Patents

Literature

172results about How to "Reduce the difficulty of production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

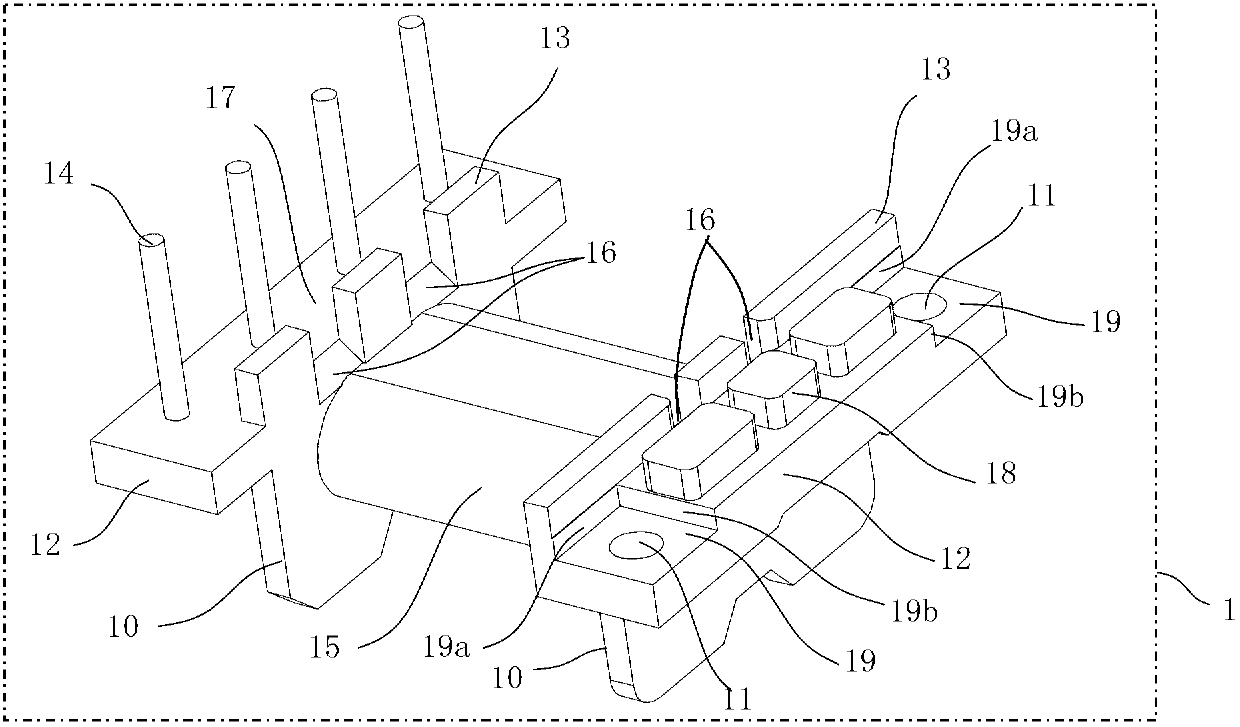

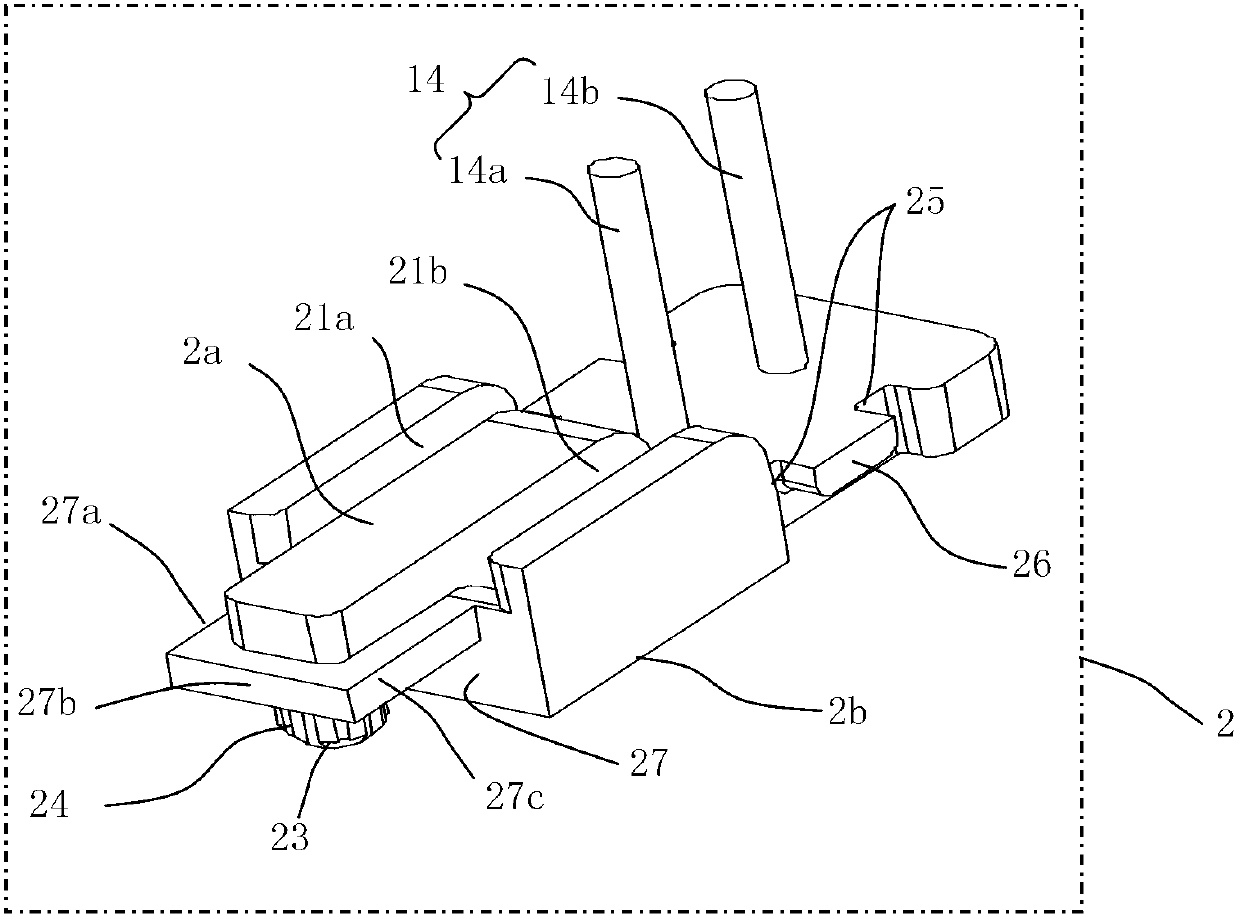

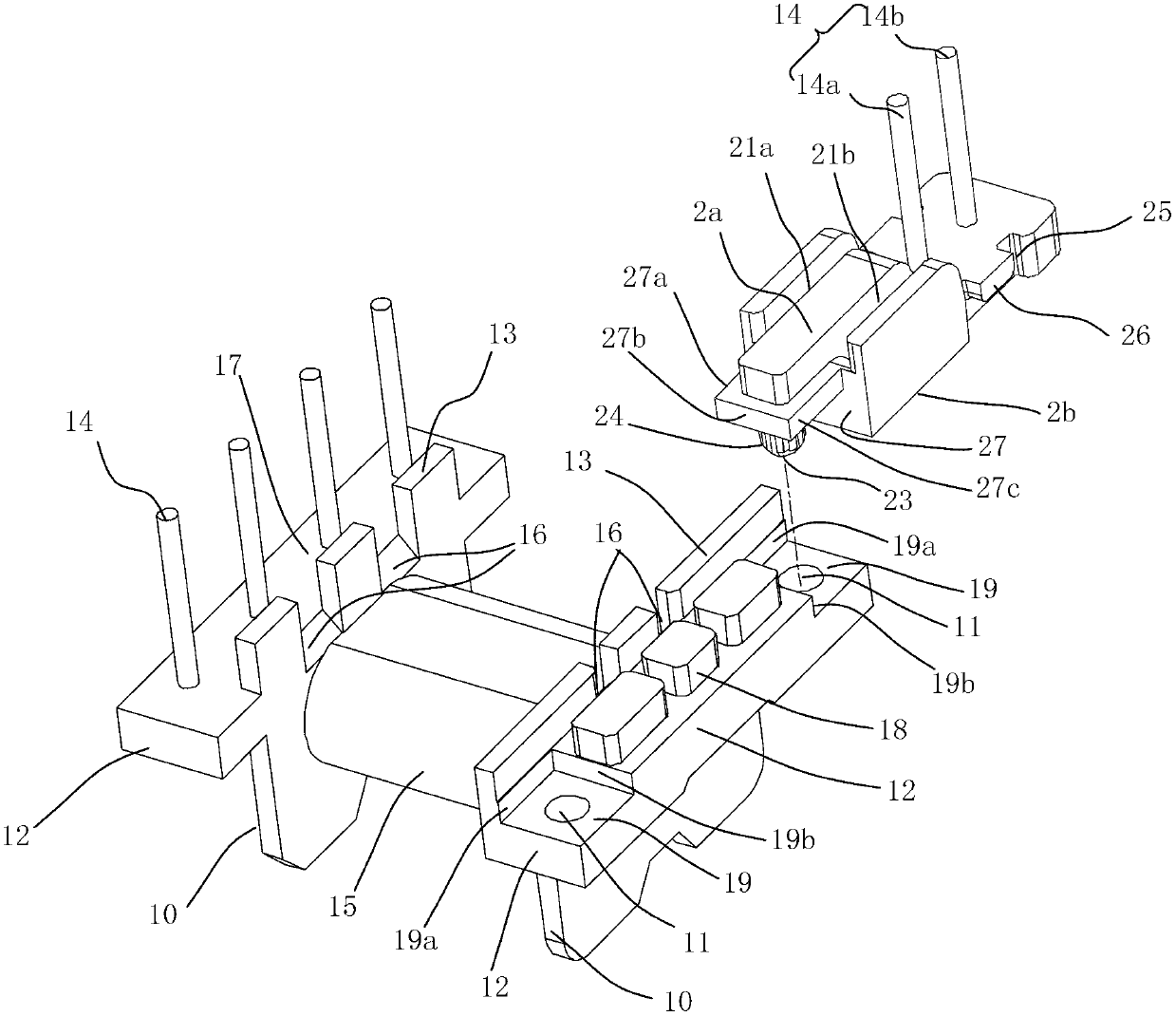

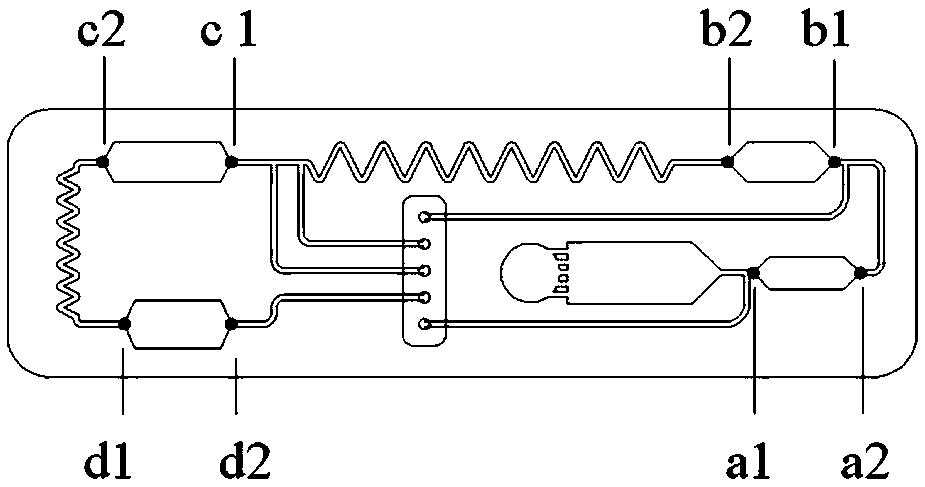

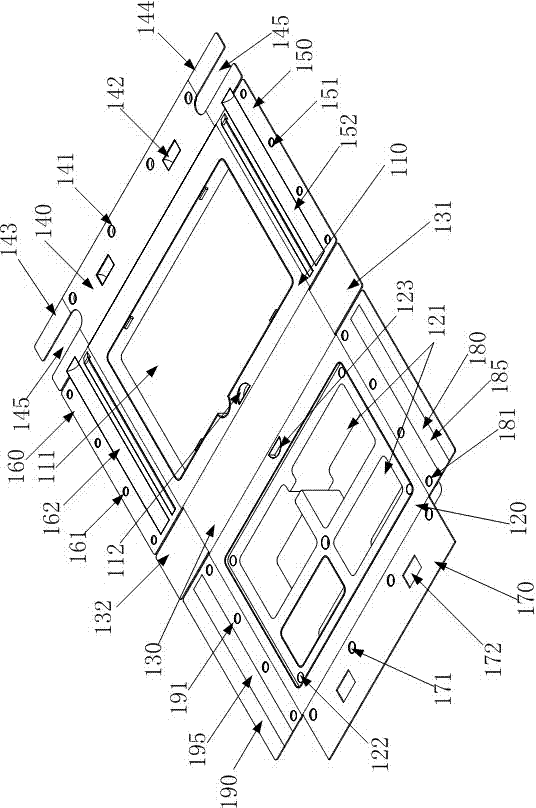

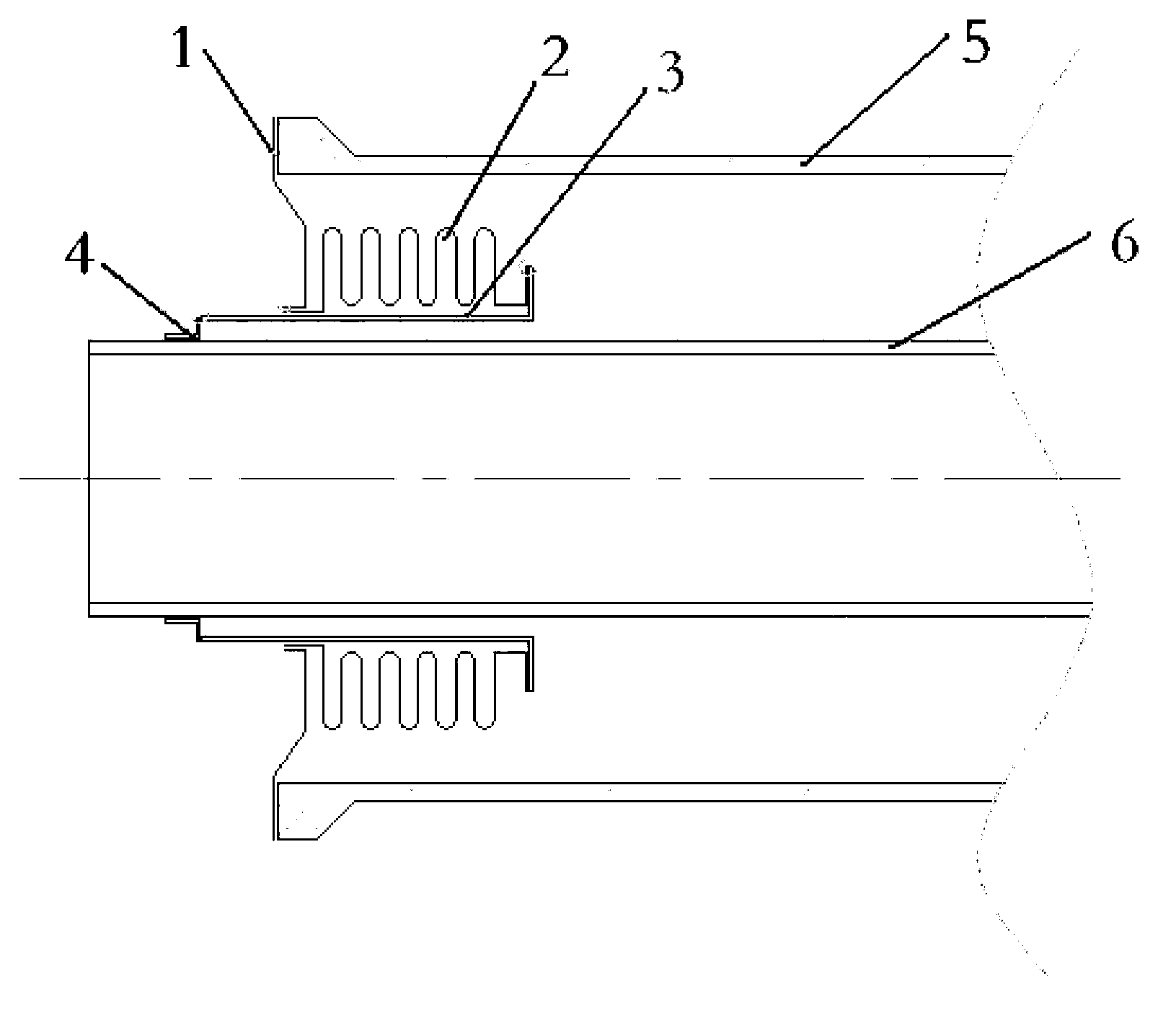

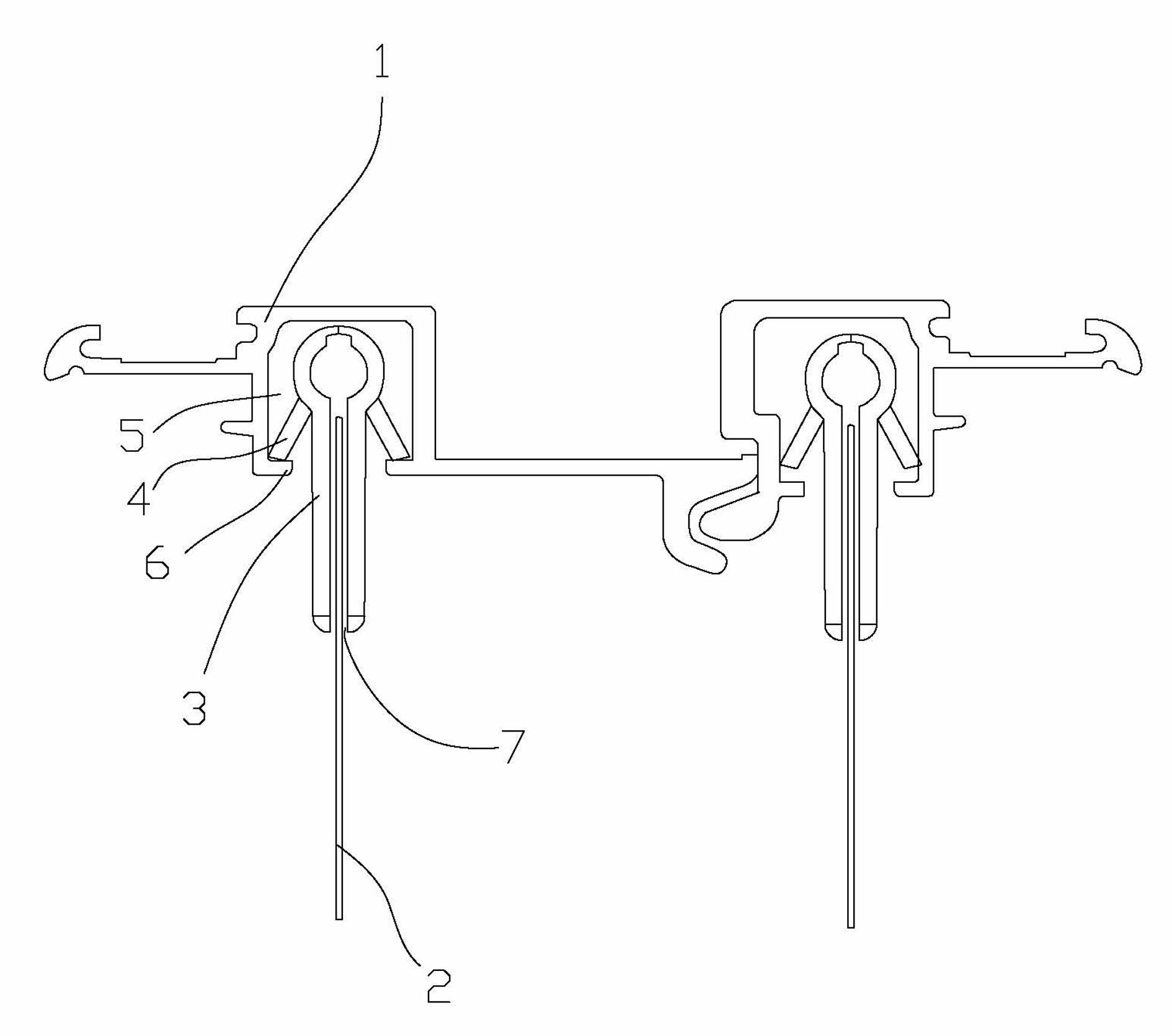

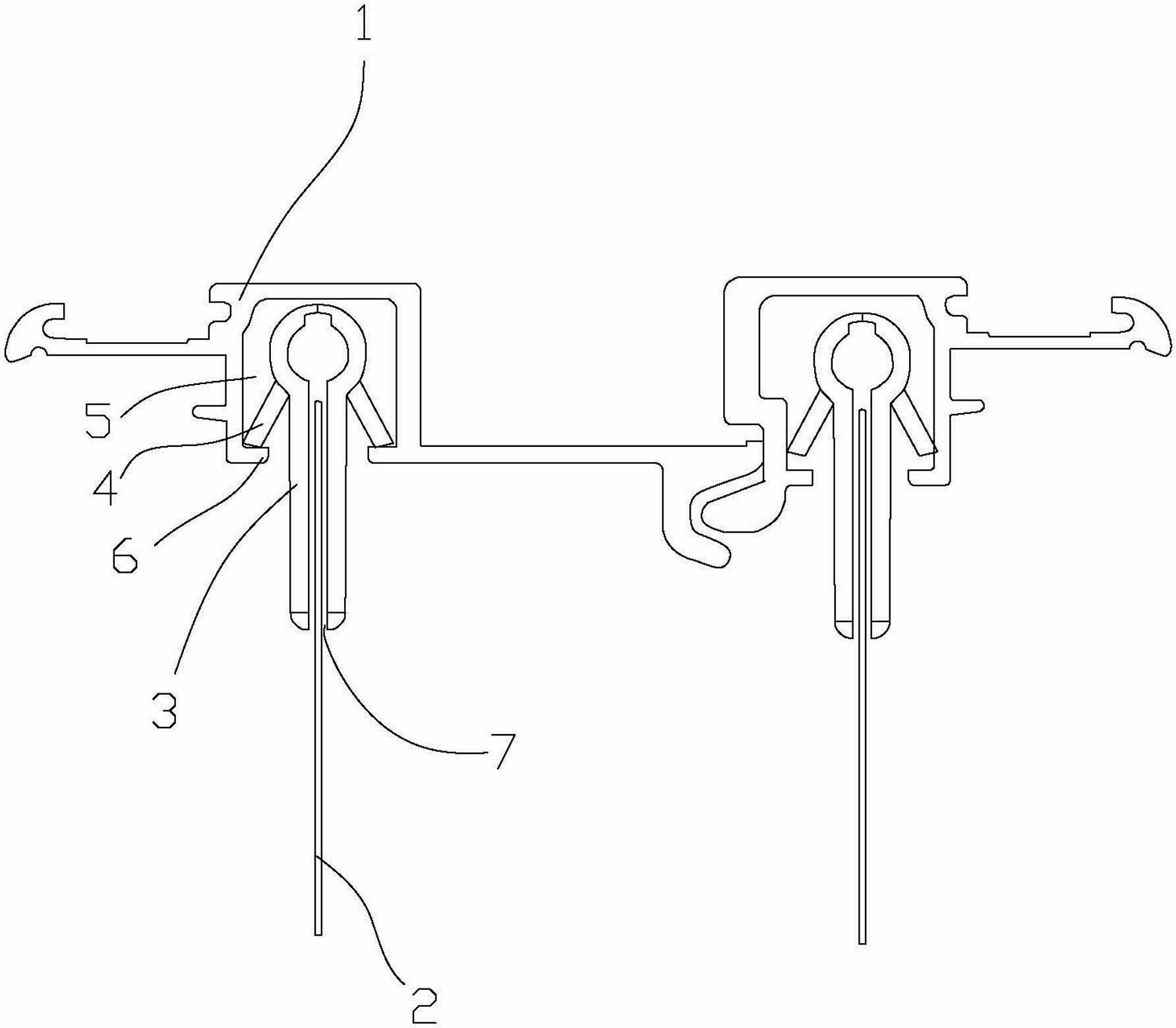

Combined adjustable transformer bobbin and transformer applying same

ActiveCN102867625ASmall sizeReduce the difficulty of production processTransformers/inductances coils/windings/connectionsLower faceBobbin

The invention discloses a combined adjustable transformer bobbin. The transformer bobbin comprises a bobbin body which is mainly composed of a main frame and at least one plug connector. The main frame comprises a winding part, and a wiring part and a bayonet socket which are respectively transversally arranged at the two ends of the winding part; the wiring part and the bayonet socket both comprise a long horizontal support plate, and the wiring part further comprises at least one wiring terminal vertically arranged on the lower deck of the support plate; the plug connector mainly comprises a long horizontal mounting plate and at least one wiring terminal vertically arranged on the lower face of one end of the mounting plate; and a connecting structure is arranged the upper face of the other end of the mounting plate and the lower face of the support plate of the bayonet socket. The invention further discloses a transformer which applies the bobbin. Through the matching and assembling of the main frame and the plug connector and the adjustment of the mounting angle of the plug connector, the electric gap and the electric creepage distance are increased to satisfy the standard requirement and to realize isolation of the single circuit or a plurality of circuits of a primary winding and a secondary winding. According to the combined adjustable transformer bobbin, the volume of the transformer is reduced, saves arrangement room of the circuit board is reduced and the difficulty is reduced in the production process.

