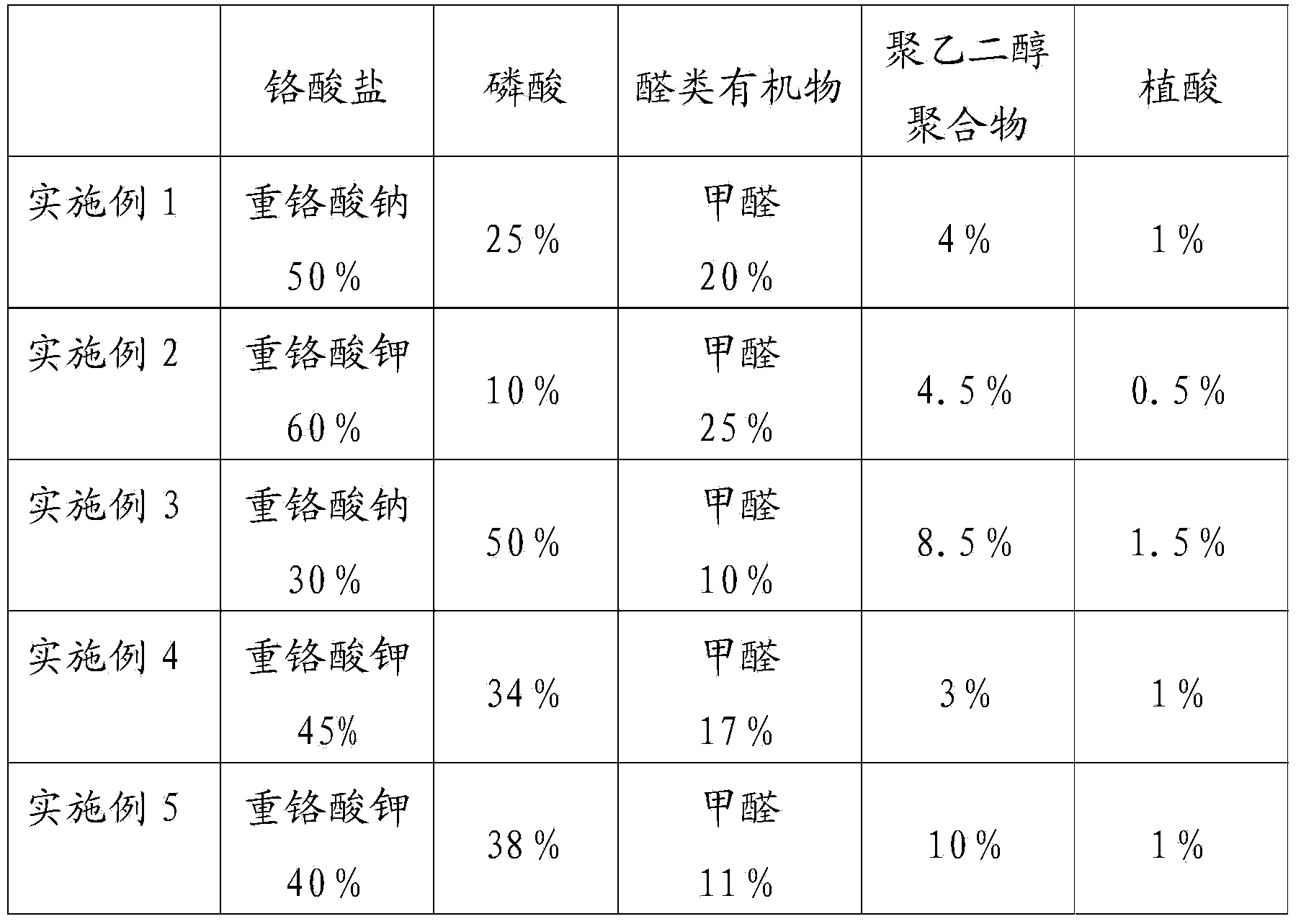

The invention discloses a roller coating conversion treatment agent for a colored coated steel plate, and solves the problems of poorer corrosion resistance, high production cost and long conversion treatment time of a conventional roller coating conversion treatment agent. The roller coating conversion treatment agent comprises the following components as solutes by the weight percentage: 30-60% of chromate, 10-50% of phosphoric acid, 10-25% of an aldehyde organic matter, 3-10% of a polyethylene glycol polymer, and 0.5-1.5% of phytic acid, wherein the sum of the component percentages is 100%; a mixing weight ratio of the solutes to a solvent is 1:9-12, and the solvent is deionized water. The roller coating conversion treatment agent is good in stability, low in production cost, good in corrosion resistance, excellent in performance, short in conversion time, and suitable for fast conversion treatment of a large colored coated steel plate production line.

