Patents

Literature

75 results about "Synthetic bone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

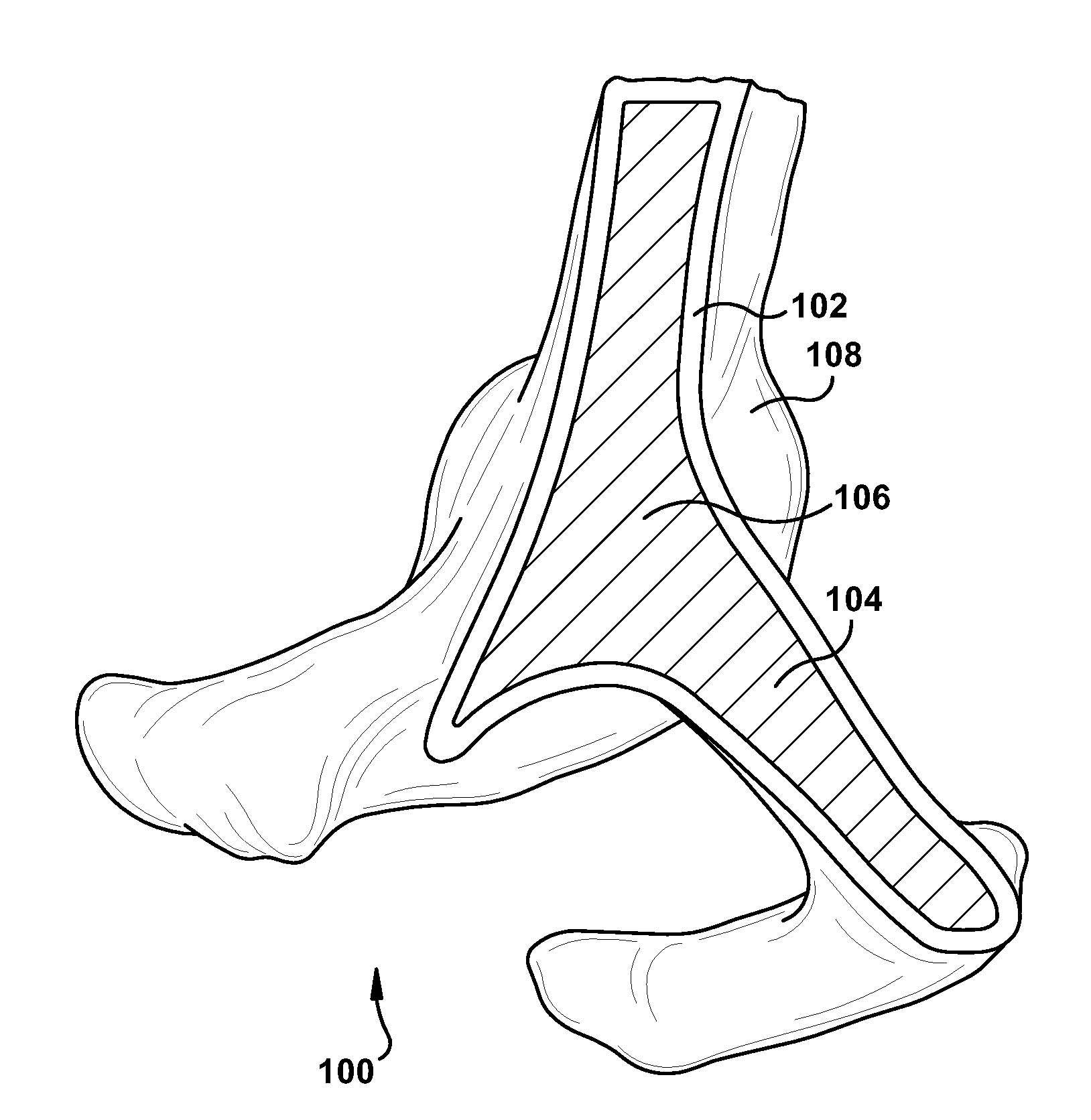

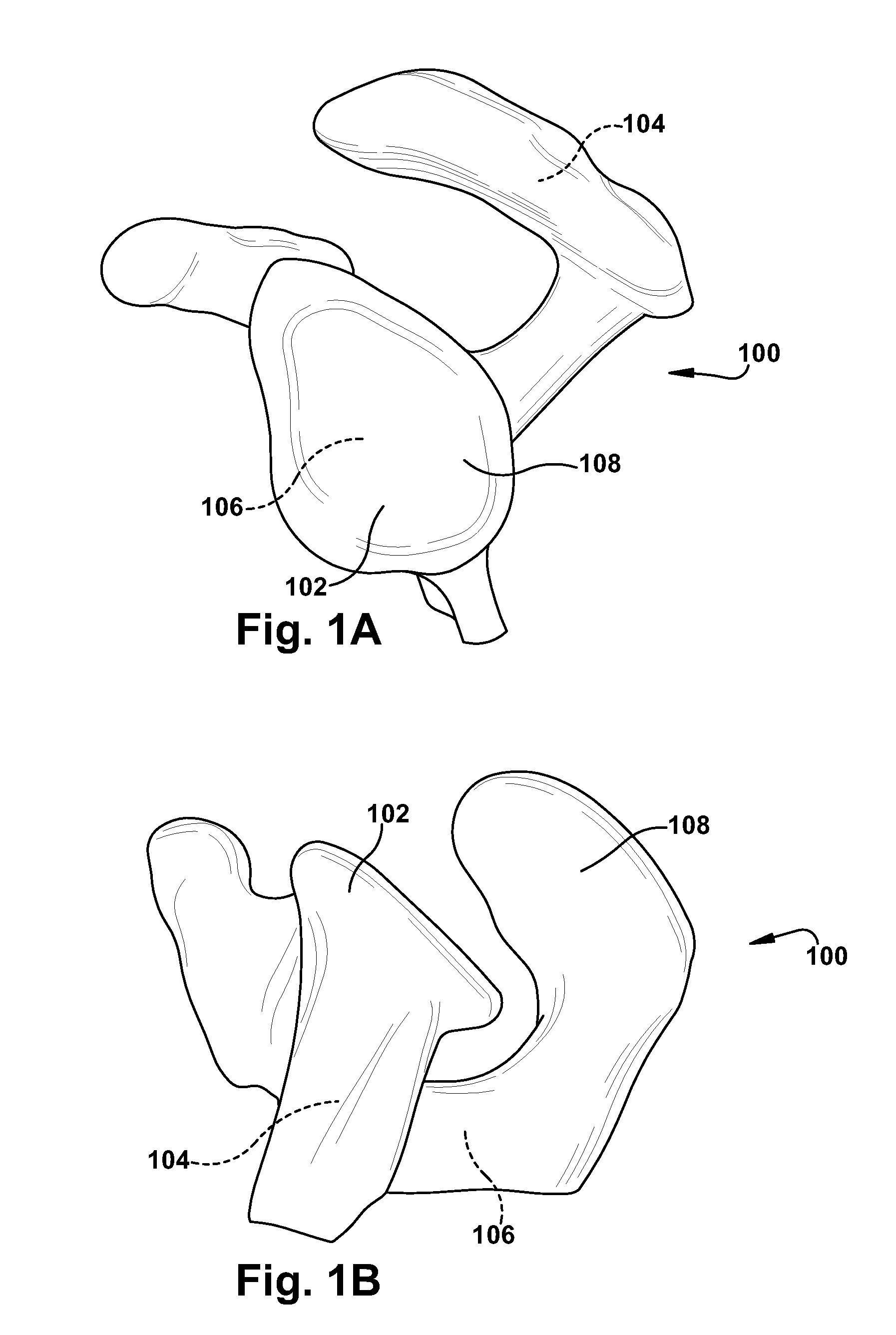

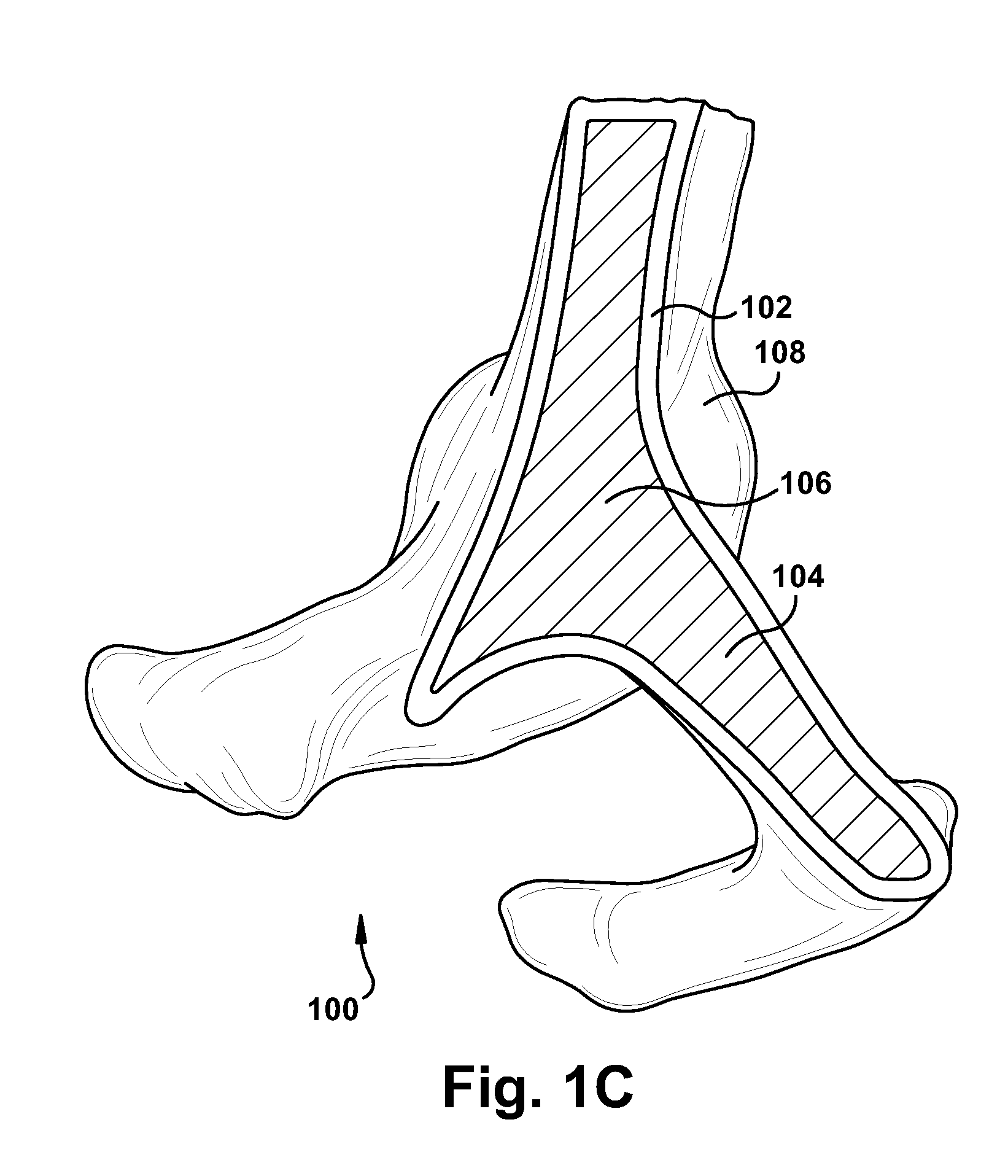

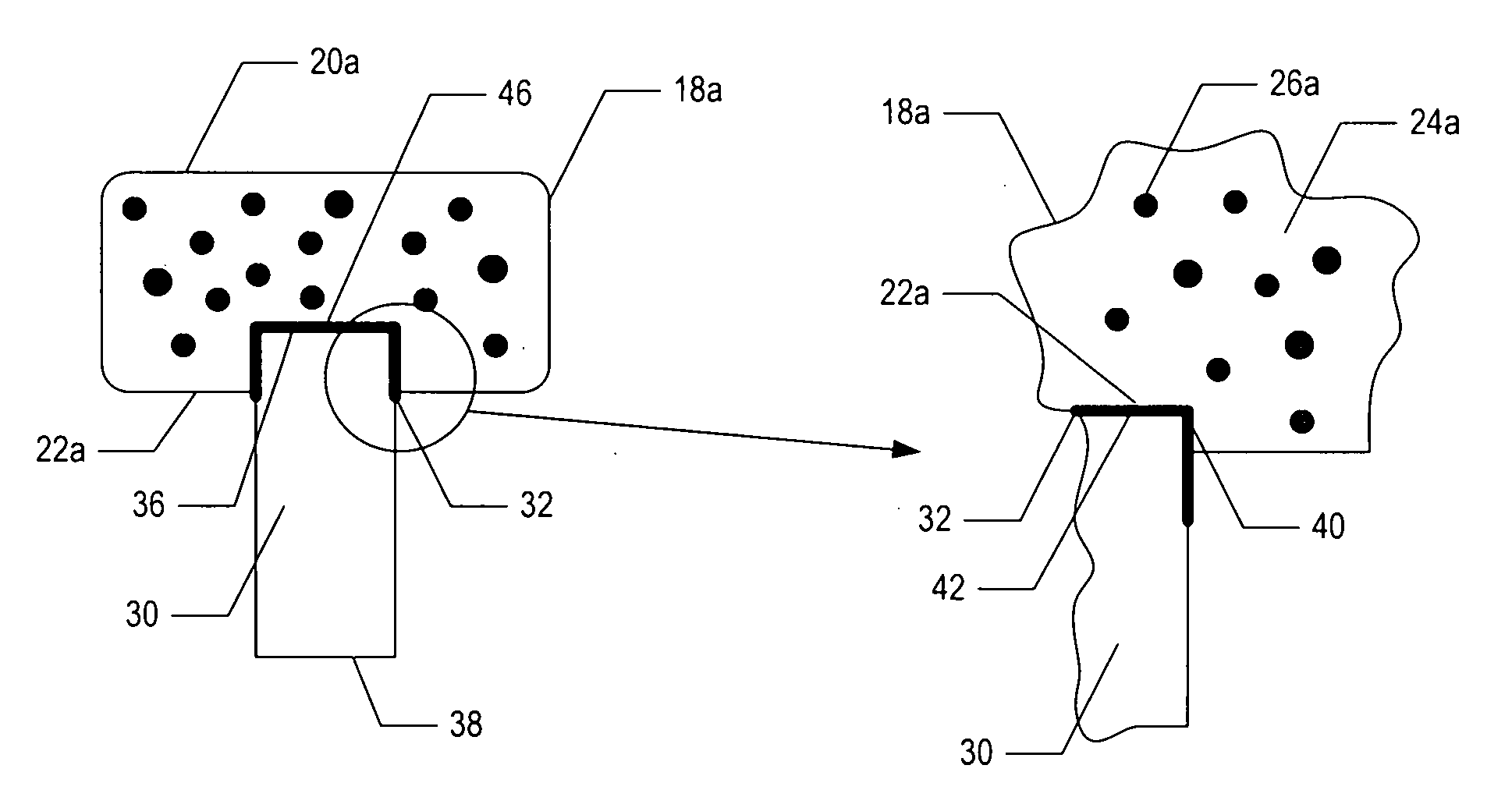

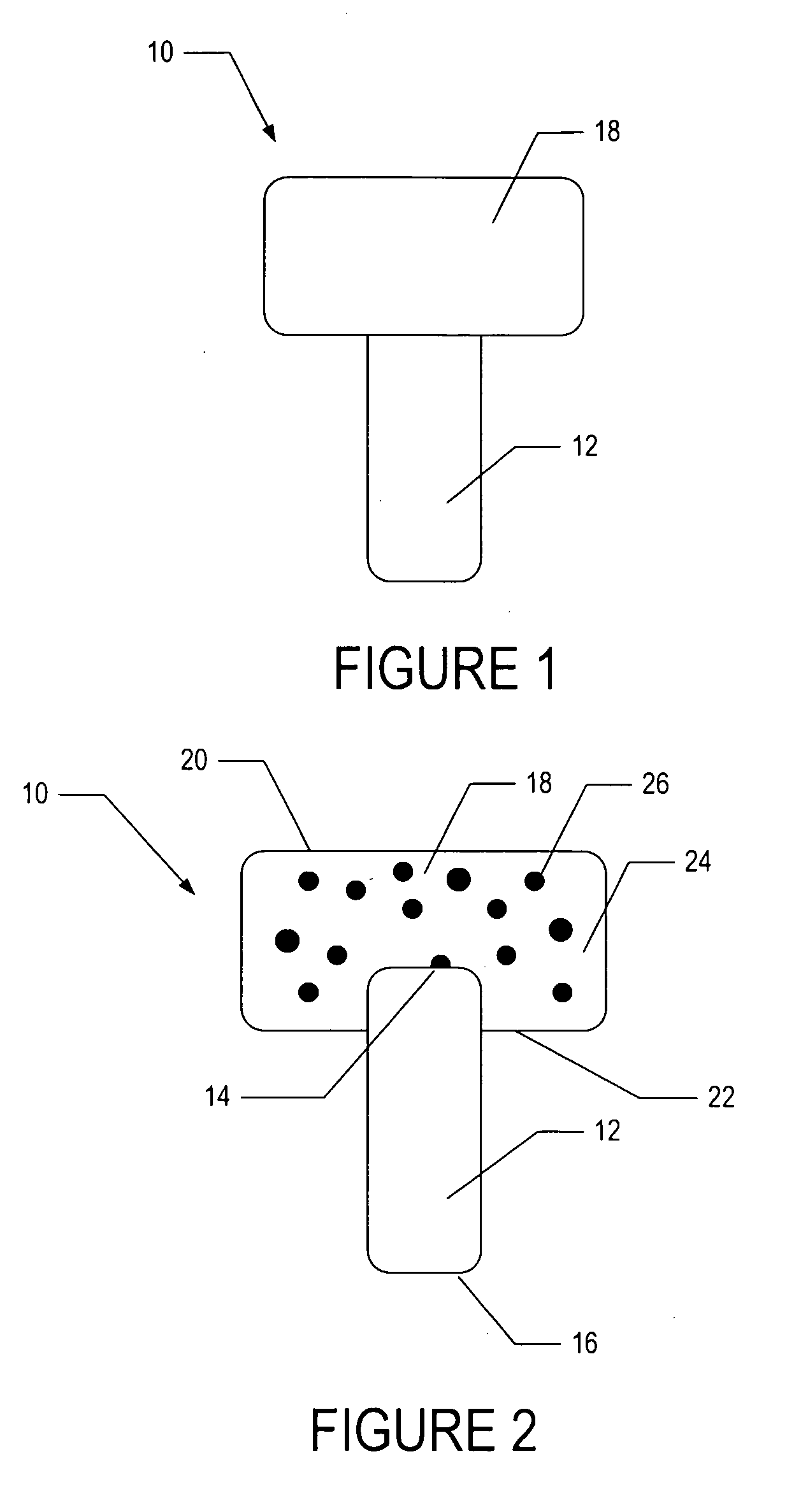

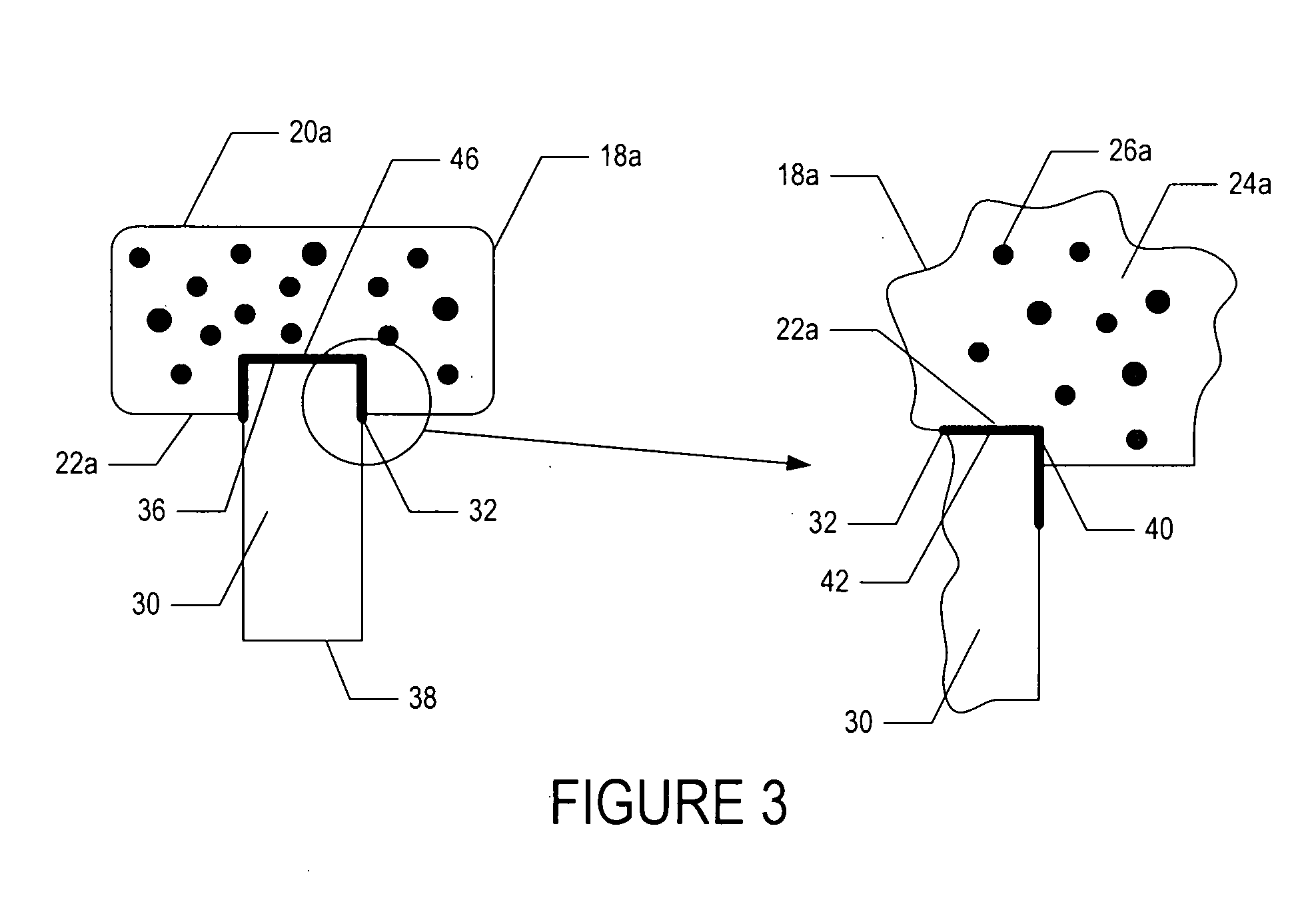

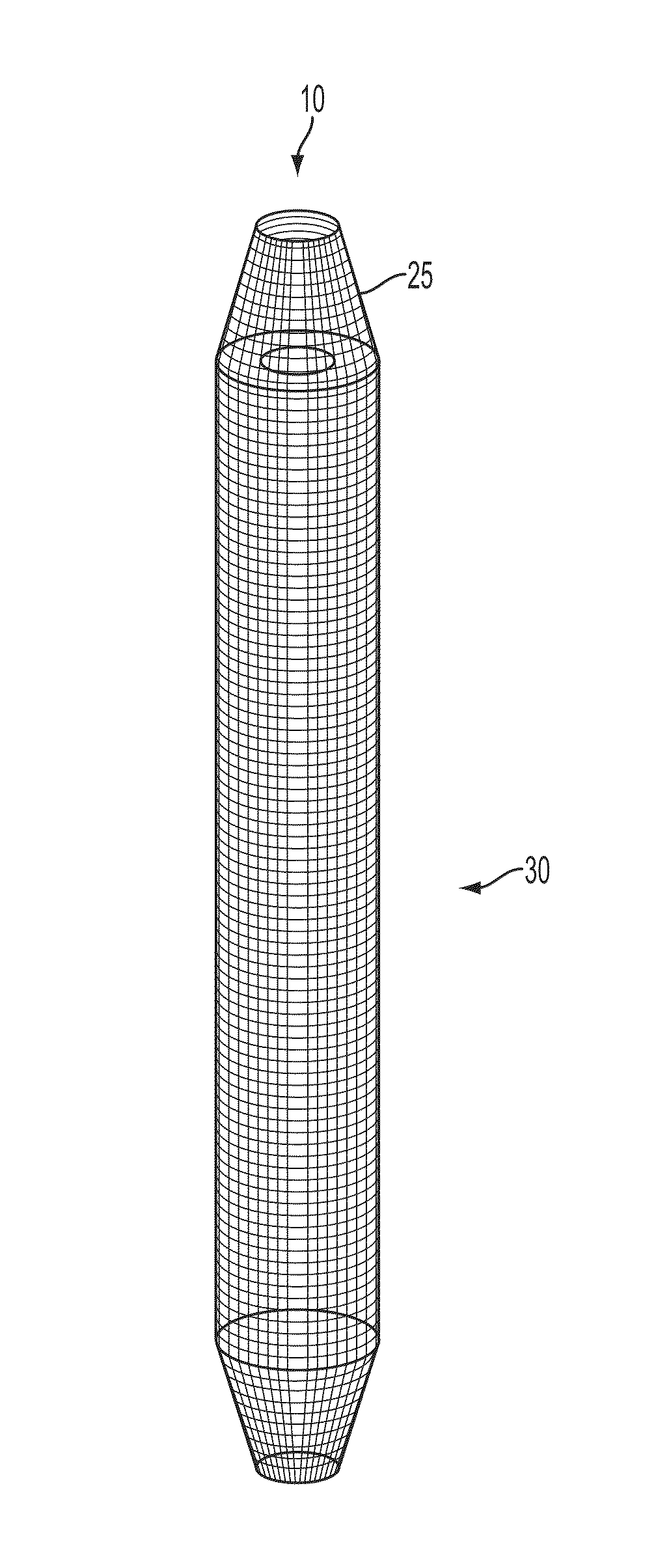