Owner:MORNSUN GUANGZHOU SCI & TECH

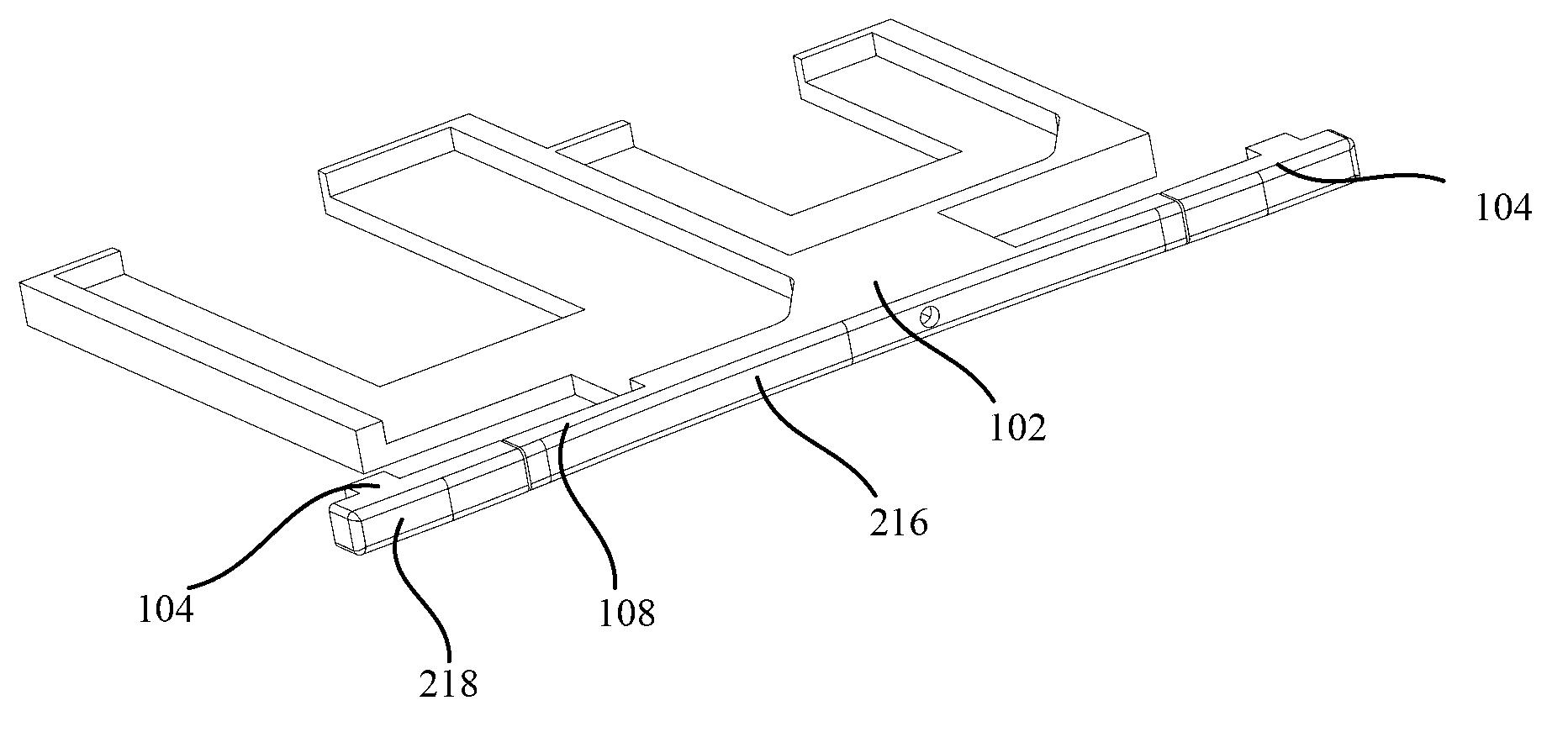

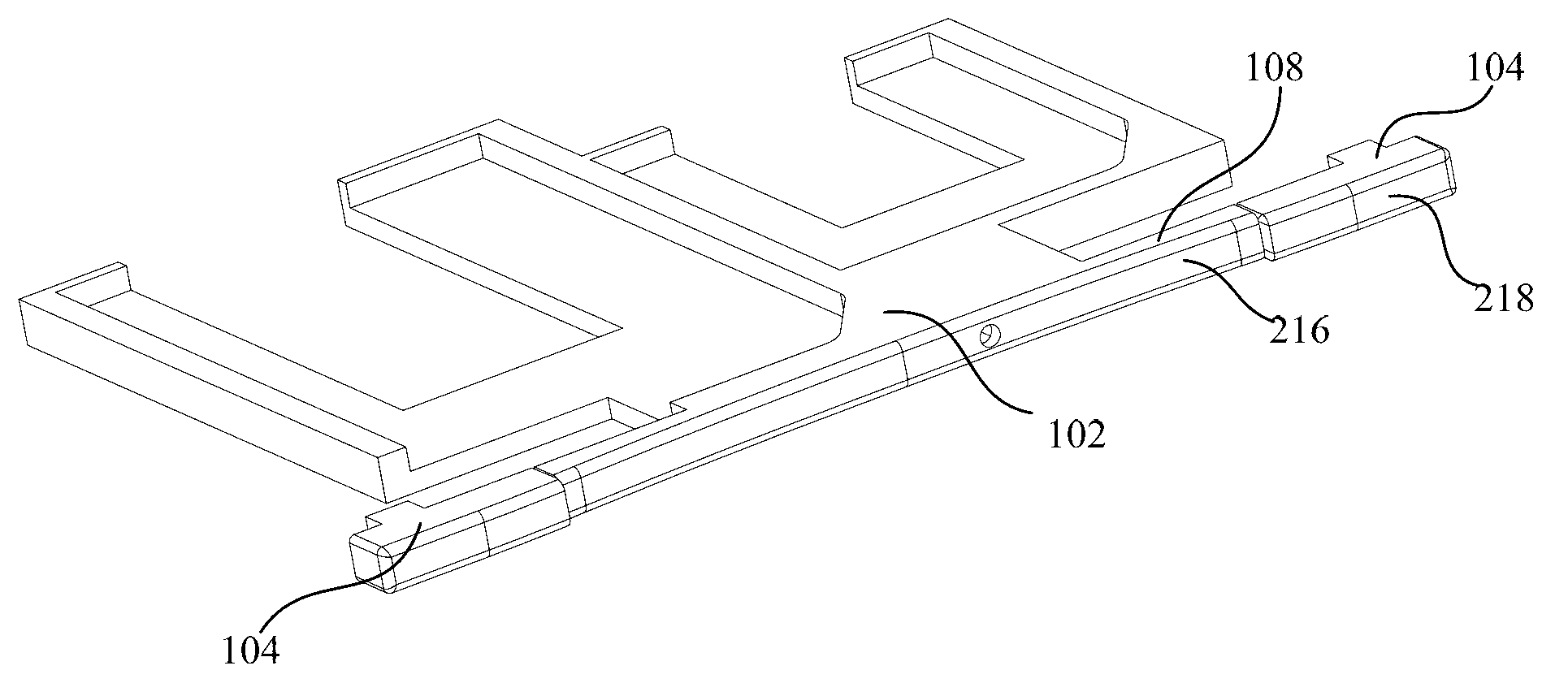

Mobile terminal and card holding device

InactiveCN103248732AReduce the number of openingsReduce manufacturing costTelephone set constructionsKey pressingComputer terminal

The invention provides a mobile terminal, which comprises a card holder and a key, wherein the key is arranged on the card holder; a side face of the mobile terminal is provided with an open groove; the card holder is inserted into the open groove; and the key is positioned at the opening of the open groove. The invention also provides a card holding device. Through the technical scheme, the card holder can be combined with a side edge key of the terminal in the terminal design, so that the number of holes formed in the side edge of a terminal shell is reduced, the production and manufacturing cost is reduced, and meanwhile, a practical and beautiful effect is achieved.

Owner:DONGGUAN YULONG COMM TECH +1

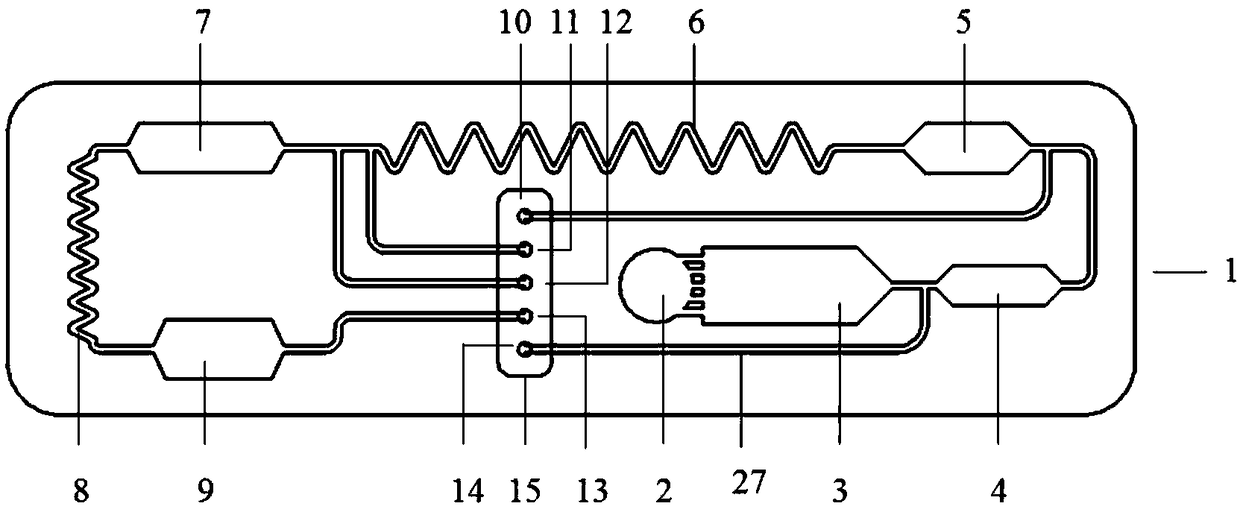

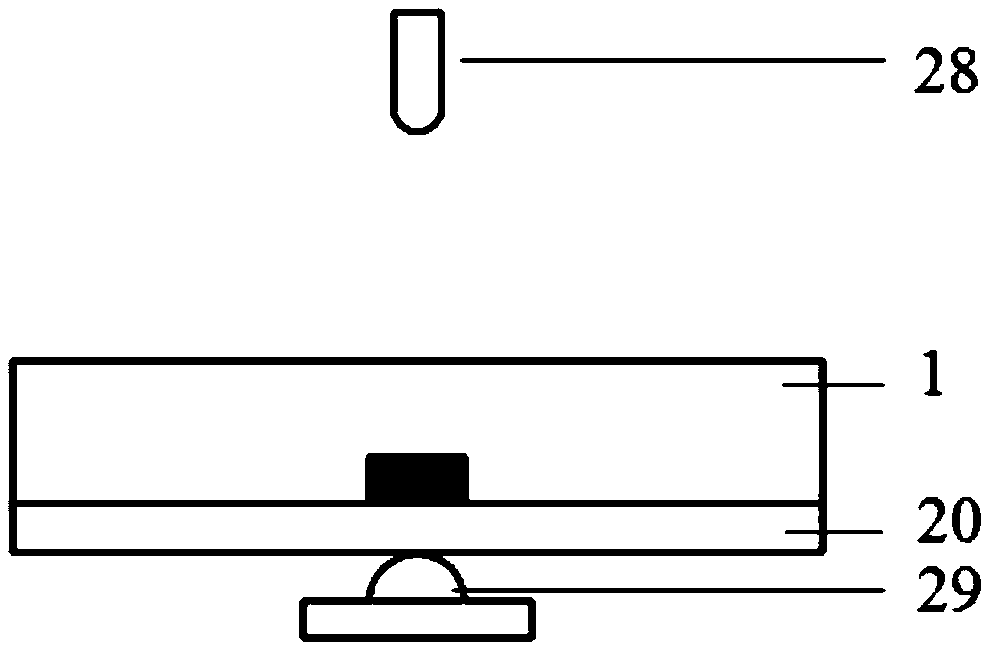

Microfluidic chip and analytical instrument with same

PendingCN108704677AEasy to useSimple structureLaboratory glasswaresBiological testingEngineeringInstrumentation

The invention discloses a microfluidic chip. The microfluidic chip comprises a main chip body, a sample inlet, an air inlet, a liquid driving force inlet, a branched air channel, a main fluid channeland multiple functional cavities, wherein the sample inlet, the air inlet, the liquid driving force inlet, the branched air channel, the main fluid channel and the functional cavities are formed in the main chip body; the main fluid channel is communicated with the functional cavities, and the liquid driving force inlet is used for being connected with a liquid driving device capable of driving fluid to flow in the main fluid channel and the functional cavities. The specific liquid quantifying cavities are used for recognizing, positioning and quantifying liquid samples, the manufacturing technological difficulty of the chip is lowered, the accuracy of quantification is improved, and the microfluidic chip is particularly suitable for quantifying and testing full-blood samples.

Owner:GUANGZHOU WONDFO BIOTECH

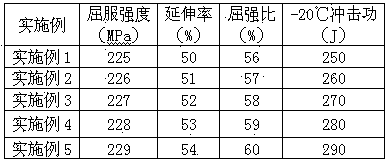

Economical low yield point steel and production method thereof

The invention belongs to the technical field of steel, and relates to rolled steel and a production method of the rolled steel, in particular to economical low yield point steel and a production method of the economical low yield point steel. Chemical components of the economical low yield point steel comprise, by weight, 0.03-0.1% of C, 0.1-0.3% of Si, 0.1-0.5% of Mn, 1.0-3.0% of Cr, 0.1-0.2% of Ni, 0.1-0.2% of Cu, 0.01-0.02% of Ti, P<=0.015%, S<=0.0020%, the balance Fe and the balance unavoidable impurity elements. The production method comprises a smelting process, a rolling process and a heat treatment process. The steel has the reasonable chemical component design and the simple production process, and the economical low yield point steel with the stable performance is obtained through the rolling process and the heat treatment process.

Owner:NANJING IRON & STEEL CO LTD

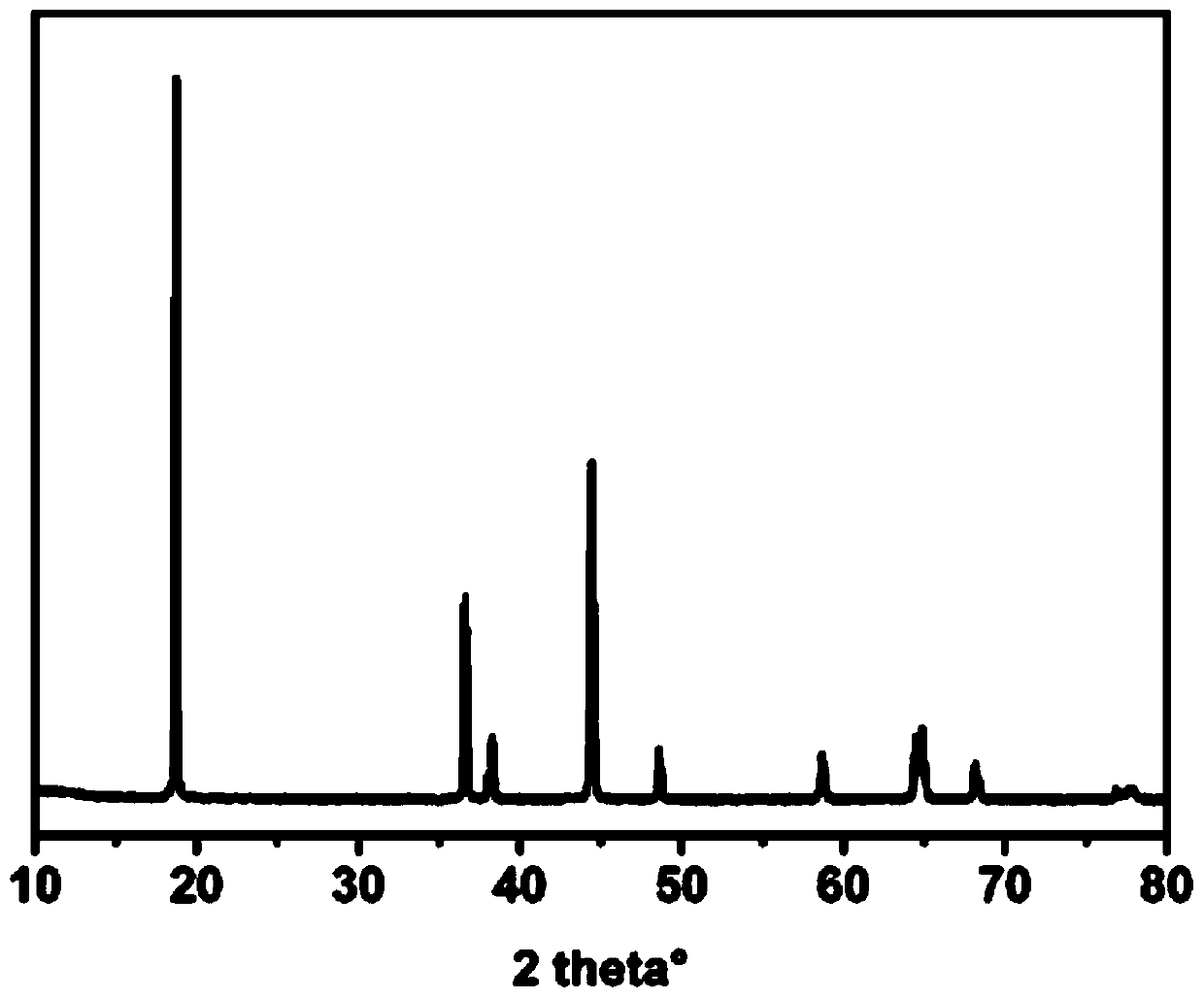

Low-angle-difference nanocrystalline magnetically soft alloy magnetic core for intelligent electric meter and preparation method thereof

ActiveCN105861959AExcellent soft magnetic propertiesImprove thermal stabilityTransformers/inductances magnetic coresMagnetic materialsAlloyInductor

The invention belongs to the field of magnetically soft alloy and particularly discloses a low-angle-difference nanocrystalline magnetically soft alloy magnetic core for an intelligent electric meter and a preparation method thereof. The molecular formula of the magnetic core is shown as follows: Fe100-a-b-c-d-eSiaBbMcCudNbeM'f, wherein a, b, c, d, e and f are atomic percents, 8<=a<=14, 2<=b<=10, 0.8<=c<=3, 1<=d<=4, 0.5<=e<=2, 0.02<=f<=0.5, the balance is Fe and unavoidable impurities, M is Al or Zn, and M' is one or more of Y, Gd, V, Mo, Mn, Ge, Er, Ga and Sn. The magnetic core which is prepared through a resultant magnetic field annealing treatment method and is excellent in soft magnetic property is further provided, and the requirement for high-precision measurement with a low-angle-difference mutual inductor for the intelligent electric meter is met.

Owner:NEW MATERIALS TECH JIANGSU AMORPHD

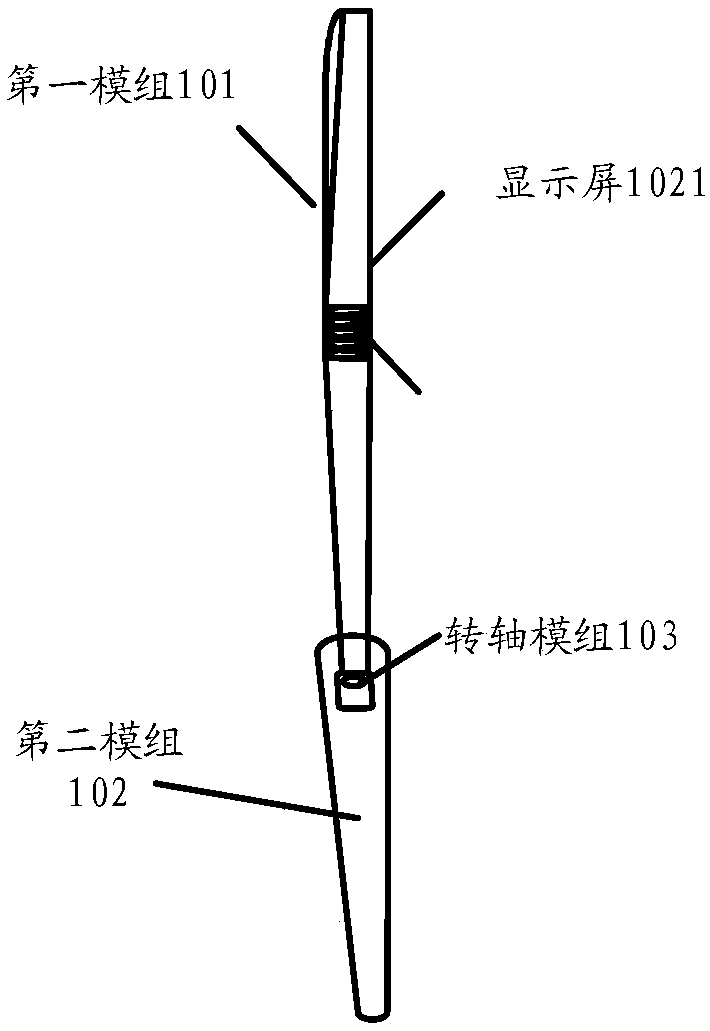

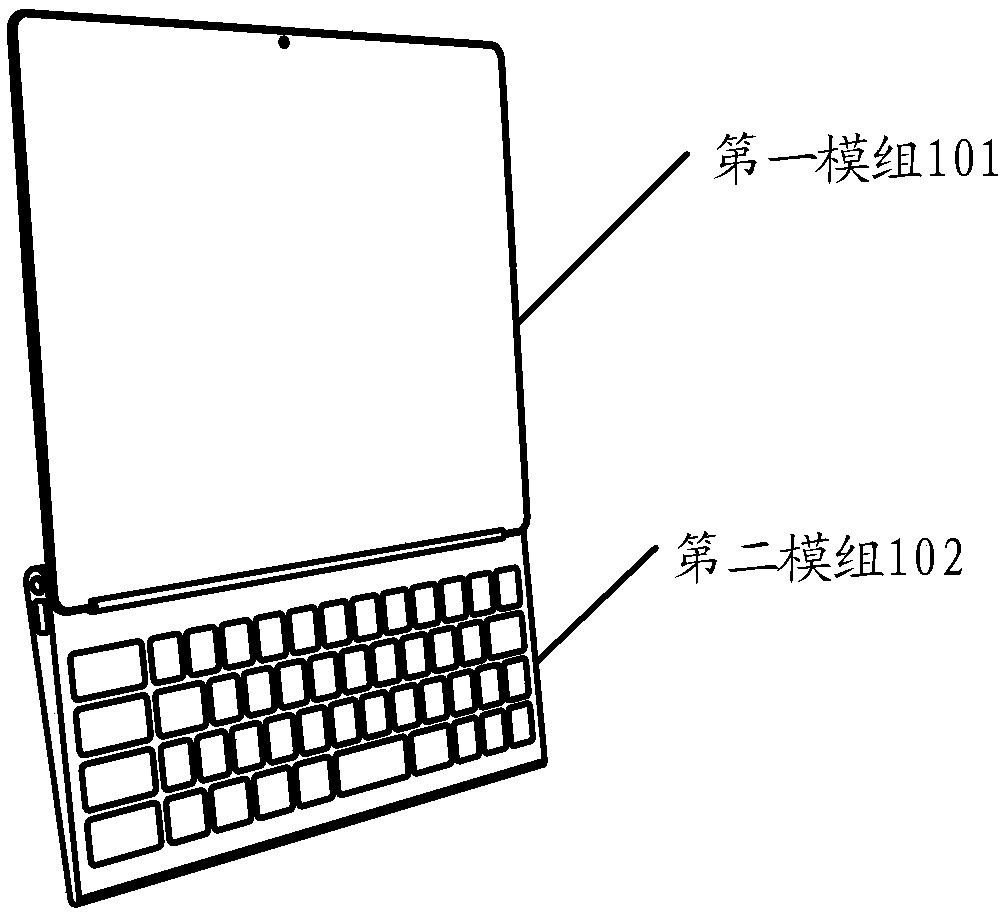

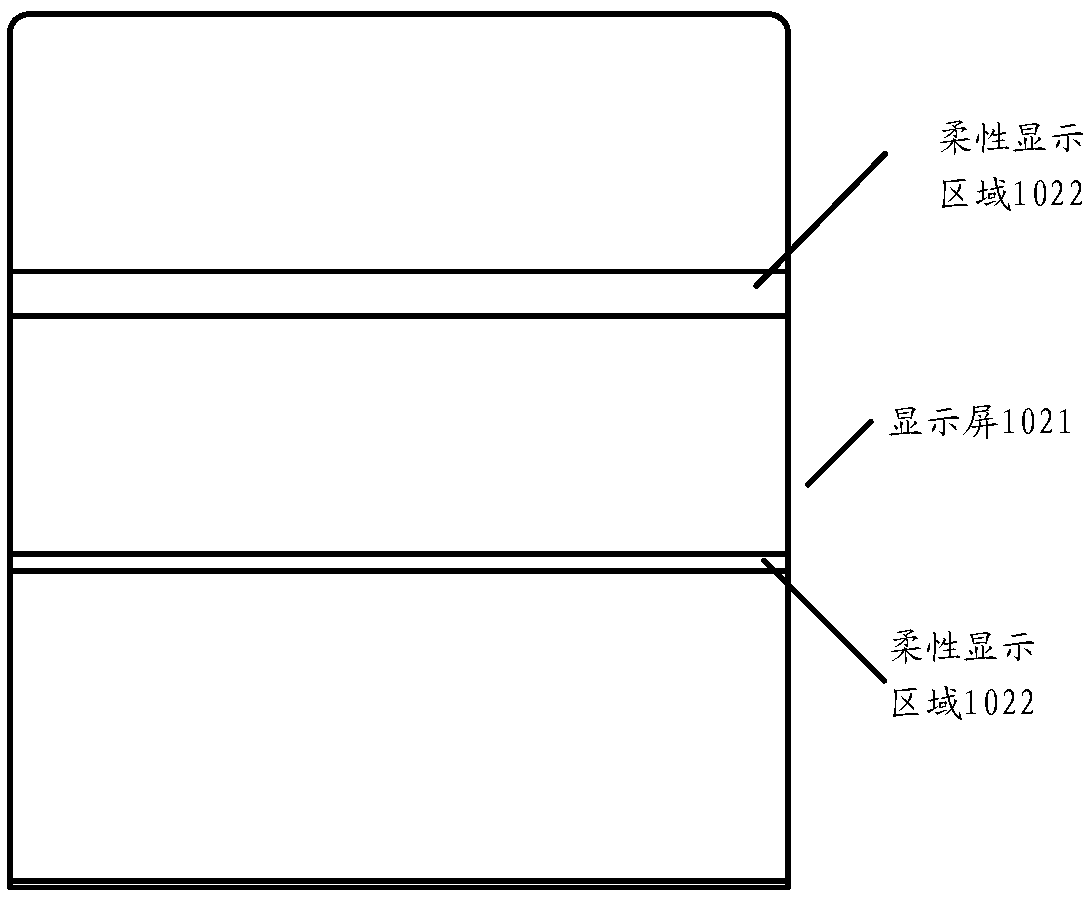

Electronic device and information processing method

ActiveCN108845621AIncrease the display areaReduce difficultyDigital data processing detailsInformation processingFlexible display

An embodiment of the invention discloses an electronic device and an information processing method. The electronic device comprises a first module and a second module; the second module comprises a display screen; the first module and the second module are connected with each other through a rotating shaft; the display screen comprises a flexible display area, wherein the flexible display area hasat least one bending axis and the bending axis and the rotation axis of the rotating shaft satisfy a parallel condition, and the flexible display area is used for unfolding or folding the display screen through its own bending.