Owner:武汉钢铁有限公司

Modified bamboo fiber reinforced composite polypropylene-based aromatic cupboard board and preparation method thereof

InactiveCN106084848AHigh strengthEasily damagedConjugated synthetic polymer artificial filamentsNon-woven fabricsMethacrylateAntioxidant

The invention discloses a modified bamboo fiber reinforced composite polypropylene-based aromatic cupboard board. The bamboo-plastic board is prepared from raw materials in parts by weight as follows: 50-60 parts of modified bamboo fibers, 20-30 parts of polypropylene, 5-10 parts of polyphenylene sulfide, 4-6 parts of maleic anhydride grafted polypropylene, 0.4-0.5 parts of guaiac wood oil, 1-2 parts of zinc methacrylate, 0.4-0.5 parts of hectorite, 0.1-0.2 parts of hexadecyl trimethyl ammonium bromide, 1-2 parts of hydrogenated castor oil, 0.1-0.2 parts of an antioxidant, 5-8 parts of an ionic liquid and 10-20 parts of deionized water.

Owner:ZBOM HOME COLLECTION CO LTD

Method for extracting plant source pesticides total alkaloids of sophora flavescens

ActiveCN101283690BLow costReduce manufacturing costBiocideArthropodicidesPesticide residueFiltration

The invention relates to a method for extracting plant-based total matrines used as pesticide and belongs to the technical field of pesticide extraction and production. The method comprises the steps of pulverization, extraction, filtration and evaporation drying. The method has the advantages of physical extraction, no chemical contamination during production, no toxicity or harm of product and no pesticide residue; can increase the extraction rate, extract yield and alkaloid content of matrine; can minimize the production cost; and provides advanced techniques and basic conditions for industrial production and agricultural use of matrine biopesticide.