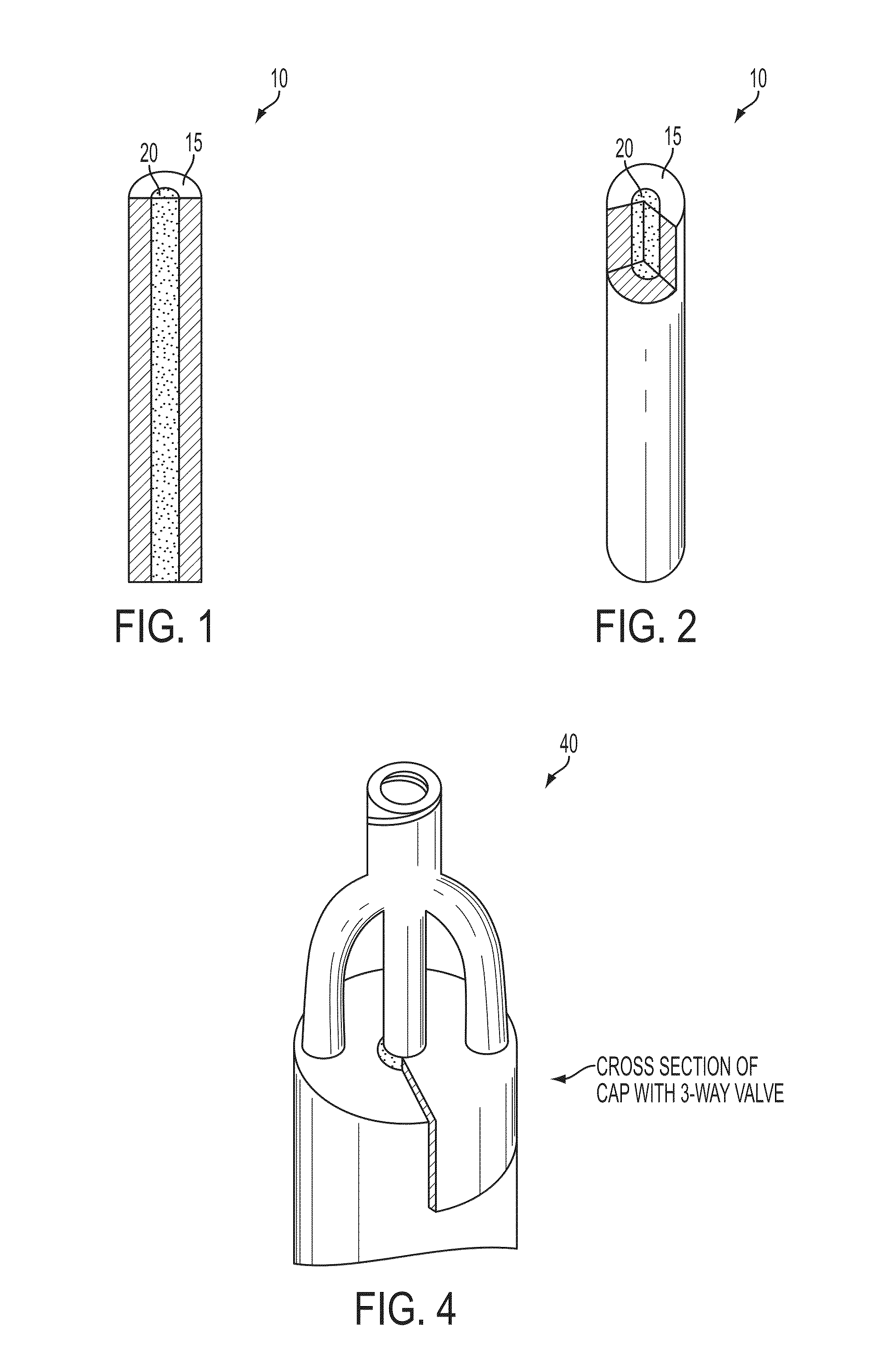

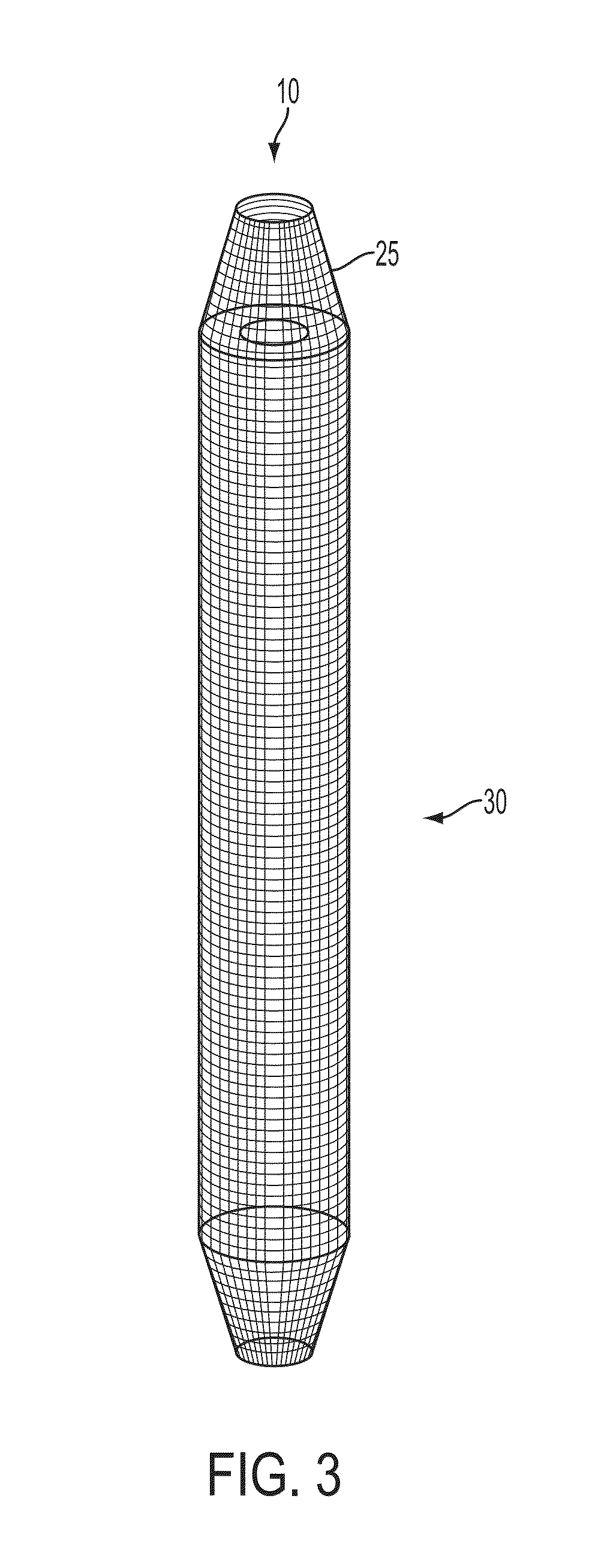

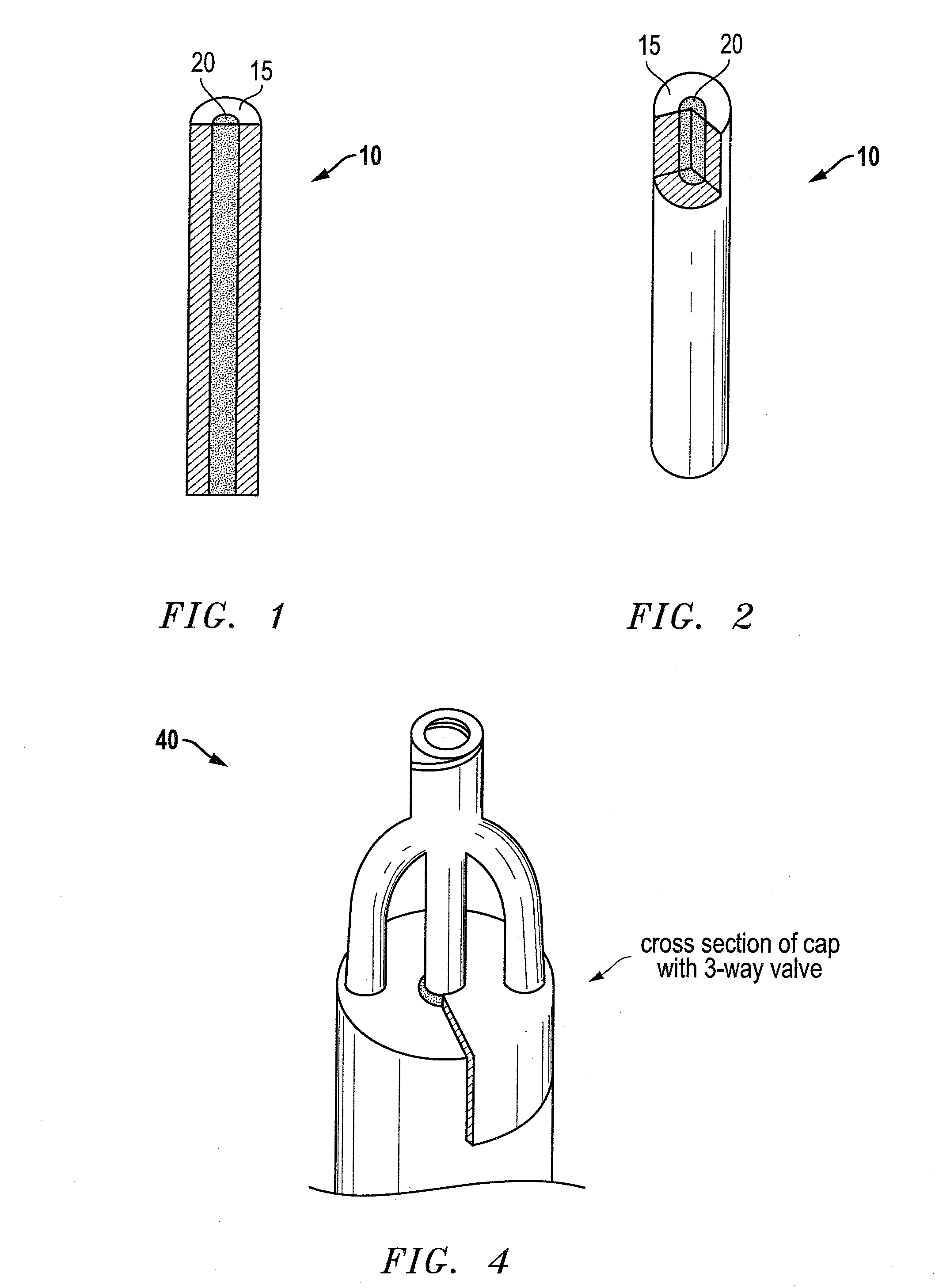

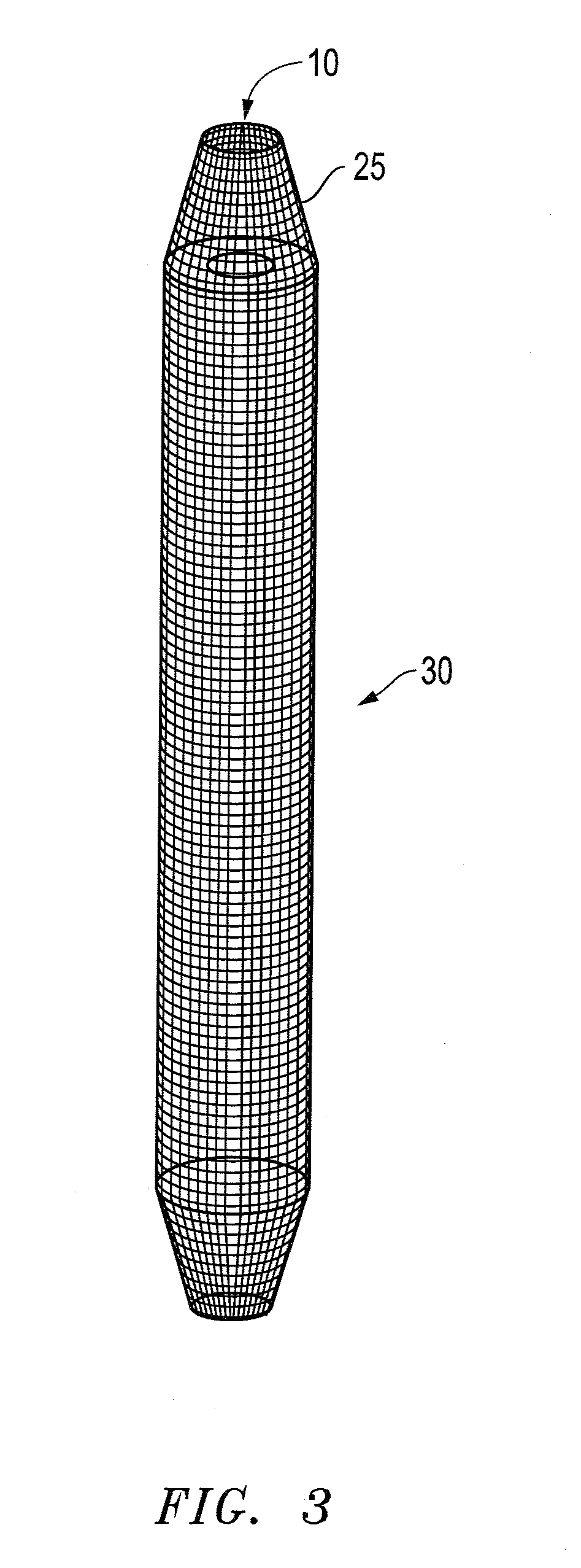

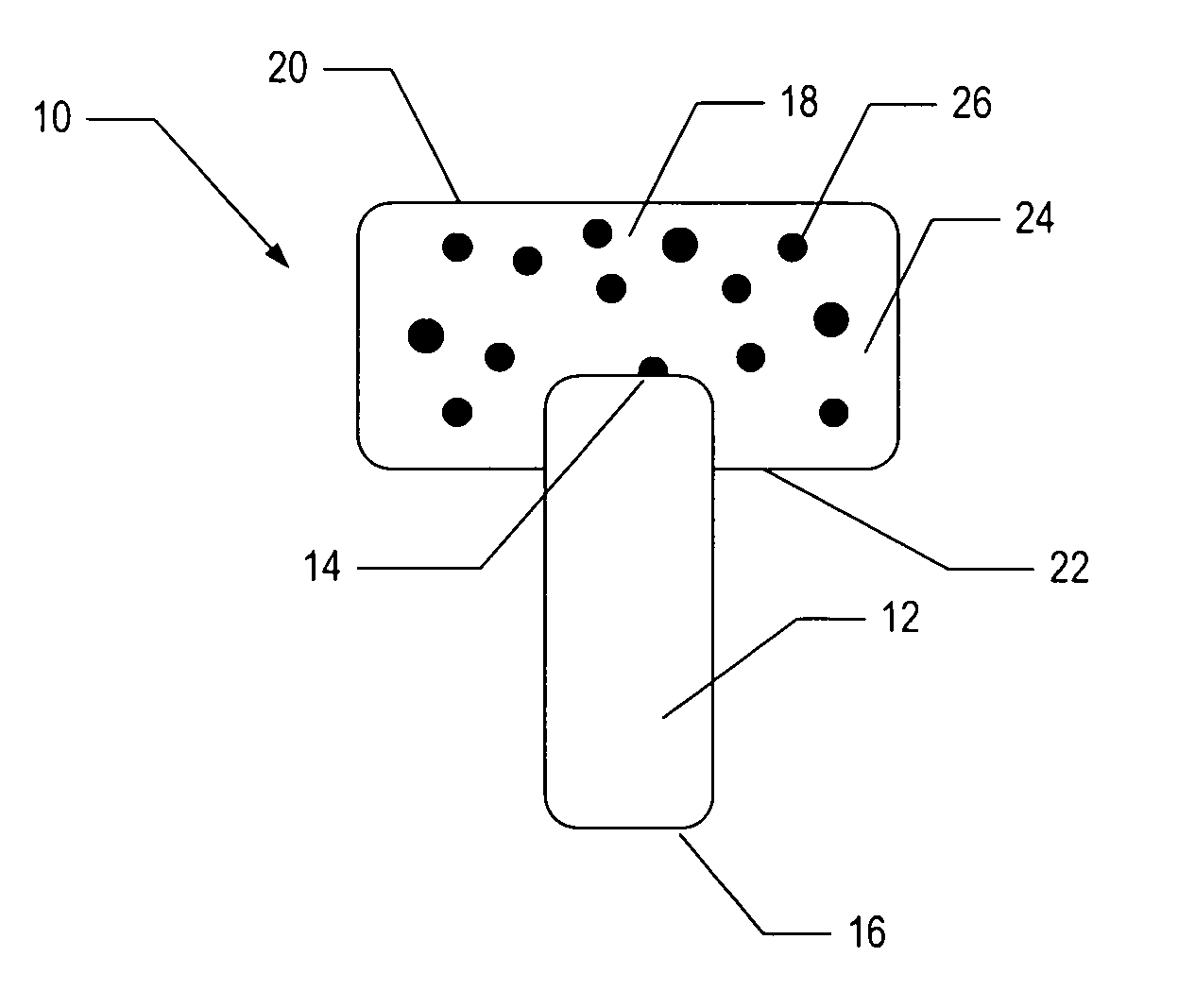

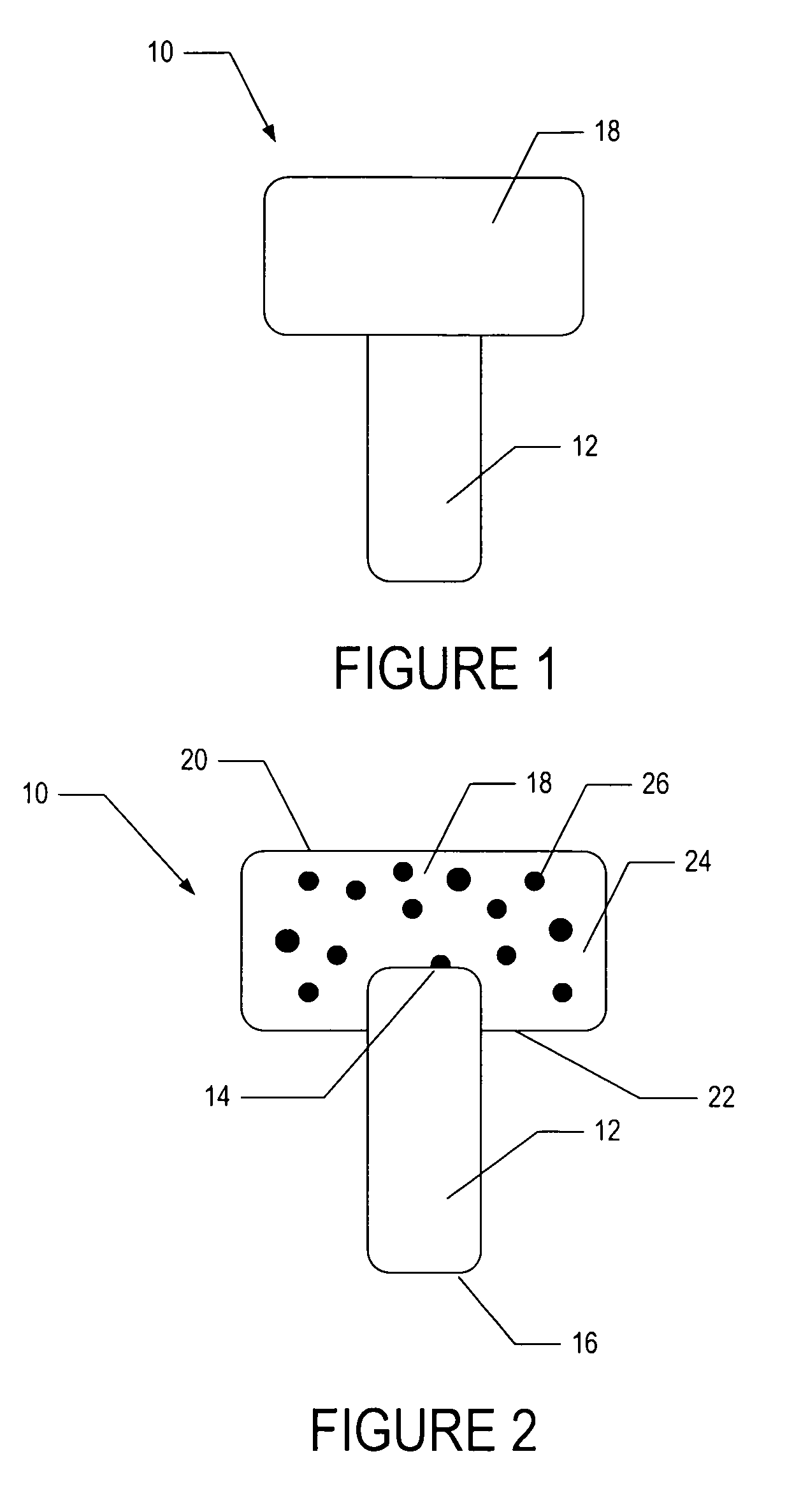

Synthetic bone model and method for providing same

InactiveUS20130085590A1Additive manufacturing apparatusEducational modelsFilling materialsSynthetic bone