Owner:LENOVO (BEIJING) CO LTD

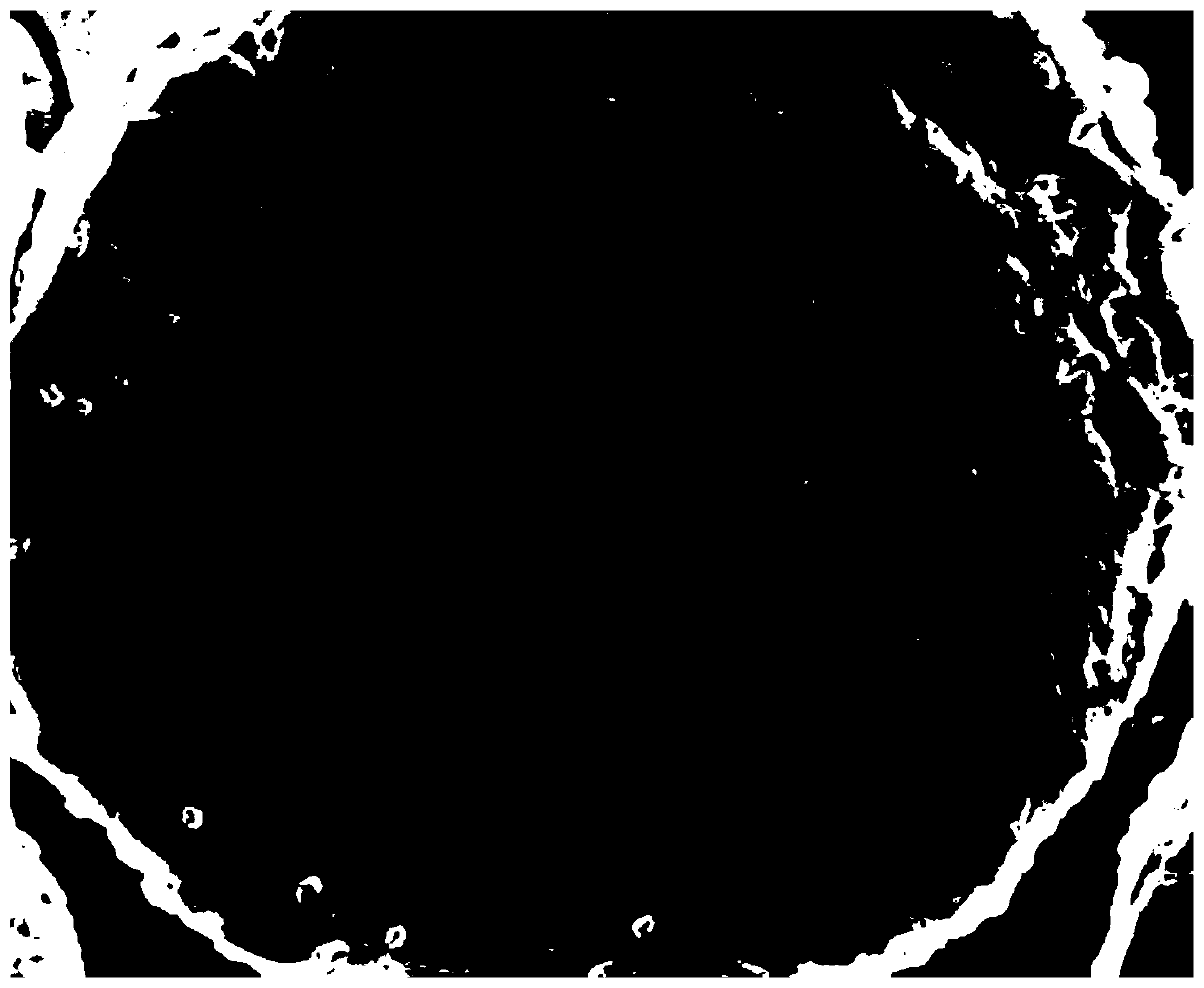

High-nickel positive electrode material with primary particles being directionally arranged, and preparation method for high-nickel positive electrode material

ActiveCN109713297AGood dispersionFacilitated releaseCell electrodesSecondary cellsLithiumThermal insulation

The preparation method comprises the following steps: (1) adding a high-nickel positive electrode material precursor, a lithium source and a dopant capable of reducing the surface energy of a crystalsurface 003 of a layered structure of the high-nickel positive electrode material into a mixing kettle, and performing stirring and uniform mixing to obtain a mixture; (2) putting the mixture obtainedat the step (1) into a muffle furnace for sintering, performing thermal insulation, cooling and screening to obtain the high-nickel positive electrode material with primary particles being directionally arranged, wherein the molecular formula of the high-nickel positive electrode material with primary particles being directionally arranged is LiNixMyO2, x is greater than or equal to 0.5 and lessthan 1, y is greater than or equal to 0 and less than 0.5, x + y is equal to 1, and M is one or more than one metal element. According to the invention, the growth orientation and shape of primary particle crystals are controlled by selecting a dopant capable of reducing the surface energy of a specific crystal face of the crystal, so that the high-nickel positive electrode material secondary particles with long circulation and high safety are obtained, wherein the primary particles in the high-nickel positive electrode material secondary particles are arranged in a radial manner and grow directionally.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

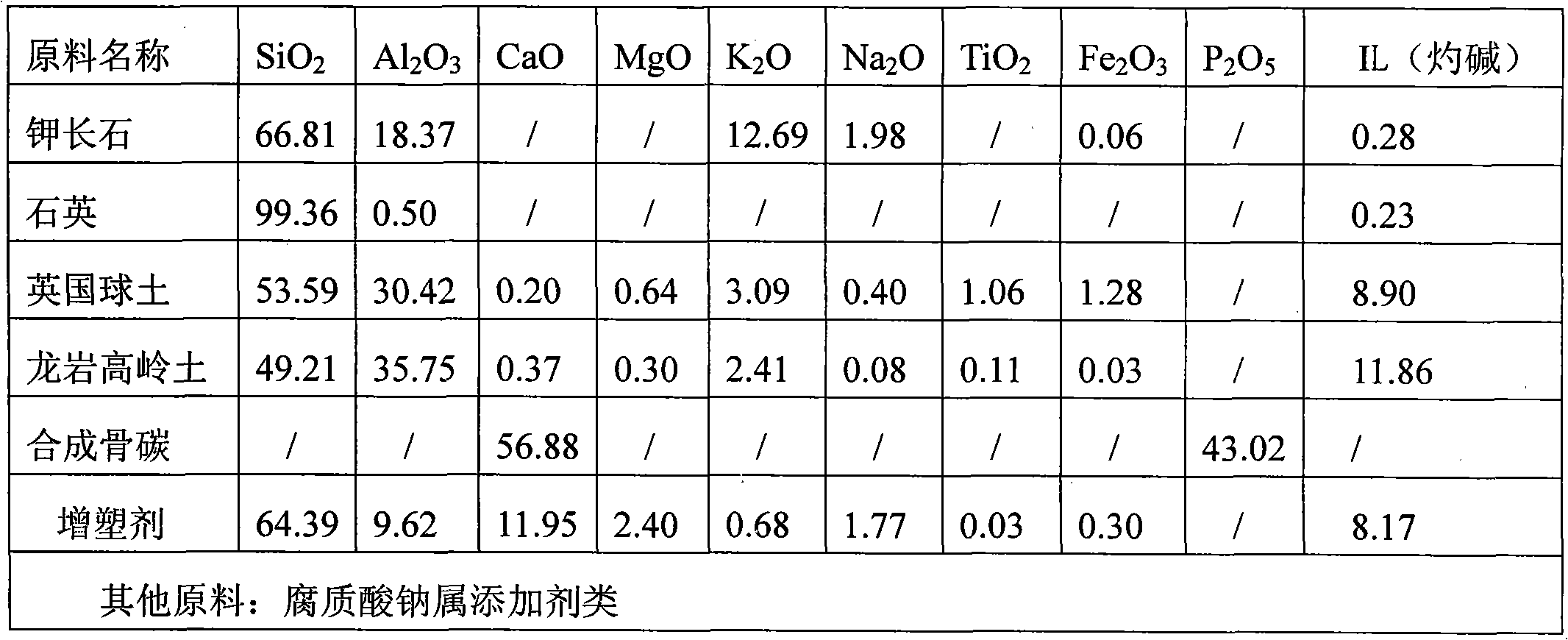

Bone china paste and preparing technology thereof

The invention discloses a bone china paste and a preparing technology thereof. The bone china paste comprises the following components by weight percent: 34.0-38.0% of SiO2, 12.0-16.0% of Al2O3, 0.2-0.4% of Fe2O3, 0.05-0.2% of TiO2, 24.5-27.0% of CaO, 0.5-1.5% of MgO, 18.0-21.0% of P2O5 and 0-4.0% of K2O and Na2O2, wherein the sum of the weight percent of the compounds is 100%. Ball clay is introduced in the bone china paste to increase the plasticity of the paste; and synthetic bone char is used to replace natural bone char, thus the dependence of the mass production of the bone china paste to natural bone char can be lowered and the paste can have reasonable chemical composition and better physical performance indexes; and the formability of paste can be improved, the production technology difficulty of bone china can be reduced, the qualification rate of products can be greatly increased, and technical supports can be provided for the batch production of bone china.

Owner:SHENZHEN YONG FENG YUAN IND

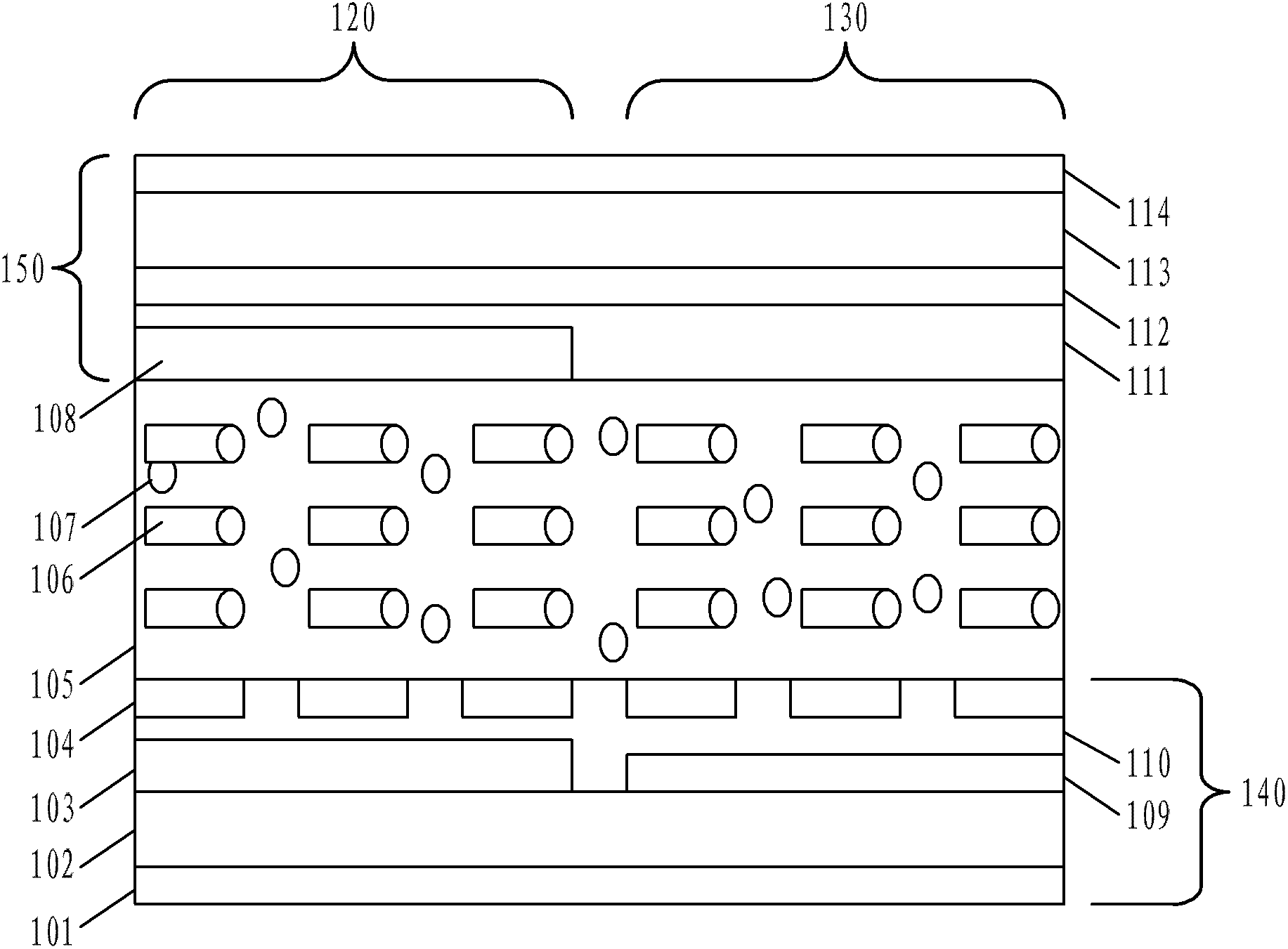

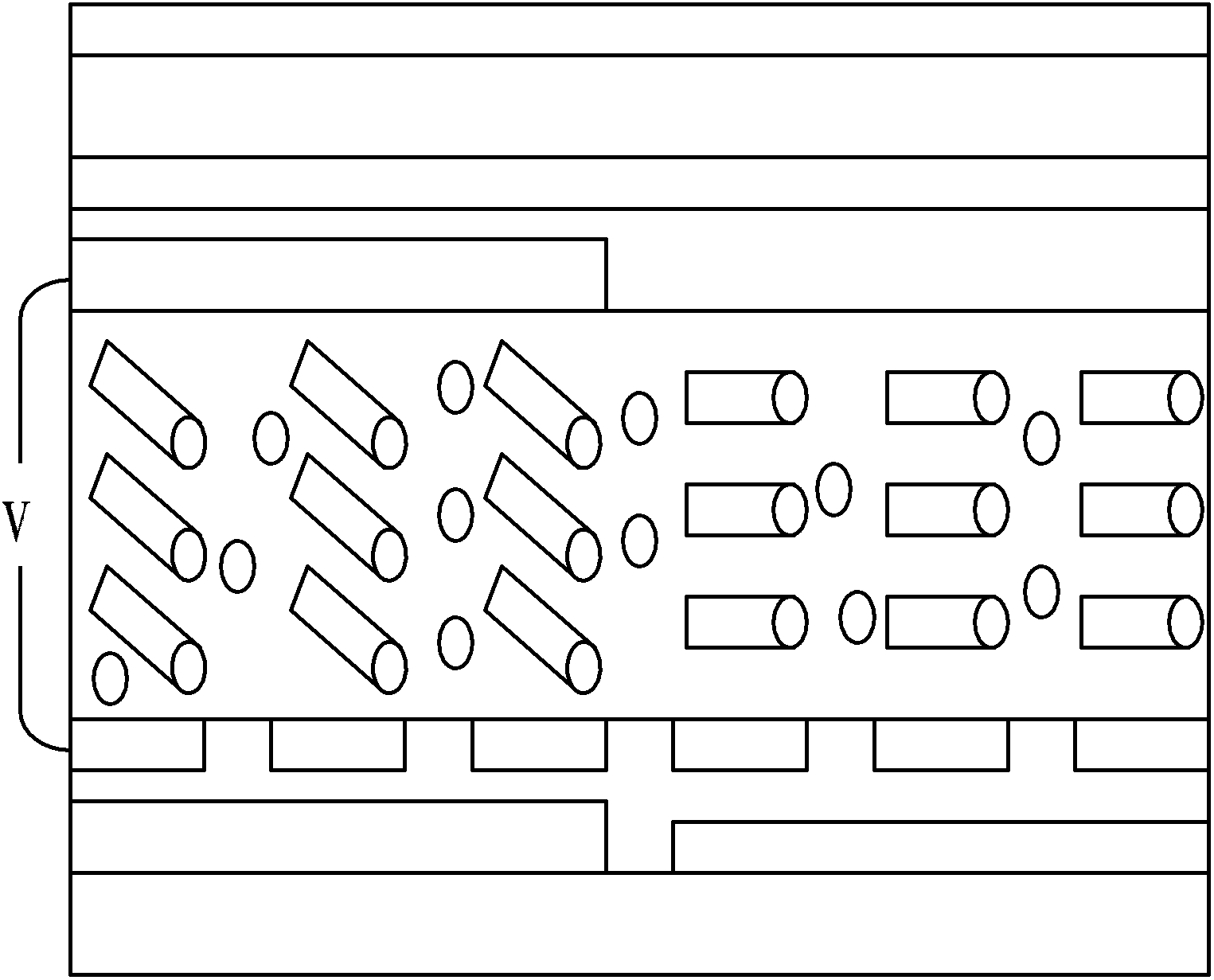

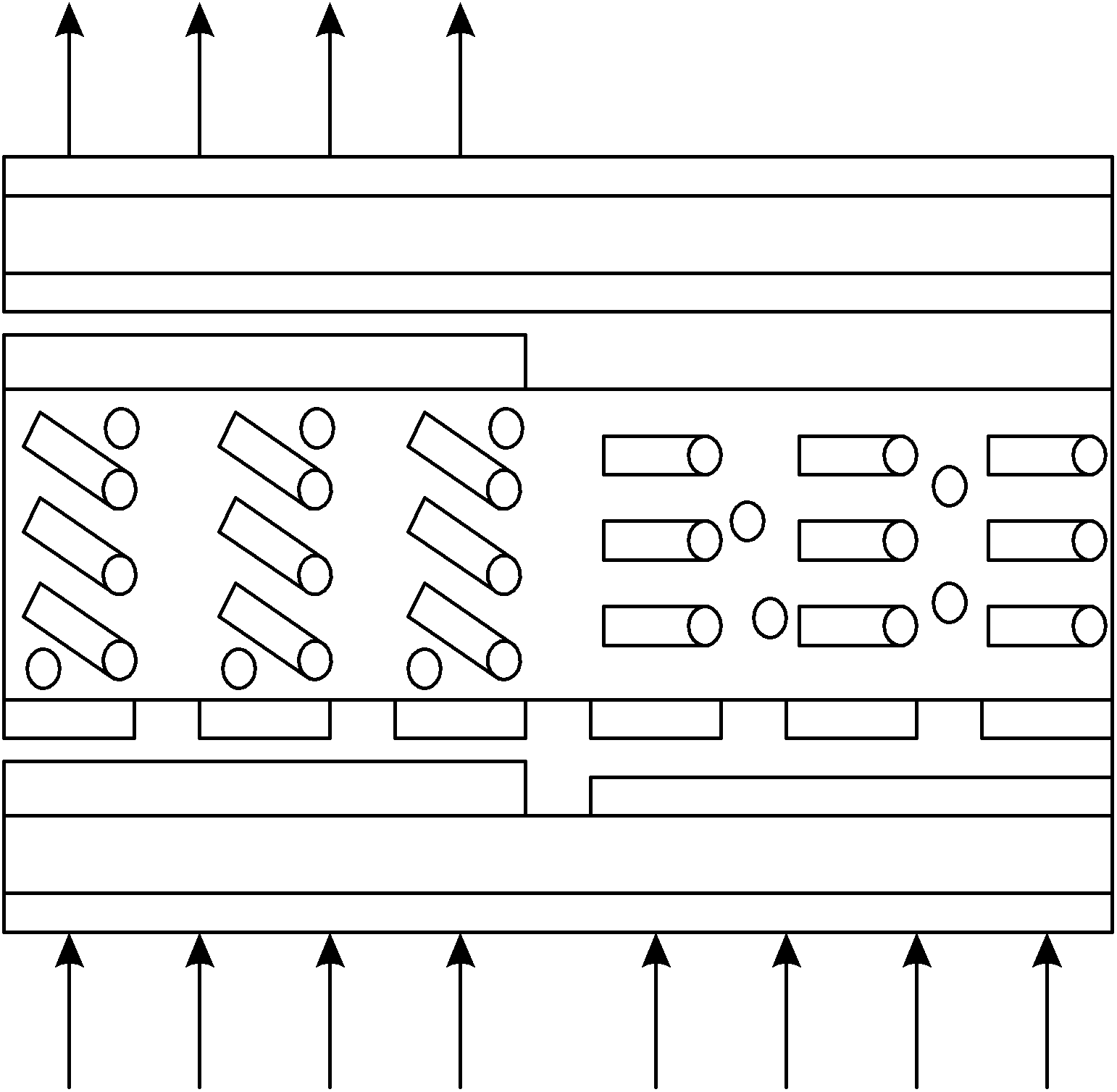

Semi-transmitting half-reflection liquid crystal display and manufacturing method thereof

ActiveCN102629034AReduce the difficulty of production processReduce manufacturing costNon-linear opticsLiquid-crystal displayLiquid crystal

The invention provides a semi-transmitting half-reflection liquid crystal display and a manufacturing method thereof. The semi-transmitting half-reflection liquid crystal display comprises a plurality of pixels, wherein each pixel comprises a transmission region and a reflection region which are adjacent to each other and have the same box thickness; each pixel also comprises a first transparent electrode arranged between a liquid crystal layer and an array substrate; the transmission region of each pixel comprises a second transparent electrode arranged between the liquid crystal layer and a color film substrate; a voltage difference is formed between a first voltage applied by the first transparent electrode and a second voltage applied by the second transparent electrode; due to the voltage difference, an initial optical delay of the liquid crystal layer positioned in each transmission region is one second of wavelength; in each pixel, an initial optical delay of the liquid crystal layer positioned in the reflection region is three fourths of wavelength, so that the transmission region and the reflection region of each pixel have different optical delays; and due to the adoption of the design of equal box thicknesses of the transmission regions and the reflection regions, the manufacturing process is simple.

Owner:BOE TECH GRP CO LTD

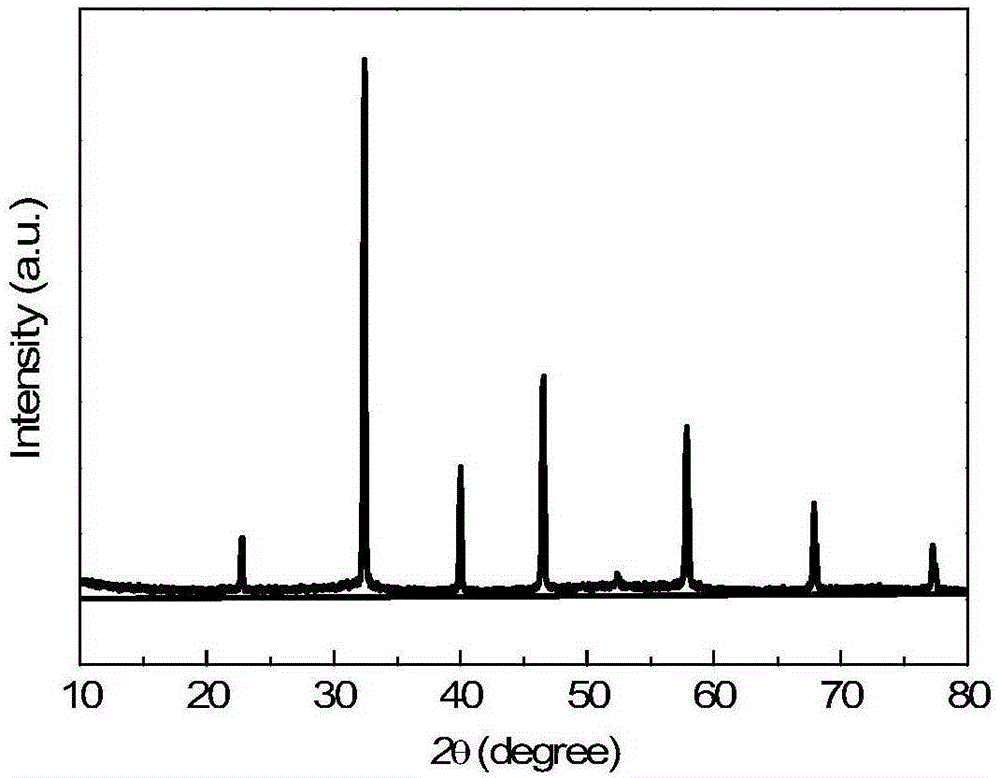

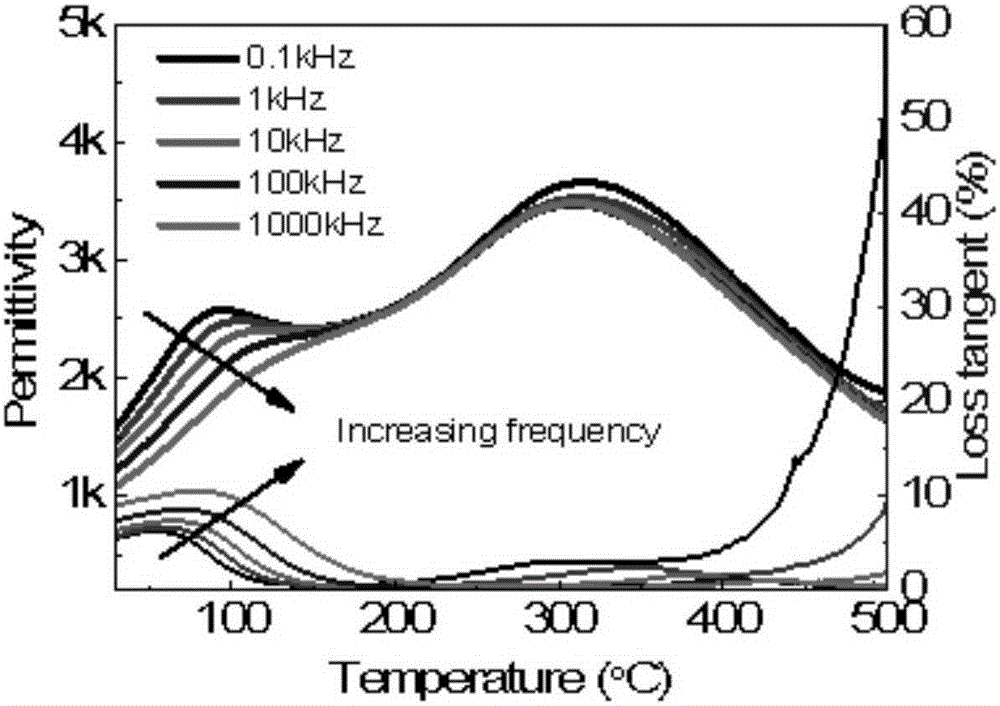

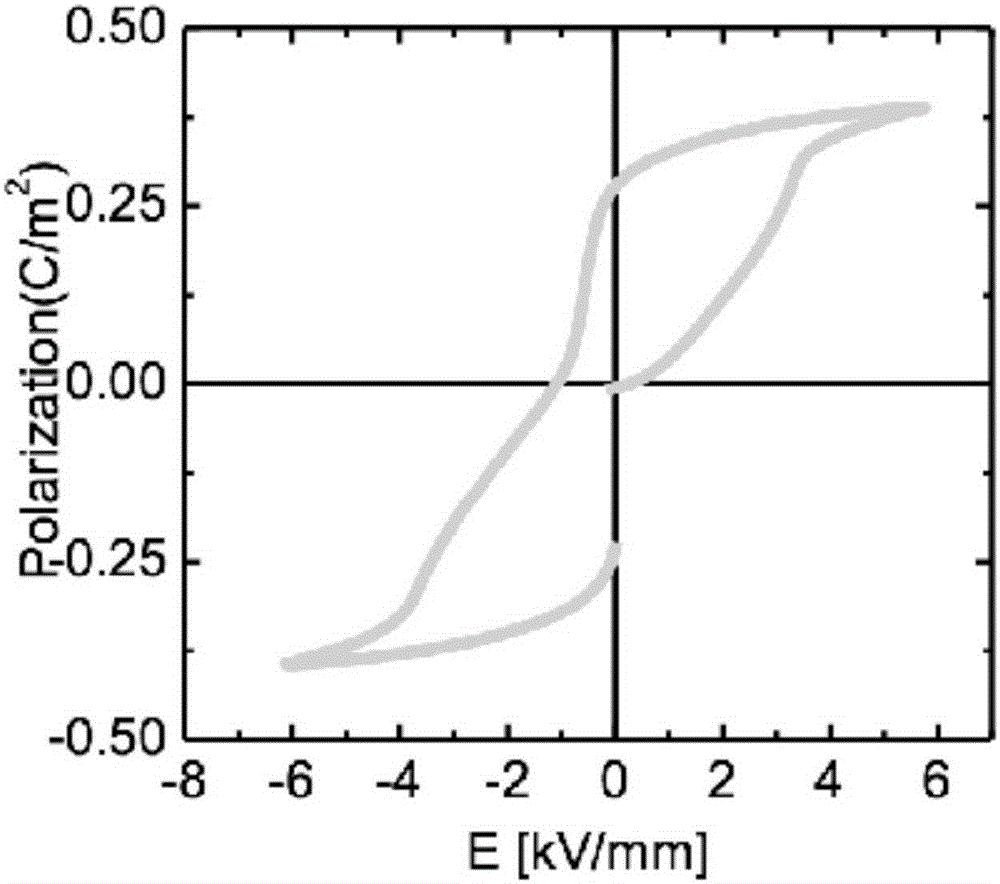

Large-strain low-drive electric field relaxation and ferroelectric composite lead-free piezoelectric ceramic and preparation method thereof

InactiveCN105198411ANo pollutionReduce the difficulty of production processElectric fieldDry pressing

The invention discloses large-strain low-drive electric field relaxation and ferroelectric composite lead-free piezoelectric ceramic and a preparation method thereof. The method includes: acquiring a component A, (1-x1-y1)Bi0.5Na0.5TiO3-x1Bi0.5K0.5TiO3-y1AgNbO3, wherein 0.16< / =x1< / =0.22, 0.01< / =y1< / =0.03; or (1-x2-y2)Bi0.5Na0.5TiO3-x2BaTiO3-y2AgNbO3, wherein 5< / =x2< / =0.07, 0.01< / =y2< / =0.03; and a component B, (1-z)Bi0.5Na0.5TiO3-zBaTiO3, wherein 0.05< / =z< / =0.07; or (1-w)Bi0.5Na0.5TiO3-wBi0.5K0.5TiO3, wherein 0.16< / =w< / =0.22; after drying, heating, pre-sintering, ball-milling and drying, pre-sintering each component for 3 hours; after grinding, mixing ferroelectric lead-free ceramic B and relaxation lead-free piezoelectric ceramic B, performing ball-milling for 4 hours, and performing PVA granulating, dry-pressing forming, sintering and polishing to obtain the composite lead-free piezoelectric ceramic. The performance is improved, production technical difficulty is lowered, and cost is lowered.