Owner:SHANDONG MEI LUO FU AGRI POLYTRON TECH

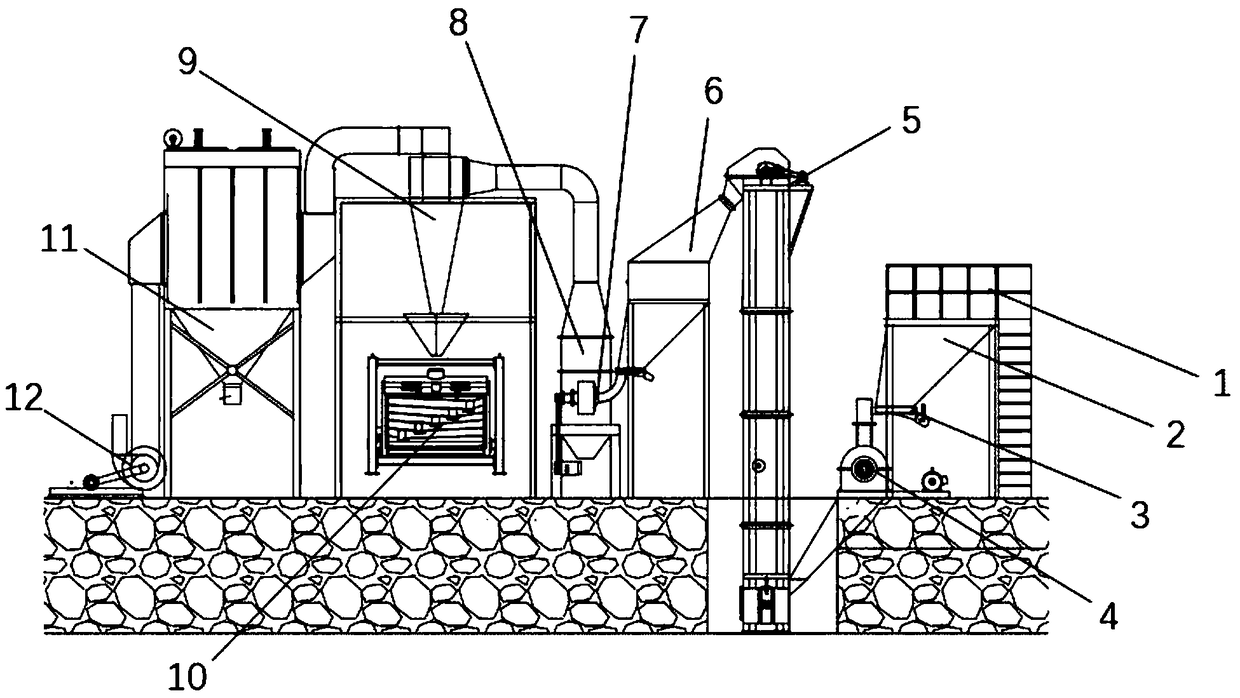

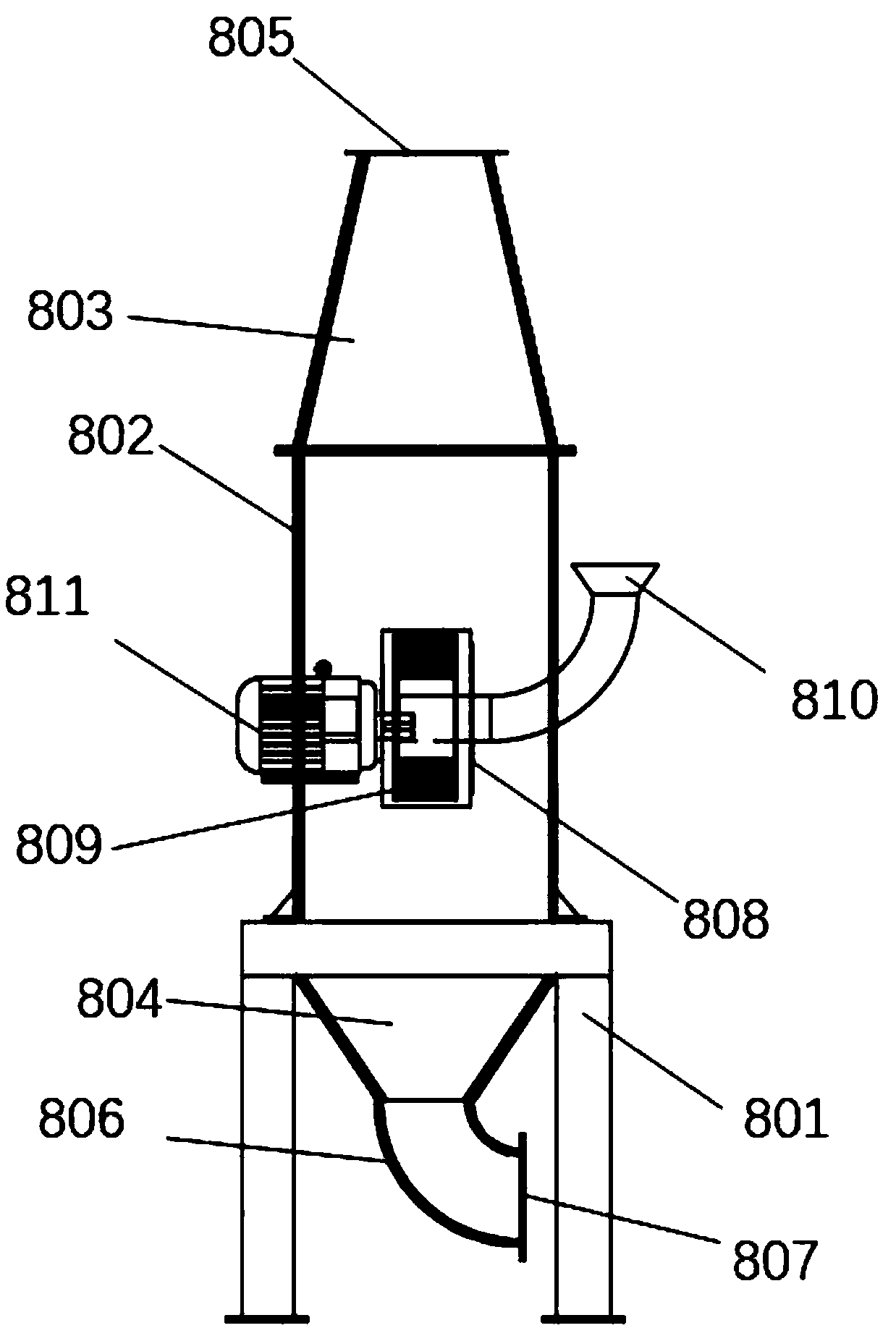

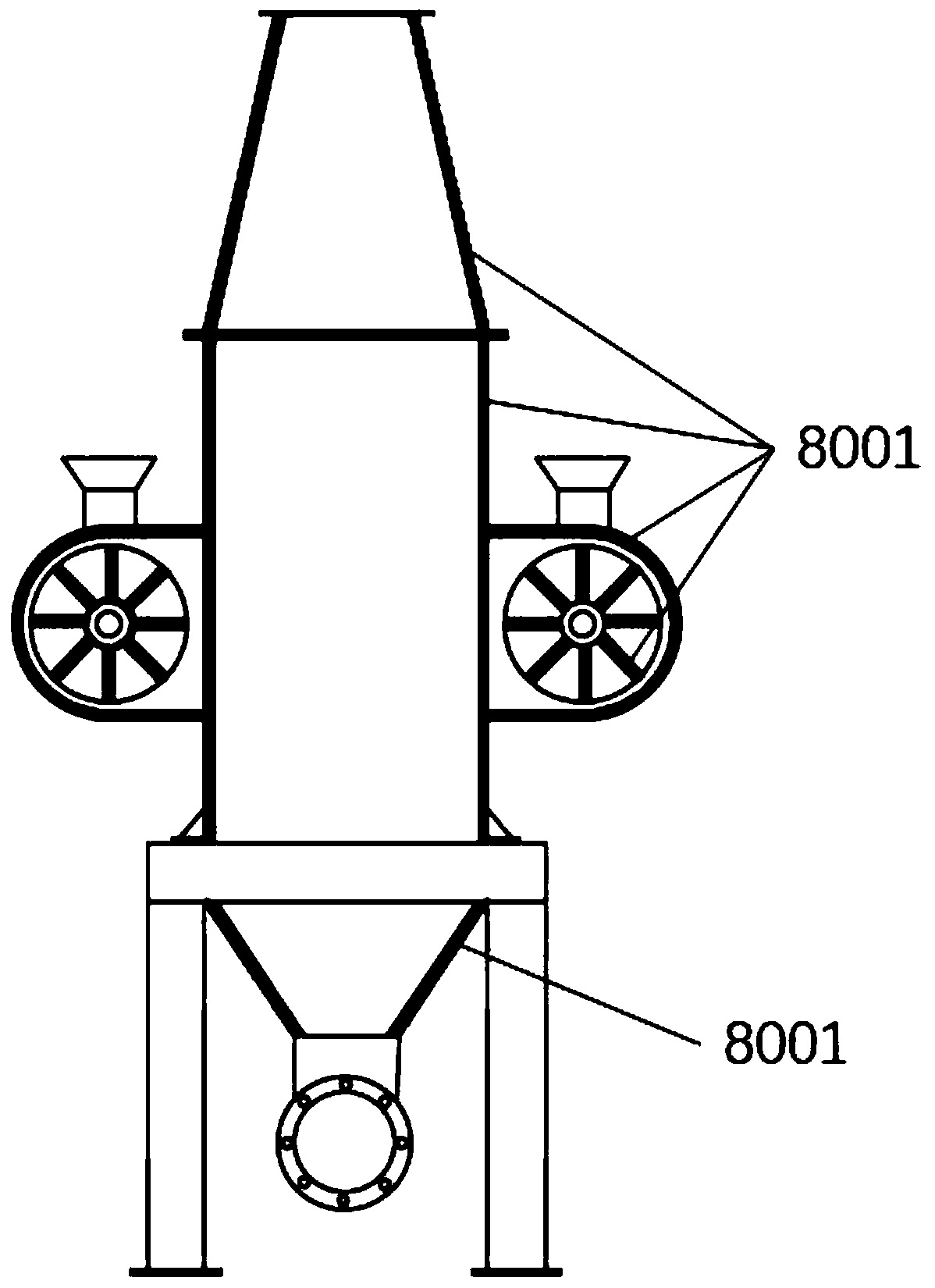

Metallic silicon series pelletizing device

PendingCN108722634AAvoid negative effectsImprove cleanlinessVortex flow apparatusGrain treatmentsSmall footprintCrusher

The invention discloses a metallic silicon series pelletizing device. The device comprises a charging platform, a raw material bin, a vibration feeder, a hammering crusher, a bucket type lifting machine, a particle bin, an electromagnetic vibrating feeder, a grinding machine, a cyclone separator, a swinging screen, a pulse dust collector and a centrifugal fan, wherein the raw material bin is erected on the charging platform; the vibrating feeder is arranged at the bottom part of the raw material bin and is connected to the hammering type crusher through a pipeline; and the hammering type crusher is downwards connected to the lower end of the bucket type lifting machine and is used for lifting materials. According to the abovementioned mode, the metallic silicon series pelletizing device has the advantages the materials are oppositely impacted and crushed into particles, so that the adverse influence of a metal paste to a silicon series material can be completely avoided; the product cleanness is improved; the color and luster of a product is improved; the whole production line is environmentally friendly; a small area is used; the energy consumption in operation is low; and the production cost can be effectively controlled.