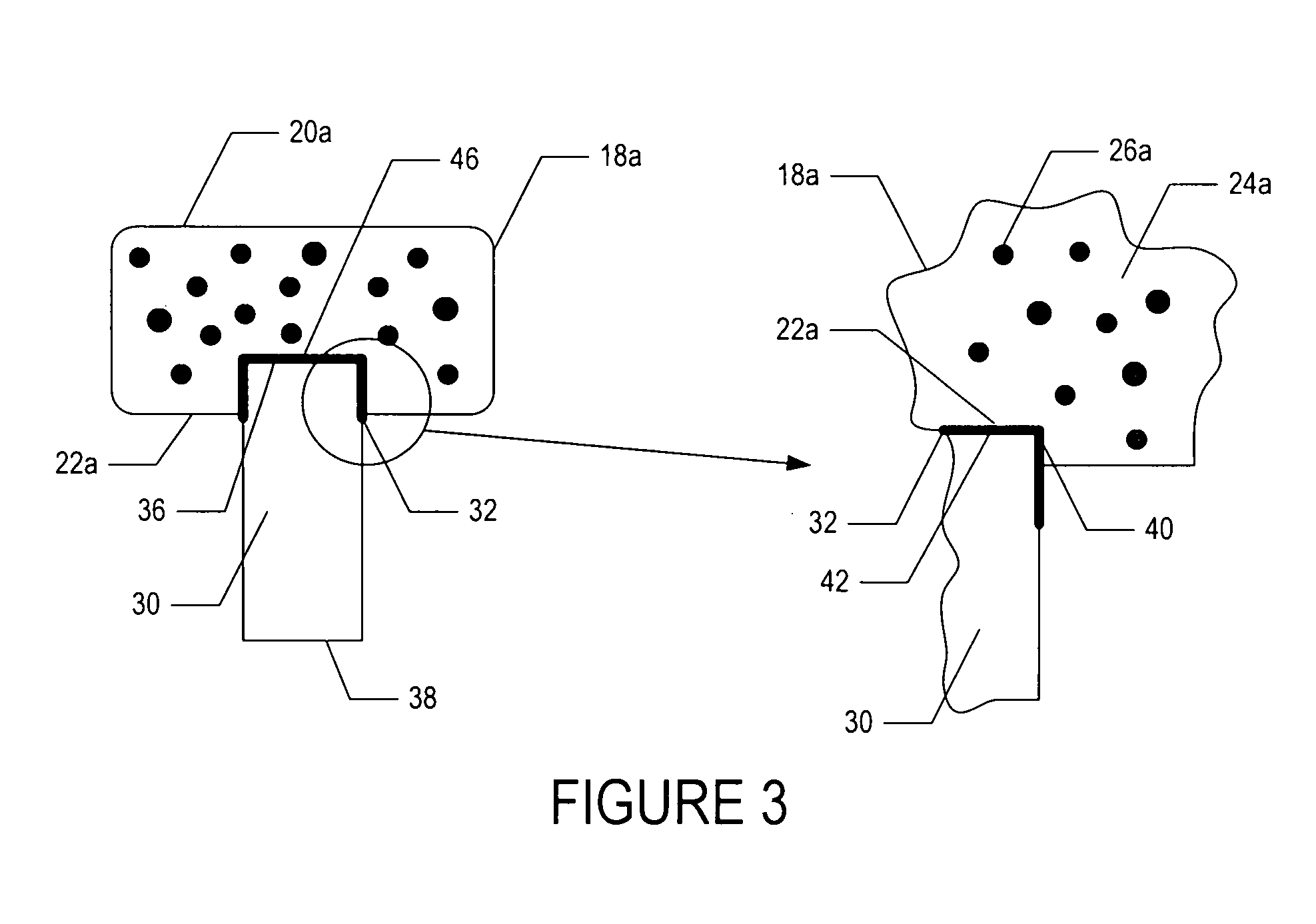

A method for providing a synthetic bone model of a subject bone includes providing a file with data representing a three-dimensional subject bone. Manufacturing instructions are generated based upon at least a portion of the data. The manufacturing instructions are transferred to a manufacturing device. A thin-walled outer shell of the synthetic bone model is created directly from the manufacturing instructions using the manufacturing device. The outer shell defines an inner cavity. A filler material is placed within at least a portion of the inner cavity. A synthetic bone model is also disclosed.

Owner:THE CLEVELAND CLINIC FOUND

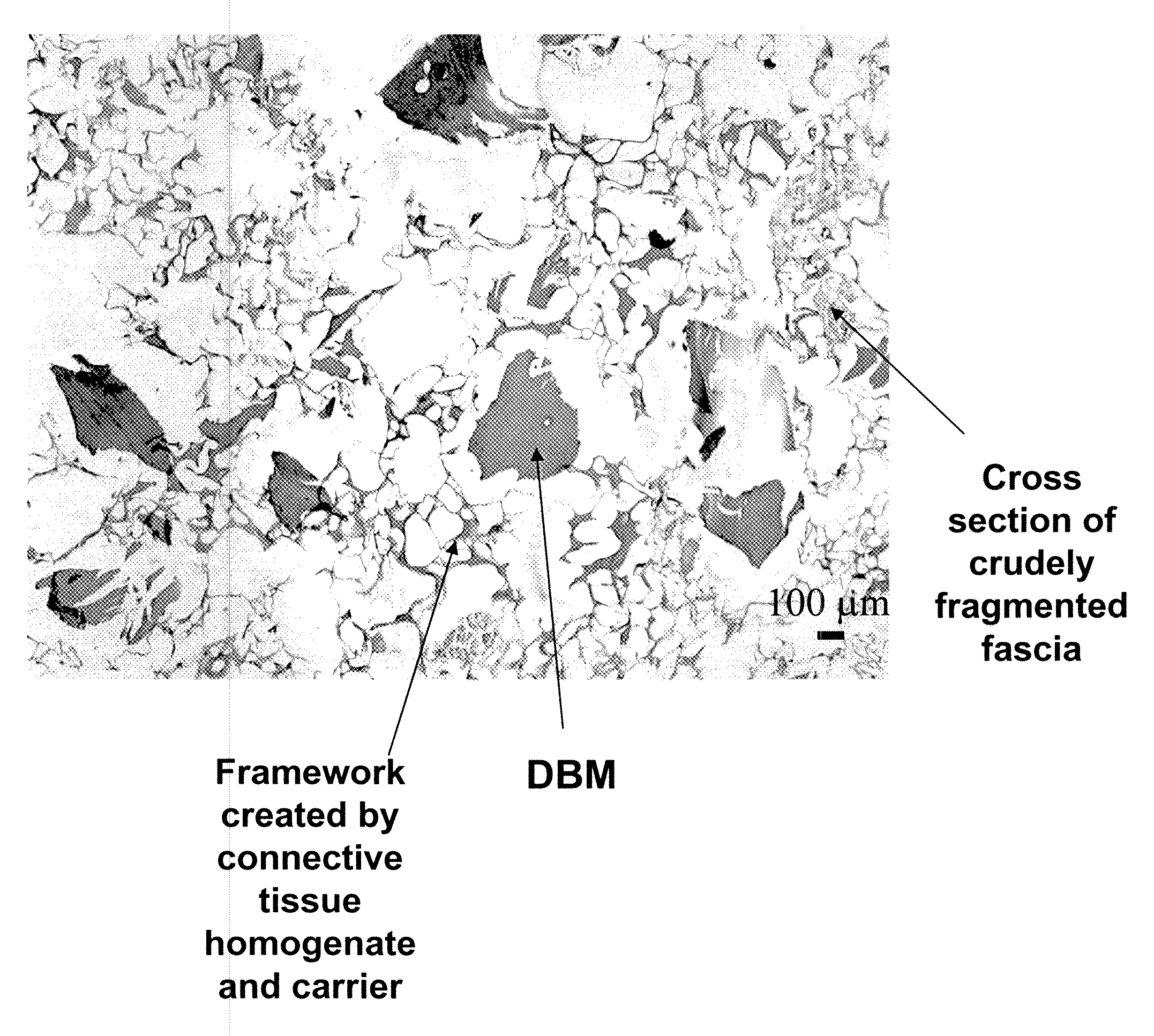

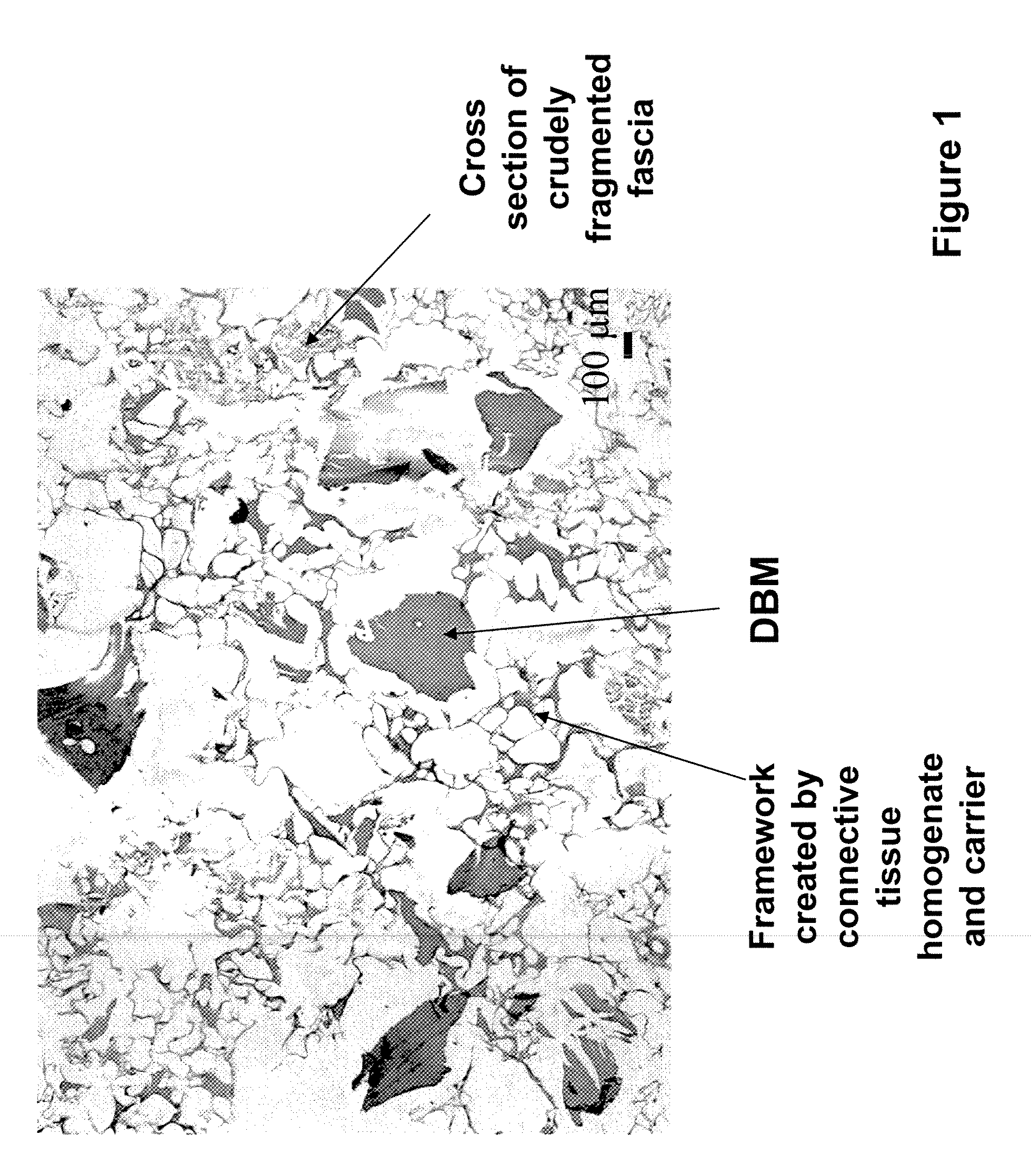

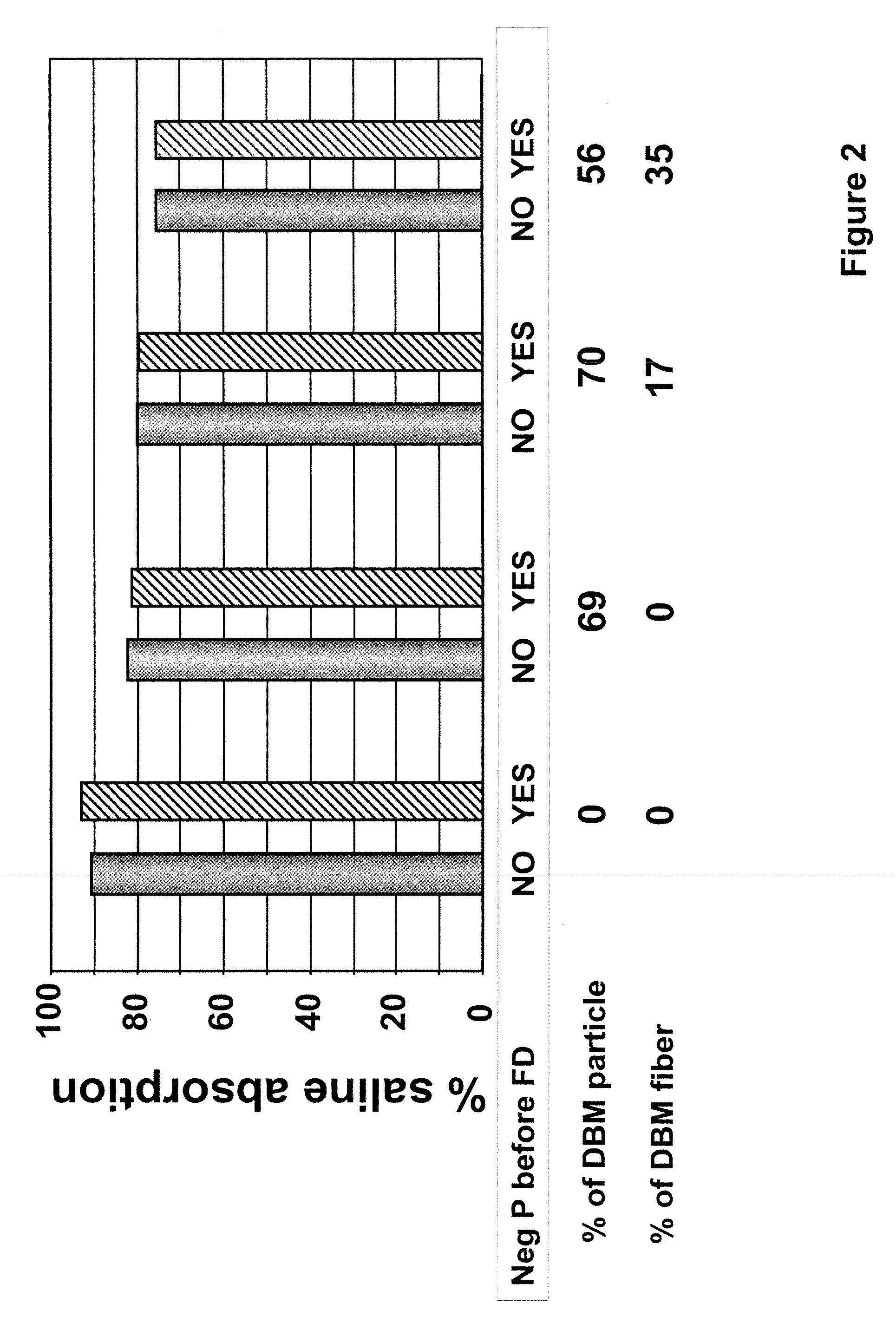

Composition for a Tissue Repair Implant and Methods of Making the Same

ActiveUS20100036503A1Stay in shapeHigh affinityBone implantTissue regenerationTissue repairFreeze-drying