Owner:张海波

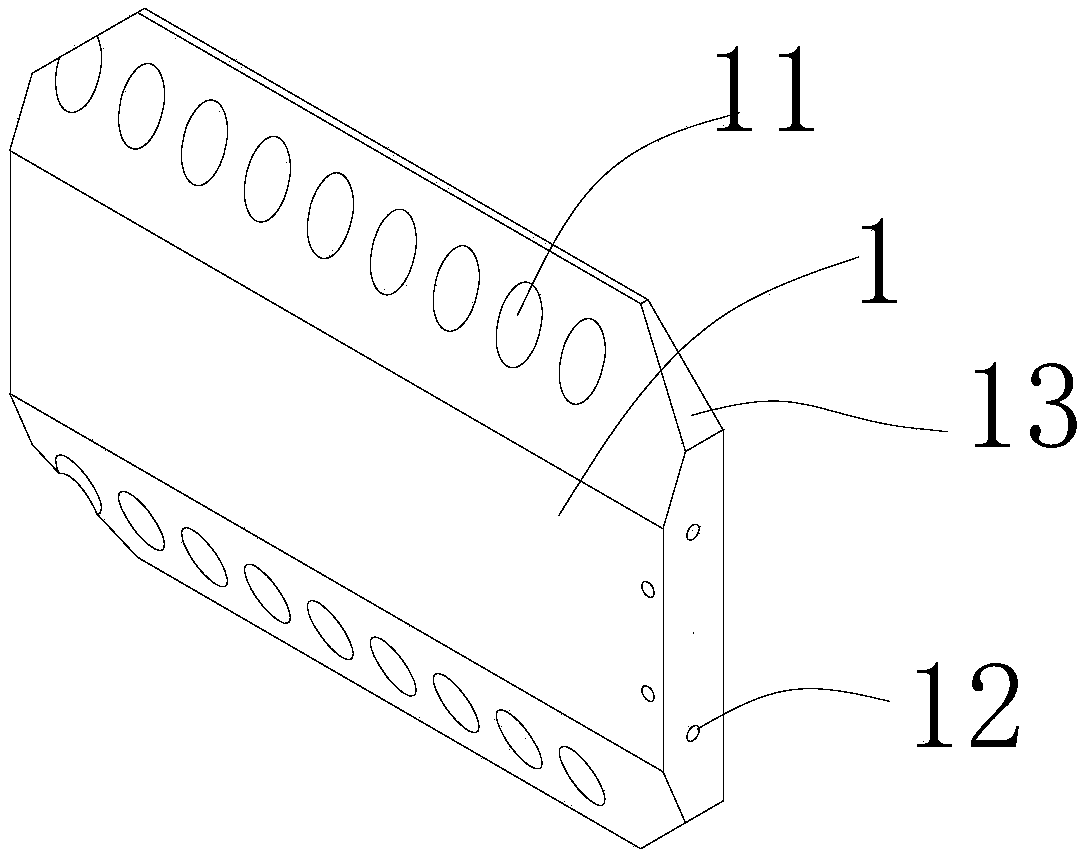

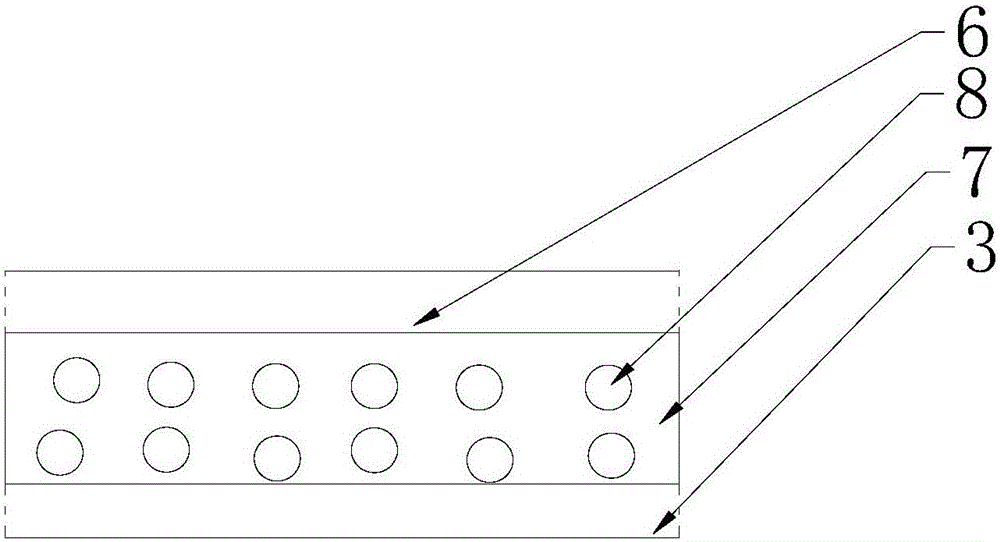

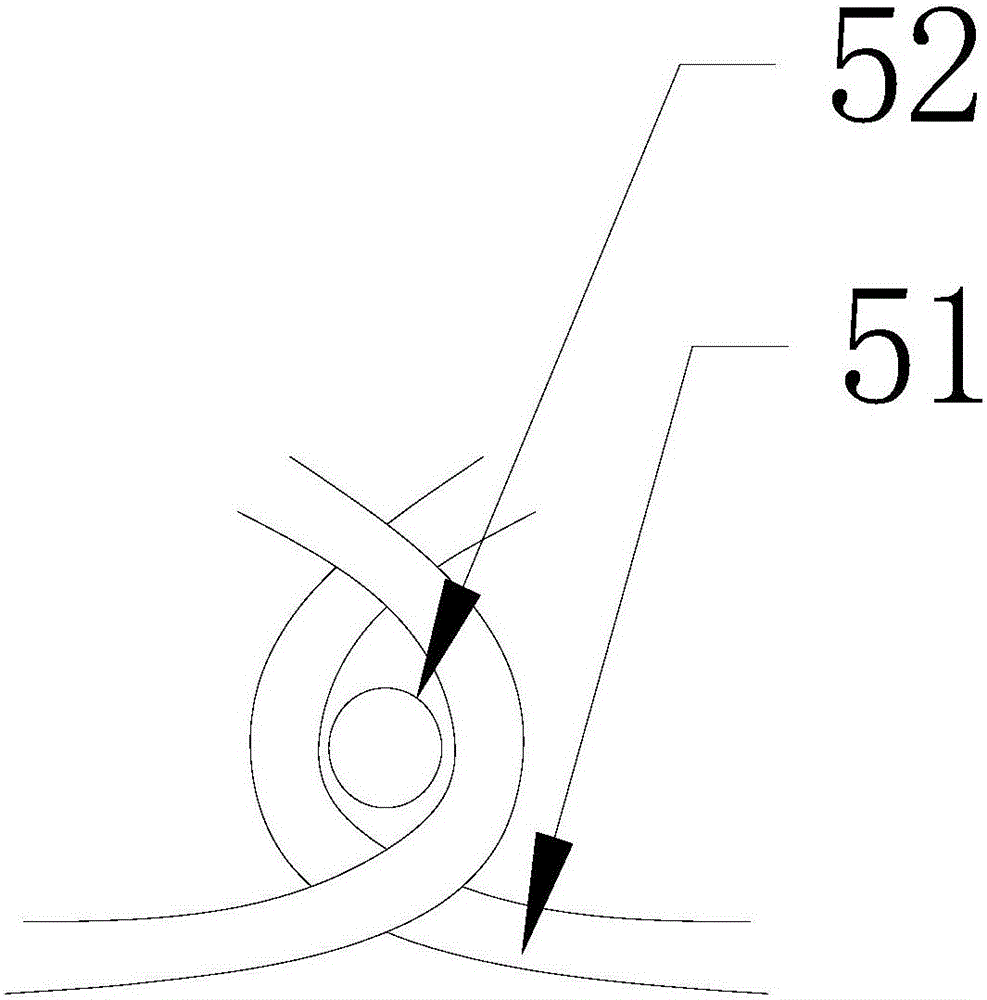

Novel galvanometer for laser machining equipment

ActiveCN108161219AShort preparation timeImprove efficiencyLaser beam welding apparatusLaser processingGalvanometer

The invention provides a novel galvanometer for laser processing equipment. The galvanometer body is a flake-like structure, and the galvanometer is characterized in that the galvanometer body is madeof aluminum or aluminum alloy; one face of the galvanometer body is plated with a reflecting film formed as a reflecting surface; one end of the galvanometer body is connected to a rotating output end of a motor, and the rotation axis is located in the galvanometer body, and is parallel to the mirror surface; the galvanometer body is internally provided with a plurality of hollow holes arranged in parallel, and partition walls between adjacent hollow holes are formed as reinforcing ribs of the galvanometer; the hollow holes are formed opposite the rotation axis, parallel to the mirror surface, and penetrate from one end of the galvanometer body to the opposite end; The novel galvanometer has the advantages that the structure design is original, the production cost is low and the materialsare different, so that it is convenient for production and industrialization, and the service life is long.

Owner:GUANGZHOU NEW CKLASER CO LTD

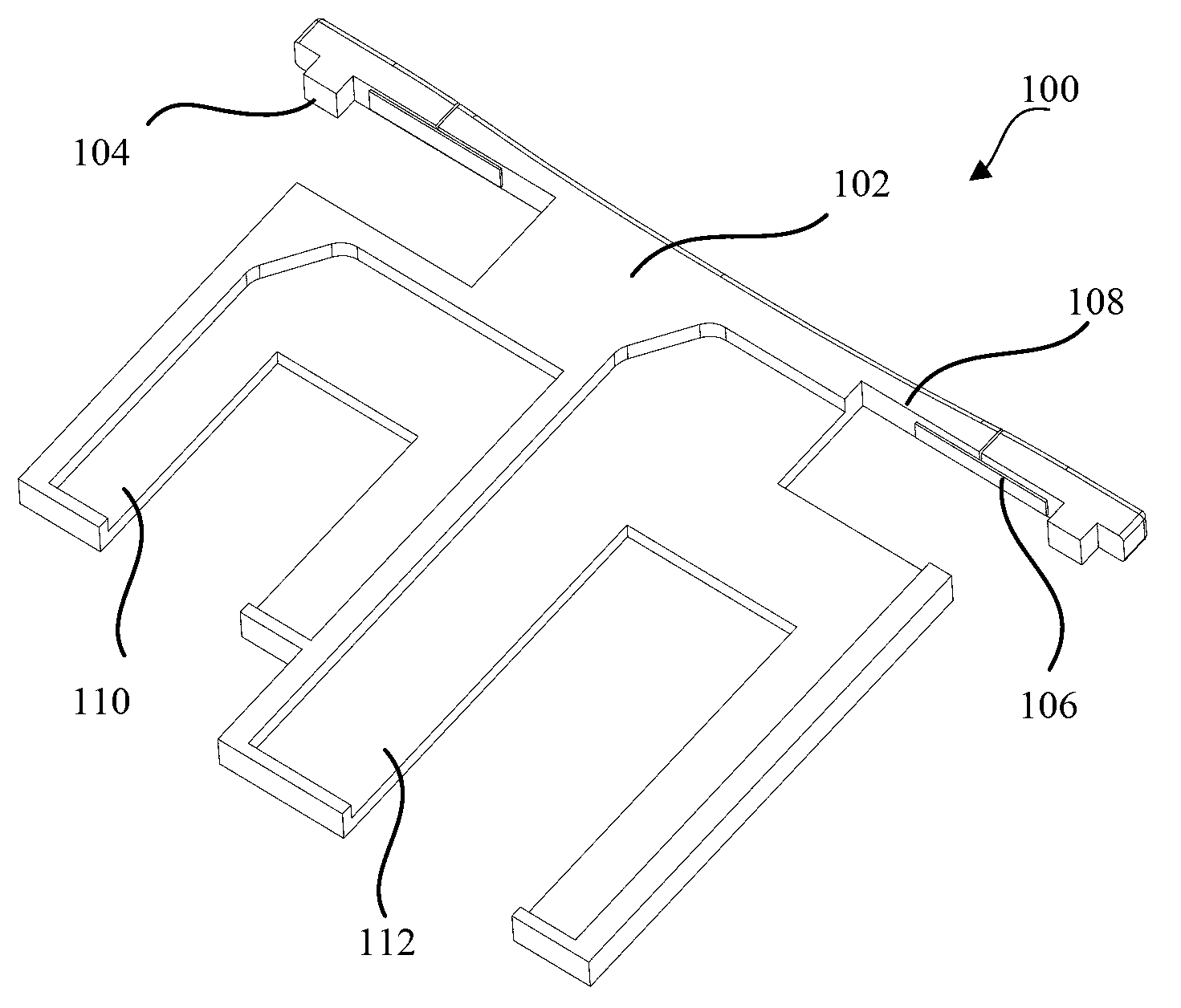

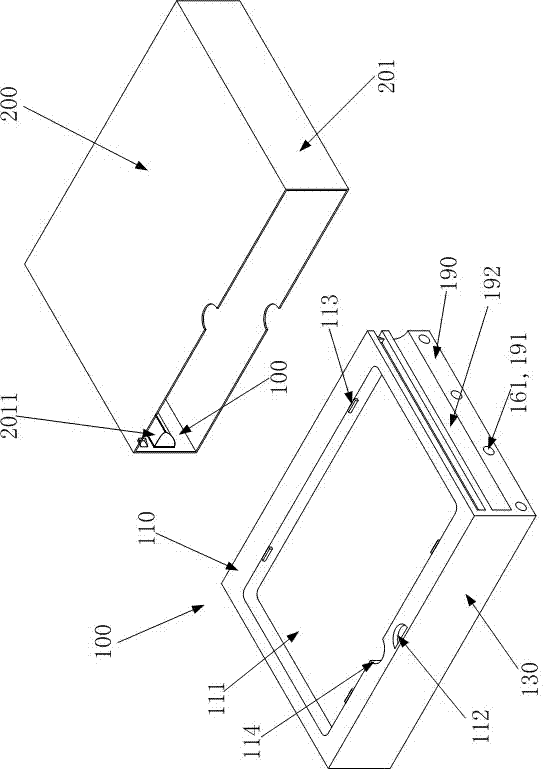

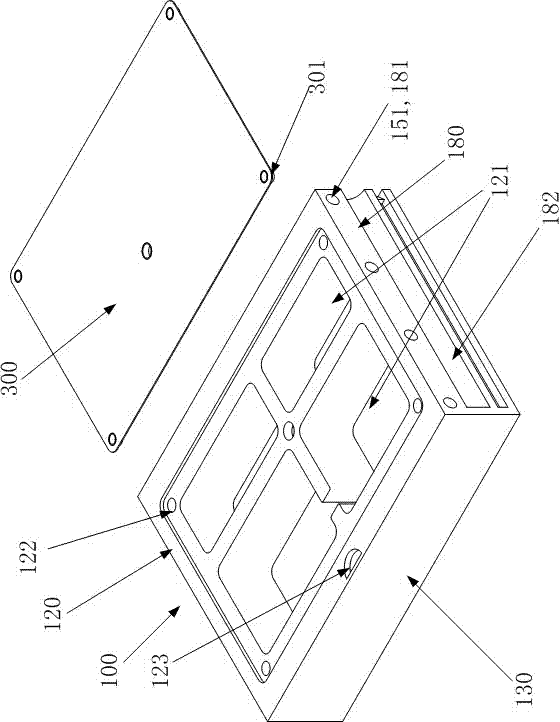

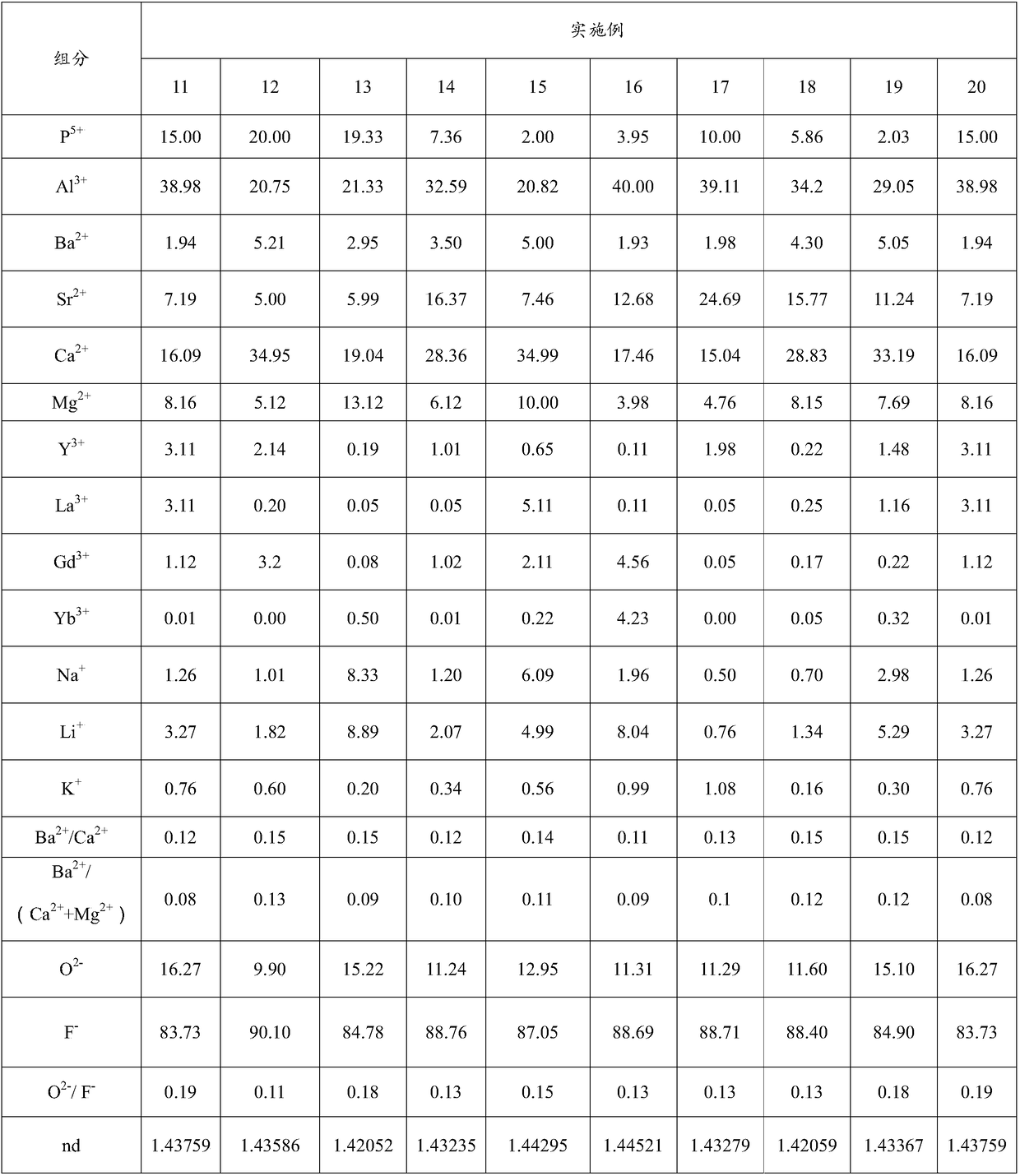

Package box of tablet personal computer

ActiveCN103029886AImprove toughnessHigh strengthPackaging vehiclesContainers for machinesEngineeringPersonal computer

The invention relates to a package box of a tablet personal computer. The package box comprises an outer casing (200) and a buffer positioning body (100), wherein the buffer positioning body (100) is formed through folding a blistered plate and comprises a first panel (110), a second panel (120) and a middle connecting plate (130), a host machine groove (111) is arranged in the first panel (110), an accessory groove (121) is arranged in the second panel (120), the first panel (110) and the second panel (120) are folded along connecting parts between the first panel (110) and the middle connecting plate (130) and between the second panel (120) and the middle connecting plate (130), and a shape that the host machine groove (111) is opposite to the accessory groove (121) is formed. The designed package box has the advantages that the toughness is good, the intensity is high, the labor is saved, environment protection and no toxicity are realized, the formation according to different shapes of products can be realized, and concave-convex blistered products are formed, so the processing difficulty is reduced through being compared with that of the traditional package box, and more than 20 percent of production cost is reduced.

Owner:MYS GRP CO LTD

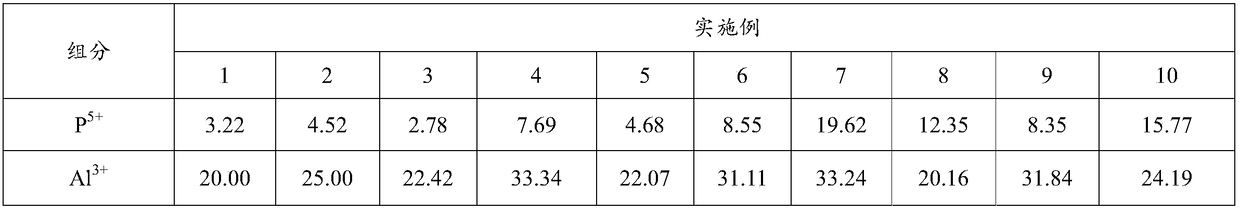

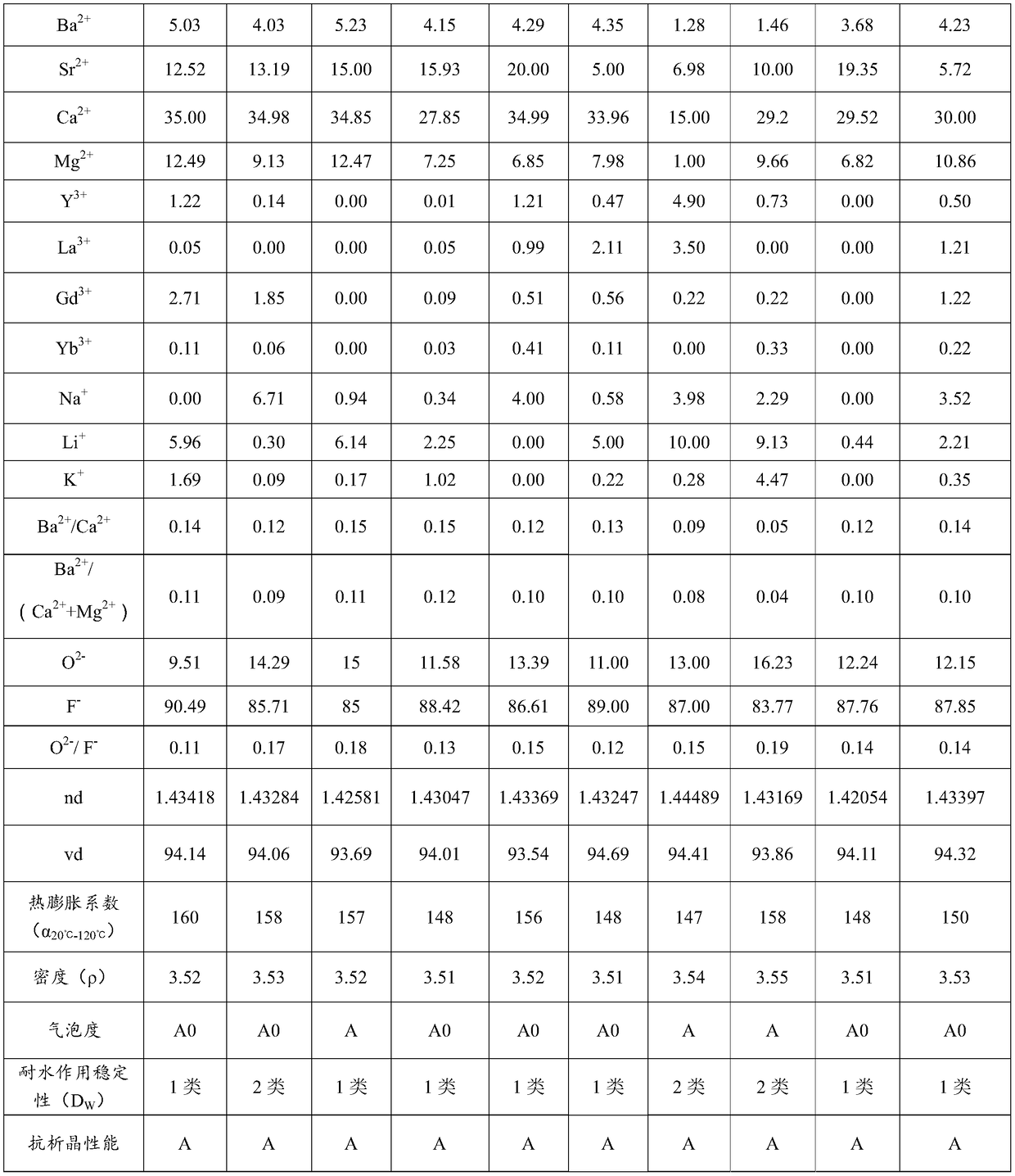

Fluorophosphate optical glass, optical prefabricated component, optical element and optical apparatus

InactiveCN109160728ALow densityIncrease the level of air bubblesOptical elementsRefractive indexThermal expansion

The invention provides fluorophosphate optical glass, an optical prefabricated component, an optical element and an optical apparatus, and belongs to the technical field of optical glass. The opticalglass contains the following components in percentage by mol based on cations: 2-20% of P<5+>, 20-40% of Al<3+>, 0.5-10% of Ba<2+>, 5-25% of Sr<2+>, 15-35% of Ca<2+> and 1-15% of Mg<2+>, wherein Ba<2+> / Ca<2+> is 0.01-0.155; anions contain the following components in percentage by mol based on anions: F<-> and O<2->, wherein O<2-> / F<-> is 0.105-0.2. According to the fluorophosphate optical glass, the optical prefabricated component, the optical element and the optical apparatus disclosed by the invention, the Ba<2+> / Ca<2+> content proportion is adjusted, so that the density of the optical glassis reduced, and the bubble degree grade and the crystallization resistance performance of the optical glass are improved; the O<2-> / F<-> content proportion is adjusted, so that the thermal expansioncoefficient of the optical glass is reduced, the optical glass is unlikely to be damaged in the die pressing course and the hot processing course, and the glass formation stability is improved. The refractive index (nd) of the fluorophosphate optical glass is 1.42-1.45, the Abbe number (vd) is 93-96, the density (rho) is 3.55 g / cm<3> or below, the bubble degree is B level or above, the thermal expansion coefficient is 160*10<-7> / K or below, the water resistant effect stability (Dw) is 2 type or above, and the crystallization resistance performance is excellent.

