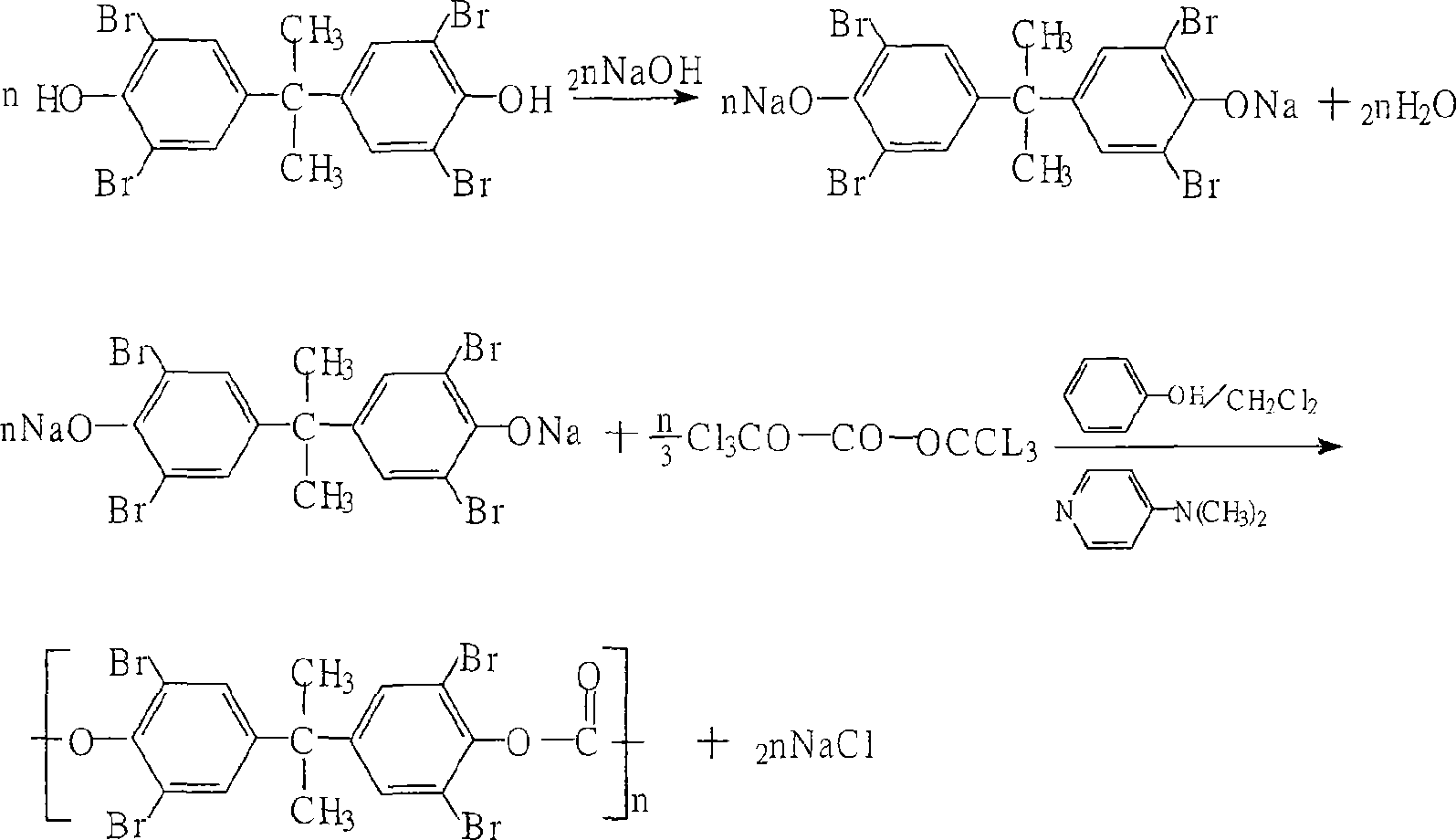

Method for preparing tetrabromo-bisphenol A polycarbonate

A technology of tetrabromobisphenol and ultramolecular weight, which is applied in the field of preparation of ultramolecular weight tetrabromobisphenol A polycarbonate, can solve the problem that the molecular weight cannot be fixed within a certain range, the target product cannot be controlled, and application value has not been found, etc. problems, to achieve the effects of low toxicity, safe operation, convenient storage and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In a 3000mL four-necked flask with an electric stirrer, add 204.8g (0.376mol) of tetrabromobisphenol A, 750mL of water, 0.25g of polymerization inhibitor phenol, dissolve with 5% sodium hydroxide, and then filter cloth Filter, then add dropwise 111.7g (0.376mol) of triphosgene previously dissolved in 500mL of dichloromethane and filtered through a filter cloth at 25±3°C, after dropping, adjust the pH of the system to 10 with 15% NaOH solution, and keep warm for 30min . The reaction mixture was diluted with 1000 mL of dichloromethane, 0.2 g of 4-N,N-dimethylaminopyridine was added, 18% NaOH solution was added dropwise to maintain the pH of the reaction mixture = 10, and the mixture was stirred for 30 min. After completion of the reaction, use 5% dilute hydrochloric acid to adjust the pH to 7 to end the reaction, separate the organic layer, and wash it three times with deionized water, then add ethanol to precipitate a white solid powder, filter it to dryness, and dry it ...

Embodiment 2

[0030] In a 3000mL four-necked flask with an electric stirrer, add 204.8g (0.376mol) of tetrabromobisphenol A, 750mL of water, 0.15g of polymerization inhibitor phenol, dissolve with 5% sodium hydroxide, and then filter cloth Filter, then add dropwise 111.7g (0.376mol) of triphosgene previously dissolved in 500mL of dichloromethane and filtered through a filter cloth at 25±3°C, after dropping, adjust the pH of the system to 10 with 20% NaOH solution, and keep warm for 30min . The reaction mixture was diluted with 1000 mL of dichloromethane, 0.3 g of 4-N,N-dimethylaminopyridine was added, 20% NaOH solution was added dropwise to maintain the pH of the reaction mixture = 10, and the mixture was stirred for 60 min. After completion of the reaction, use 5% dilute hydrochloric acid to adjust the pH to 7 to end the reaction. Separate the organic layer and wash it three times with deionized water. Add ethanol to precipitate a white solid powder. Filter and dry in vacuum to obtain tetr...

Embodiment 3

[0032]In a 3000mL four-neck flask with an electric stirrer, add 204.8g (0.376mol) of tetrabromobisphenol A, 750mL of water, 0.35g of polymerization inhibitor phenol, dissolve with 5% sodium hydroxide, and then filter cloth Filter, then add dropwise 111.7g (0.376mol) of triphosgene previously dissolved in 500mL of dichloromethane and filtered through a filter cloth at 25±3°C, after dropping, adjust the pH of the system to 10 with 15% NaOH solution, and keep warm for 40min . The reaction mixture was diluted with 1000 mL of dichloromethane, 0.2 g of 4-N,N-dimethylaminopyridine was added, and 15% NaOH solution was added dropwise to maintain the reaction mixture pH=10, and stirred for 40 min. After the reaction is completed, adjust the pH to 7 with 5% formic acid to end the reaction, separate the organic layer, and wash it three times with deionized water, then add methanol to precipitate a white solid powder, filter and dry, and dry in vacuum to obtain tetrabromobisphenol with a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com