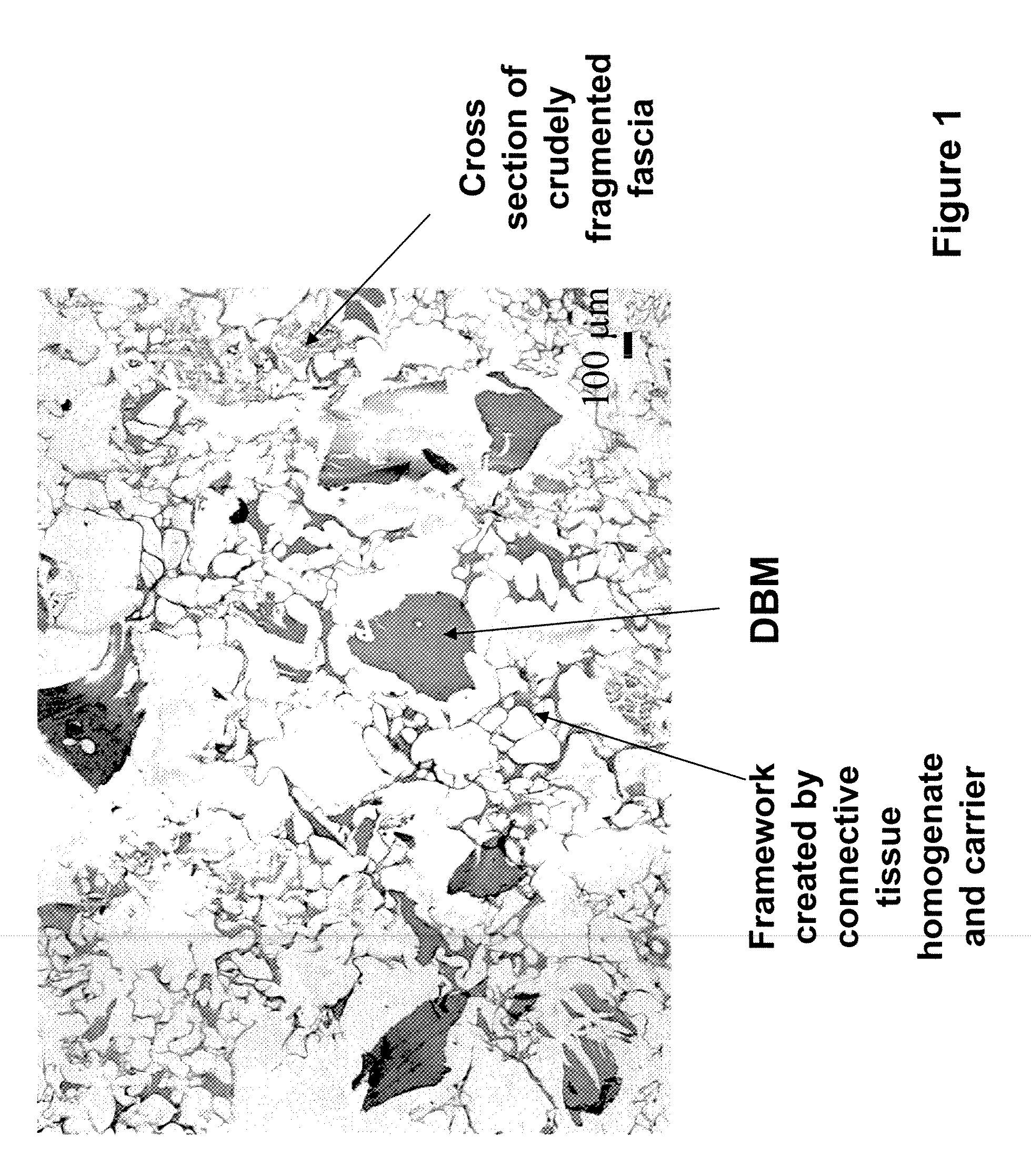

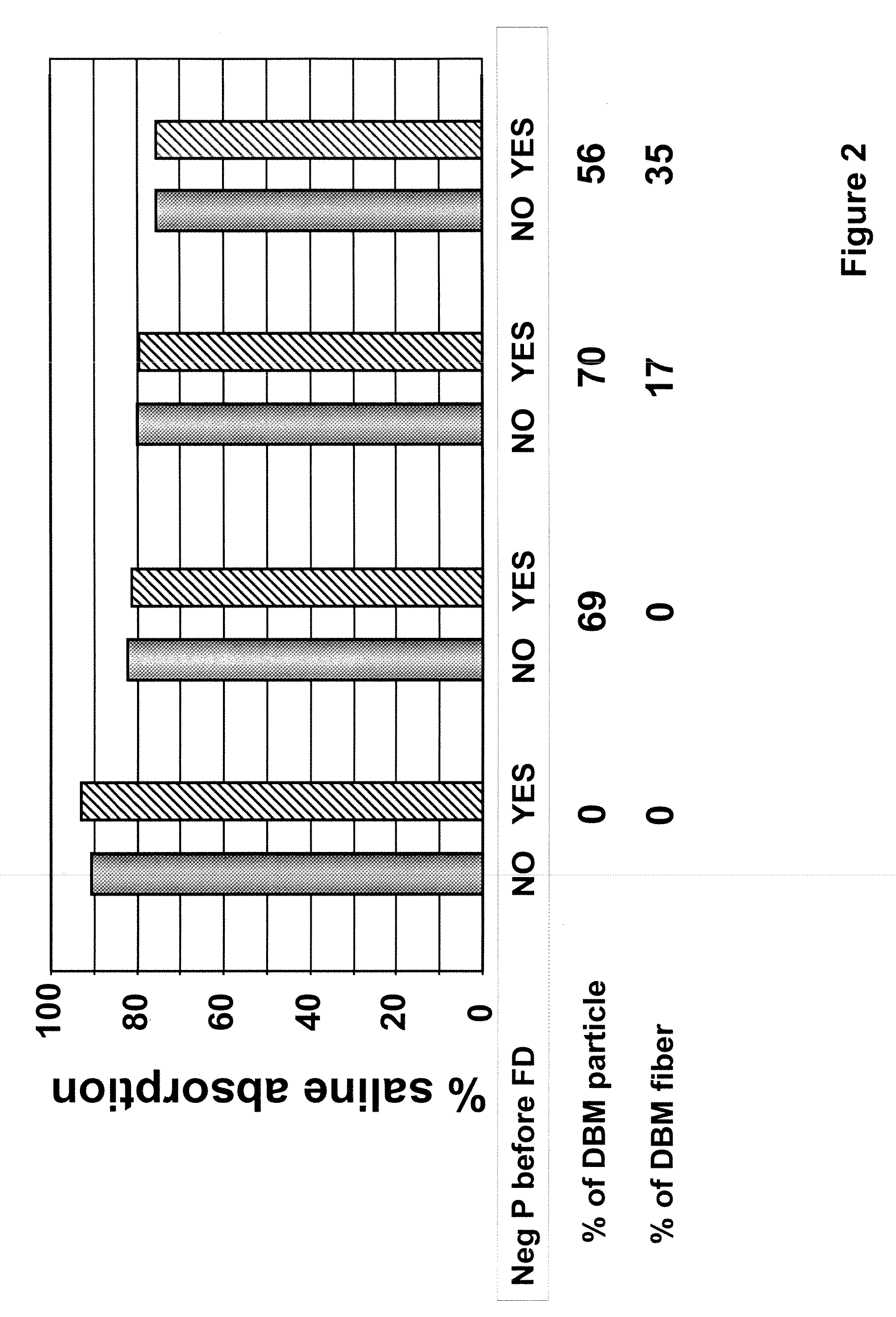

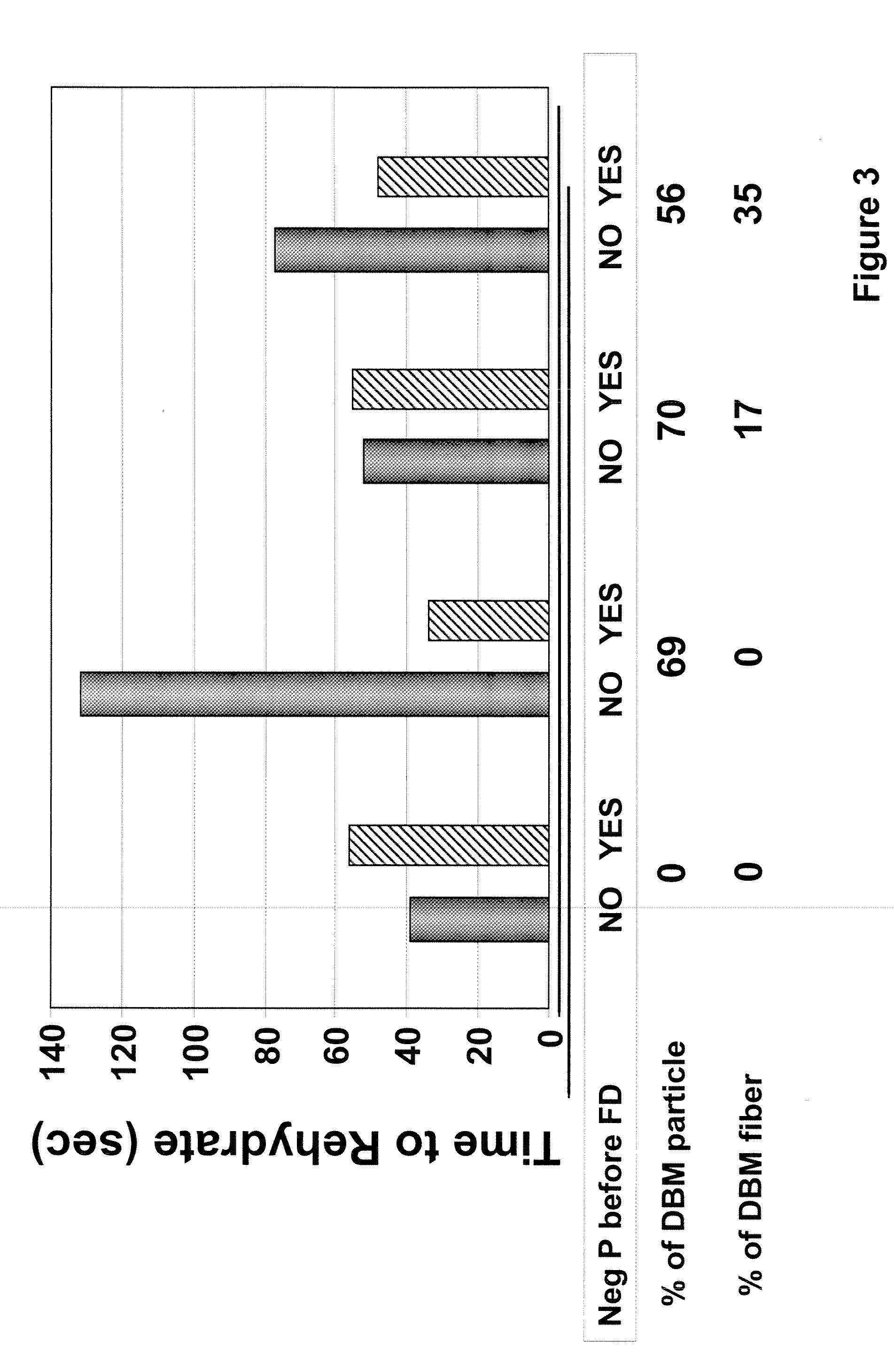

The invention is directed to a process for making a tissue repair implant having a porous sponge-like structure to repair bone, cartilage, or soft tissue defects by producing a connective tissue homogenate from one or more connective tissues; mixing the connective tissue homogenate with a carrier solution to produce a connective tissue carrier; optionally mixing one or more natural or synthetic bone fragements with said connective tissue carrier to produce a tissue repair mixture; freezing or freeze-drying the tissue repair mixture to produce a porous sponge-like structure and create a three-dimensional framework to entrap the natural or synthetic bone fragments, treating the frozen or freeze-dried porous sponge-like structure with one or more treatment solutions to produce a stabilized porous sponge-like structure. A crudely fragmented connective tissue from one or more connective tissues is optionally mixed with the tissue repair mixture before freezing or freeze-drying. The tissue repair implant having a porous sponge-like structure is optionally combined with one or more bioactive supplements or one or more agents that have bioactive supplement binding site(s) to increase the affinity of growth factors, differentiation factor, cytokines, or anti-inflammatory agents to the tissue repair implant. The invention is further directed toward applying such tissue repair implant for tissue repair.

Owner:LIFENET HEALTH

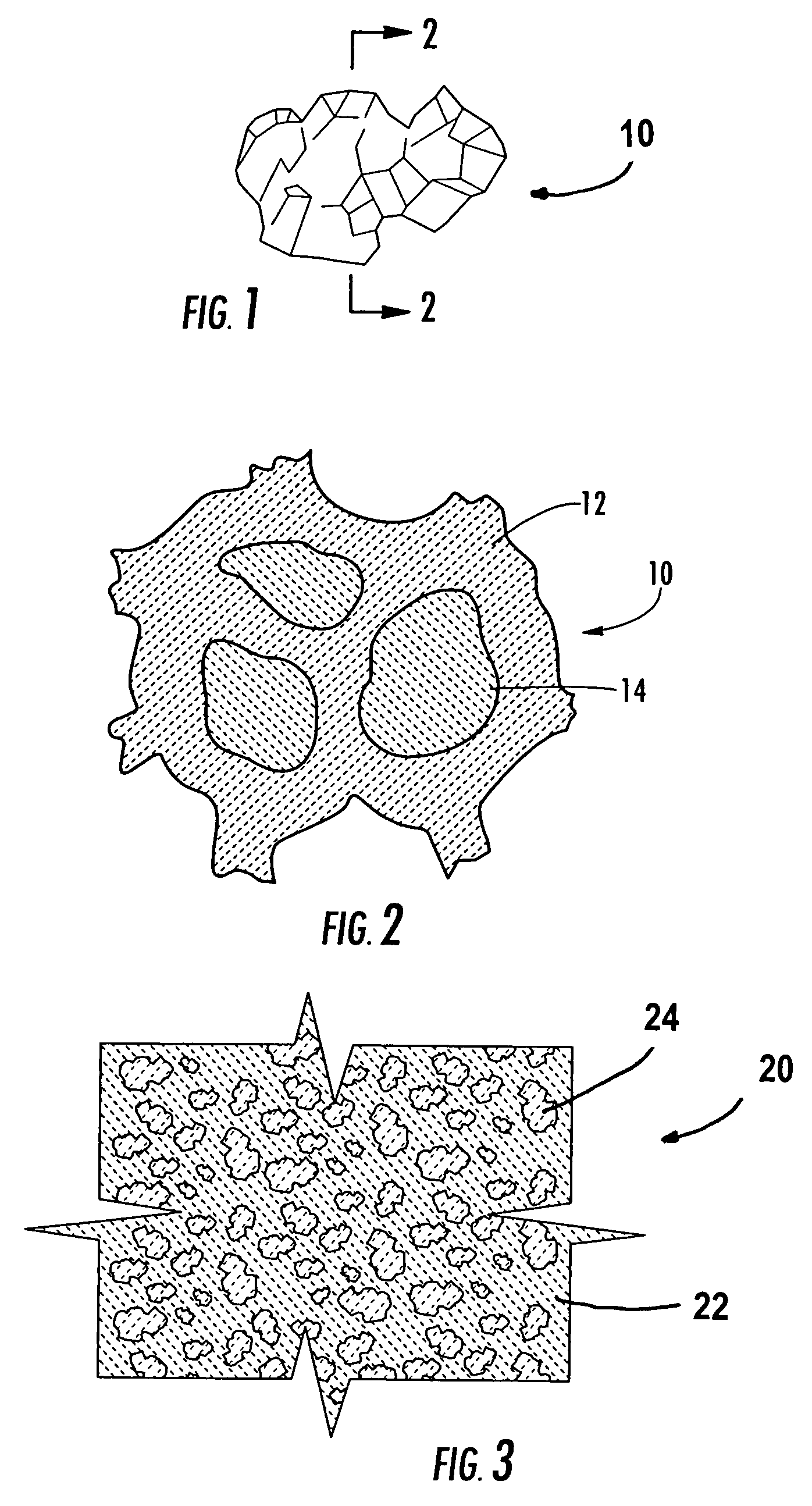

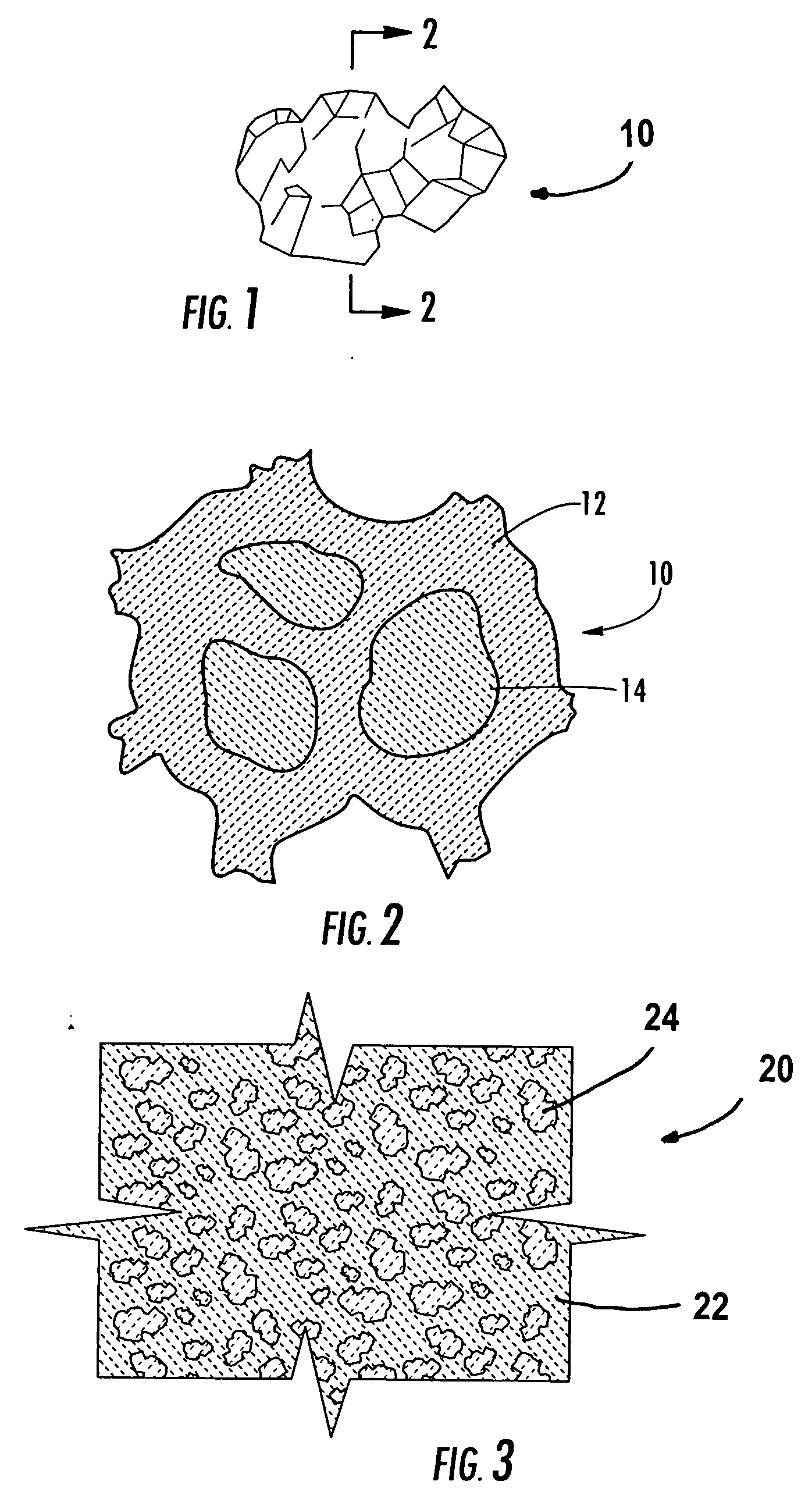

Synthetic bone substitute material

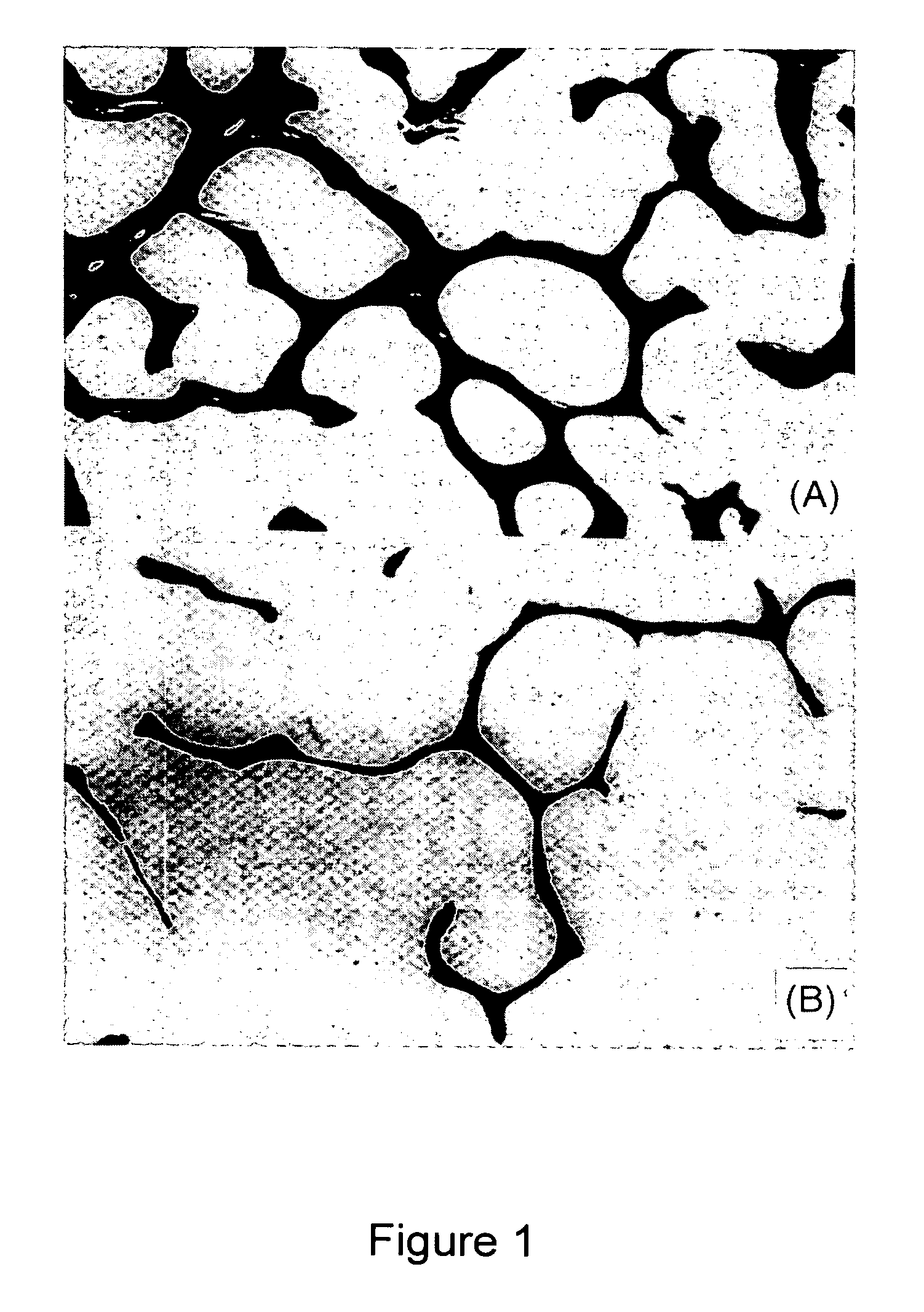

ActiveUS7250550B2Improve stabilityResorbed more quicklyBone implantUnknown materialsSulfateSynthetic bone

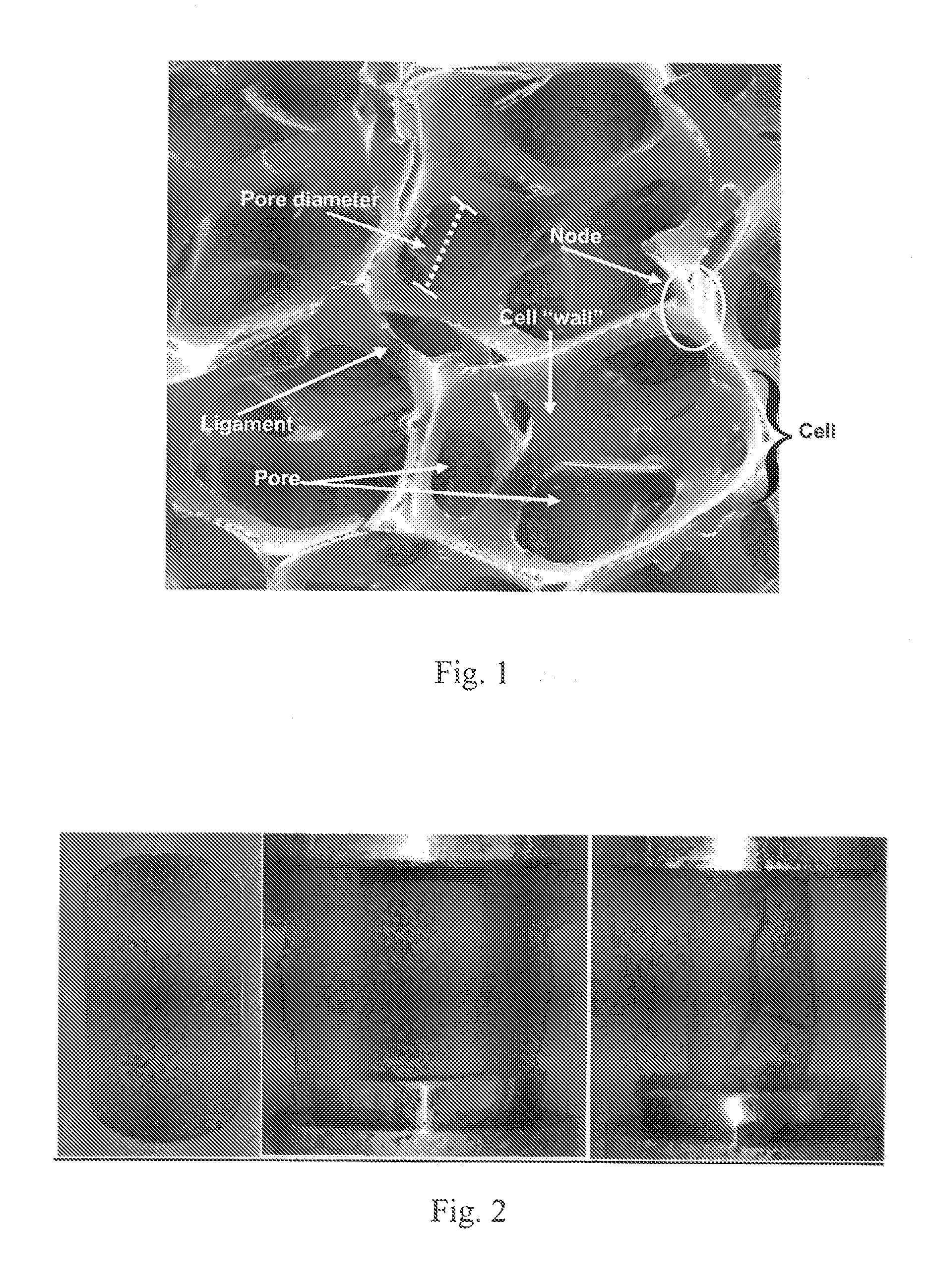

The invention includes a synthetic bone substitute material suitable for use as a replacement for cancellous bone in a bone graft composition, the material comprising a reticulated framework of interconnecting bioceramic struts defining an interconnecting interstitial void volume, and a solid non-porous composition substantially filling the interstitial void volume and in intimate contact with the reticulated framework, the pore-filling composition comprising calcium sulfate. Calcium triphosphate is a preferred bioceramic material for the reticulated framework.