Owner:CDGM OPTICAL GLASS

Coaxial cable

ActiveCN105741969ASimple structureImprove shock absorptionCoaxial cables/analogue cablesInsulated cablesFiberCoaxial cable

The invention discloses a coaxial cable. The coaxial cable comprises a conductive body, a foamed insulating layer, an outer conductor layer, a fiber sleeve and an insulating layer which are arranged from inside to outside in sequence, wherein the fiber sleeve is provided with a framework with frame holes; the framework is made from second fibers in a fusing manner; the framework is fixedly connected with the outer conductor layer and the insulating layer; first fibers are alternately inserted in the frame holes; and the first fibers are connected mutually to form a net shape. The coaxial cable provided by the invention adopts the framework structure made from the second fibers, and the fiber sleeve woven by the first fibers woven with metal wires, so that the coaxial cable is simple in structure, good in shock absorption effect, and relatively high in bending and stretching resistance; due to the fiber material, the metal wires can be woven conveniently, so that the coaxial cable protective layer has a relatively good shielding effect, the cost of the overall cable is relatively low, the weight of the cable is relatively low, and the cable obtains a higher economic effect; and due to the fiber material, the chemical performances of the coaxial cable protection layer can be expanded and improved conveniently.

Owner:HANGZHOU FUTONG ELECTRIC WIRE & CABLE

Tight connecting device of glass tube and metal tube

InactiveCN102840703AAvoid heat dissipationAvoid corrosionSolar heat devicesPipe connection arrangementsAlloyEngineering

The invention discloses a tight connecting device of a glass tube and a metal tube. The metal tube is sleeved inside the glass tube. The tight connecting device comprises a transition tube, a metal end cover, and a corrugated tube; the metal tube is sleeved outside the metal tube; one end of the transition tube is connected to the metal tube and the other end of the transition tube is provided with an outward edge and extends into the glass tube; the metal end cover is made of an expansion alloy material and sleeved on the transition tube; the peripheral edge is sealed on the end face of an opening of the glass tube in a hot pressing manner; the corrugated tube is sleeved on the transition tube at the inner side of the metal end cover; one end and the inner peripheral edge of the metal end cover are welded together, and the other end of the metal end cover is welded on the outward edge of the transition tube. The tight connecting device has the beneficial effects that assembling components are reduced; the production cost is reduced; the quantity of welded junctions is halved; the production technology difficulty is reduced; the yield is improved; and the heat collecting efficiency and the service life of a vacuum tube are effectively improved and prolonged.

Owner:山东威特人工环境有限公司

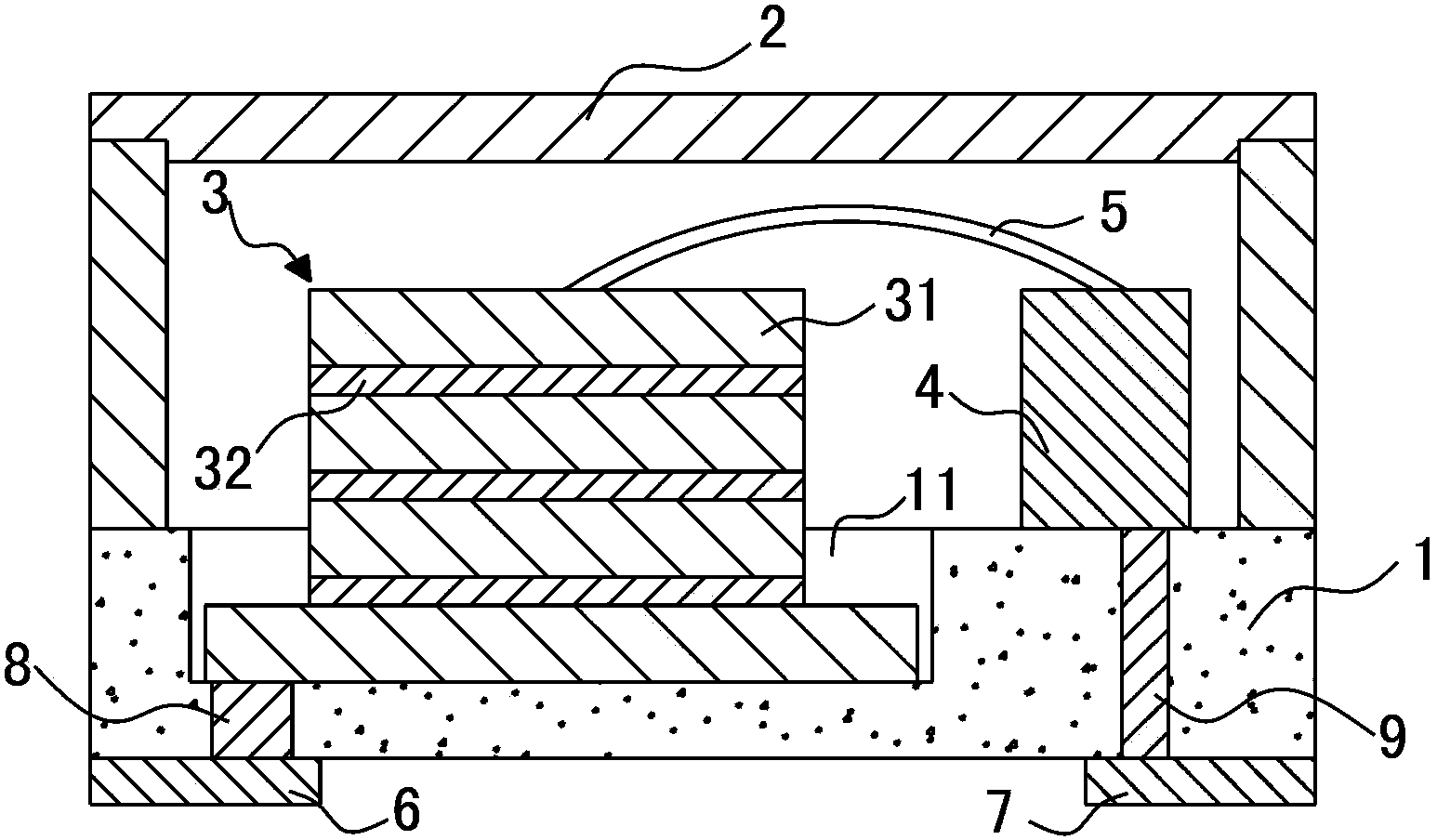

Diode packaging structure

ActiveCN104347556AFirmly connectedNot easy to shakeSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureEngineering

The invention relates to a semiconductor structure, and specifically relates to a diode packaging structure. The diode packaging structure comprises a substrate, a packaging body arranged at the upper end surface of the substrate, and a plurality of electrodes arranged at the lower end surface of the substrate. The upper end of the substrate is provided with a groove, the groove is internally provided with a tube core assembly, the upper end surface of the substrate is provided with a bonding block, the tube core assembly and the bonding block are connected through a lead wire, the packaging body and the substrate form a cavity, and the tube core assembly and the bonding block are arranged in the cavity. According to the invention, the problem of bonding between the tube core assembly and the electrodes is effectively solved, the connection between the tube core assembly and the bonding block is facilitated, the production process difficulty is lowered, the production efficiency is improved, the lead wire connecting the tube core assembly and the bonding block is not easily shaken and is not easily broken, and the quality of a manufactured product is enabled to be better. Besides, the diode packaging structure also has the advantages of good sealing performance, high heat dissipation performance and the like.

Owner:CHINA ZHENHUA GRP YONGGUANG ELECTRONICS CO LTD STATE OWNED NO 873 FACTORY

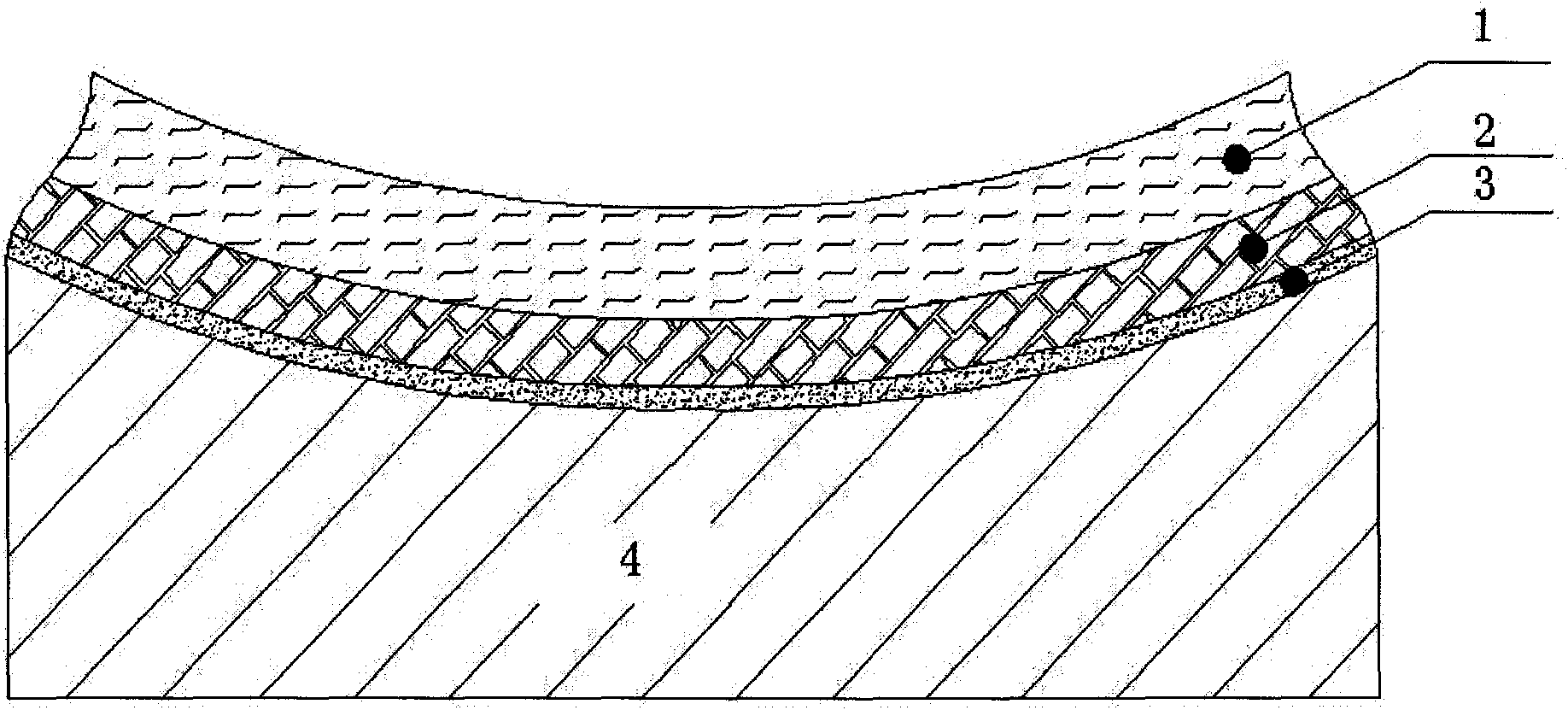

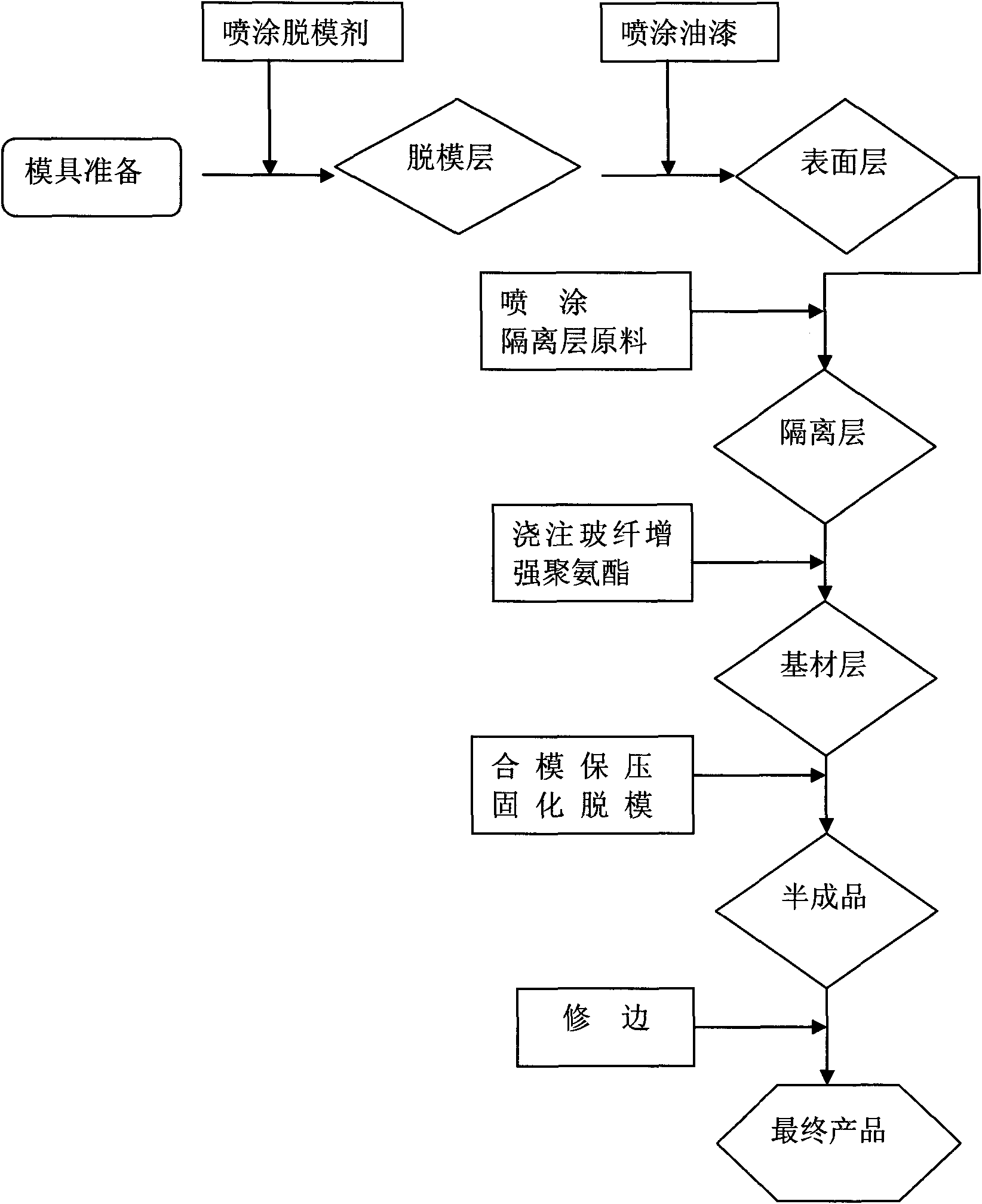

Novel long glass fiber-reinforced polyurethane technique capable of being produced into A-class surface product

InactiveCN101787201ASolve process problemsReduce processPolyurea/polyurethane coatingsSpecial surfacesPolyesterChemistry

The invention relates to a long glass fiber-reinforced polyurethane product and a production technique, and the finished product of the long glass fiber-reinforced polyurethane is mainly used as a substitute for certain metal parts in the automobile manufacturing industry, particularly an automobile A-class surface product. The long glass fiber-reinforced polyurethane contains glass fibers and polyurethane combination which account for 10 percent to 40 percent of the total weight of a finished product, and the polyurethane combination contains a certain amount of isocyanate and polyether glycol or isocyanate and polyester polyol. The production technique includes steps such as mould preparation, release layer spraying, paint spraying, isolating layer material spraying, glass fiber-reinforced polyurethane pouring, mould-closed pressure-maintained solidification and demoulding. By means of methods such as 'in-mould paint spraying technique' and 'isolating layer material spraying', the invention solves the technical problem that the long glass fiber-reinforced polyurethane material can be hardly produced into the A-class surface product. Moreover, since the product can be produced in one step, the process is shortened compared with metal part machining, the production difficulty is decreased, and the product has the advantages of high strength, light weight, good sound-insulating and heat-insulating effects and the like.

Owner:HUBEI QIXING TRUCK & CABIN MFG

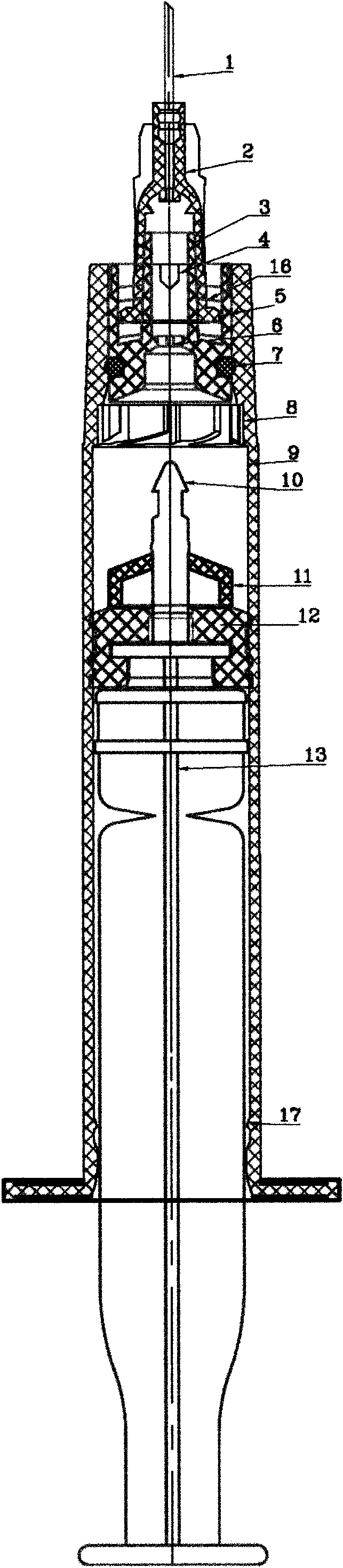

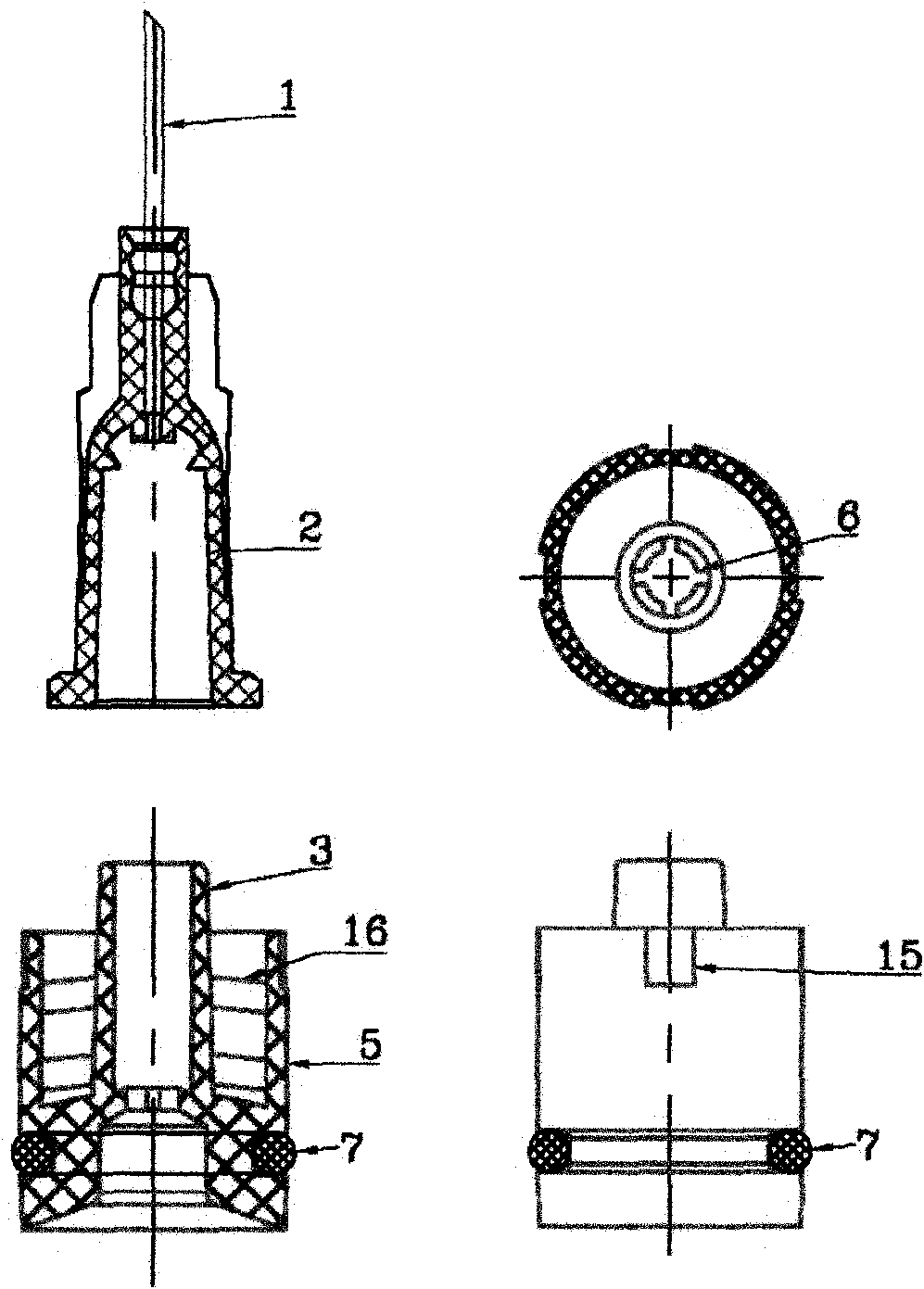

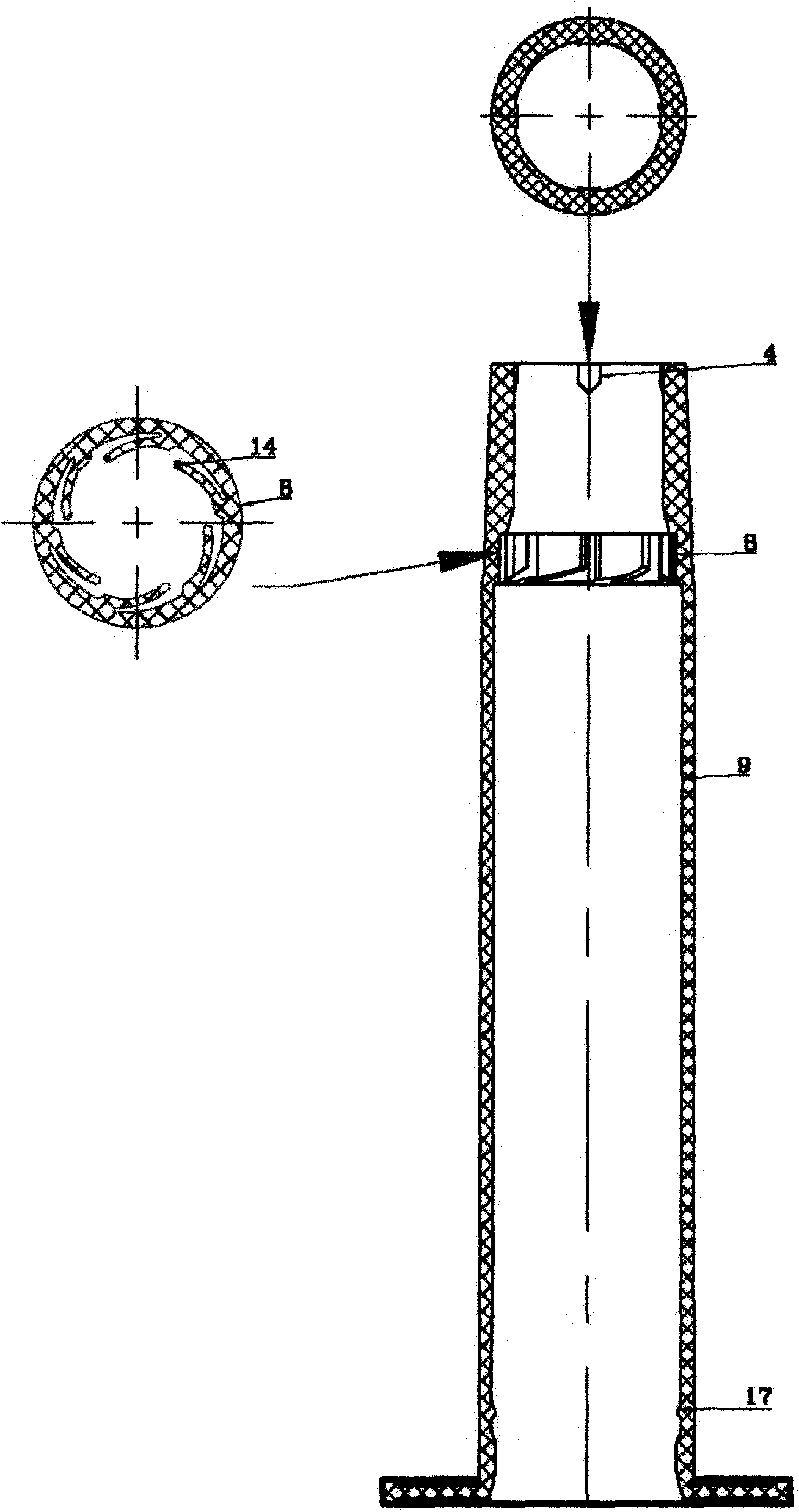

Safety self-destructive syringe

InactiveCN101810900AReduce the difficulty of production processReduce the difficulty of manufacturing processIntravenous devicesBiomedical engineeringCost savings

The invention discloses a safety self-destructive syringe, and the difference thereof from the prior art lies in: the syringe, an extension shrapnel on the neck of the inner syringe of the syringe, a core rod, a piston sleeved on the front end of the core rod, a piston fixing seat, a replaceable needle seat which is matched with the syringe body and can be pulled back, a seal ring, a needle seat and a needle. The replaceable needle seat is fixed and matched with the extension shrapnel on the neck of the inner syringe of the syringe body at the rear part. After injection is over, the piston fixing seat on the front end of the core rod pushes the extension shrapnel on the neck of the syringe outwards; and after the injection, a pull-back connection column on the front end of the core rod smoothly pulls the needle seat back into the syringe body, and a ring on the syringe body which prevents the core rod from being pushed back and being pulled out is used for locking the core rod, so that the core rod cannot move forwards or be pulled back. The safety self-destructive syringe breaks through the design philosophy of a traditional syringe, and has the advantages of reasonable structural design, high safety, low manufacturing process difficulty, few procedures, cost saving, easy production and easy popularization.