Owner:张拴三

Modified bamboo fiber reinforced polycarbonate-based composite cabinet board and preparation method thereof

InactiveCN106189308AImprove compatibilityControl production costsConjugated synthetic polymer artificial filamentsNon-woven fabricsMaleic anhydridePolyvinyl alcohol

The invention discloses a modified bamboo fiber reinforced polycarbonate-based composite cabinet board. The bamboo-plastic board is prepared from, by weight, 50-60 parts of modified bamboo fibers, 4-5 parts of calcium sulfate whiskers, 20-30 parts of polycarbonate, 5-6 parts of tributyl phosphate, 1-2 parts of hydrogenated castor oil, 8-10 parts of maleic anhydride grafted polyvinyl alcohol, 0.1-0.2 part of antioxygen, 5-8 parts of ionic liquid and 1-2 parts of zinc methacrylate.

Owner:ZBOM HOME COLLECTION CO LTD

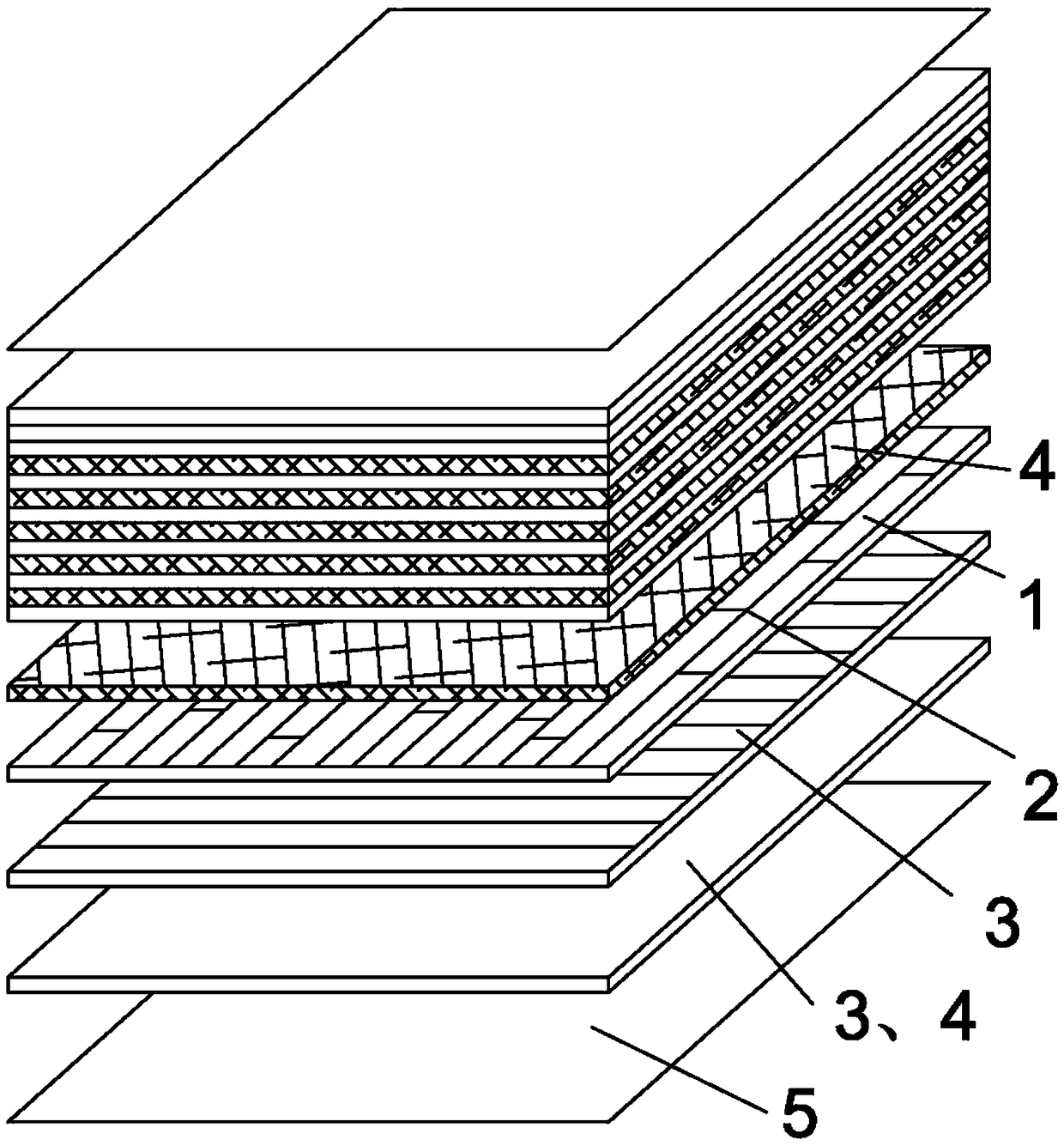

Container floor and machining method thereof

PendingCN109397410AEffective control of production costsReduce dosageCane mechanical workingReed/straw treatmentWood veneerWood machining

The invention belongs to the technical field of bamboo wood machining, and particularly relates to a container floor and a machining method thereof. According to the container floor machining method,multiple different pressures, temperatures and time are adopted for repeatedly carrying out hot pressing curing on a plate blank for making the container floor, in the hot pressing curing process, water in bamboo and wood veneer can be gradually drained, it is ensured that the quality problem of the plate blank due to the high water containing rate is avoided, meanwhile, the whole machining production time is shortened, and production cost is effectively controlled. A whole long rectangular bamboo piece unit prepared in the container floor can replace a part of wood veneer in the prior art, the use amount of the wood veneer can be effectively saved, and the production cost of the container floor can be effectively reduced.

Owner:福建省和普新材料有限公司

Novel power generation device

PendingCN112761913AReasonable choiceExquisite structureMachines/enginesMechanical power devicesEnergy consumptionElectric power

The invention discloses a novel power generation device. The novel power generation device comprises child vehicles, a mother vehicle, a main track and a charging maintenance workshop, wherein the middle of the mother vehicle is connected to a shaft of a mother vehicle support on the lower portion of the mother vehicle, the mother vehicle is provided with a plurality of child vehicle stopping positions, the child vehicles are arranged on the child vehicle stopping positions, one side of the mother vehicle is connected with the closed main track, the main track is connected with the charging maintenance workshop at crossroads through branch tracks, the main track penetrates through the charging maintenance workshop, and the multiple crossroads are arranged at an inlet and an outlet of the main track. Compared with the prior art, the novel power generation device has the advantages that the overall structure is simple and exquisite, the mother vehicle is driven to rotate through the gravity of the child vehicles, and a power generator is driven to generate power through rotation of the mother vehicle, so that green energy is used, the problems of large power loss, environment pollution, energy consumption and low power generation efficiency in the traditional power generation process are greatly solved, the production cost and the later maintenance cost are effectively controlled, the part selection, the connection mode and the overall working principle are reasonable, and the novel power generation device has good applicability and is convenient to popularize.