Owner:WRIGHT MEDICAL TECH

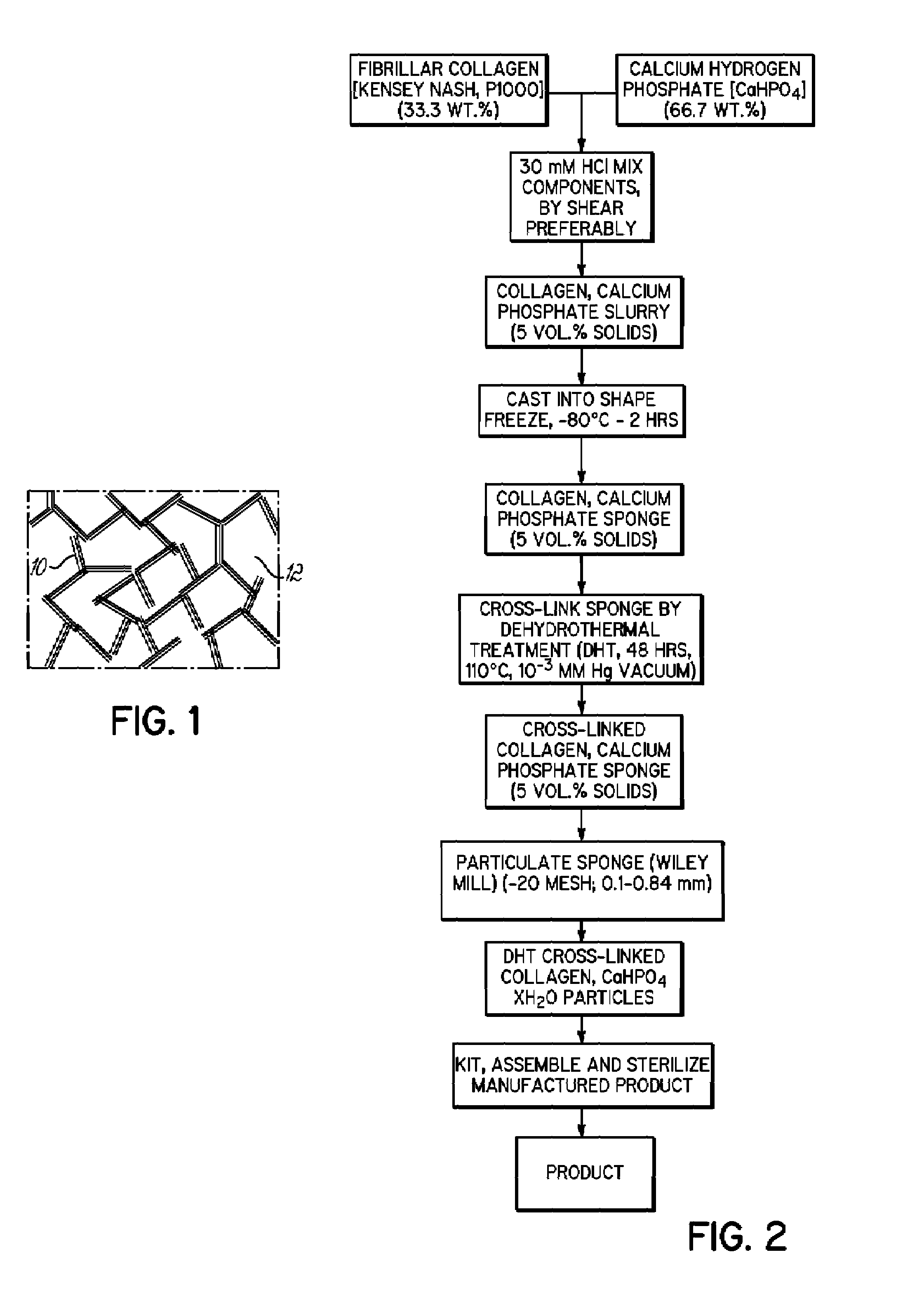

Bone growth particles and osteoinductive composition thereof

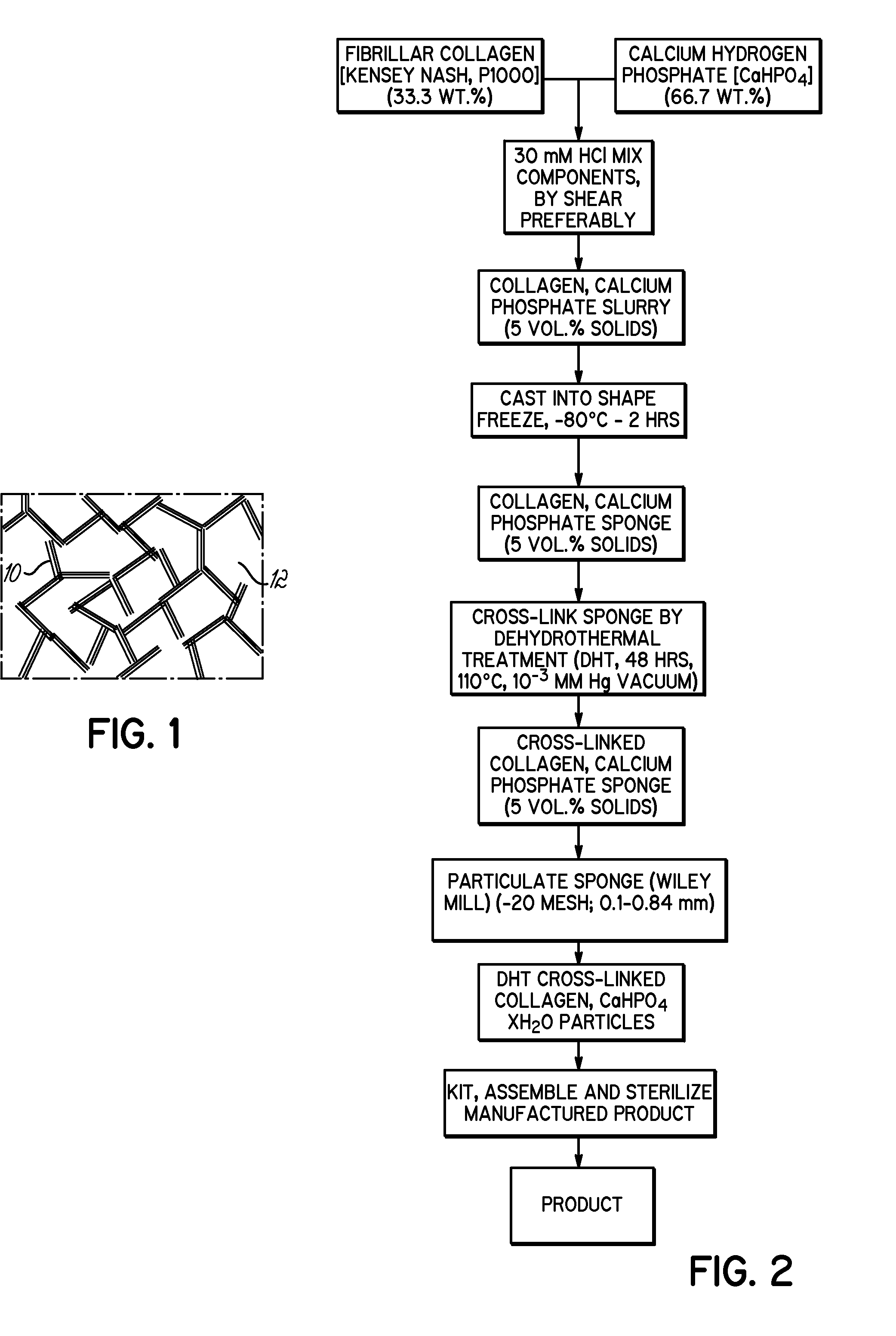

InactiveUS20080152687A1Reduce deliveryEnhance in vivo formationPowder deliveryCosmetic preparationsCalcium biphosphateFiber

A biocompatible synthetic bone growth composition comprising a fibrillar collagen component and a calcium phosphate component. The composition is formed into particles, and then formed into a unitary article that may be provided at the site of a skeletal defect. An osteoinductive component may be further added, either before or after forming the unitary article. The composition may be formulated as a paste or putty and facilitates bone growth and / or repair.

Owner:ZIMMER ORTHOBIOLOGICS

Synthetic osteochondral composite and method of fabrication thereof

An osteochondral composite including a hydrogel with implanted biological cells joined to a porous supportive base at a mechanically-interlocked interface is disclosed. A method of fabricating the osteochondral composite and a method of treating damaged or diseased articular cartilage by implanting an osteochondral composite are also disclosed.

Owner:UNIVERSITY OF MISSOURI

Synthetic bone substitute material

ActiveUS20060088601A1Improve stabilityResorbed more quicklyBone implantUnknown materialsSulfateSynthetic bone

The invention includes a synthetic bone substitute material suitable for use as a replacement for cancellous bone in a bone graft composition, the material comprising a reticulated framework of interconnecting bioceramic struts defining an interconnecting interstitial void volume, and a solid non-porous composition substantially filling the interstitial void volume and in intimate contact with the reticulated framework, the pore-filling composition comprising calcium sulfate. Calcium triphosphate is a preferred bioceramic material for the reticulated framework.

Owner:WRIGHT MEDICAL TECH

Bone growth particles and osteoinductive composition thereof

InactiveUS7718616B2Reduce deliveryEnhance in vivo formationPowder deliveryCosmetic preparationsCalcium biphosphateFiber

A biocompatible synthetic bone growth composition comprising a fibrillar collagen component and a calcium phosphate component. The composition is formed into particles, and then formed into a unitary article that may be provided at the site of a skeletal defect. An osteoinductive component may be further added, either before or after forming the unitary article. The composition may be formulated as a paste or putty and facilitates bone growth and / or repair.

Owner:ZIMMER ORTHOBIOLOGICS

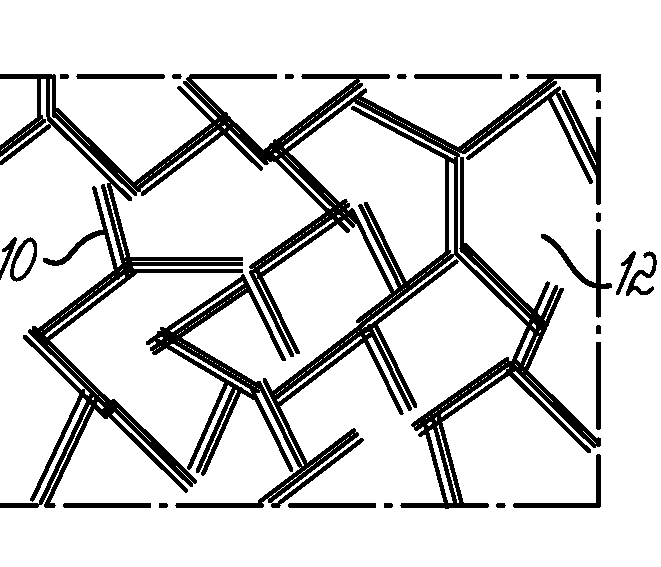

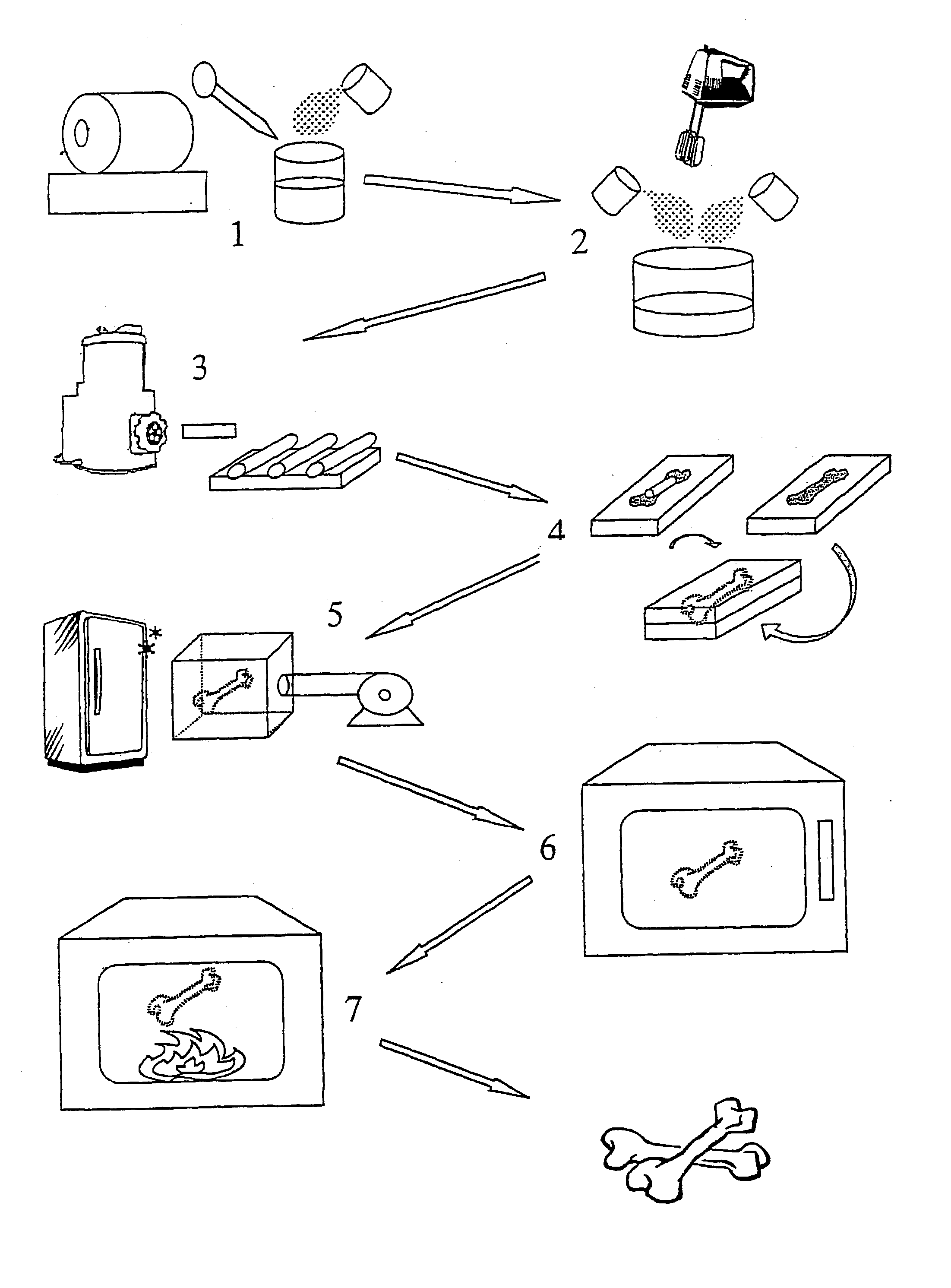

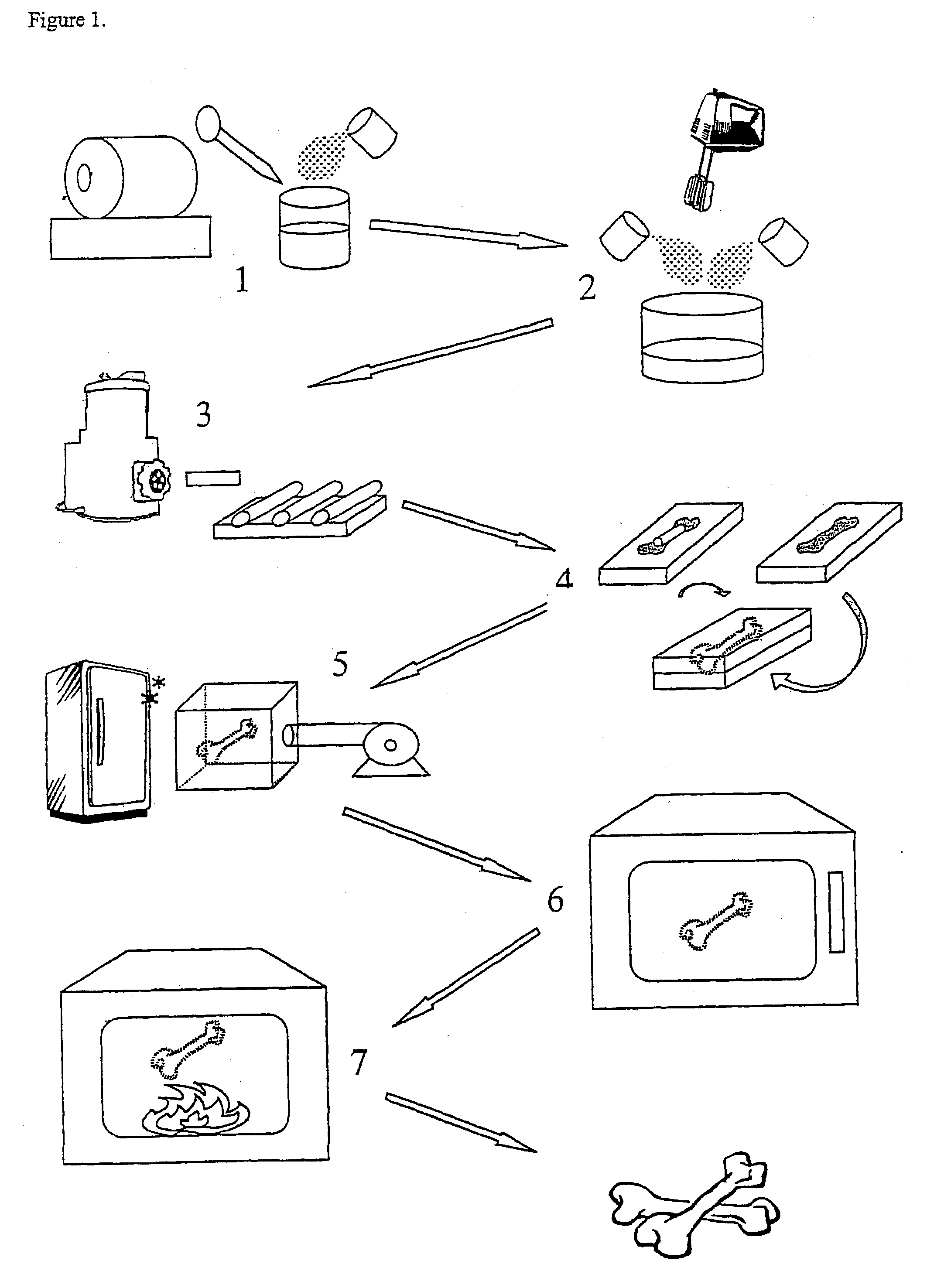

Porous synthetic bone graft and method of manufacture thereof

InactiveUS7094371B2Keep for a long timeEliminate needBone implantMovable spraying apparatusSynthetic bone graftArtificial bone

A process for preparing artificial bone is described which comprises: (i) preparing a mixture of a finely divided bio-compatible ceramic powder, an organic binder and a pore-forming agent in an inert liquid to form a body and causing at least some of the pore-forming agent to align along a common axis; (ii) optionally shaping the resulting body; (iii) allowing the pore-forming agent to form a porous structure in the body; (iv) heating the shaped body to a temperature sufficient to fix the porous structure and; (v) further heating the body to eliminate residues of organic binder and pore-forming agent and to fuse it.

Owner:ORTHOGEM LTD

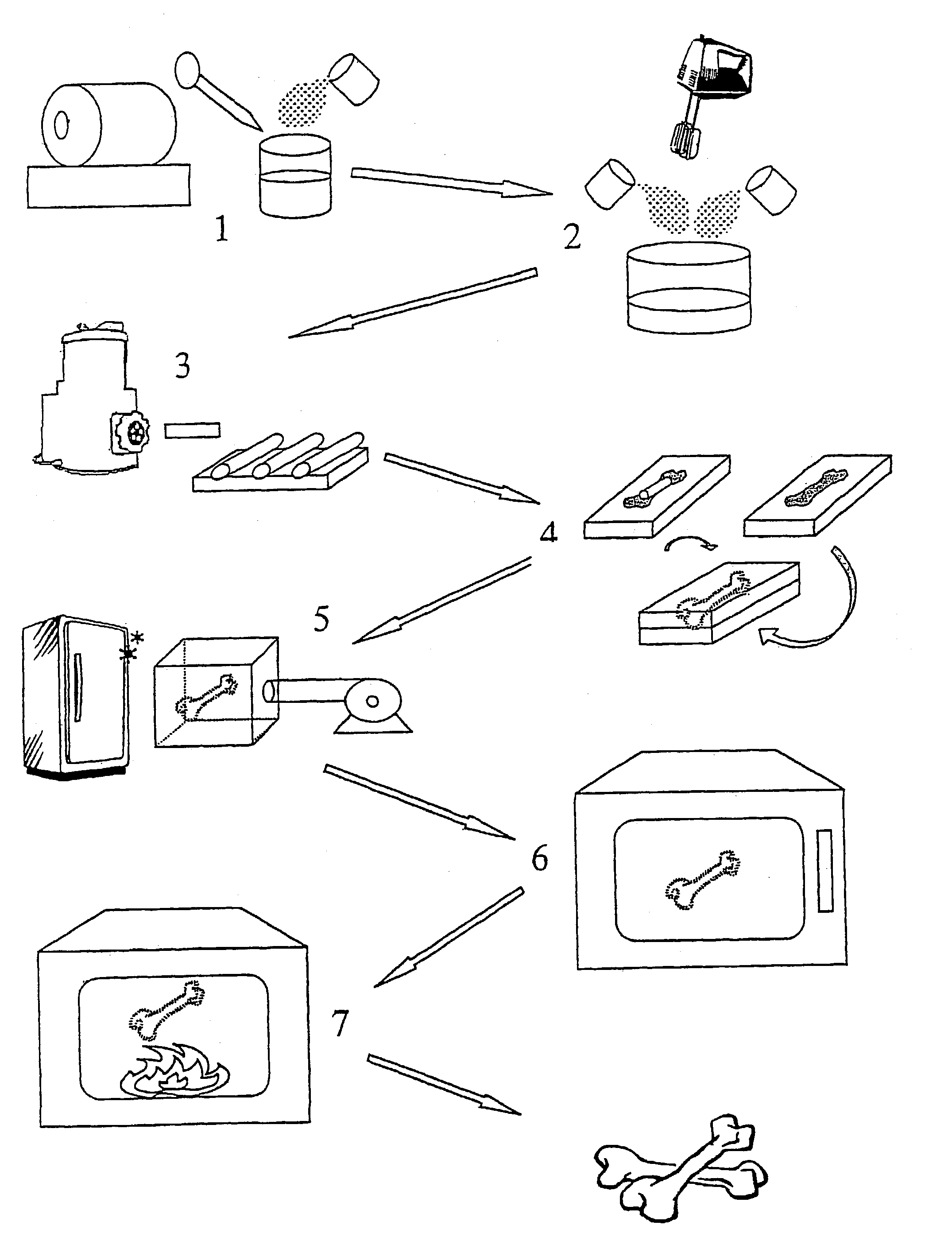

Composition for a tissue repair implant and methods of making the same

ActiveUS9132208B2Stay in shapeHigh affinityBone implantDead animal preservationTissue repairConnective tissue fiber

The invention is directed to a process for making a tissue repair implant having a porous sponge-like structure to repair bone, cartilage, or soft tissue defects by producing a connective tissue homogenate from one or more connective tissues; mixing the connective tissue homogenate with a carrier solution to produce a connective tissue carrier; optionally mixing one or more natural or synthetic bone fragements with said connective tissue carrier to produce a tissue repair mixture; freezing or freeze-drying the tissue repair mixture to produce a porous sponge-like structure and create a three-dimensional framework to entrap the natural or synthetic bone fragments, treating the frozen or freeze-dried porous sponge-like structure with one or more treatment solutions to produce a stabilized porous sponge-like structure. A crudely fragmented connective tissue from one or more connective tissues is optionally mixed with the tissue repair mixture before freezing or freeze-drying. The tissue repair implant having a porous sponge-like structure is optionally combined with one or more bioactive supplements or one or more agents that have bioactive supplement binding site(s) to increase the affinity of growth factors, differentiation factor, cytokines, or anti-inflammatory agents to the tissue repair implant. The invention is further directed toward applying such tissue repair implant for tissue repair.

Owner:LIFENET HEALTH

Composite bone graft device

A composite bone graft which comprises an allograft bone component; a synthetic bone substitute, wherein the synthetic bone substitute is in contact with the allograft bone component. The composite is arranged within a resorbable mesh casing.

Owner:SPINESMITH PARTNERS

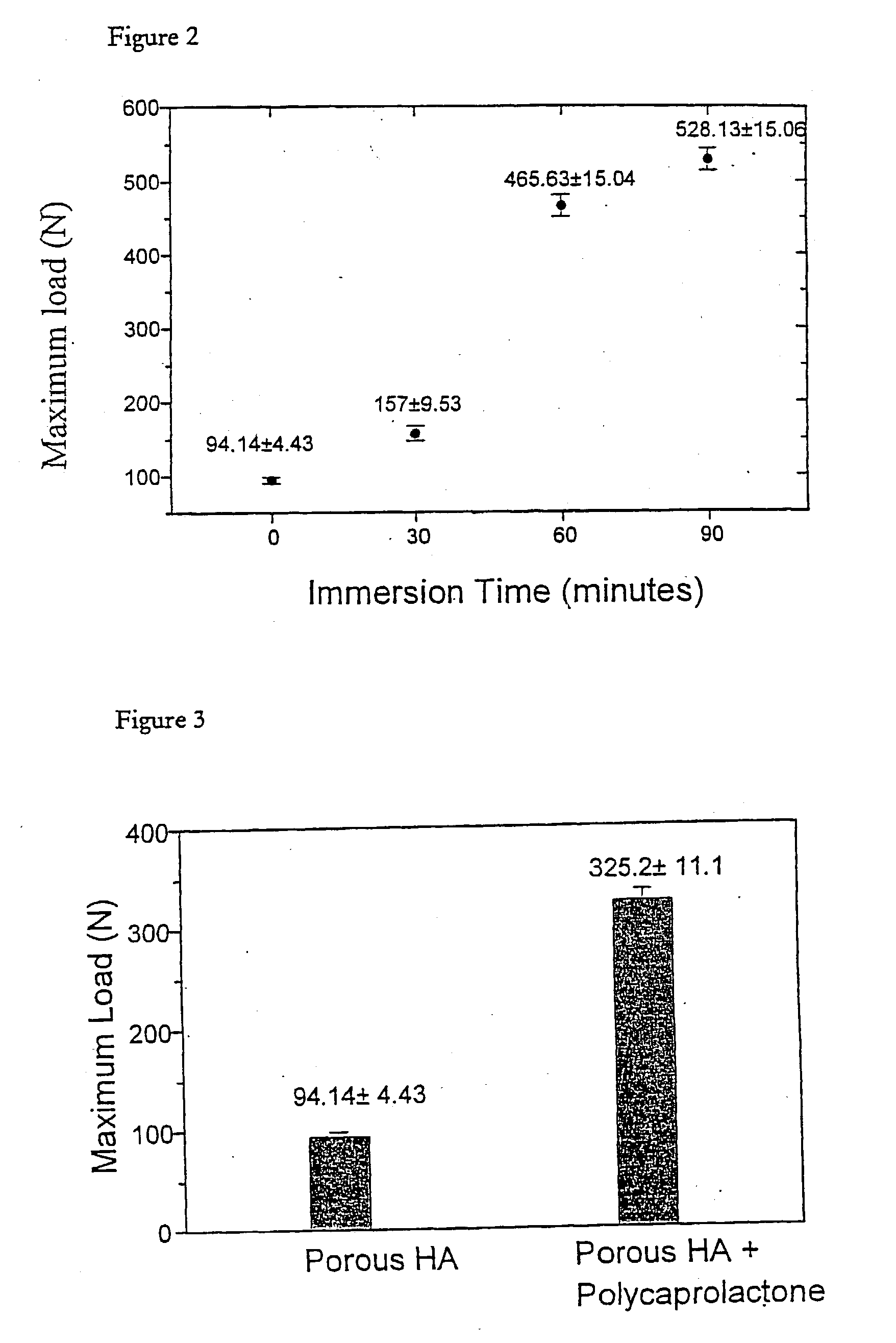

Porous calcium phosphate networks for synthetic bone material

A porous composition comprising a hydroxyapatite material, as can be made from a mixture of calcium phosphate, calcium oxide and a removable inorganic porogen. In other embodiments, the present invention provides a method of making such a porous hydroxyapatite material or using a ternary system to prepare a two-phase composition enroute to a biomimetic bone material.