Owner:周明雄

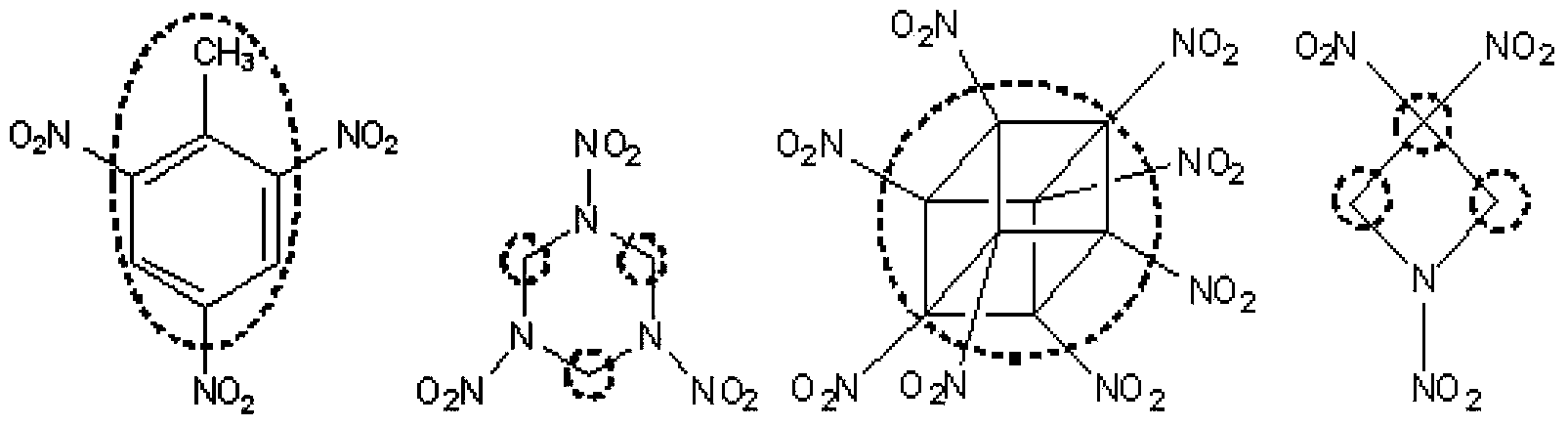

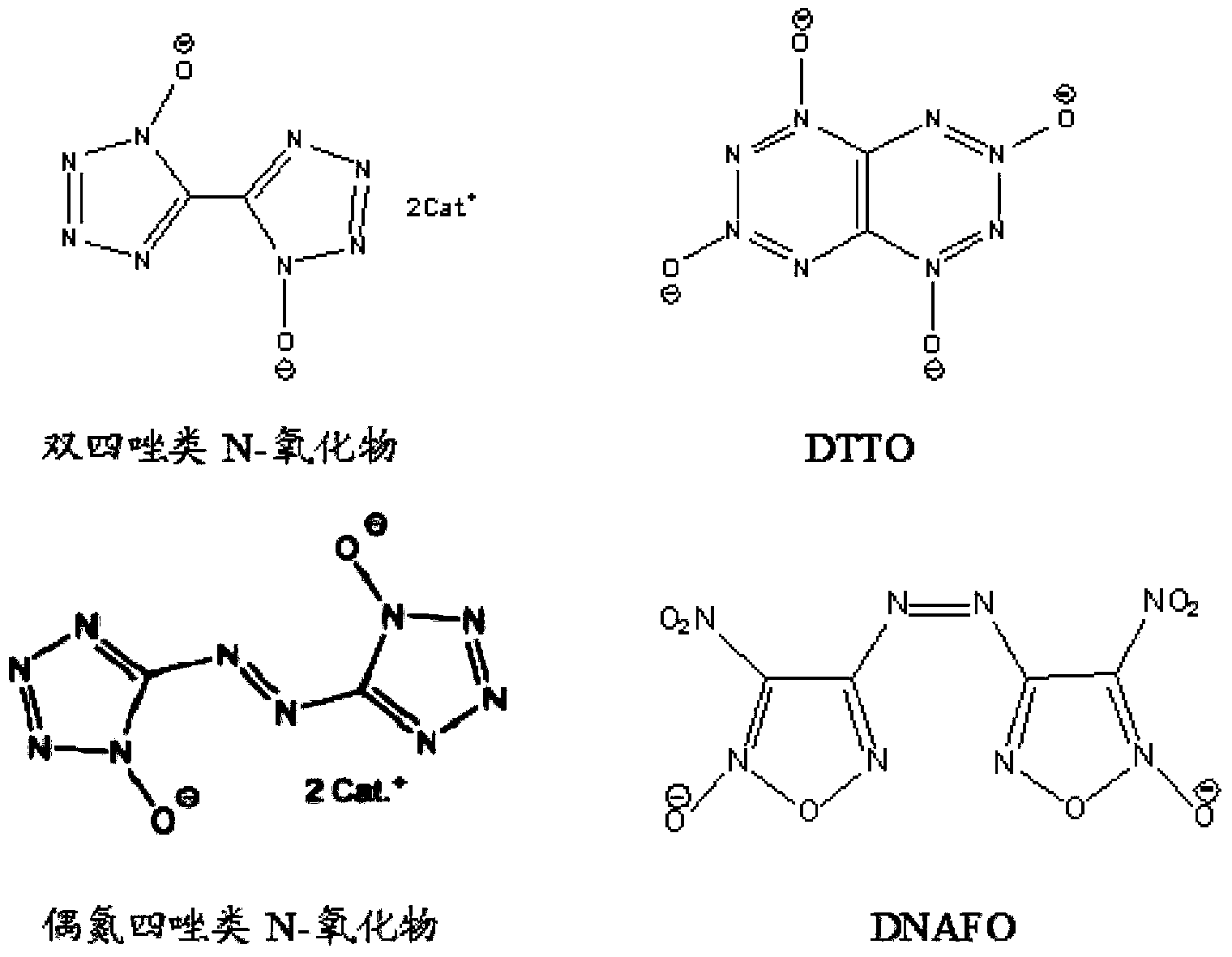

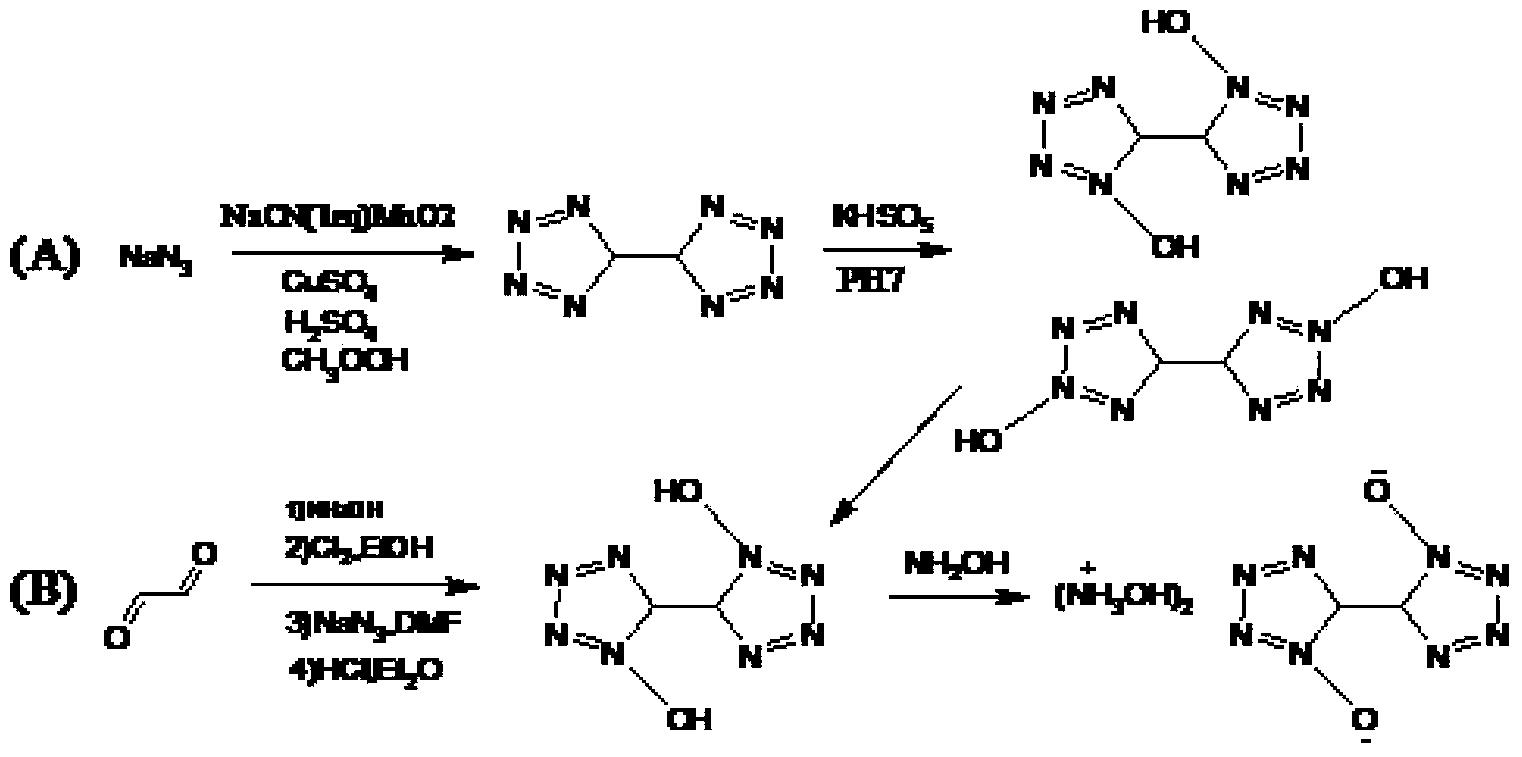

Method of synthesizing 5,5'-bistetrazole-1,1'-dioxodihydroxy ammonium salt

The invention discloses a method of synthesizing a 5,5'-bistetrazole-1,1'-dioxodihydroxy ammonium salt. The method comprises the following step: synthesizing the 5,5'-bistetrazole-1,1'-dioxodihydroxy ammonium salt by taking dichloroglyoxime, sodium azide, sodium hydroxide and hydroxylamine hydrochloride as raw materials and adopting alcohol solvents by virtue of azidation reaction, acid catalysis cyclization reaction and salt forming reaction. Compared with the prior art, the two-step reaction adopted by the method disclosed by the invention only adopts one solvent, so that not only can type of solvents be reduced, but also the after-treatment process of the azidation reaction can be cancelled. Meanwhile, the types of catalytic acids are expanded, the difficulty of the production process is lowered, the total yield of the reaction is increased, and thus, the method is an efficient and low-cost synthetic method.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

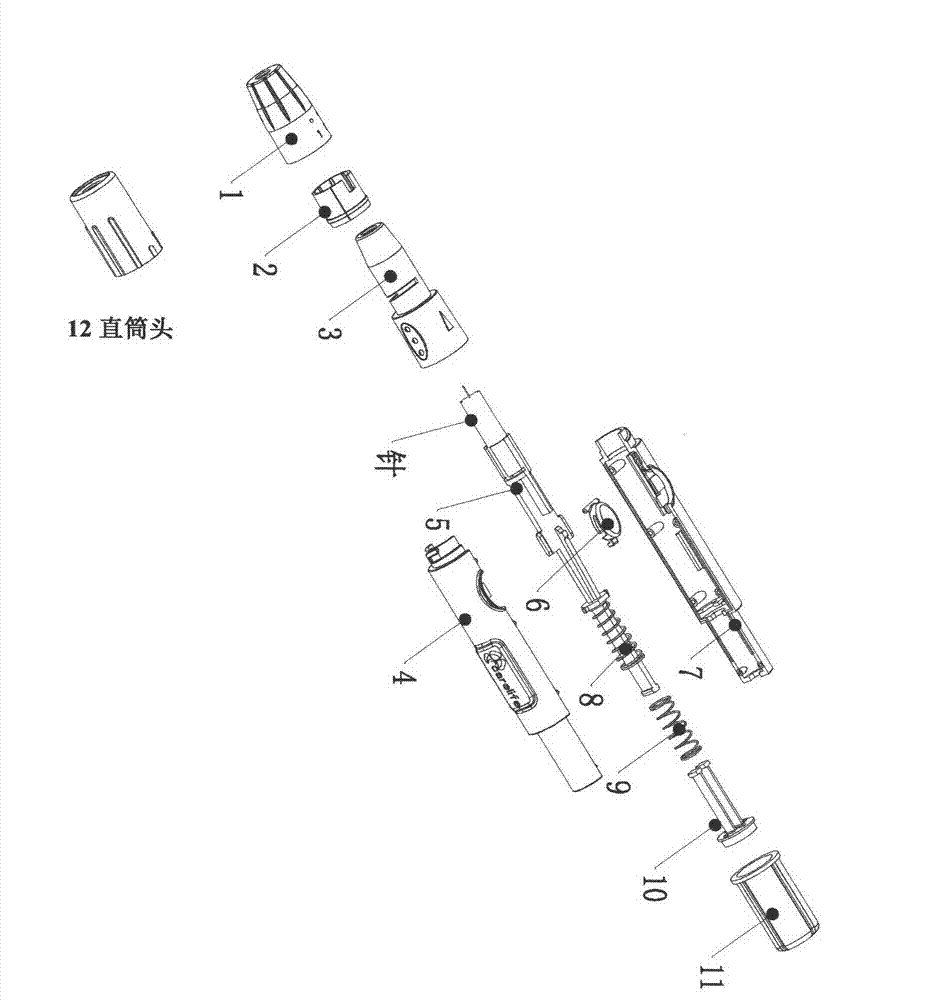

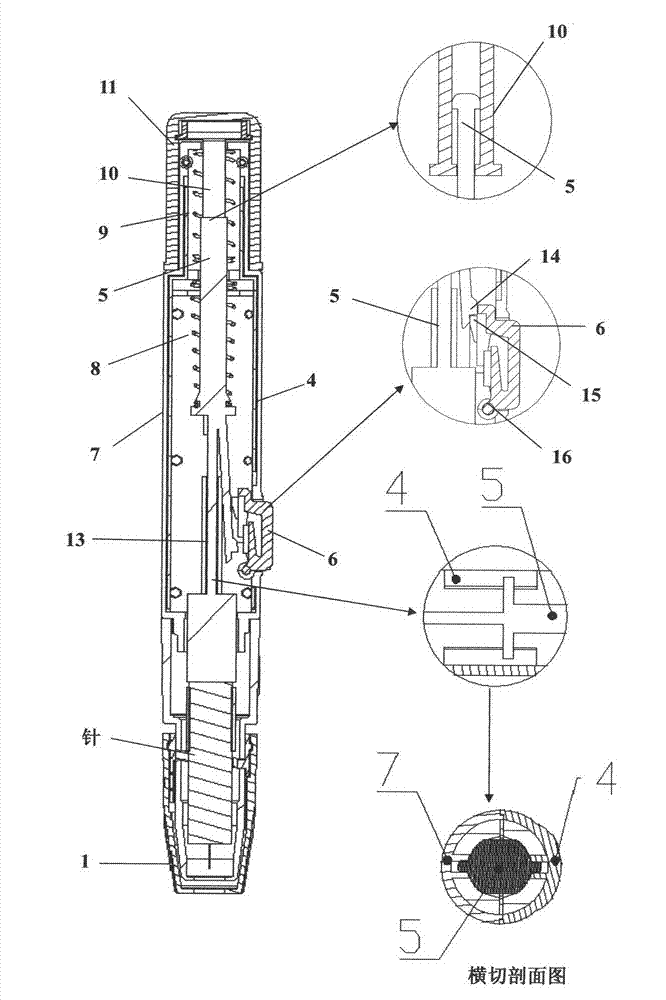

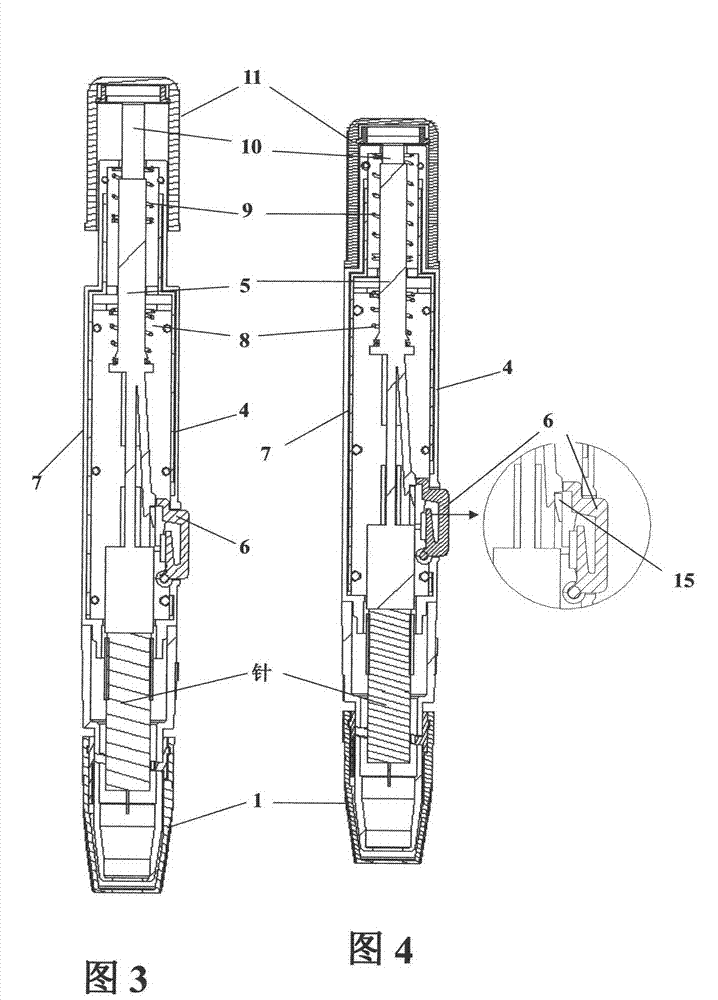

Blood collection pen

InactiveCN103190919AImprove securityReduce the difficulty of production processDiagnostic recording/measuringSensorsBlood collectionInsertion stent

The invention discloses a blood collection pen which is provided with a dual-spring lancet bracket, wherein the bracket can be mounted in a pen housing, can slide up and down in the pen housing and is used for bearing a disposable lancet or a disposable needle. A bracket sliding part in a slot in the inner side of the pen housing is moved back to prepare ejection of the disposable lancet or the disposable needle, and the lancet or the needle can be instantly ejected to an appointed position after a trigger button is pressed down and then returns to the original position under the action of springs. Therefore, the micro blood collection operation can be carried out, the whole prick and blood collection process can be finished in a very short time, and a patient does not feel pain. The blood collection pen is simple in structure and convenient and reliable to use and produce.

Owner:卞为强

Receiving end hard pin connection circuit based on 10G EPON ONU BOB optical module

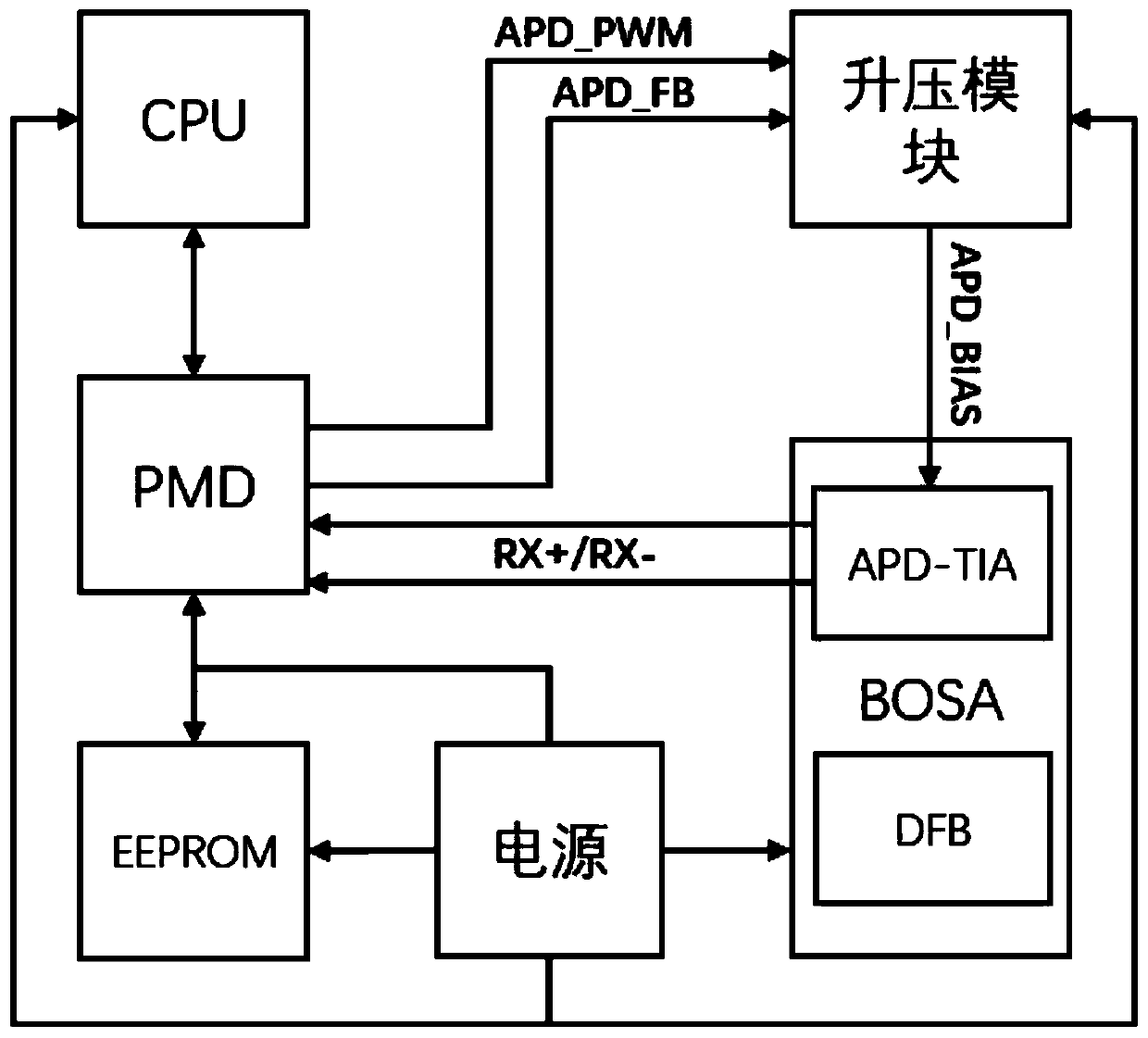

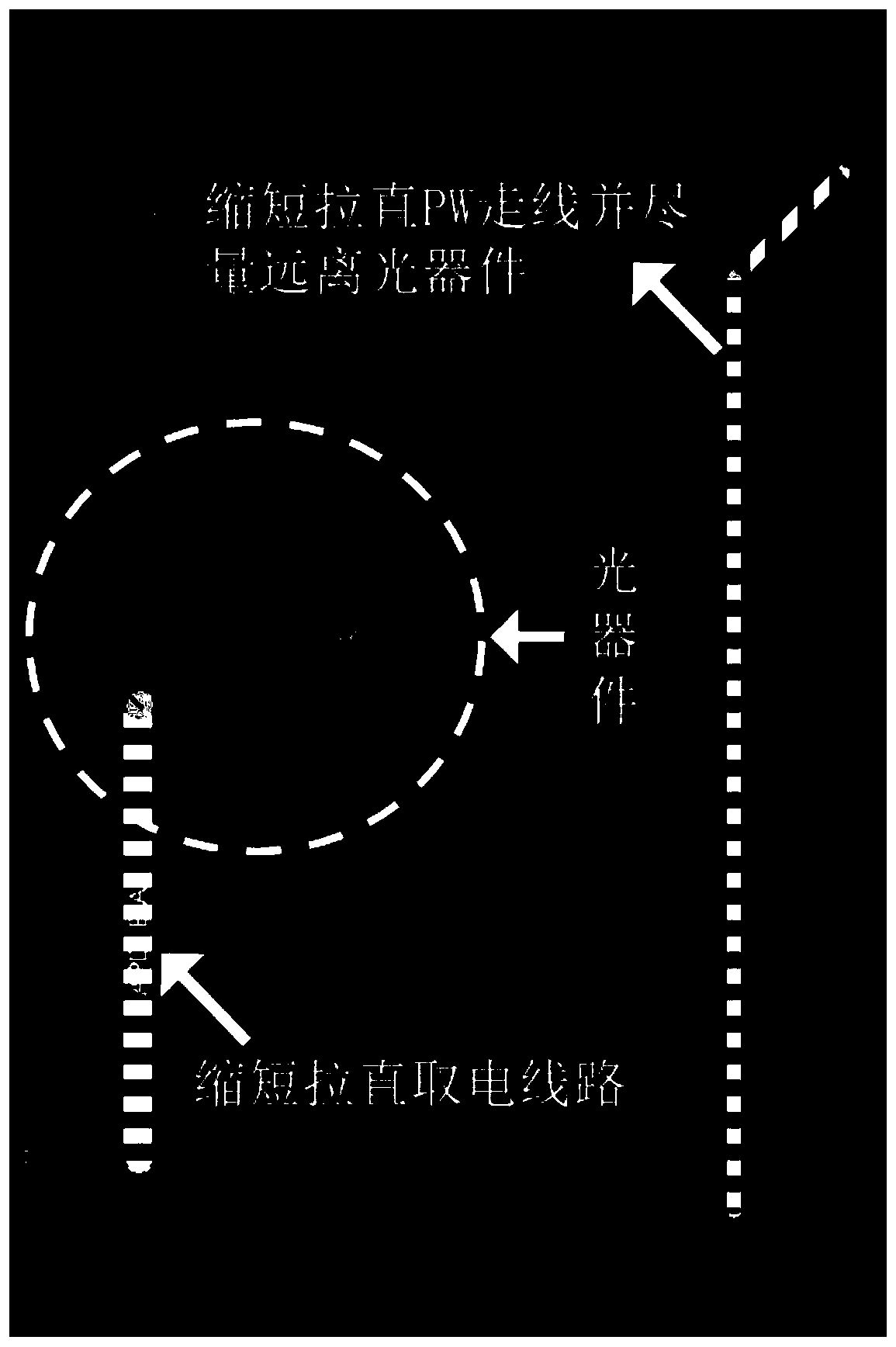

ActiveCN110995360ALow costReduce the difficulty of production processMultiplex system selection arrangementsPrinted circuit detailsDifferential lineComputer architecture

The invention discloses a 10G EPON ONU BOB optical module-based receiving end hard pin connection circuit, which comprises a CPU module, a PMD module and a BOSA module, and is characterized in that the CPU module is connected with the PMD module through a differential line, and the PMD module is connected with the BOSA module through a differential line; the LED lamp further comprises a boosting module. The output end of the PMD module is connected with the input end of the boost module through a PWM wire and an FB wire of an APD. The output end of the boost module is connected with the receiving end of the BOSA module through a BIAS wire of an APD, and an RX + pin and an RX-pin of the BOSA module are connected with the input end of the PMD module through differential wires. According to the invention, the TO46 gold pin of the receiving end of the optical device does not pass through a flexible circuit board through various modes of optimizing PWM and FB wiring of the APD, shortening the length of a differential line and carrying out impedance control, independently supplying power to the receiving end circuit of the BOSA module and the like; and moreover, the sensitivity and the bit error rate level are not worse than those of a circuit connected by using a flexible circuit board, so that the production process difficulty and the material cost are reduced.

