Coaxial cable

A coaxial cable, conductor technology, applied in the direction of coaxial cable/analog cable, insulated cable, cable, etc., can solve the problems of shock absorption effect, poor twist and tensile performance, high production cost, etc., and achieve heat resistance and aging resistance. High performance, easy production and light weight results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

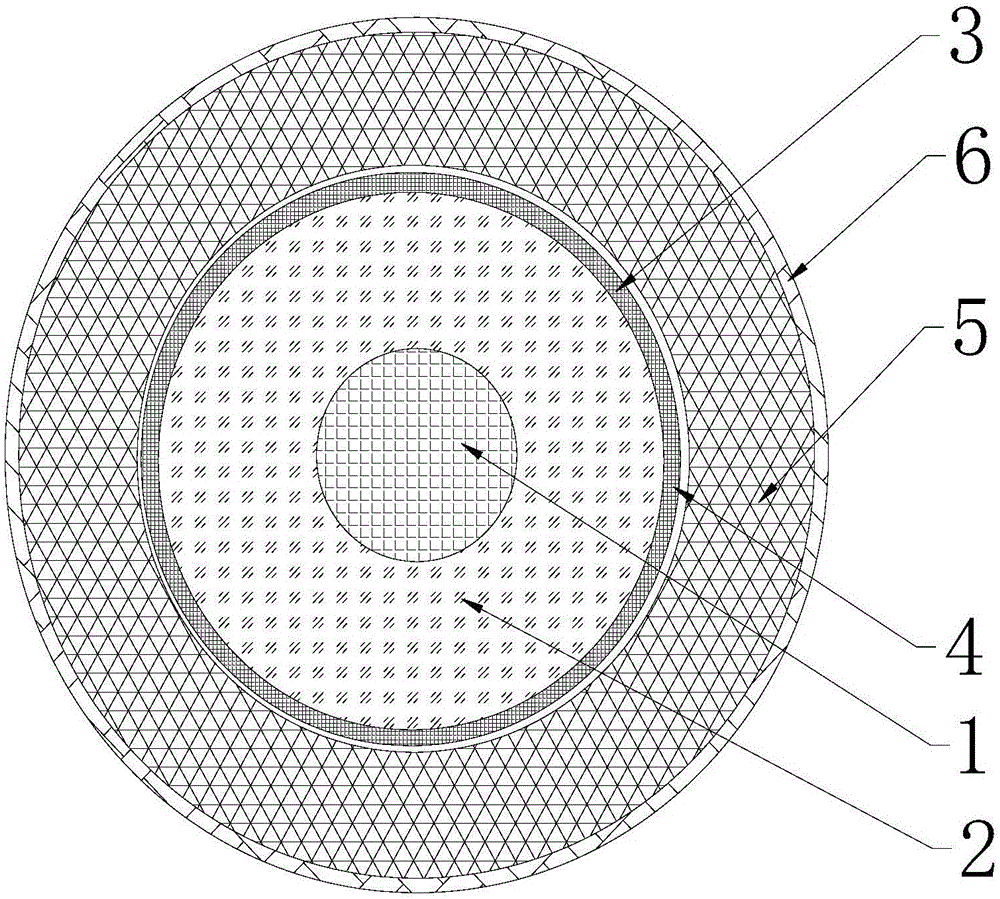

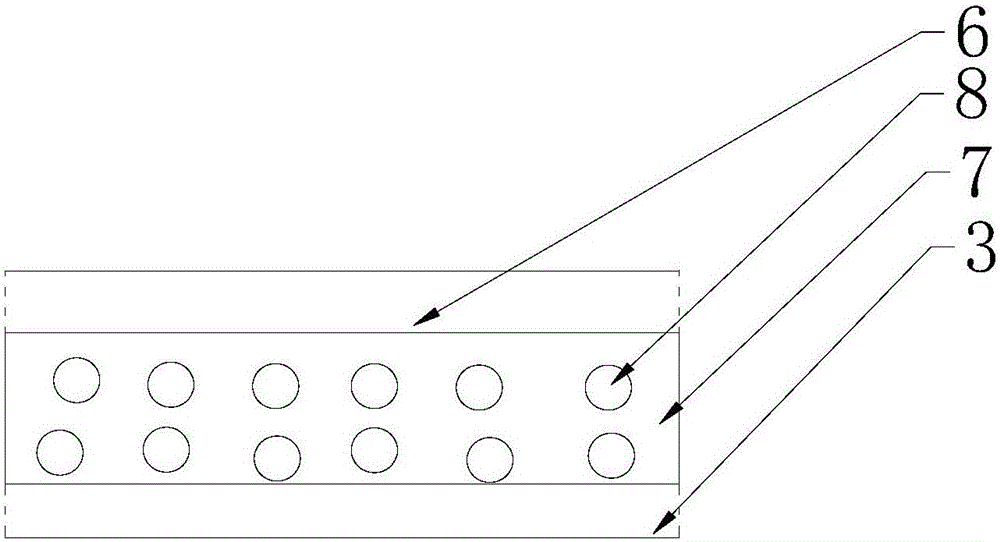

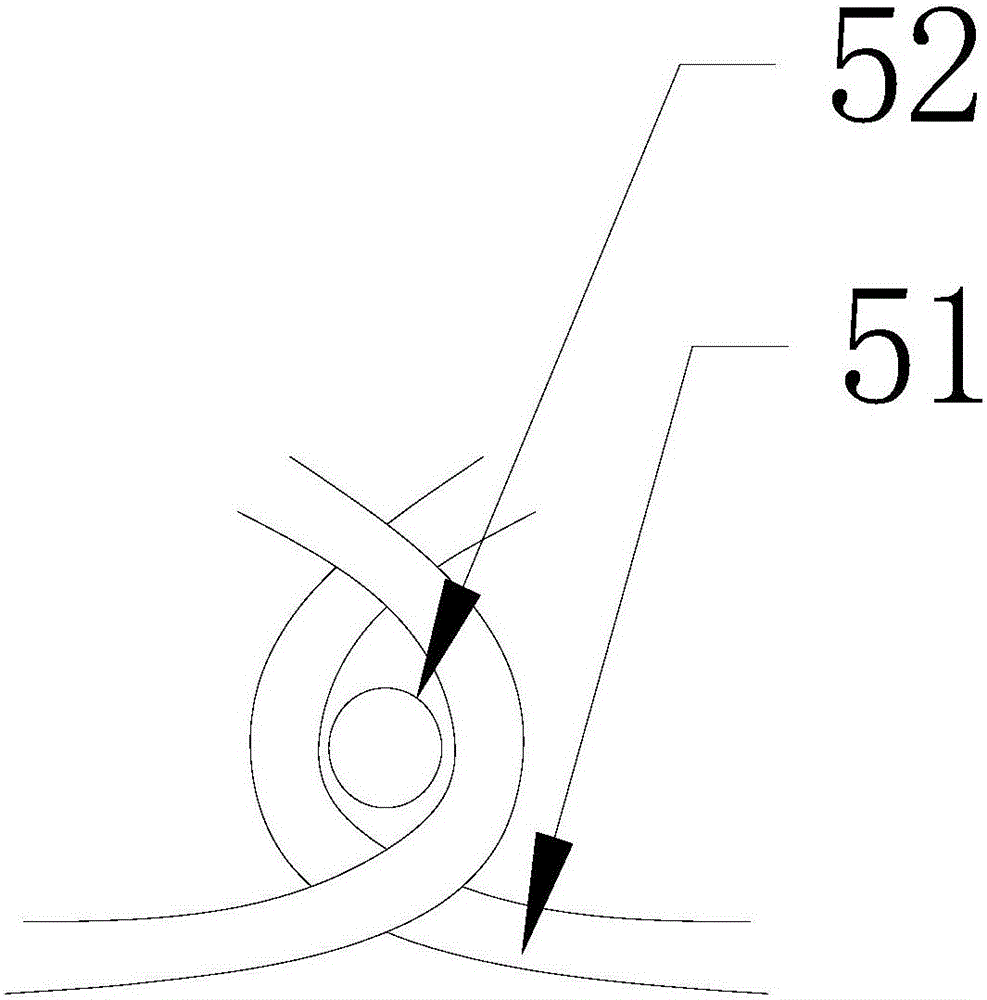

[0026] Embodiment 1: The embodiment of the present invention discloses a coaxial cable (see attached figure 1 , 2 , 3, 4), including: conductor 1, foam insulation layer 2, outer conductor layer 3, fiber sheath 5, insulation layer 6, said conductor 1, foam insulation layer 2, outer conductor layer 3, fiber sheath 5. The insulating layer 6 is arranged sequentially from the inside to the outside. The fiber sleeve 5 is provided with a skeleton 7 with frame holes 8. The skeleton 7 is made by melting the second fiber 52. The skeleton 7 is fixedly connected to the outer conductor layer 3 and the insulating layer 6, the first fibers 51 are interspersed in the frame holes 8, the first fibers 51 are braided with metal wires, and the first fibers 51 are interlinked to form a net. In the present invention, the second fiber 52 is used to make the skeleton 7 structure and the fiber sleeve 5 woven by the first fiber 51 braided with metal wires has a simple structure, good shock absorption e...

Embodiment 2

[0031] Embodiment 2: The melting temperature of the second fiber 52 is 150°C. The outer surface of the outer conductor layer 3 facing the fiber sleeve 5 is provided with a heat-insulating and corrosion-resistant coating film 4, and the fiber material with a melting temperature of 100°C-150°C has a lower melting temperature, and the heat required for melting is lower. When external hot air is used for heating, the heat-insulating and corrosion-resistant coating film effectively blocks the influence of heat transfer on the foam insulation, effectively reducing the difficulty of the production process.

[0032] The insulating layer 6 has a thickness of 5mm. The 2mm-5mm polyethylene insulation layer is mainly used for waterproofing and penetration of the coaxial cable. It does not need the insulation layer 6 to have a greater impact on the physical properties of the coaxial cable such as shock absorption. It only needs a thickness of 2-5mm to achieve Anticipated requirements, its...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com