Owner:UNIV OF MASSACHUSETTS

Device for selective biological synthesis of a bone tissue

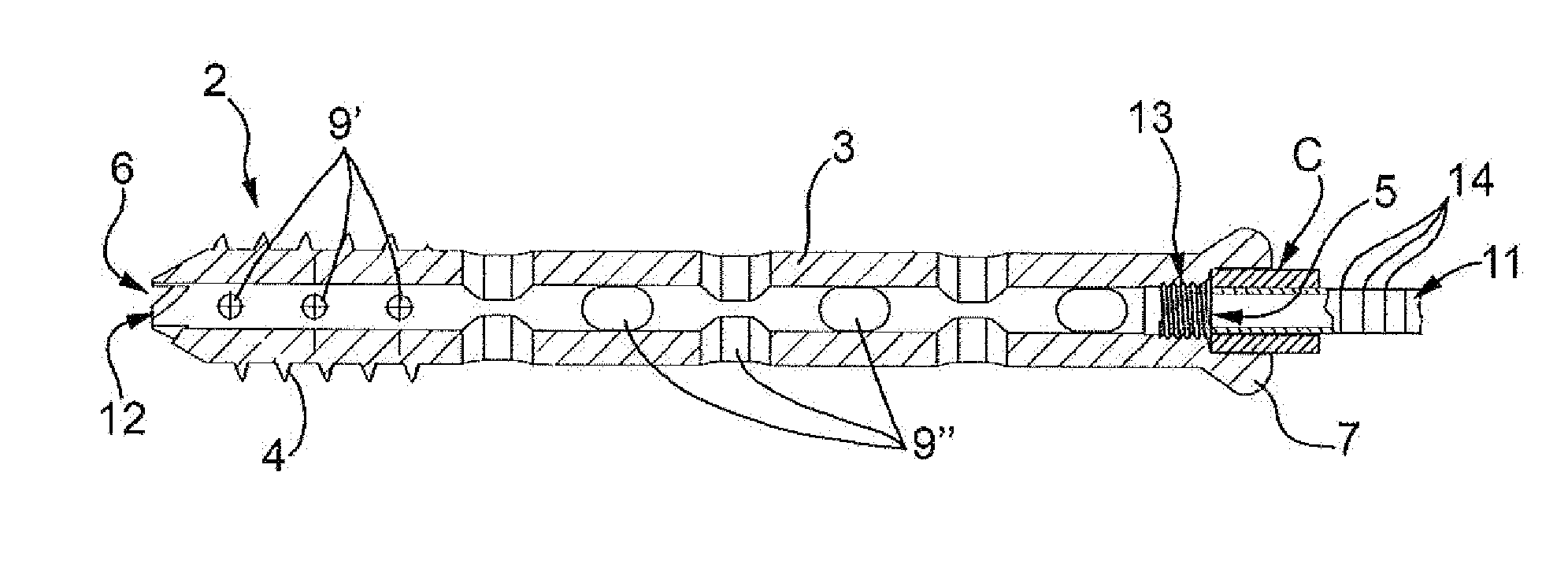

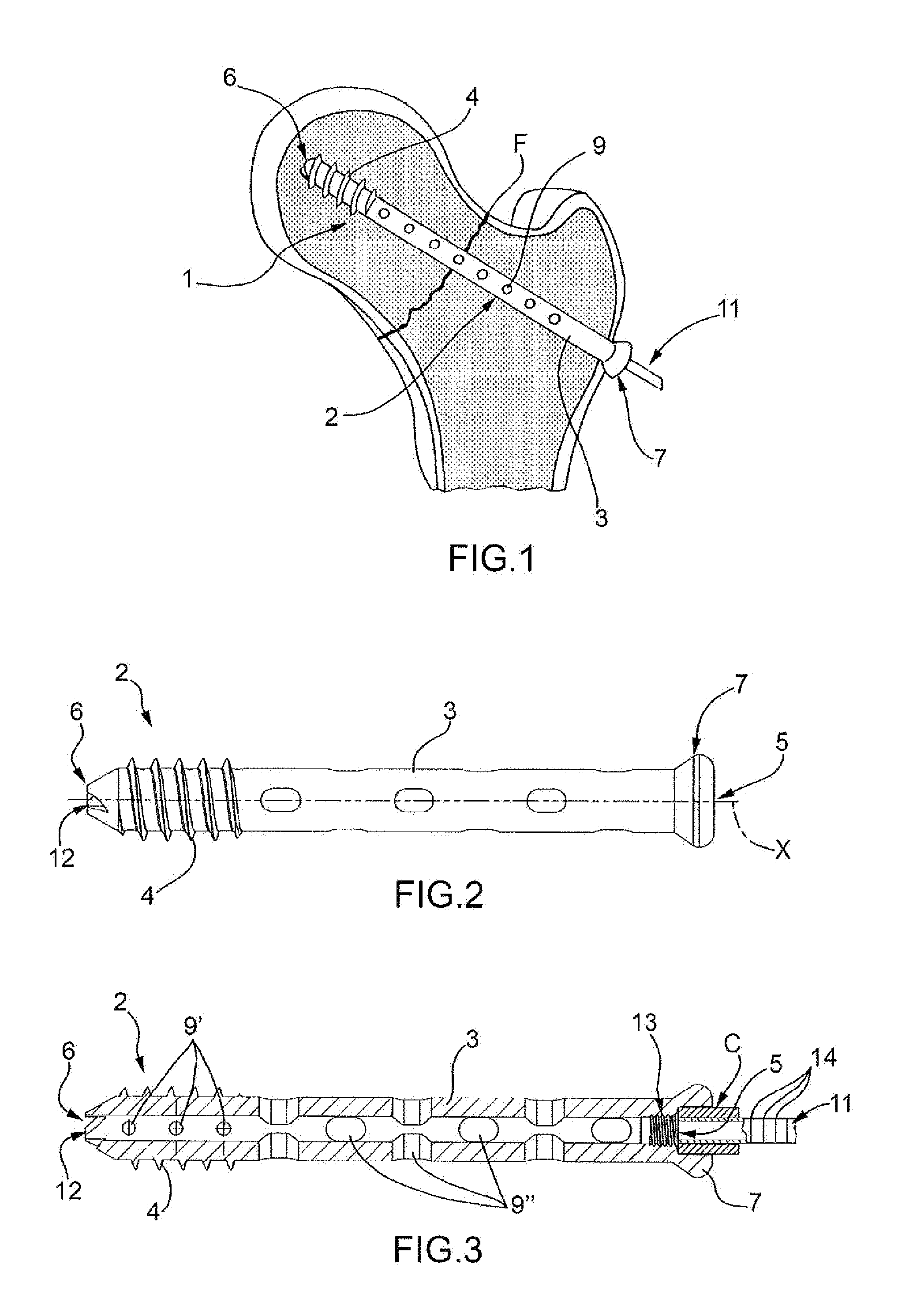

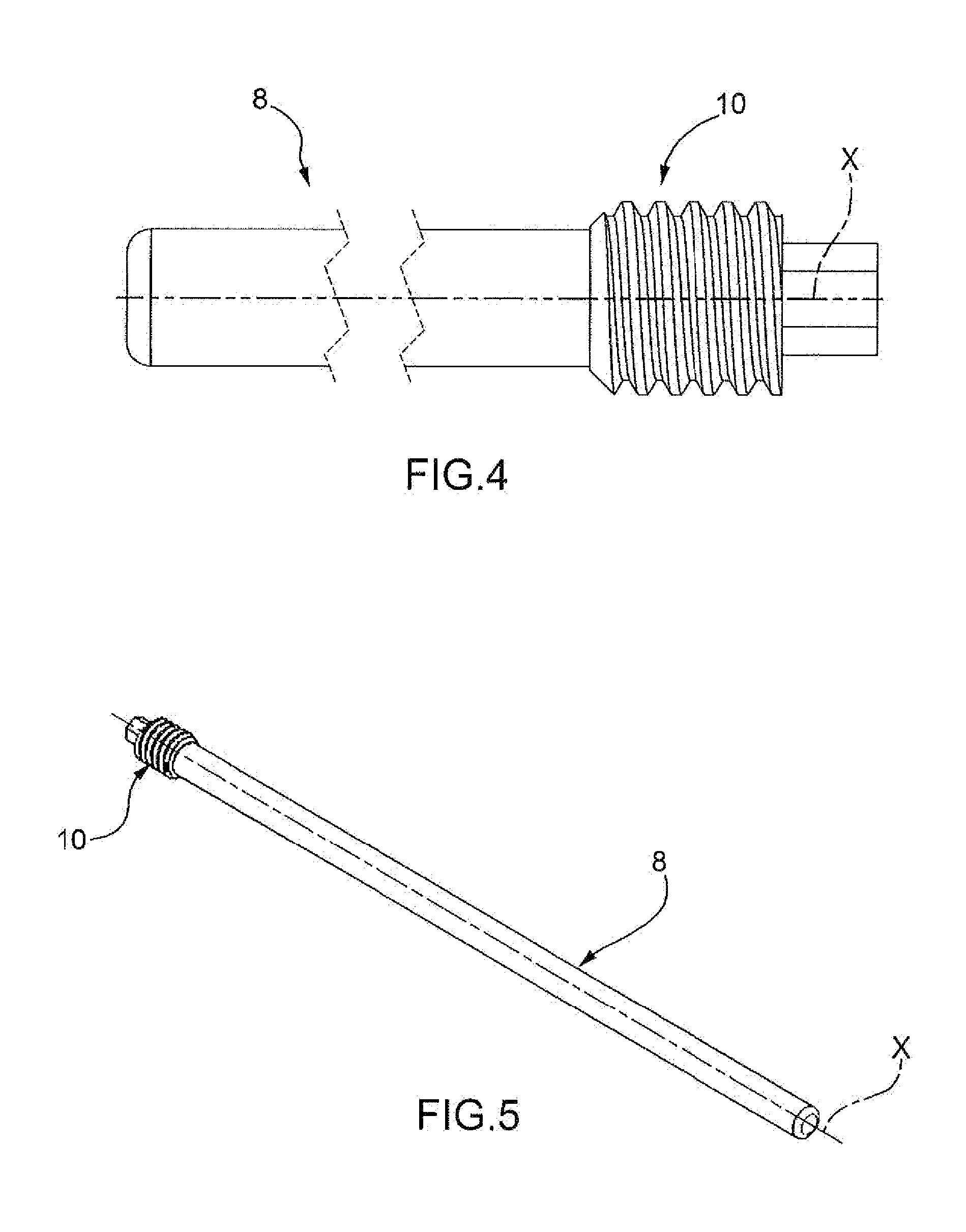

Device for selective biological synthesis of a bone tissue including a screw for the stabilization of a fracture or of a porotic bone tissue, wherein said screw is arranged along an axis (X), substantially longitudinal with respect to said screw, and it is constituted by an extended body, from a first end or tip and from a second end or head, wherein at least said extended body and said second end or head include a longitudinal channel, wherein said extended body has at least one hole or slot, wherein said device includes a pin inserted into the longitudinal channel and provided with means for releasable connection with said screw, for reinforcing the device and for the releasable closure thereof.

Owner:GIANCOLA PROF RINALDO

Reinforced osseous porcelain and process for producing same

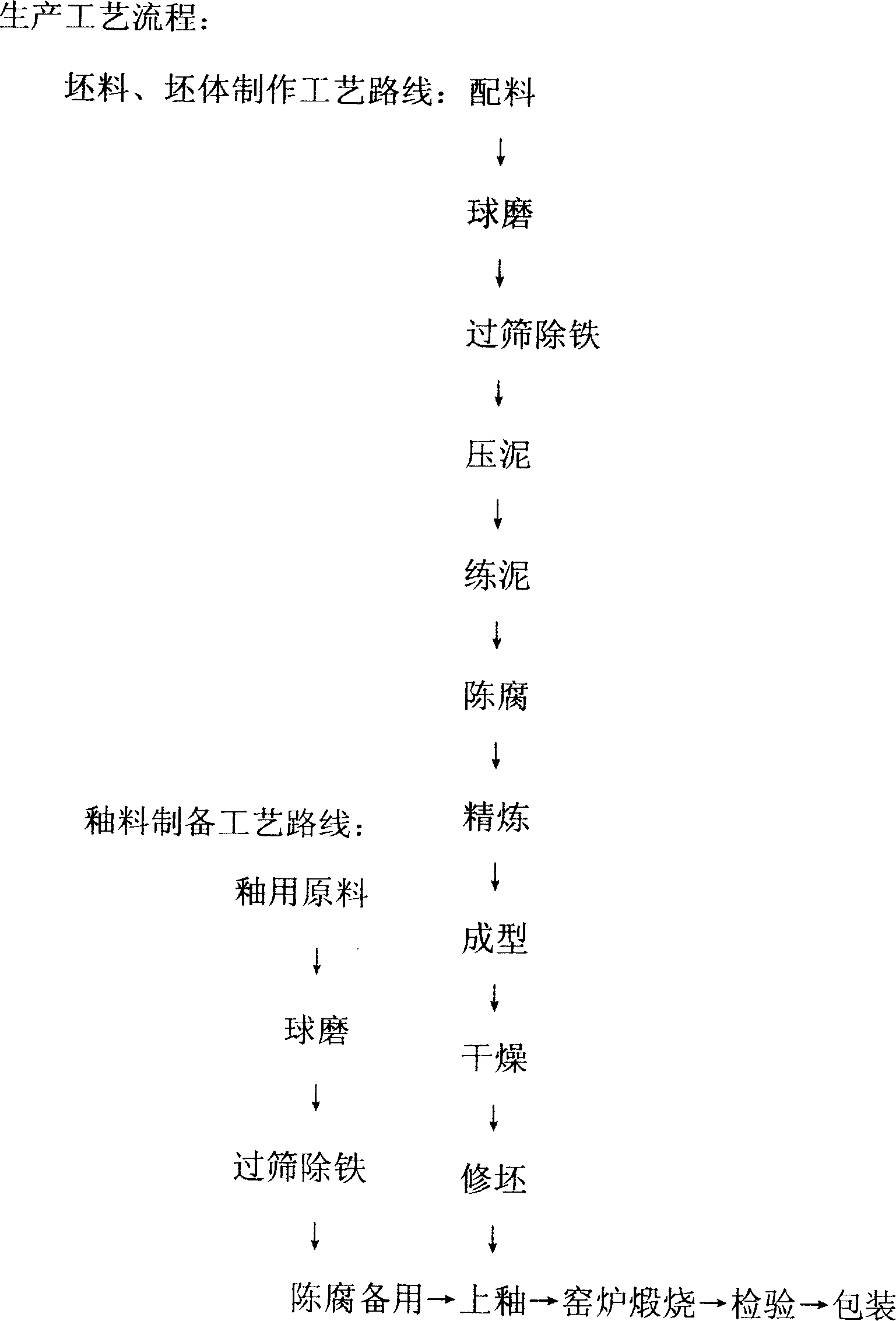

The invention discloses a sclerotin intensification ceramic and manufacturing technique, which comprises the following elements: dragon rock wash mud, Hunan feldspar, Guizhou clay, alpha-alumina powder and synthetic bone meal. The manufacturing technique comprises the following steps: blanking; making blank body; preparing frit; making magentify step. The sclerotin intensification ceramic realizes the primary firing, which reduces the energy and improves the transverse strength.

Owner:潮州市波士发陶瓷制作有限公司

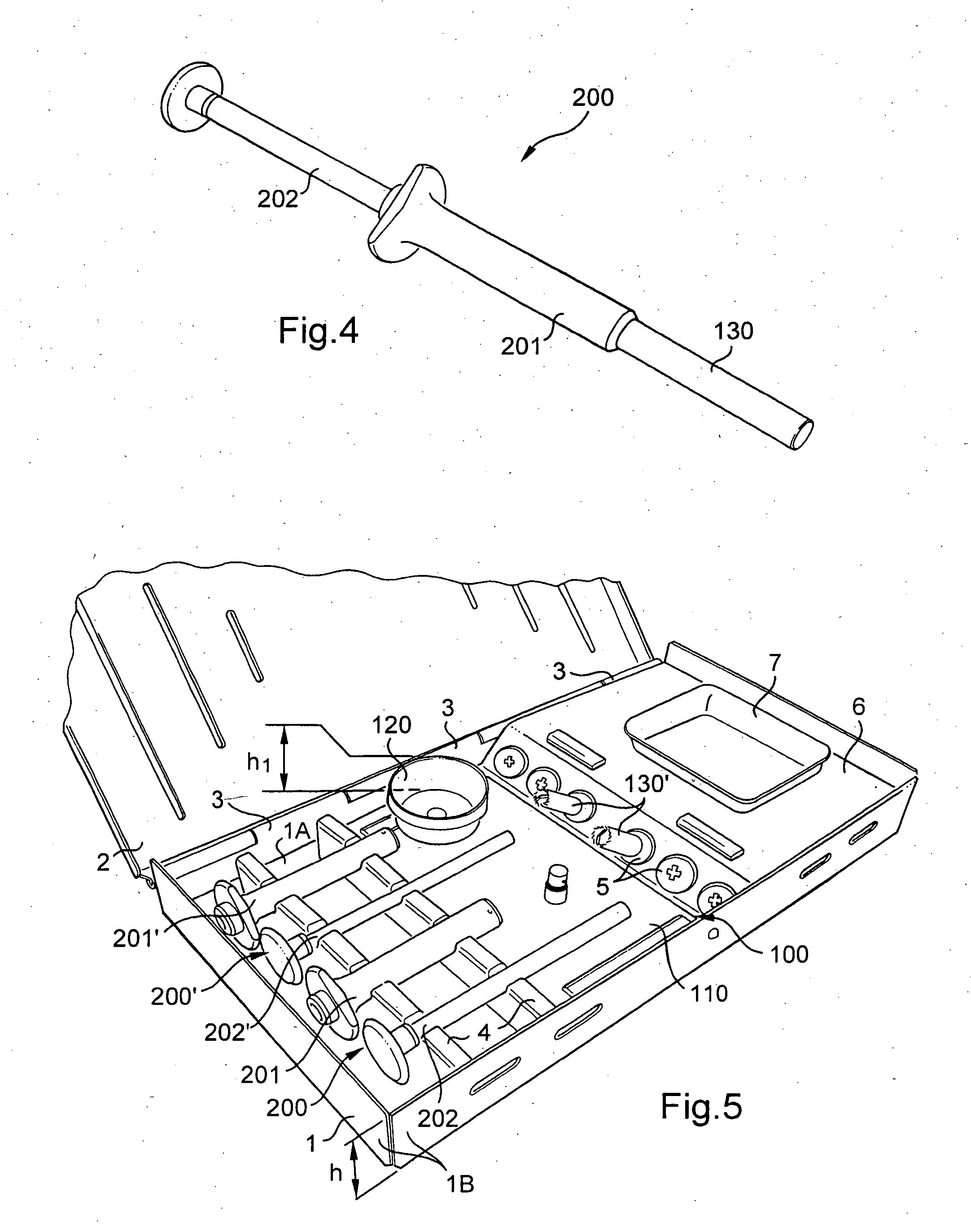

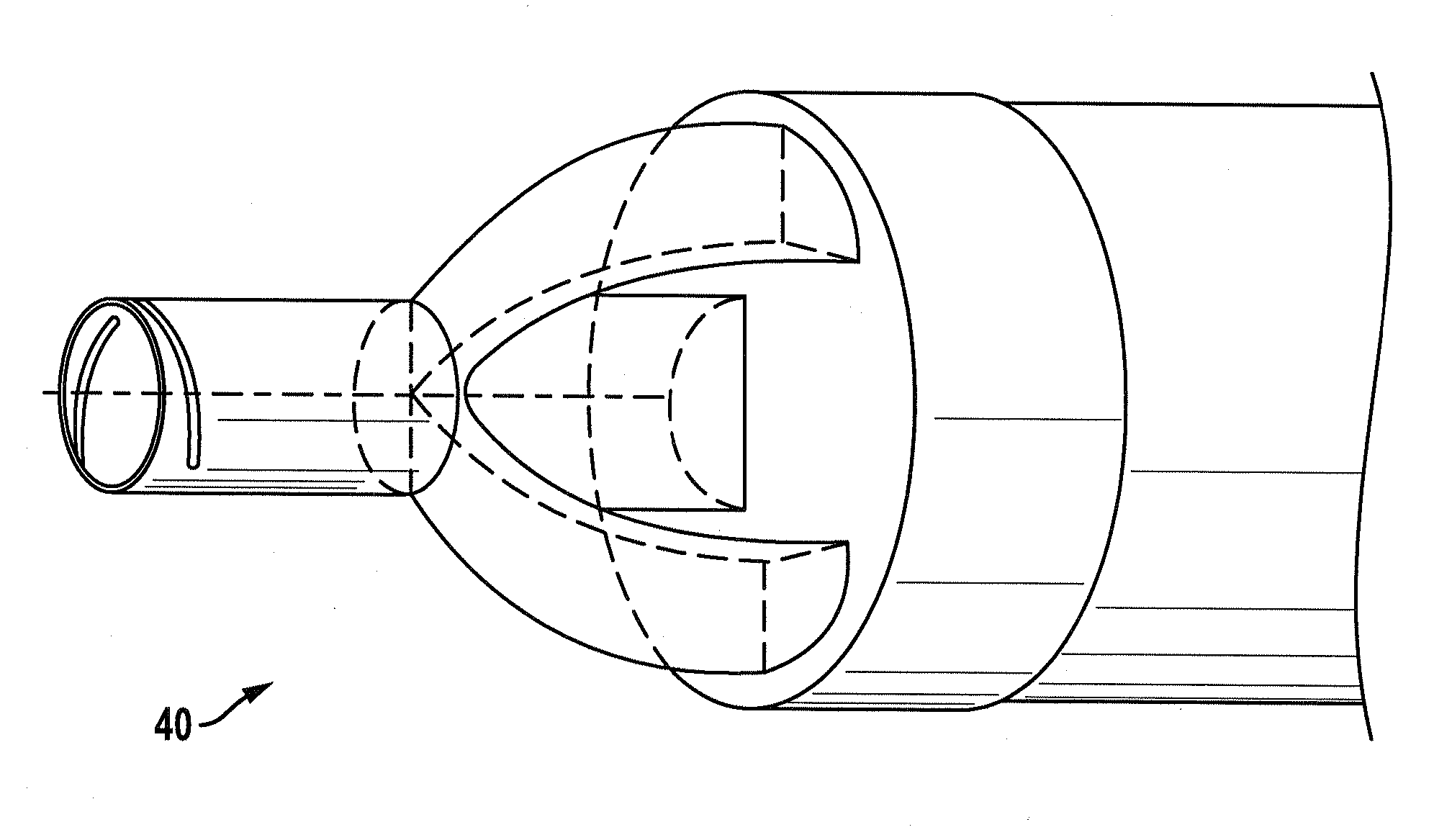

Kit for preparing a bone filler mixture, a cartridge specially adapted to said kit, and an implantation set including said kit