Owner:SICHUAN TIANYI COMHEART TELECOM

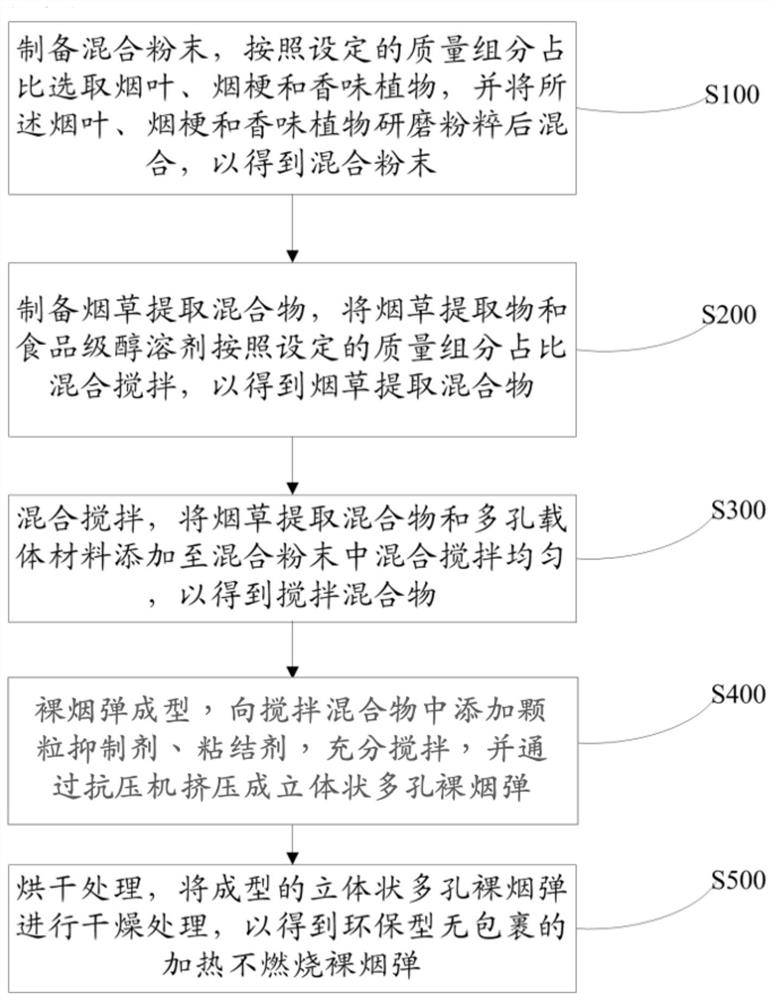

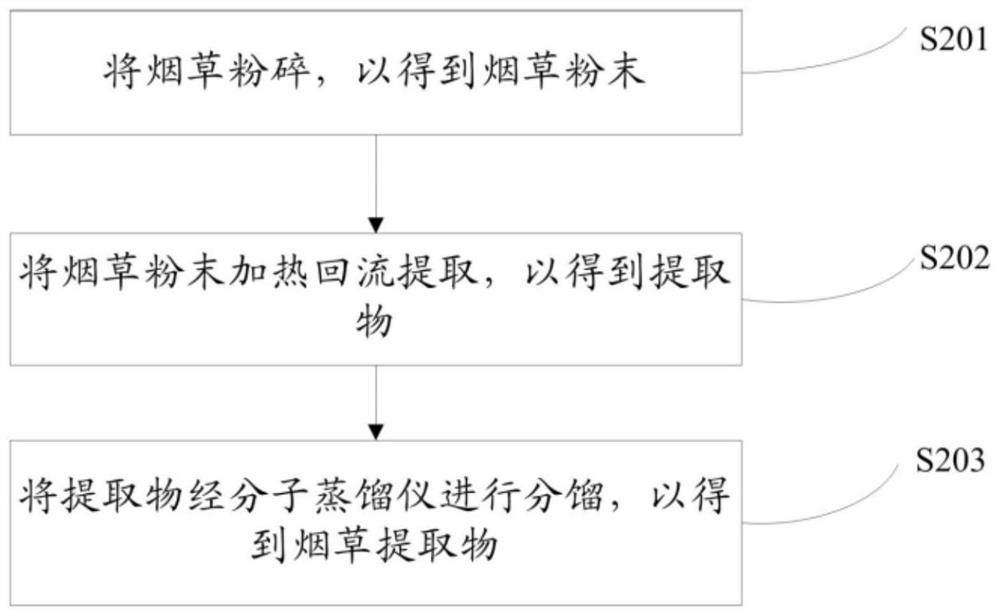

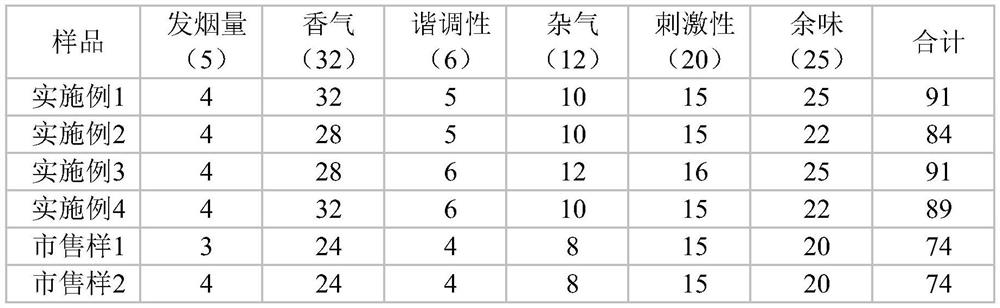

Environment-friendly unwrapped heating non-combustible naked smoke cartridge

ActiveCN112471590APrevent volatilizationInhibit aggregationTobacco treatmentCigar manufactureBiotechnologyHazardous substance

The invention discloses an environment-friendly unwrapped heat-not-burn naked smoke cartridge. The cartridge comprises the following components in percentage by mass, 20-60% of mixed powder, 10-20% ofporous carrier material, 10-20% of tobacco extraction mixture and 1-5% of binder. The invention further discloses a preparation method of the environment-friendly unwrapped heat-not-burn naked smokecartridge. The tobacco extract comprises the following components in percentage by weight, 10-40% of porous carrier material, 15-50% of tobacco extract mixture, 1-10% of particle aggregation inhibitorand 10-40% of binder. According to the environment-friendly unwrapped heating non-combustion naked smoke cartridge, emission of harmful substances in smoke can be effectively inhibited; meanwhile, apaper tube, a filter tip and a blocking piece needed by a traditional cigarette are not needed, the naked cigarette cartridge is adopted, production process difficulty is lowered, use of raw materialsis reduced, and the cigarette is more environmentally friendly. Compared with naked smoke cartridges, the composition has advantages of abundant smoke generation amount, good aroma quality, soft andfine smoke, no unpleasant firewood smell offensive odor, small irritation, comfortable aftertaste and better user experience.

Owner:NEW FLAME INTELLIGENT MFG (SHENZHEN) CO LTD

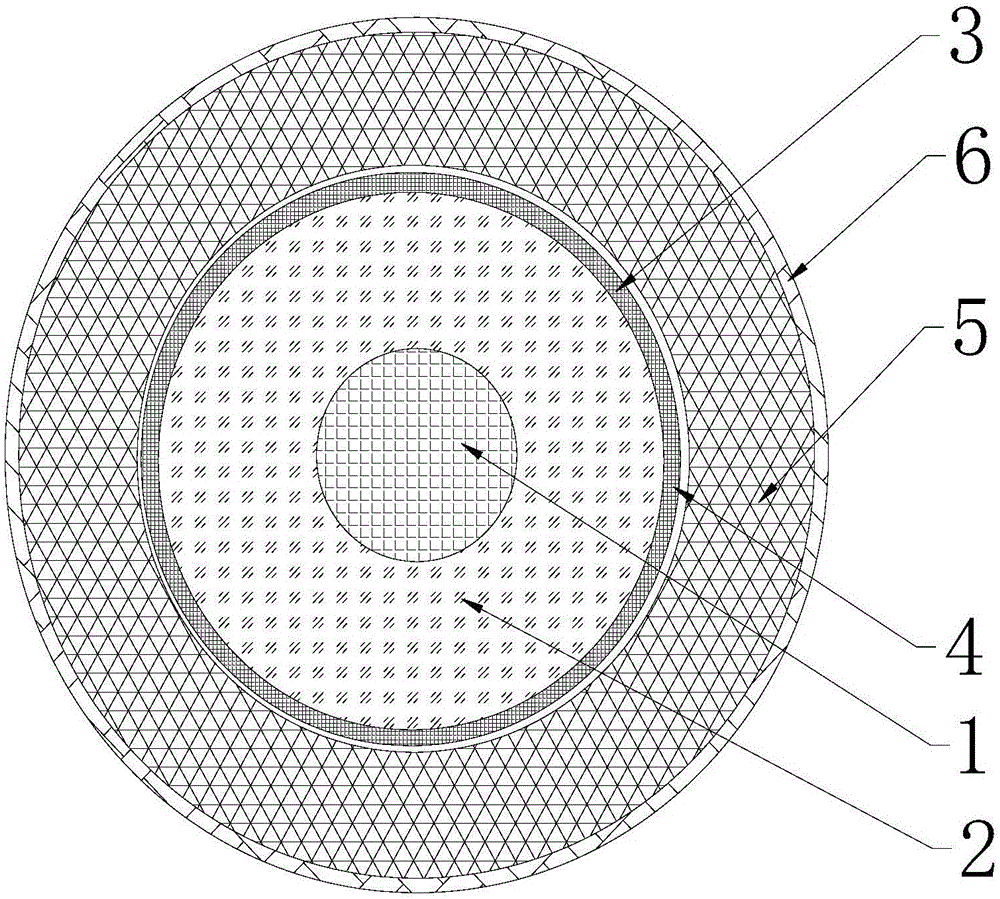

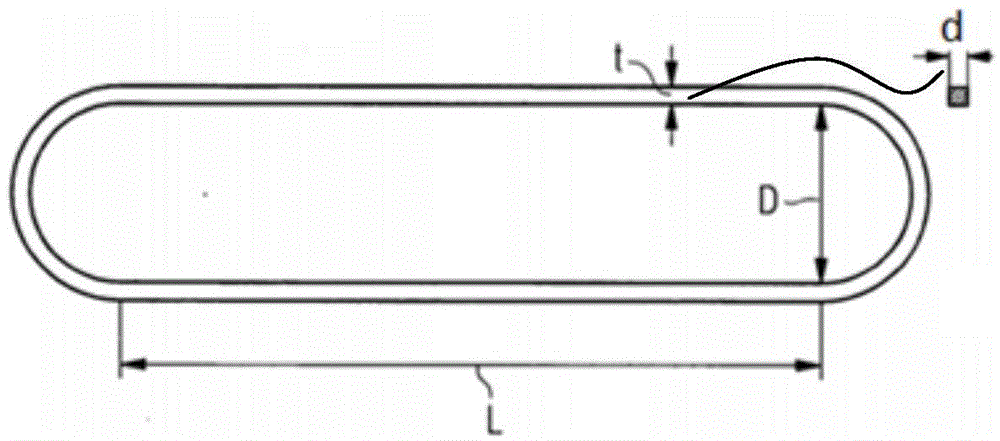

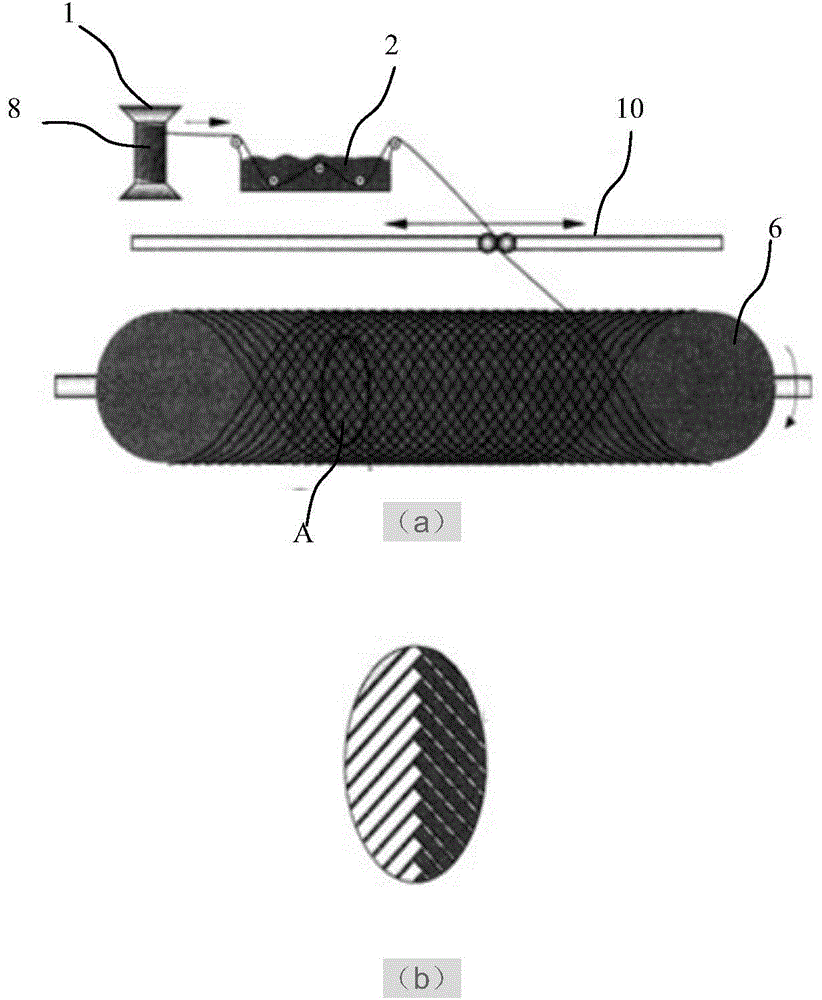

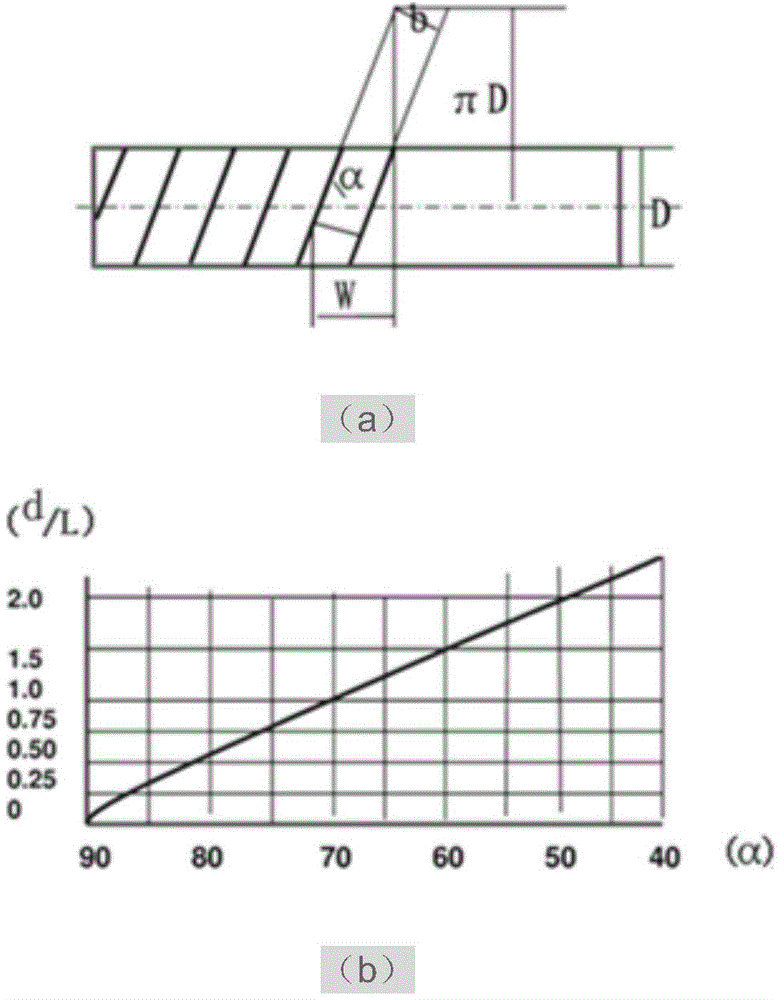

Production apparatus and manufacturing method of fiber-reinforced ring

The present invention discloses a production apparatus and a manufacturing method of a fiber-reinforced ring. The production apparatus comprises a yarn twisting shaft for winding of roved twists, a core mold and a drive system, wherein the drive system drives the core mold to rotate. The production apparatus further comprises a yarn winding mouth and a flattening device, wherein the yarn twisting shaft, the yarn winding mouth and the flattening device are sequentially aligned, a through hole for penetrating-through of the yarn twist is formed in the yarn winding mouth, and the outlet end of the through hole presents the flat cross-sectional shape. According to the production apparatus and the manufacturing method of the present invention, only the single-direction winding is adopted to wind the fiber-reinforced ring, such that the space linkage limitation of the existing winding machine is overcome, the problems of bridging, cavity and the like during the winding process are improved, the performance of the fiber-reinforced ring is increased, and the difficulty and the complexity of the production process are reduced.

Owner:SHENZHEN UNITED IMAGING HEALTHCARE CO LTD

Compressor exhaust silencer structure

ActiveCN108343590AImprove performanceFew partsPositive displacement pump componentsPositive-displacement liquid enginesResonant cavityExhaust valve

The invention discloses a compressor exhaust silencer structure which is applied to the technical field of compressors. The compressor exhaust silencer structure comprises a silencer and an exhaust pipe, wherein the silencer comprises a shell with an air inlet and an exhaust hole; the shell forms a silencing cavity between the air inlet and the exhaust hole; a clapboard for dividing the silencingcavity into a front silencing cavity and a rear resonant cavity is arranged in the shell; a clapboard through hole is formed in the clapboard; the exhaust pipe comprises a rear exhaust pipe connectedwith the exhaust hole; the rear exhaust pipe is provided with a necking throttle section matched with the clapboard through hole; and an airflow channel(s) for communicating the front silencing cavityand the rear resonant cavity is / are arranged on the clapboard and / or the rear exhaust pipe. According to the compressor exhaust silencer structure provided by the invention, an external silencer cavity structure is adopted, so that a performance of a compressor is improved; the rear exhaust pipe is provided with the necking throttle section so as to form inner exhaust throttle, so that the partsare less, the process is simple, and the difficulty of a production process and the material and process cost are reduced; and by adopting a resonance design of the rear resonant cavity and the airflow channels, the exhaust pulse of the compressor is reduced, and the matching sound quality is improved.

Owner:WANBAO GROUP COMPRESSOR CO LTD

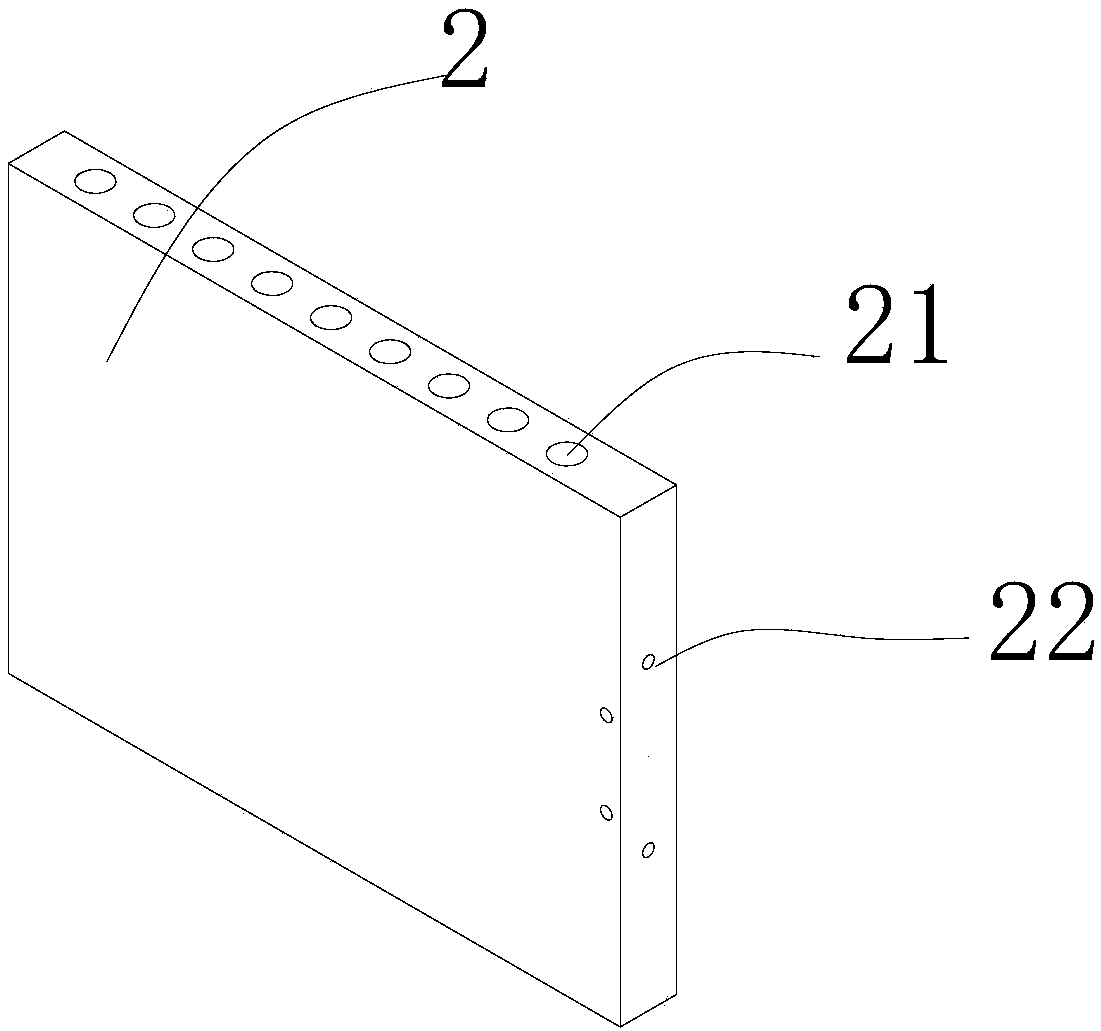

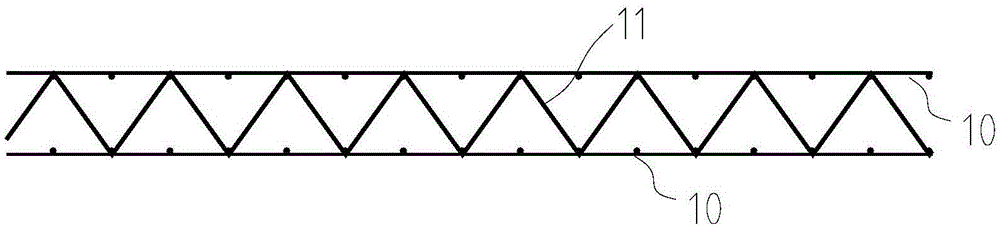

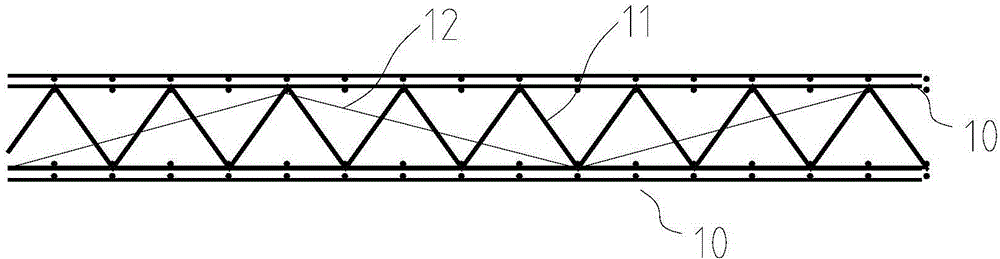

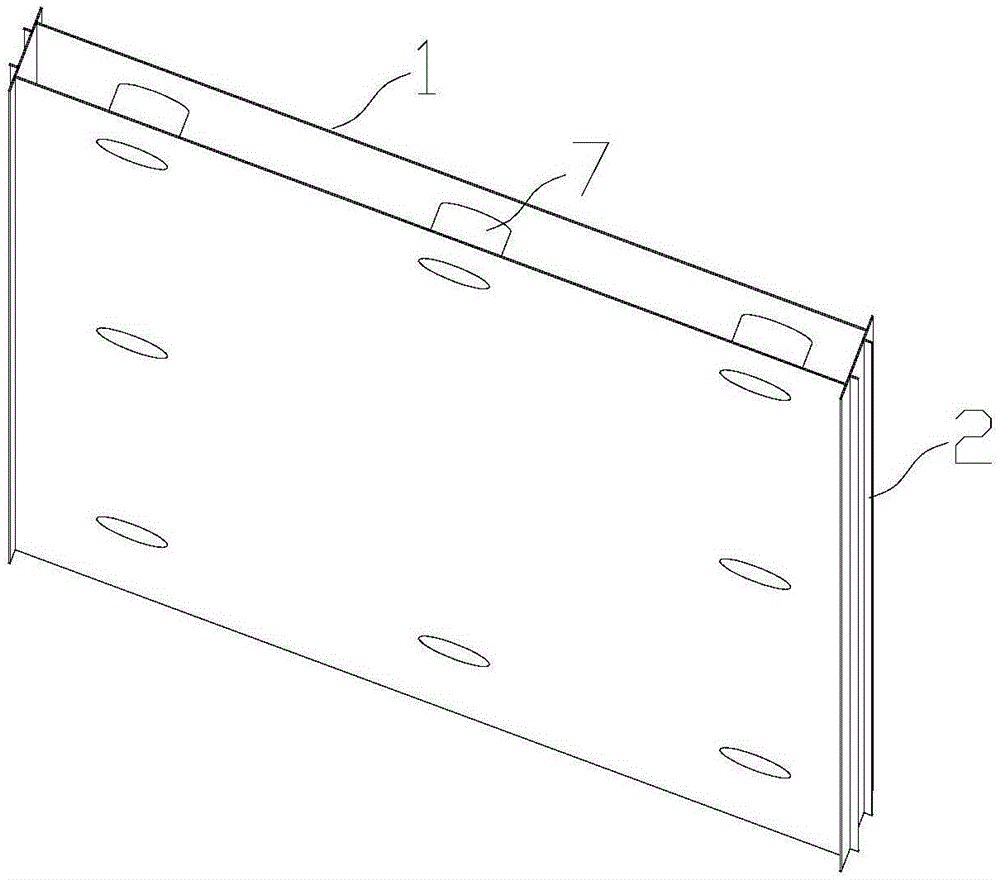

Prefabricated hollow slab

InactiveCN105155770AReduce the difficulty of production processLow costBuilding componentsEngineering

The invention provides a prefabricated hollow slab, which comprises a top layer, a bottom layer, a hollow device and a special grid truss for the prefabricated hollow slab, wherein the hollow device is arranged between the top layer and the bottom layer; the special grid truss for the prefabricated hollow slab comprises two meshes in opposite and separated arrangement; at least one rib in vertical arrangement to the meshes is arranged between the two meshes; at least one penetrated transverse pipe is arranged on the pipe wall of the hollow device; and the hollow device is arranged between the two meshes. Therefore the prefabricated hollow slab can be formed through one-step casing in a prefabricated hollow slab forming mold; the occurrence of the condition of nonuniform prefabricated hollow slab hole wall cannot be caused; the at least one transverse pipe transversely penetrating through a pipe body is arranged on the pipe wall of the pipe body; a concrete post body can be formed in the prefabricated hollow slab; and two slab surfaces of the prefabricated hollow slab can be tensioned into a whole.

Owner:CHINA MINSHENG ZHUYOU

Suitcase lining fixing structure

The invention discloses a suitcase lining fixing structure, which is characterized by comprising an aluminum frame arranged on the lateral wall of a suitcase and a clamp strip fixed with lining cloth. The clamp strip and the aluminum frame are connected through fasteners. Therefore, the lining cloth can be fixed on the clamp strip in sewing mode, the clamp strip is connected with the aluminum frame through fastener devices, the structure is convenient in sewing and simple in installation, production time is saved, production process difficulty is reduced, and production efficiency is improved.

