Compressor exhaust silencer structure

A compressor exhaust and muffler technology, applied in the field of compressors, can solve problems such as high processing and material costs, poor exhaust pulsation effect, and increased cost of throttling pipes, so as to improve matching sound quality and reduce exhaust pulsation. , the effect of reducing exhaust pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

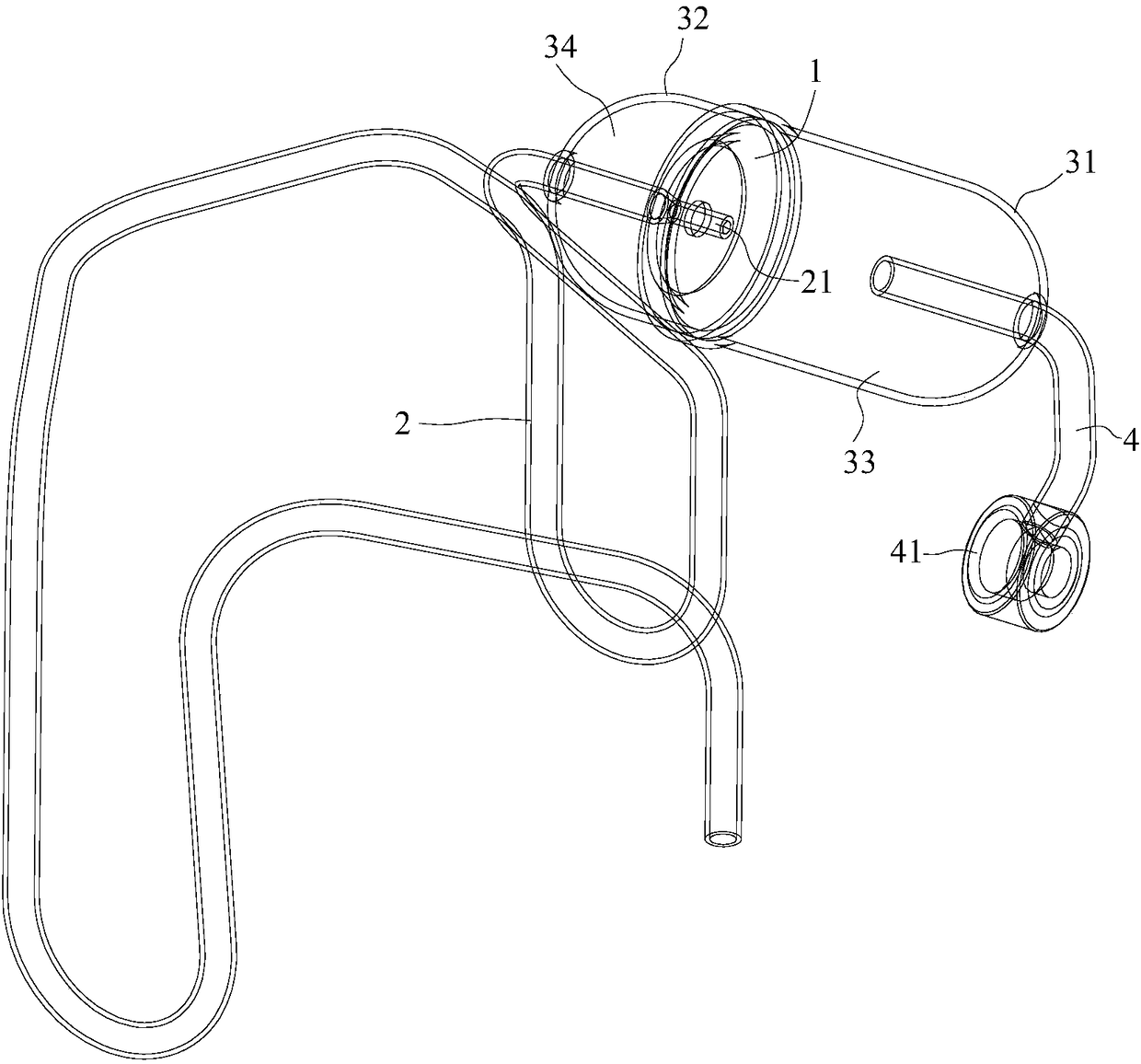

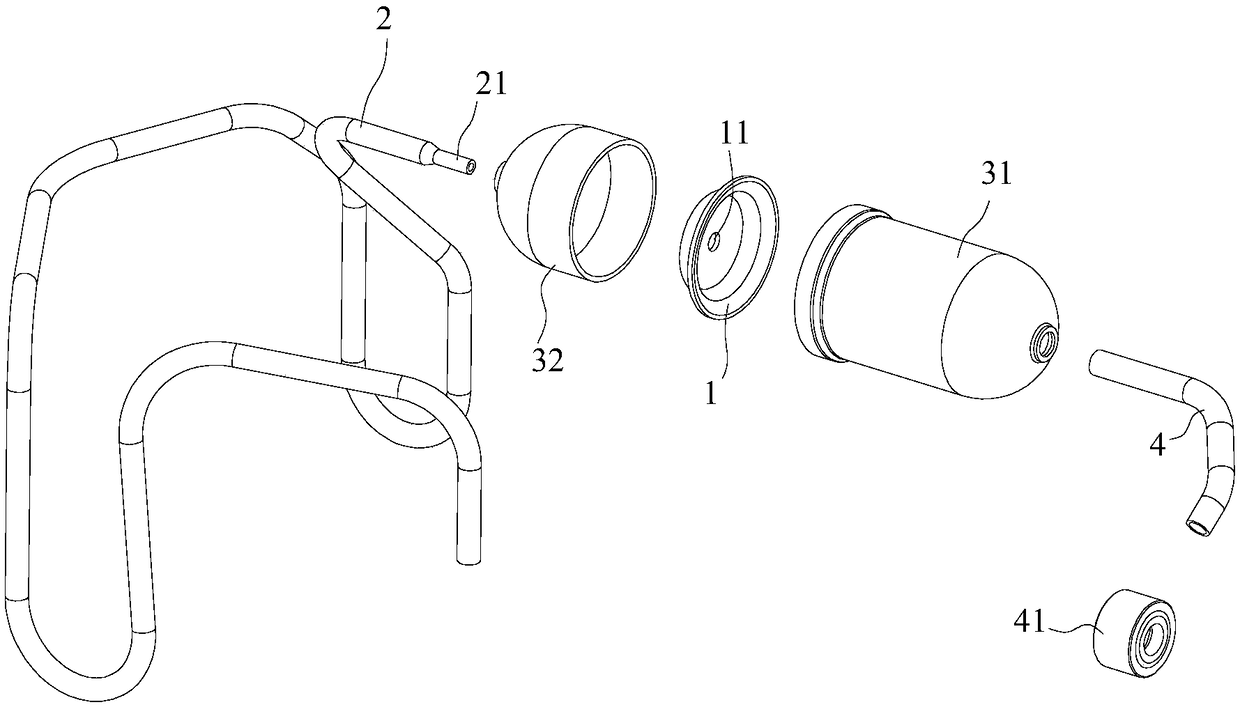

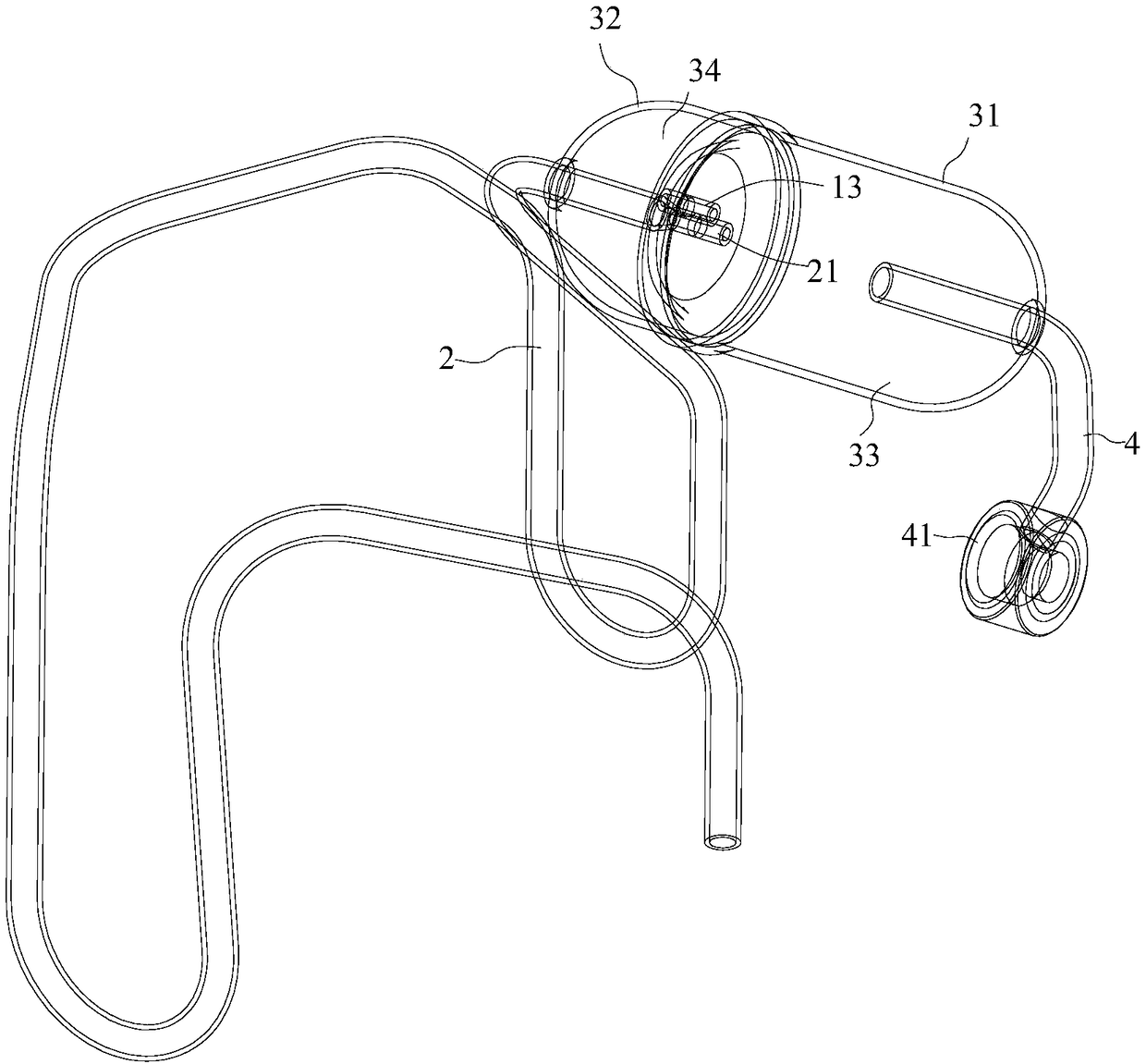

[0034] refer to Figure 1 to Figure 9 , which shows the specific structure of the preferred embodiment of the present invention. The structural characteristics of each component of the present invention will be described in detail below.

[0035] The invention provides a compressor exhaust muffler structure, which includes a muffler and an exhaust pipe. The muffler includes a shell provided with an air inlet and an exhaust port. Muffling chamber, the interior of the shell is provided with a partition 1 that divides the noise reduction chamber into a front noise reduction chamber 33 and a rear resonance chamber 34, the partition 1 is provided with a partition through hole 11, and the exhaust pipe includes a wall connected to the exhaust port. The rear exhaust pipe 2, the rear exhaust pipe 2 has a narrowing and throttling section 21 that matches the through hole 11 of the partition, and the partition 1 and / or the rear exhaust pipe 2 is provided with a conductive The airflow pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com