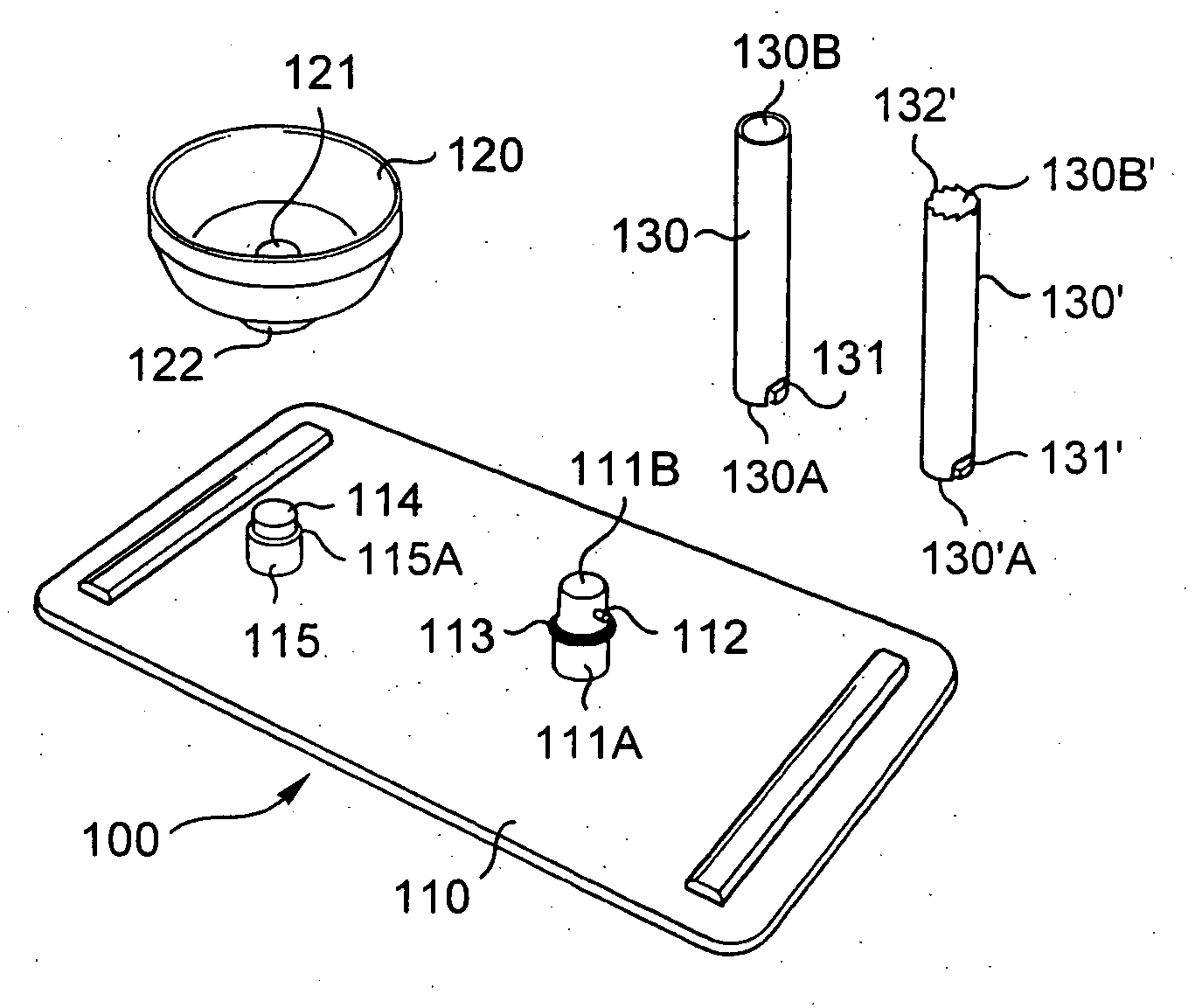

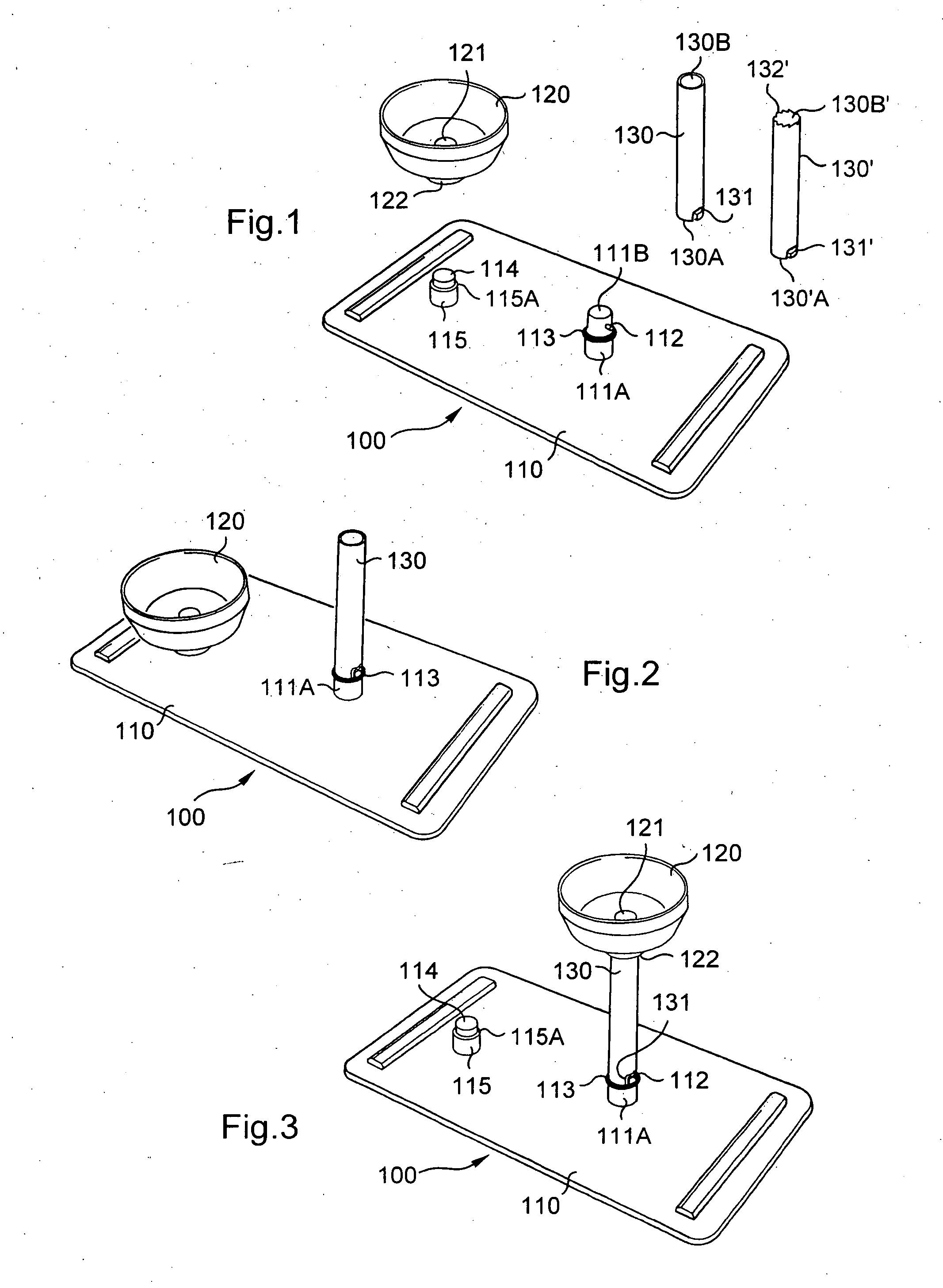

The invention relates to a kit for preparing a mixture of a natural or synthetic bone filler material with blood or physiological serum. According to the invention, the kit comprises a stand, a cup, and a tube for containing the mixture, the tube being open at both ends, the stand having receiver means for receiving one end of the tube in a vertical position, and the cup including an orifice in its center and communicating with a sleeve for releasable assembly on the other end of the tube.

Owner:DENTAK

Porous synthetic bone graft and method of manufacture thereof

InactiveUS20030171822A1Unique and extremely flexibleGood adhesionBone implantMovable spraying apparatusSynthetic bone graftArtificial bone

A process for preparing artificial bone is described which comprises: (i) preparing a mixture of a finely divided bio-compatible ceramic powder, an organic binder and a pore-forming agent in an inert liquid to form a body and causing at least some of the pore-forming agent to align along a common axis; (ii) optionally shaping the resulting body; (iii) allowing the pore-forming agent to form a porous structure in the body; (iv) heating the shaped body to a temperature sufficient to fix the porous structure and; (v) further heating the body to eliminate residues of organic binder and pore-forming agent and to fuse it.

Owner:ORTHOGEM LTD

Composite Bone Graft Kit

A composite bone graft which comprises an allograft bone component; a synthetic bone substitute, wherein the synthetic bone substitute is in contact with the allograft bone component. The composite is arranged in a core / outer layer structure.

Owner:SPINESMITH PARTNERS

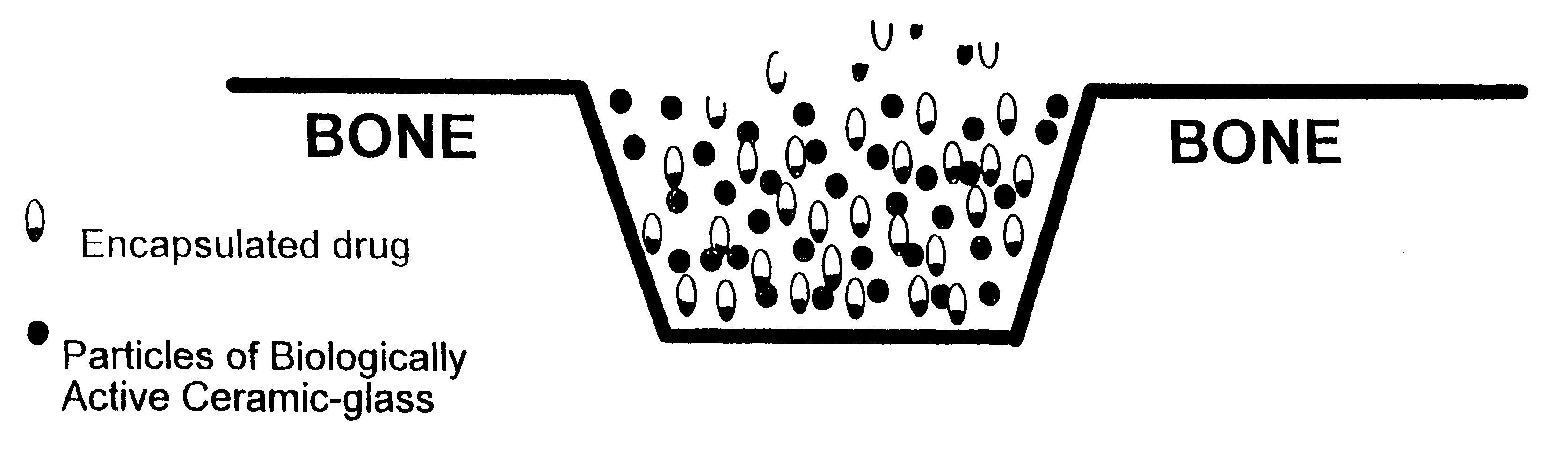

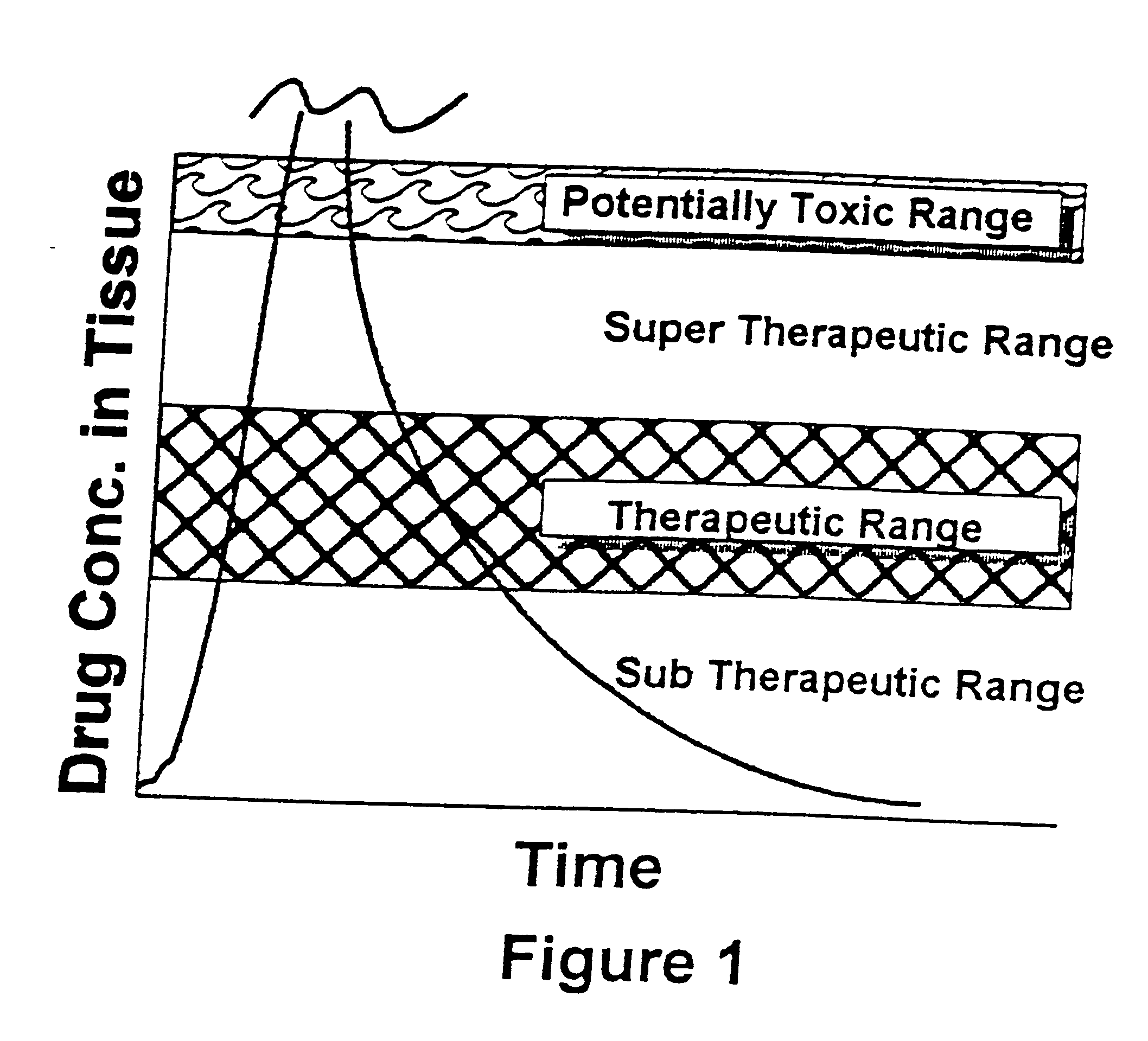

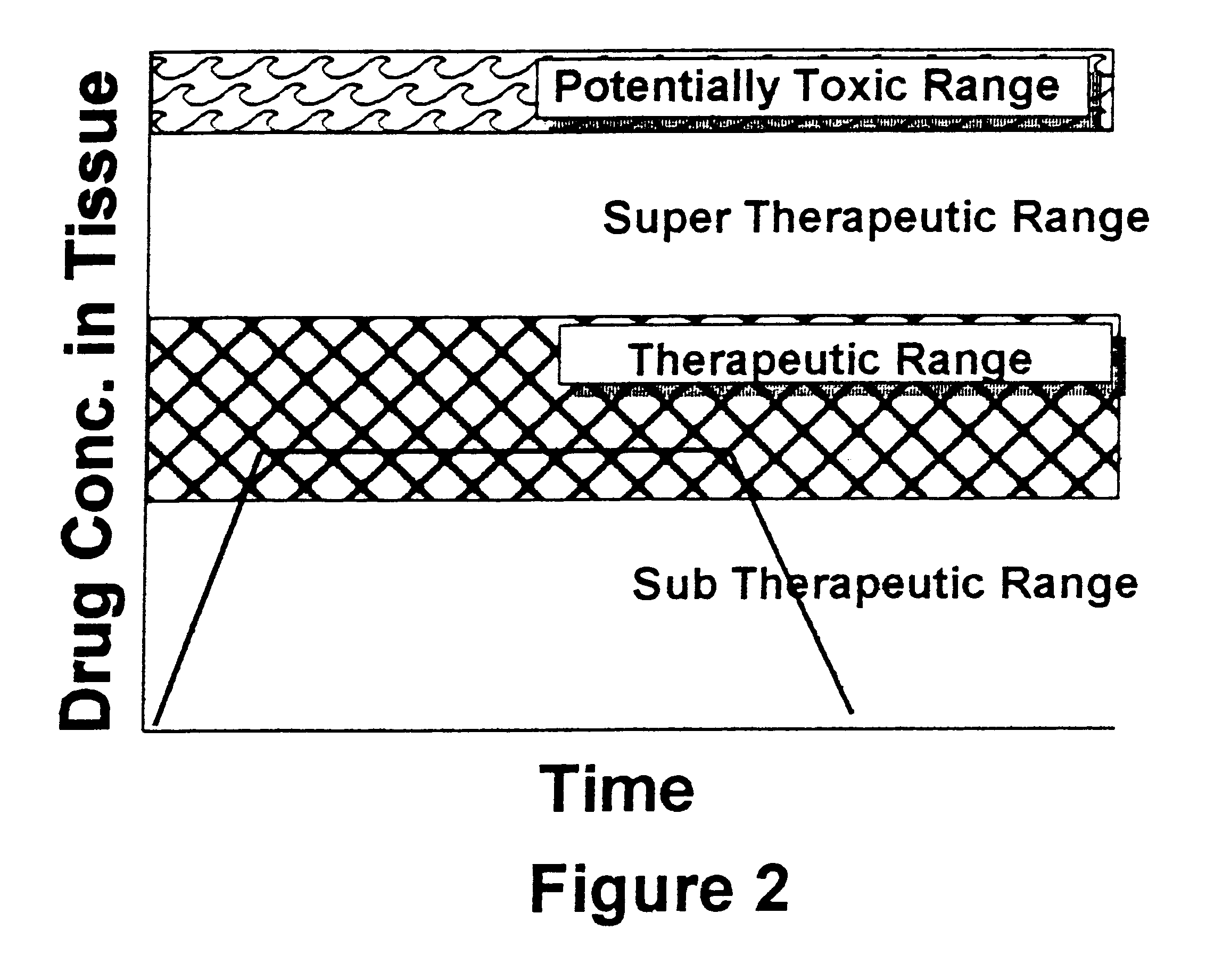

Use of biologically active glass as a drug delivery system

This invention relates to a synthetic bone replacement material impregnated with drugs such as antibiotics and growth hormones, which facilitate and promote the regeneration of bone and / or soft tissue. Methods for making the impregnated material and its medical use are also taught.

Owner:THUT PAUL D +1

Porous active artificial bone and preparation method thereof

The invention relates to a porous active artificial bone. In the porous active artificial bone, a calcium phosphate-based biological ceramic material is used as a matrix, and the porous active artificial bone comprises small pores, dense parts and directional pore channels and chelates with diphosphonate. A preparation method of the porous active artificial bone comprises the steps of preparing calcium phosphate precursor powder, compression molding a ceramic blank by using a pore-foaming agent, polyester fiber and the precursor powder, high temperature sintering into a calcium phosphate-based ceramic sintered body and forming the dense parts, the small pores distributed alternately; and immersing calcium phosphate-based ceramic sintered body in a diphosphonate solution to chelate with the diphosphonate so as to obtain the drug-loaded porous active artificial bone. The artificial bone provided by the invention has longitudinal directional pores and a porous structure suitable for osteoblast migration, propagation and growth metabolism, can slowly release small molecular drugs capable of promoting the growth of the osteoblast and inhibiting osteoclast, and is particularly suitable for the fields of treating bone defects of osteoporosis patients, dental restoration, and the like.

Owner:SHENZHEN LANDO BIOMATERIALS

Synthetic osteochondral composite and method of fabrication thereof

An osteochondral composite including a hydrogel with implanted biological cells joined to a porous supportive base at a mechanically-interlocked interface is disclosed. A method of fabricating the osteochondral composite and a method of treating damaged or diseased articular cartilage by implanting an osteochondral composite are also disclosed.