Owner:中山皇冠皮件有限公司

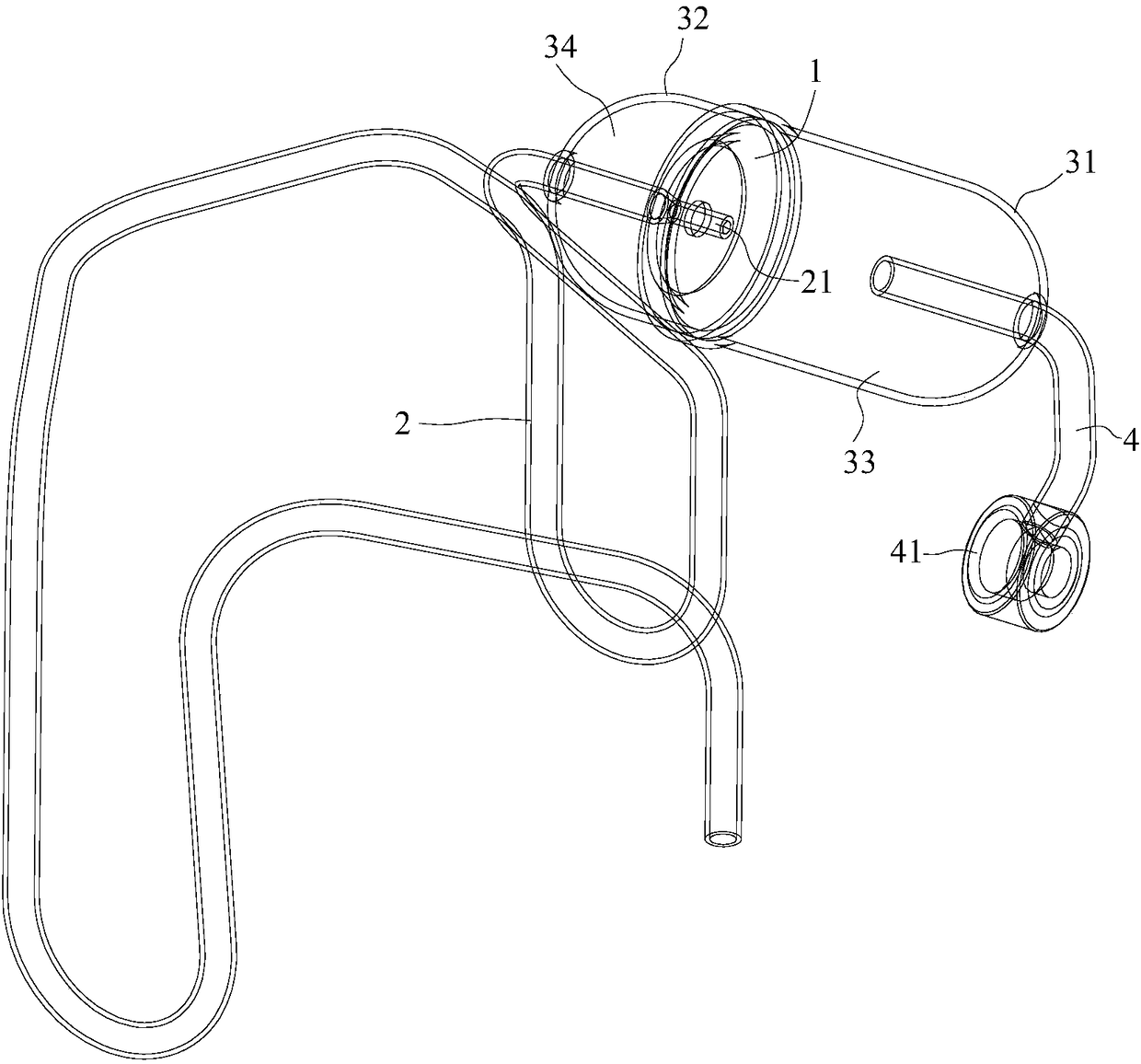

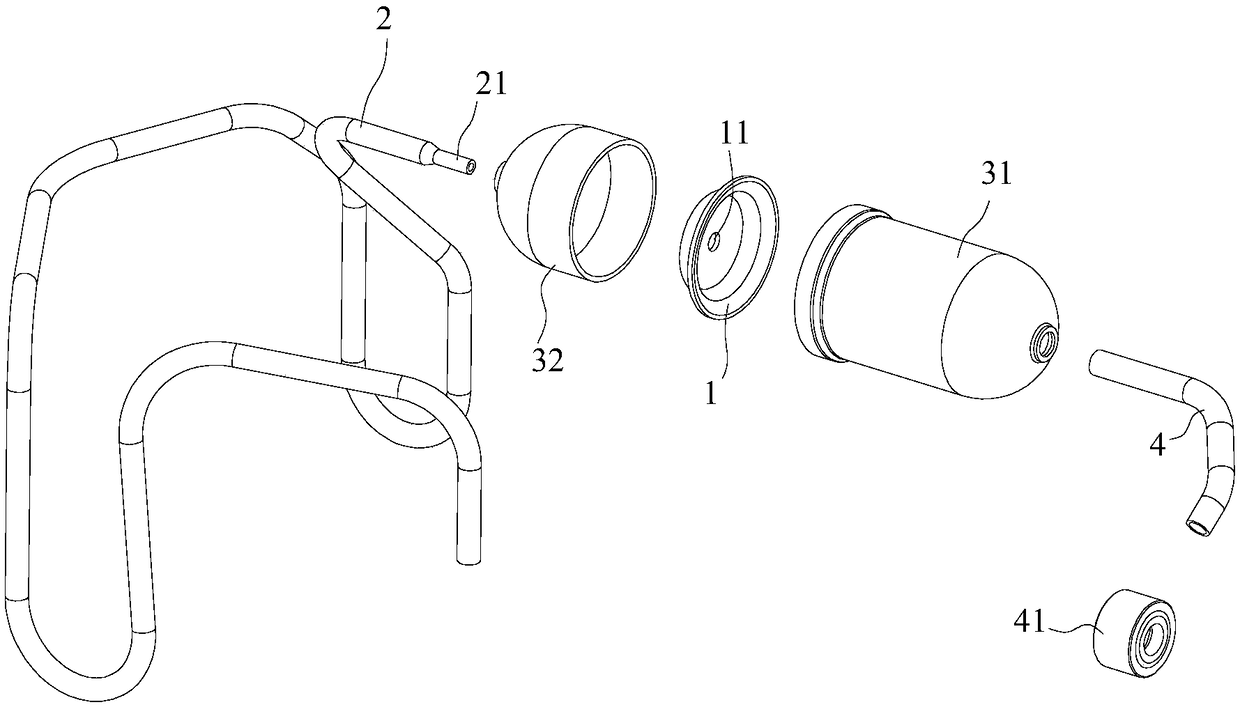

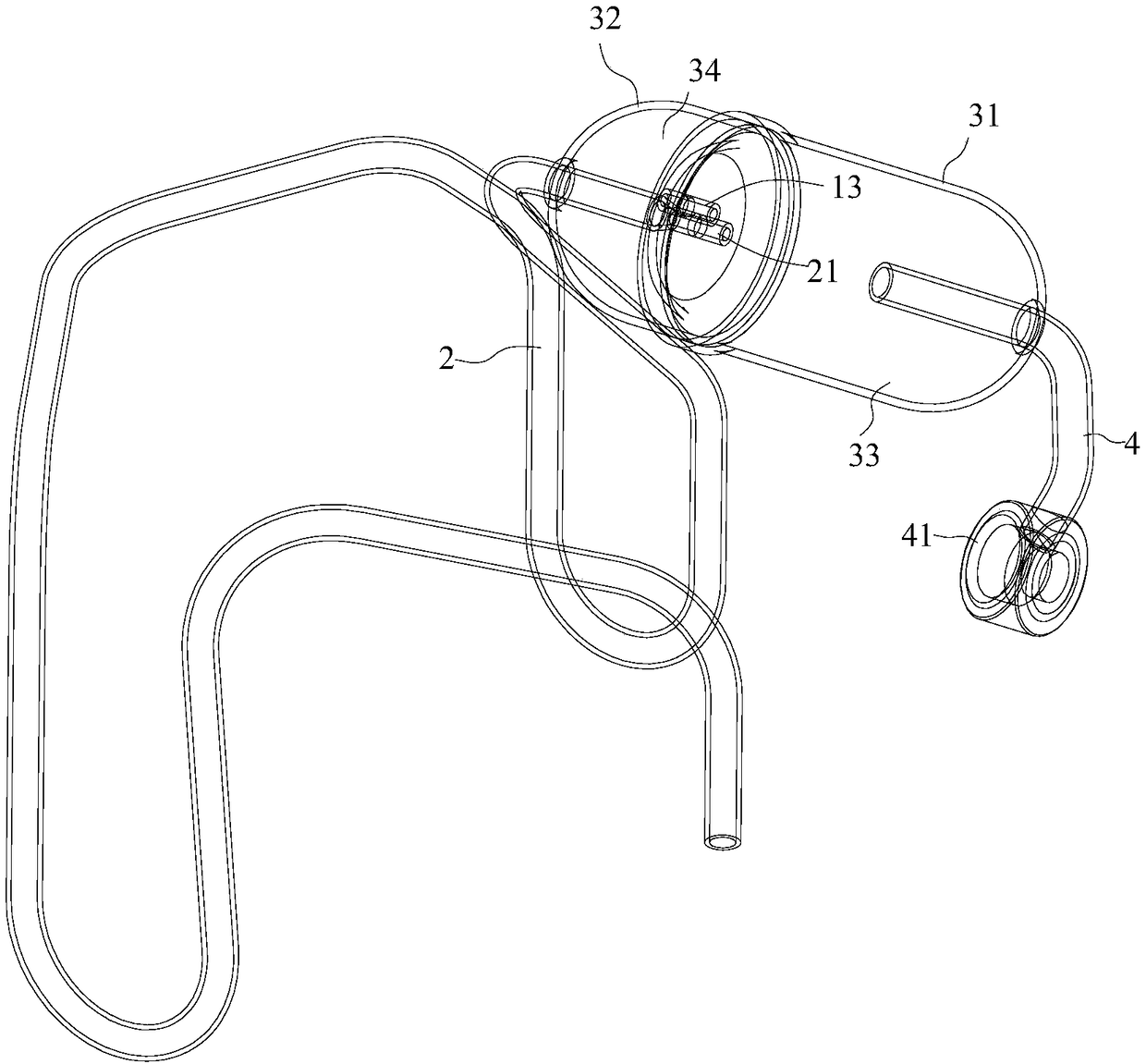

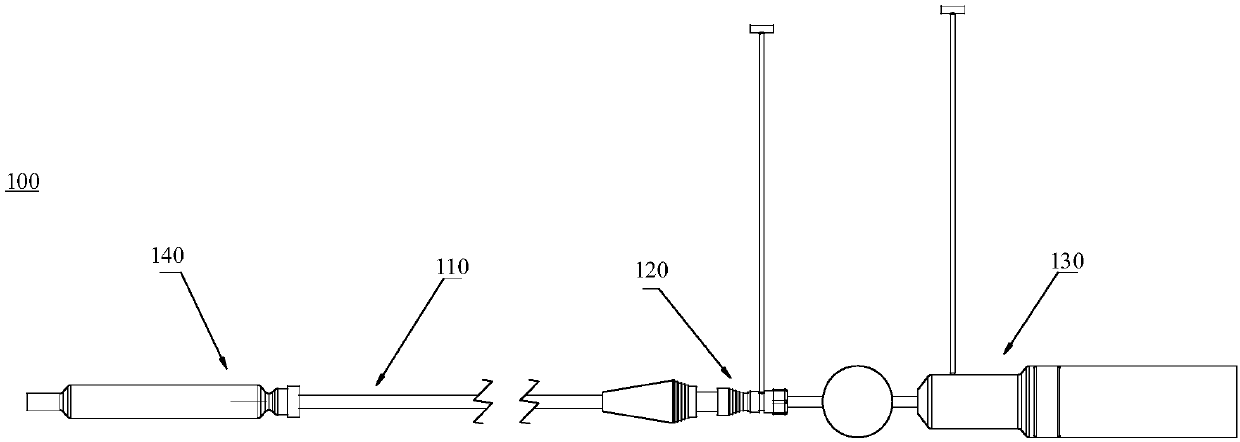

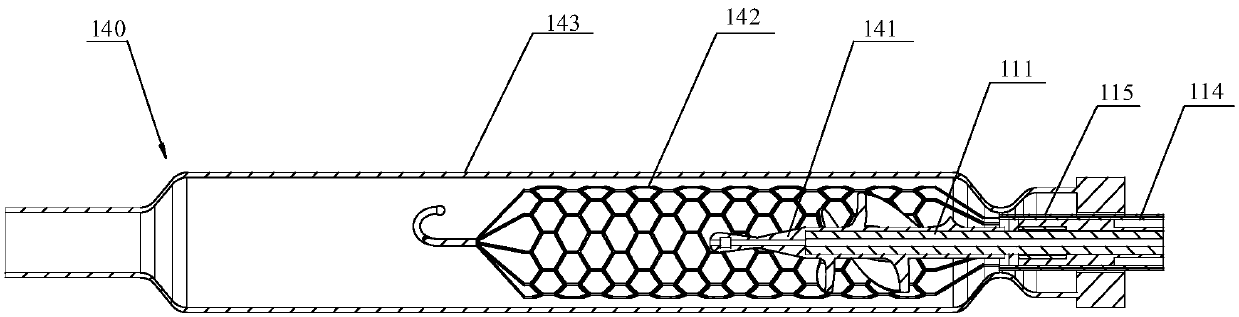

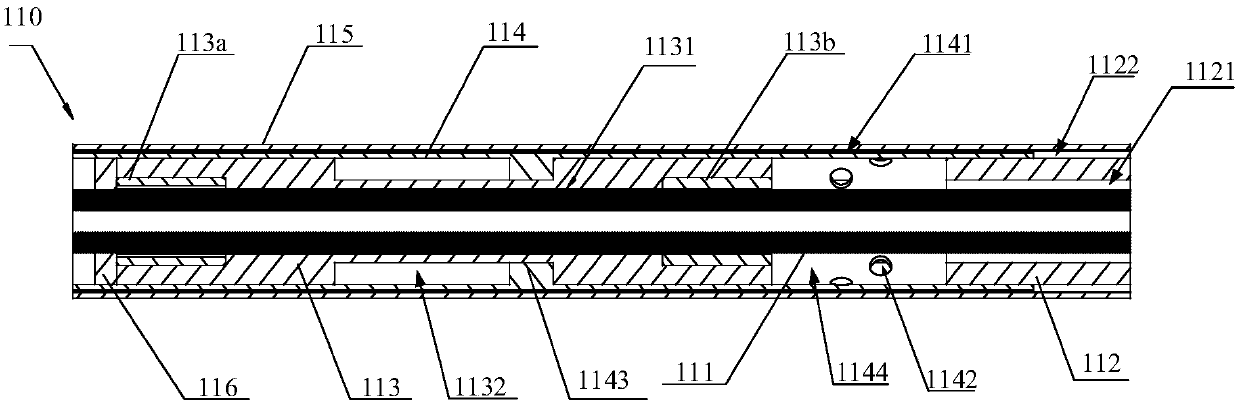

Percutaneous blood pump and injection system thereof

The invention relates to a percutaneous blood pump and an injection system thereof. The injection system comprises a starting part, a transmission assembly, an irrigating part and a reflux part whichare sequentially connected, wherein the transmission assembly comprises a transmission shaft, a net basket pipe and an outer sheath pipe; a first irrigating channel is formed along the outer surface of the transmission shaft; a second irrigating channel is formed along the inner surface of the outer sheath pipe; the first irrigating channel can communicate with the second irrigating channel; an irrigating opening which communicates with the second irrigating channel is formed in the irrigating part; and a reflux opening which communicates with the first irrigating channel is formed in the reflux part. According to the injection system of a percutaneous axial flow blood pump disclosed by the invention, the first irrigating channel can communicate with the second irrigating channel, so thatthe two irrigating channels can be irrigated simultaneously only through forming one irrigating opening; and the percutaneous blood pump is simple in structure and convenient to operate.

Owner:微创心导(上海)医疗科技有限公司

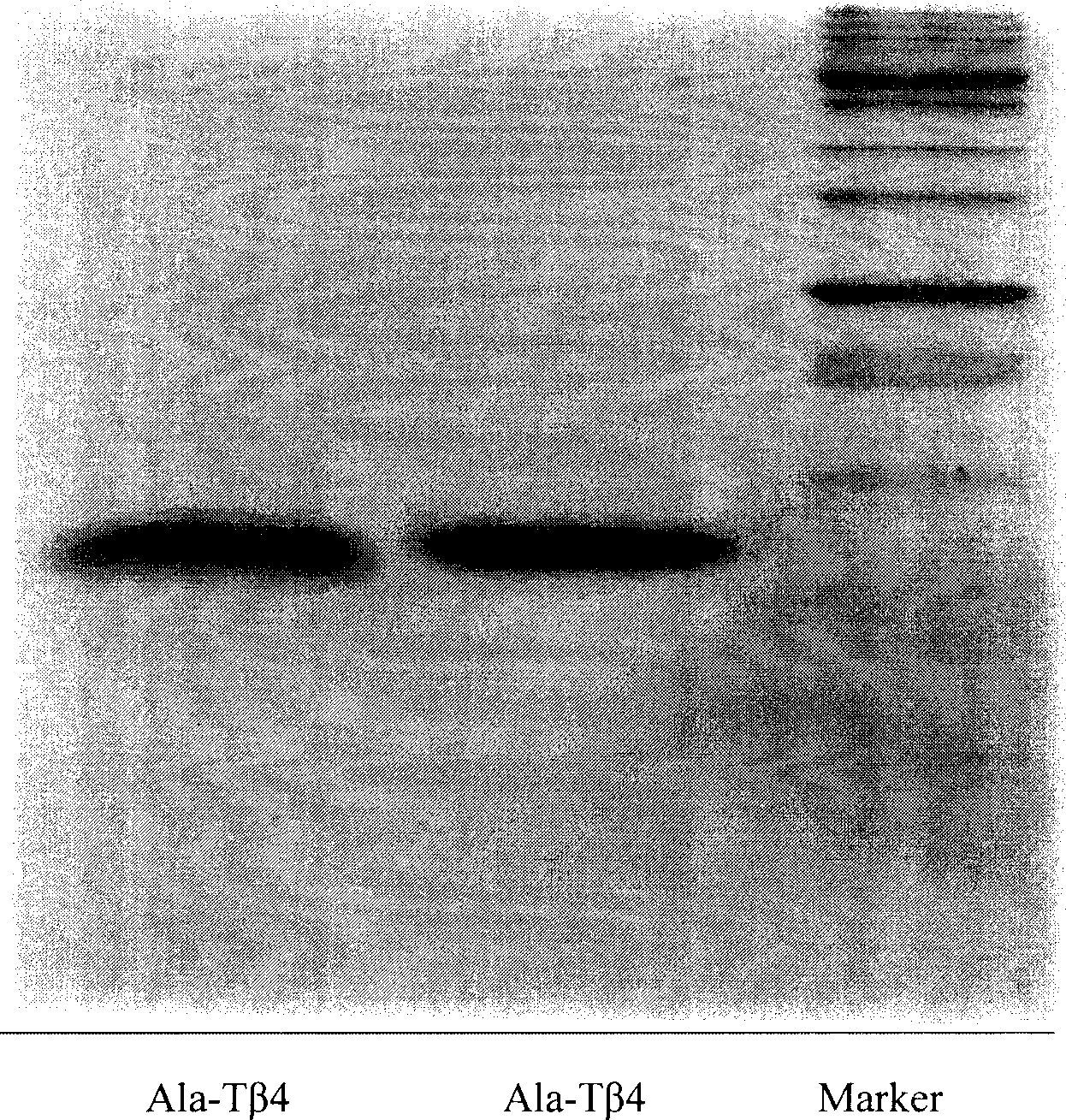

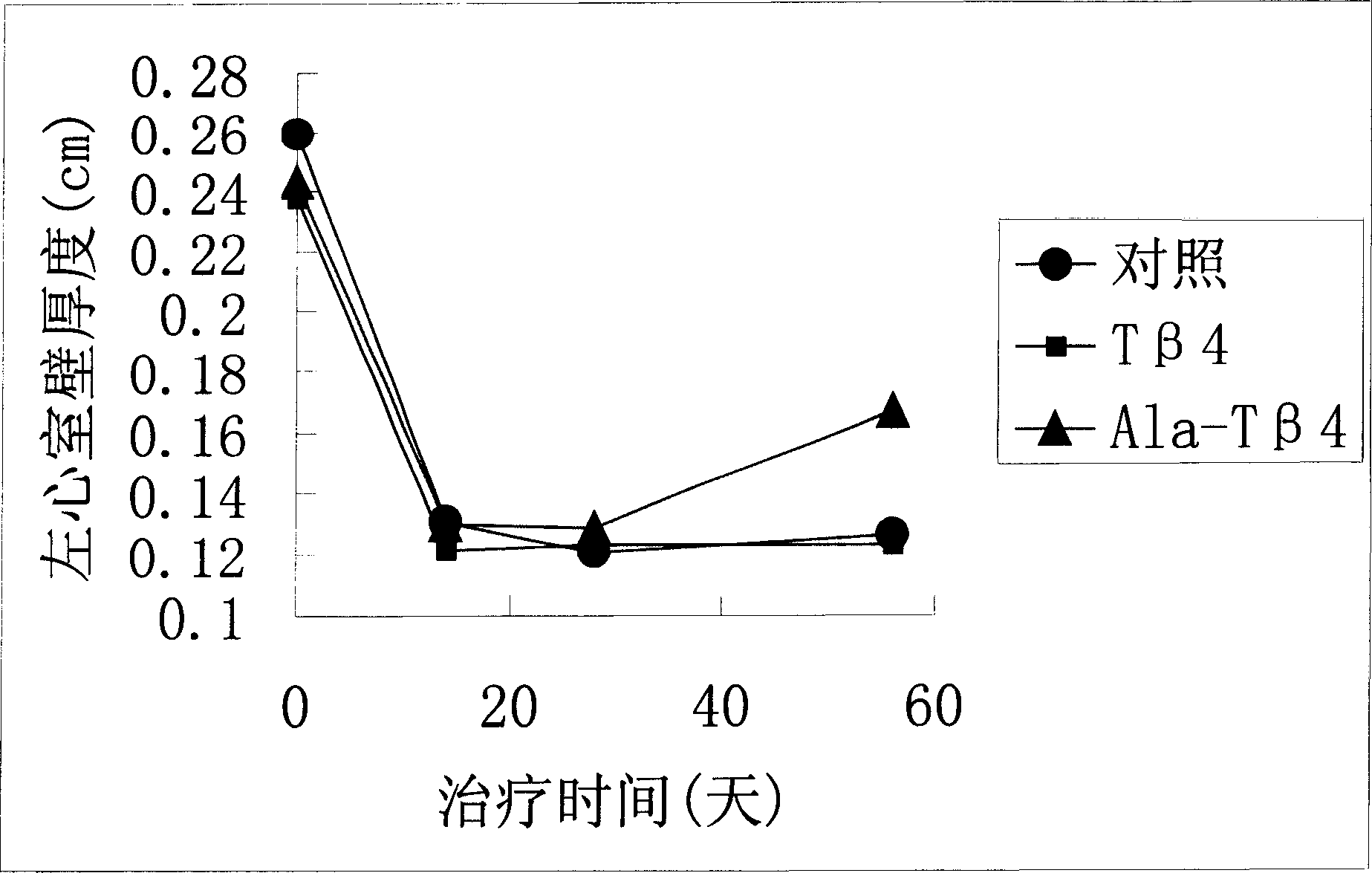

Production of high-activity extrasin beta 4 derivative by gene engineering

InactiveCN1896096AHigh purityImprove biological activitySenses disorderPeptide/protein ingredientsChemistryHigh activity

A high-activity extrasin beta-4 derivative by gene engineering method is prepared by expressing in bacterium, combing protein with natural extrasin beta-4, dissolved expressing in colibacillus, cutting and processing by fusion protease. It has stable and efficient expression, higher purity and can be used to repair skin and heart damage.

Owner:BEIJING NORTHLAND BIOTECH

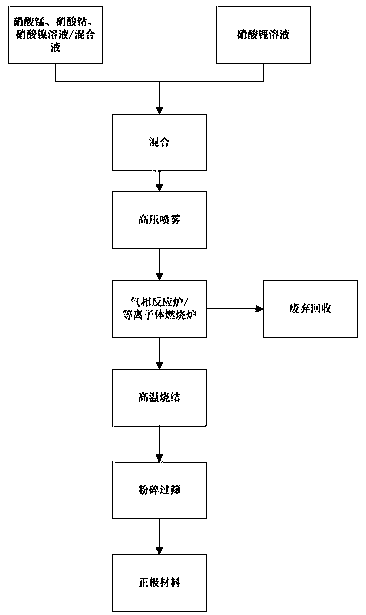

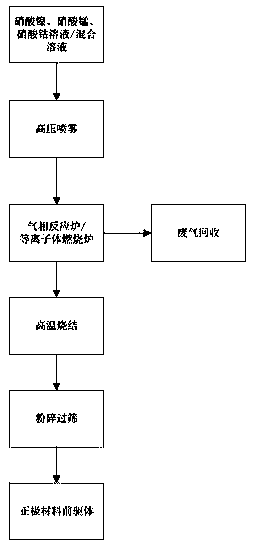

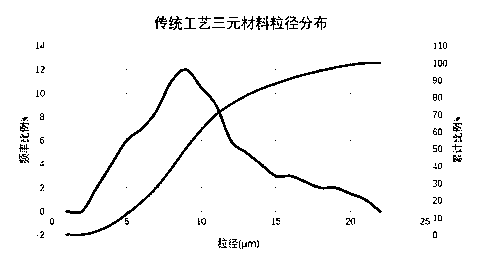

Preparation method of anode material of lithium ion battery and preparation method of precursor of anode material

InactiveCN108899483ANo speed control requiredSimple processCell electrodesSecondary cellsAluminium-ion batterySodium-ion battery

The invention relates to a preparation method of an anode material of a lithium ion battery and a preparation method of a precursor of the anode material. According to a traditional preparation mannerof the lithium ion battery, an anode material is prepared through the steps of coprecipitation, drying, lithium blending, drying and calcining, and coprecipitation conditions are difficult to control. According to the improved technical scheme, a coprecipitation method is not utilized, and a nitrate solution which can be dissolved in water and easily decomposed at a high temperature is directly subjected to hyperbaric spraying and high-temperature combustion in sequence so as to obtain the anode material. Lithium salt is mixed with Mn, Co, Ni and a water-soluble salt solution, so that the mixing uniformity is improved; and the mixture is dispersed through hyperbaric spraying, and sprayed particles react at a high temperature so as to adequately oxide reactants, so that particles with uniform size and relatively small particle size (1.5-2 microns) can be obtained. By virtue of the particles with small particle size and good uniformity, the contact between an active material and electrolyte can be promoted, so that the electrochemical properties such as multiplying power of the battery are improved.

Owner:TIANJIN XINDONGYUAN SCI & TECH

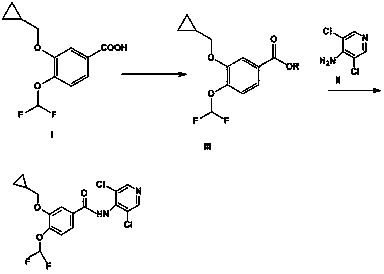

Preparation method of roflumilast

The invention belongs to the technical field of drug synthesis, and specifically relates to a preparation method of roflumilast. The preparation method comprises the following steps: (1) dissolving an activating reagent into a solvent, adding 3-cyclopropylmethoxyl-4-difluoromethoxylbenzoic acid into the solvent to carry out reactions in the presence of an alkali; (2) adding 3,5-dichloro-4-aminopyridine into the solution obtained in the step (1) to carry out reactions so as to obtain the roflumilast. The 2,4-dimethoxyl-6-chloro-1,3-5-s-triazine and other reagents used in the preparation method are conventional reagents in production, and are easily available. Moreover, the production conditions are simple. Sulfoxide chloride, which has high requirements on production conditions and severely pollutes the environment, is replaced; and conditions that are not suitable for industrialization such as high temperature reduced pressure distillation, and the like are avoided at the same time, so the preparation method is a novel synthesis method suitable for industrial operation. Because the synthesis route is reasonably designed, and the reaction activity is high, the reaction yield is prominently improved, and can reach 86-95%.

Owner:INST OF PHARMACY SHANDONG PROV ACAD OF MEDICAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com