Owner:郑学军

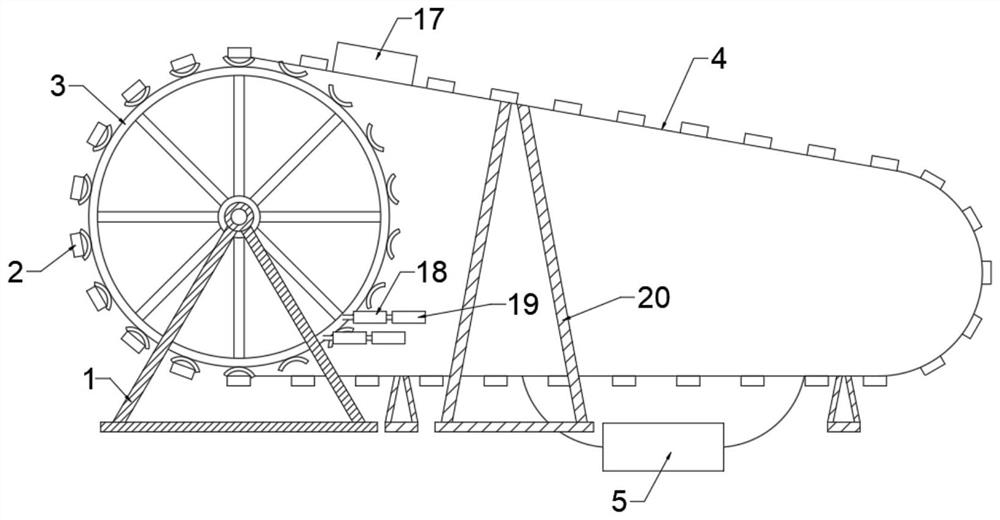

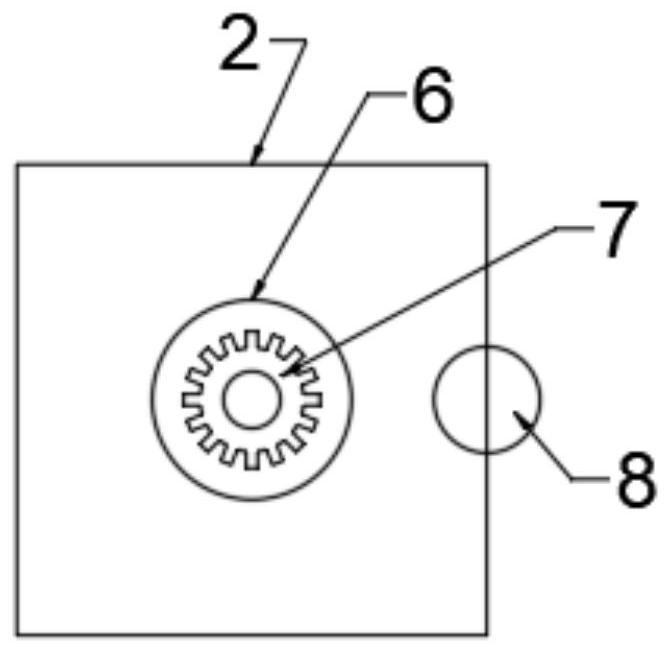

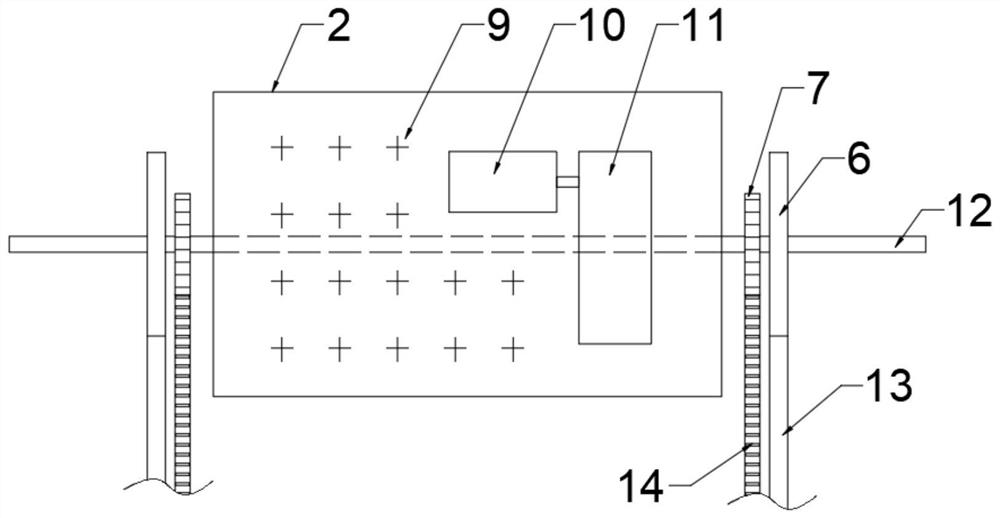

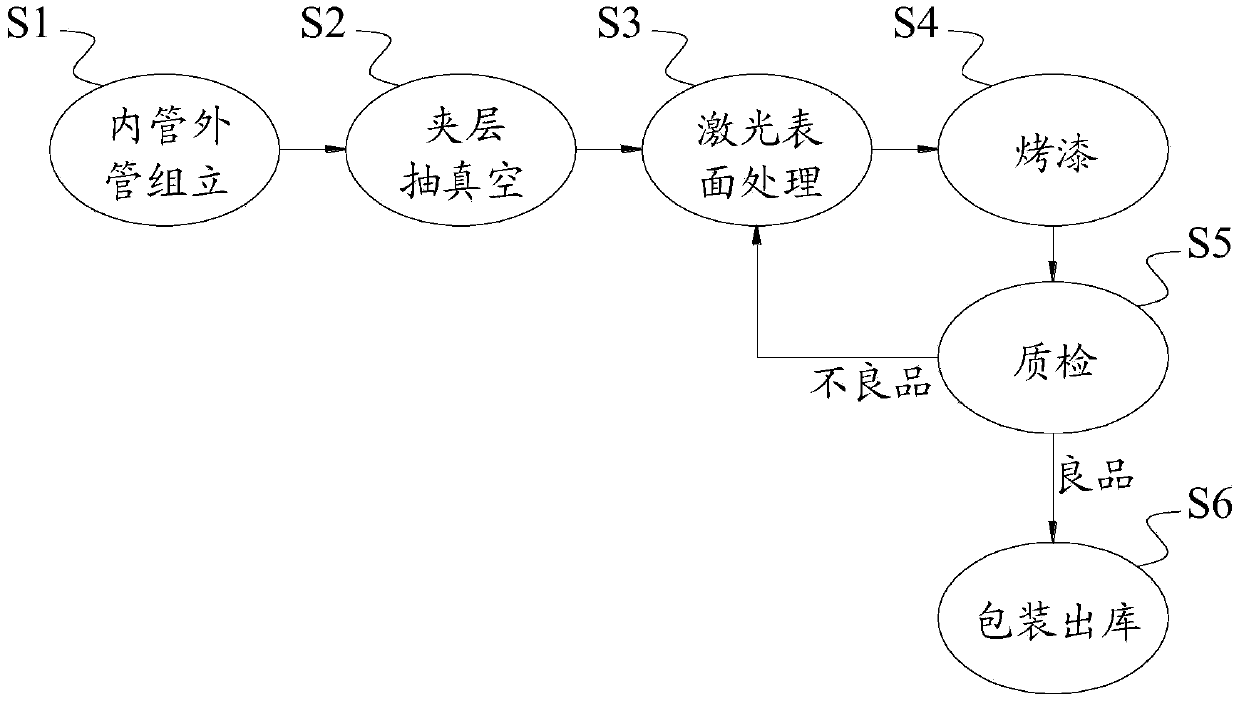

Vacuum cup and production process thereof

PendingCN111374496AReduce investmentEffective control of production costsDrinking vesselsProduction lineProcess engineering

The invention discloses a vacuum cup and a production process thereof. The production process comprises the following steps: 1) assembling and forming an inner pipe and an outer pipe; 2) vacuumizing an interlayer between the inner pipe and the outer pipe of the cup body; 3) performing laser treatment on the surface of the cup body to meet the surface requirement of a baking finish process; (4) baking finish treatment is conducted on the surface of the cup body; 5) performing quality inspection: if surface defective products appear in quality inspection, returning to the step 3) to carry out laser treatment again. According to the scheme, the original complex electrolysis, grinding, paint stripping and rust dispensing procedures influencing the health of operators are abandoned, the advantages of the laser treatment process are fully utilized to meet the surface requirements of the paint baking procedure, and the good product yield can be obtained. Compared with the prior art, the production line investment is effectively controlled by optimizing the existing production process, and the body health of operators can be ensured.

Owner:THERMOS JIANGSU HOUSEWARES

Wind power sectional-type blade

ActiveCN102518568BShorten the lengthReduce volumeFinal product manufactureWind energy generationStructural engineeringMechanical engineering

The invention discloses a wind power sectional-type blade, which comprises at least two blade sections. All the blade sections are connected in sequence through a connecting elements into a whole. The connecting element mainly comprises a connecting substrate, a plurality of blade connecting bolts and nuts of which the number corresponds to that of the blade connecting bolts, wherein both tips of the connecting substrate are respectively matched with the but joint end parts of the adjacent blade sections; the tips of the connecting substrate and the but joint end parts of the blade sections are respectively provided with a plurality of bolt holes which correspond to one another; each blade connecting bolt penetrates into the corresponding bolt holes in the connecting substrate and the blade sections; and the nuts are locked on the blade connecting bolts. According to the wind power sectional-type blade disclosed by the invention, on the premise of not influencing the air performance of the blade, the blade is designed into a plurality of blade sections, thereby, the manufacturing difficulty is reduced, the subsequent transportation work is greatly facilitated, the manufacturing and transportation cost is effectively controlled, and the assembled blade has high strength and is stable and reliable.

Owner:DONGFANG TURBINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com