Owner:UNIVERSITY OF MISSOURI

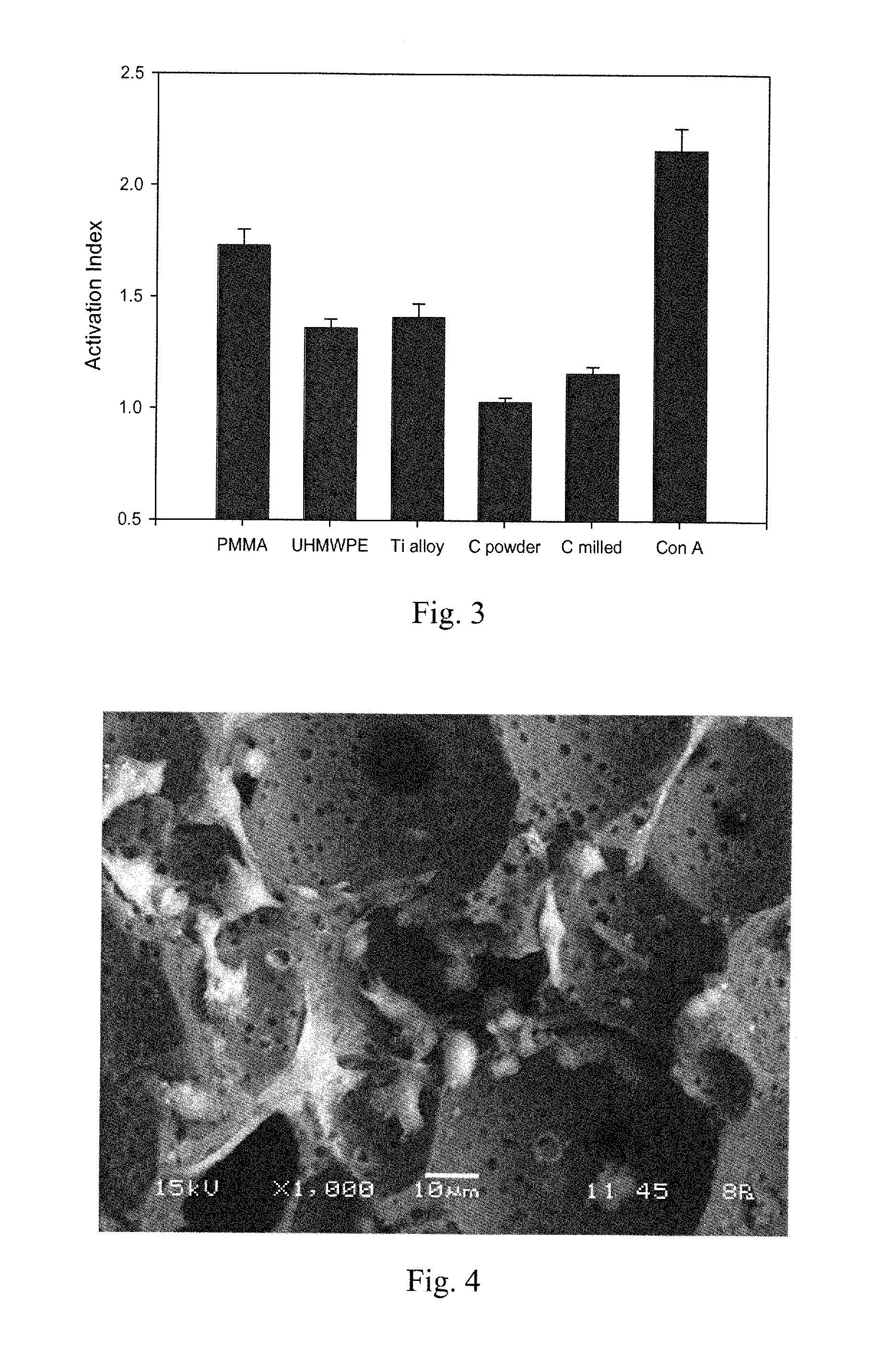

Synthetic bone grafts constructed from carbon foam materials

A porous, self-sustaining body useful as a scaffold for bone grafting is provided. The scaffold comprises a carbonaceous matrix comprising a continuous phase having a surface and defining a plurality of open spaces throughout the matrix. The internal and external surfaces of the matrix are coated with a layer or film selected from the group consisting of osteogenic materials, therapeutic agents, and combinations thereof. The porous body comprises organic materials and is substantially free of metals. Methods of making and using the porous self-sustaining body are also provided, along with kits for facilitating the same.

Owner:WICHITA STATE UNIVERSITY

Synthetic bone graft

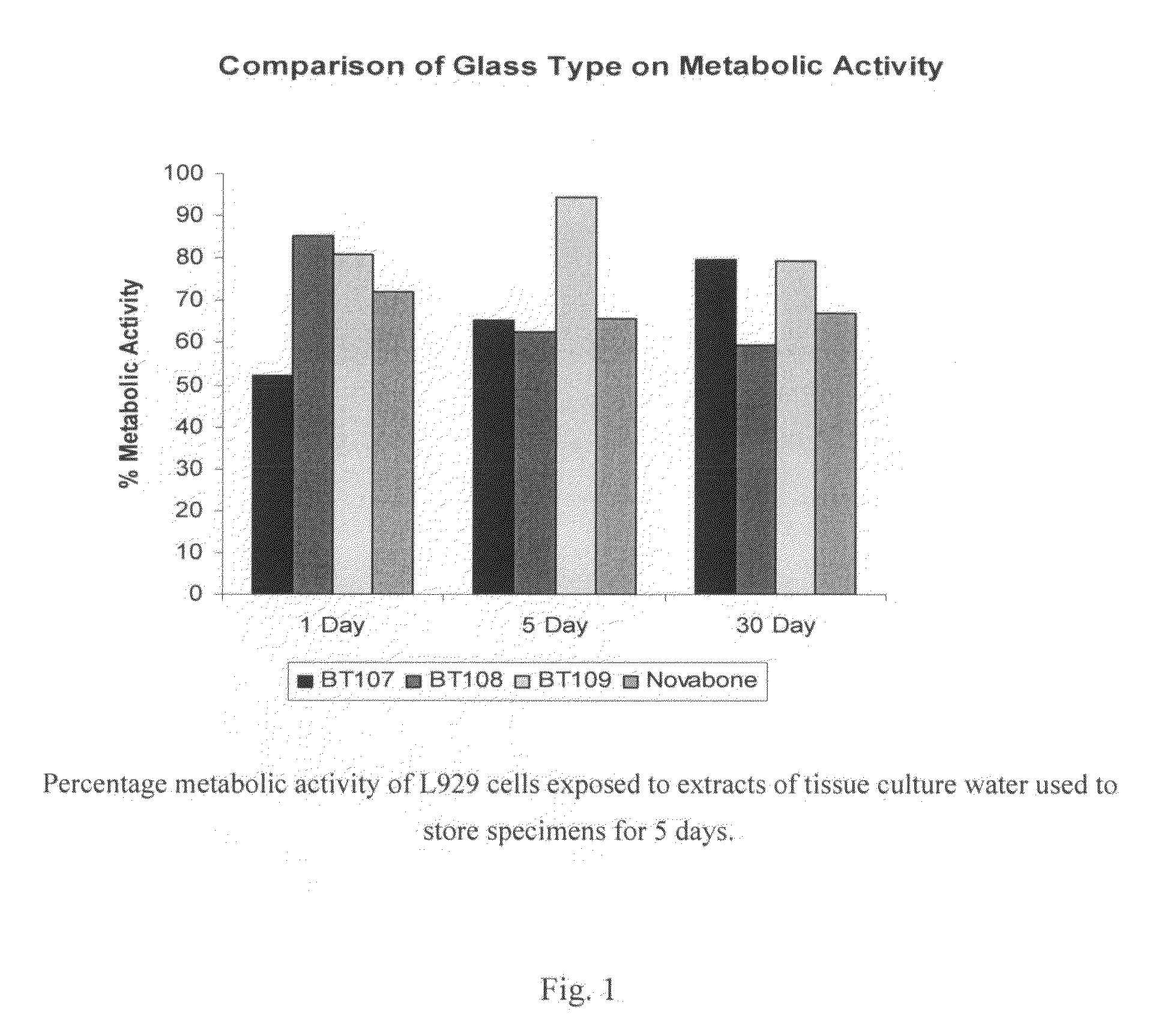

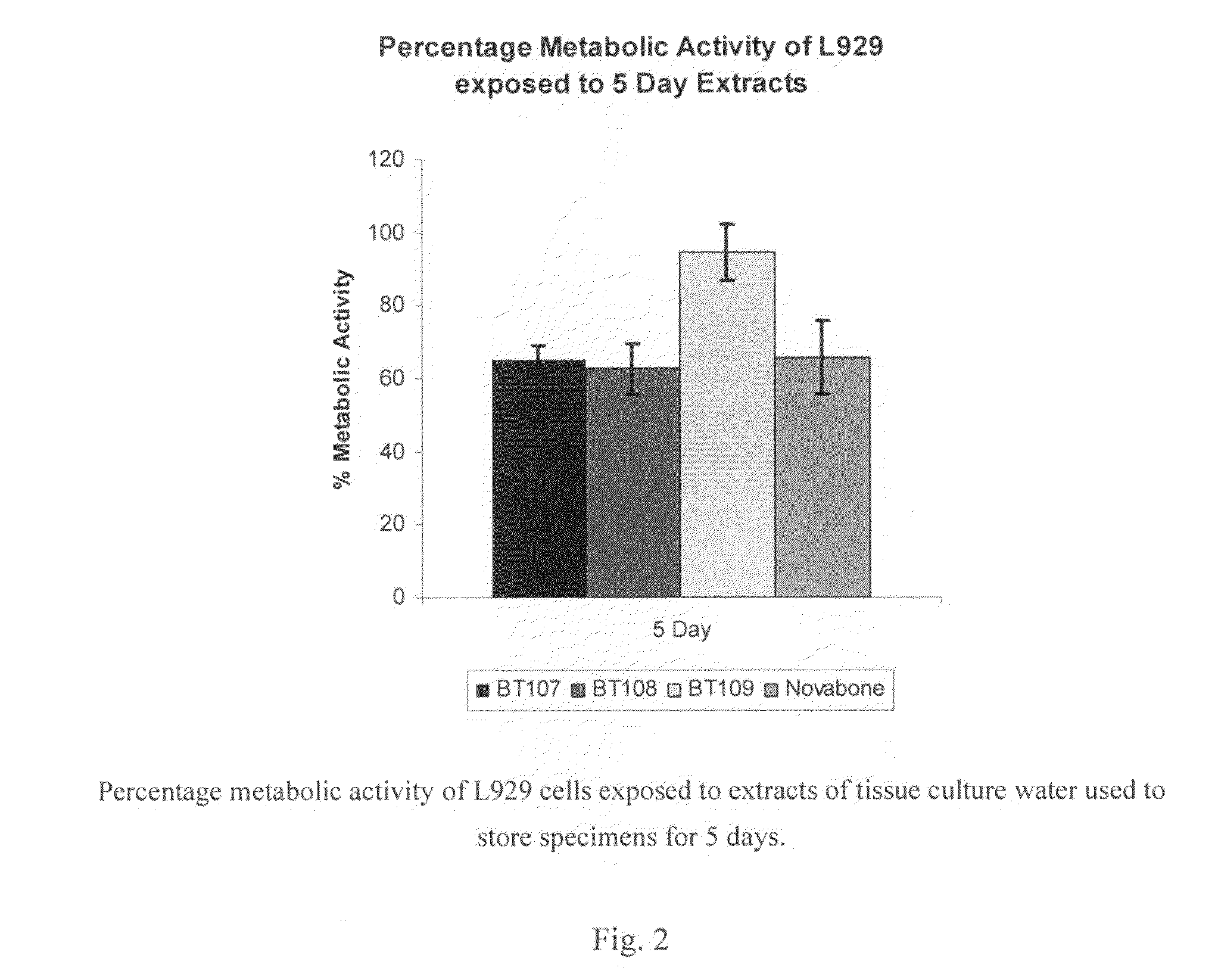

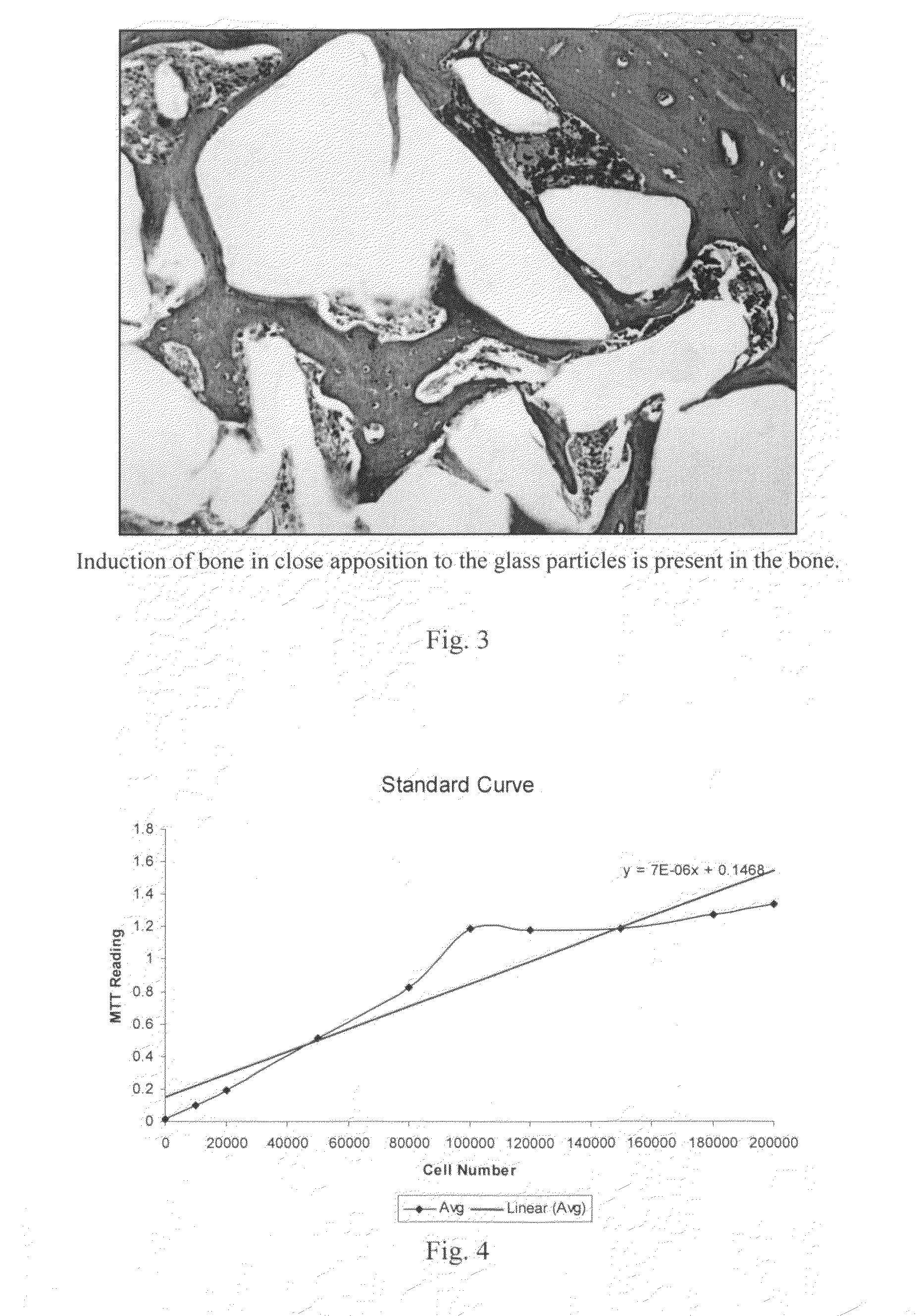

InactiveUS20080208340A1Optimise activityOptimise formationBiocideCosmetic preparationsParticulatesSolubility

A particulate glass for a synthetic bone (including dental) graft includes ZnO, SrO, and may include NaO. The glass promotes cellular metabolism, and upon implantation in living bone tissue induces bone growth at their surface. The ZnO and SrO respectively degrade to provide Zn2+ and Sr2+ ions respectively. The ions released by the glass provide anti-bacterial effects; improved bone formation in place of diseased tissue; inhibition of bone resorption; and radiopacity. There is excellent synergy between the SrO, ZnO, and NaO. The Sr2+ ions have better bone formation effects than the Zn2+ ions, but an anti-bacterial effect which is not as good. Choice of relative proportions of ZnO and SrO combined with the choice of NaO concentration to set the resorption rate allow optimisation. NaO there is control of the degradation rate of the graft; a feature which is advantageous in tailoring the grafts to specific patients and applications. Additionally the sodium (Na) in the glass imparts water solubility, allowing glasses to degrade to their ionic components.

Owner:LIMERICK UNIV OF

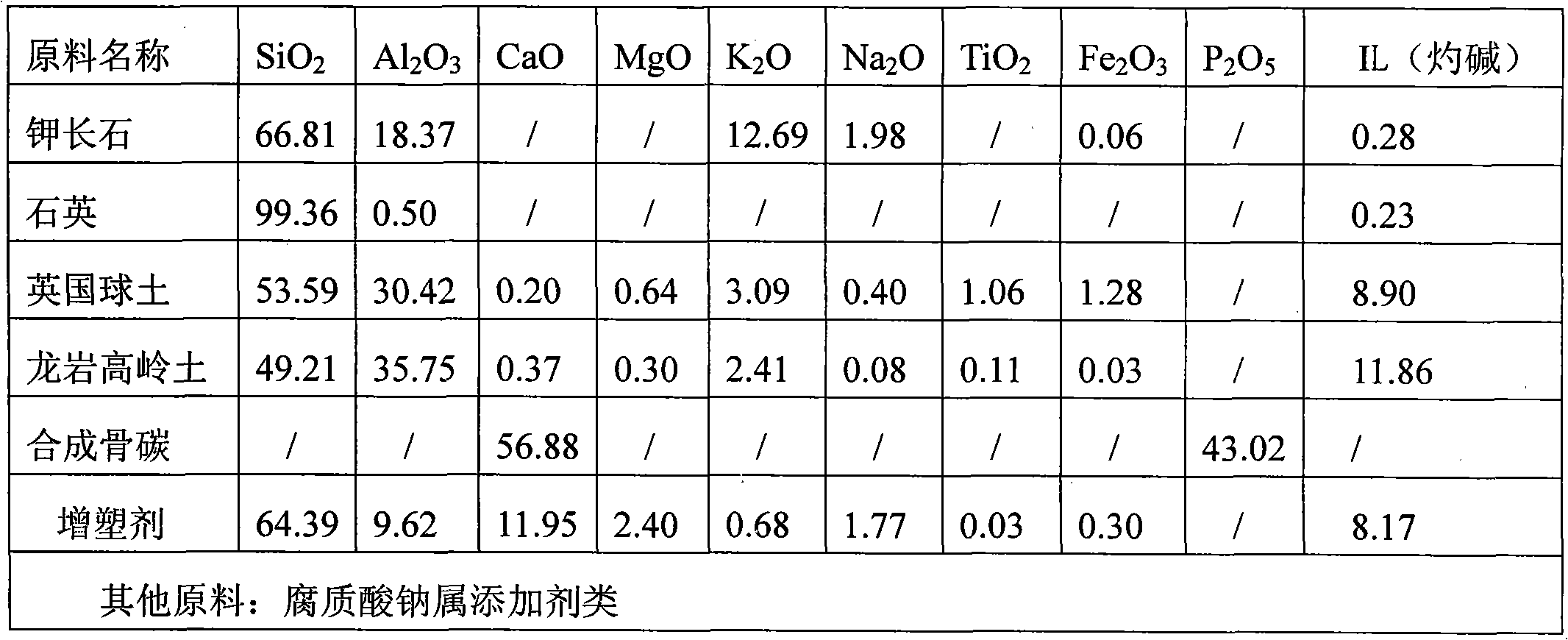

Bone china paste and preparing technology thereof

The invention discloses a bone china paste and a preparing technology thereof. The bone china paste comprises the following components by weight percent: 34.0-38.0% of SiO2, 12.0-16.0% of Al2O3, 0.2-0.4% of Fe2O3, 0.05-0.2% of TiO2, 24.5-27.0% of CaO, 0.5-1.5% of MgO, 18.0-21.0% of P2O5 and 0-4.0% of K2O and Na2O2, wherein the sum of the weight percent of the compounds is 100%. Ball clay is introduced in the bone china paste to increase the plasticity of the paste; and synthetic bone char is used to replace natural bone char, thus the dependence of the mass production of the bone china paste to natural bone char can be lowered and the paste can have reasonable chemical composition and better physical performance indexes; and the formability of paste can be improved, the production technology difficulty of bone china can be reduced, the qualification rate of products can be greatly increased, and technical supports can be provided for the batch production of bone china.

Owner:SHENZHEN YONG FENG YUAN IND

Injectible, biocompatible synthetic bone growth composition

InactiveUS20120195982A1Avoid the needPromote bone growthBiocidePeptide/protein ingredientsSulfateSynthetic bone

An injectible, biocompatible synthetic bone growth composition comprising a mineralized collagen and a calcium sulfate component. The composition is formed into injectible formulation that may be provided at the site of a skeletal defect via minimally invasive manner. An osteoinductive component may be further added, either before or after forming the unitary article. The composition may be formulated as a paste or putty and facilitates bone growth and / or repair.

Owner:BEIJING ALLGENS MEDICAL SCI & TECH

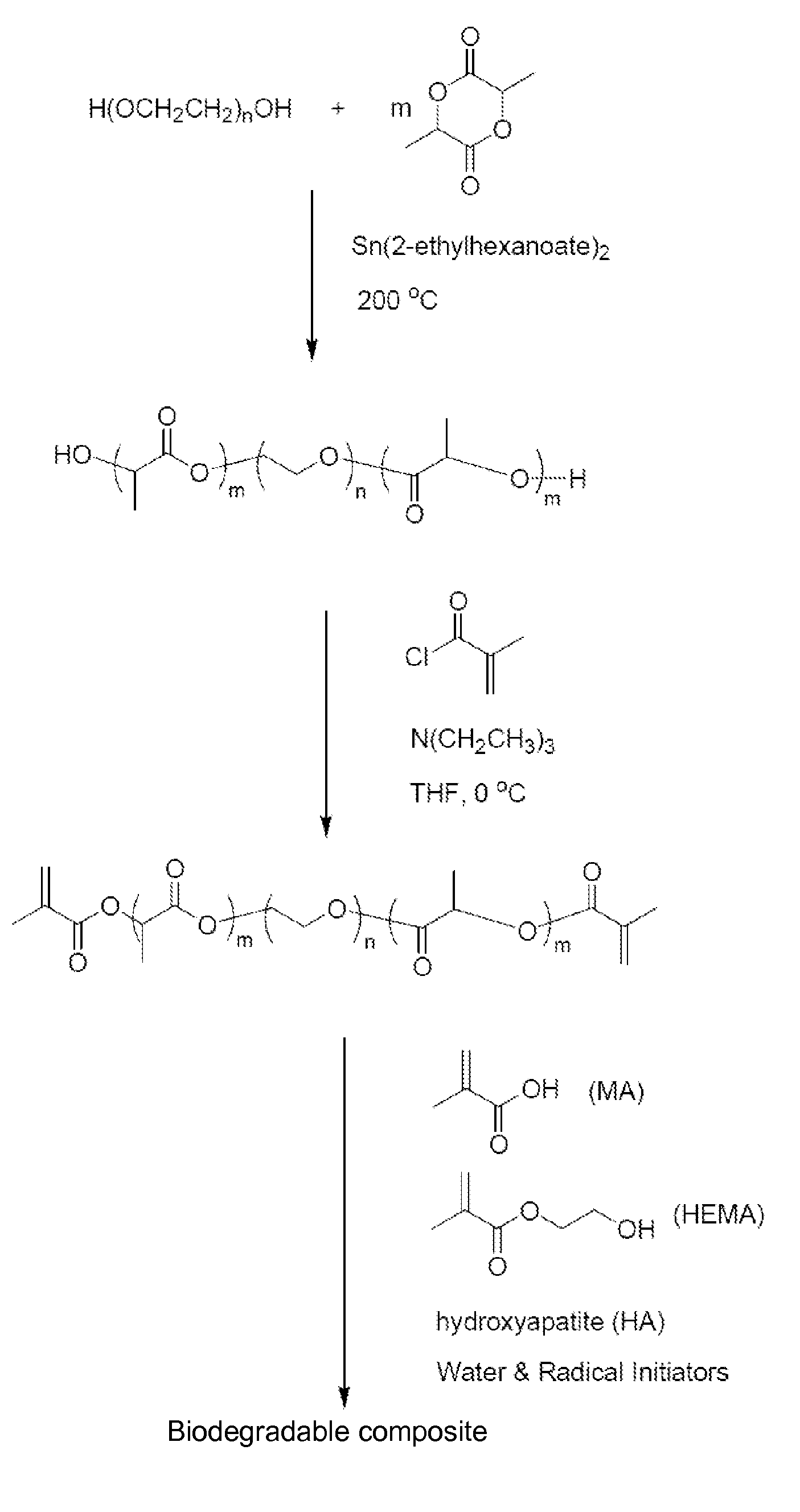

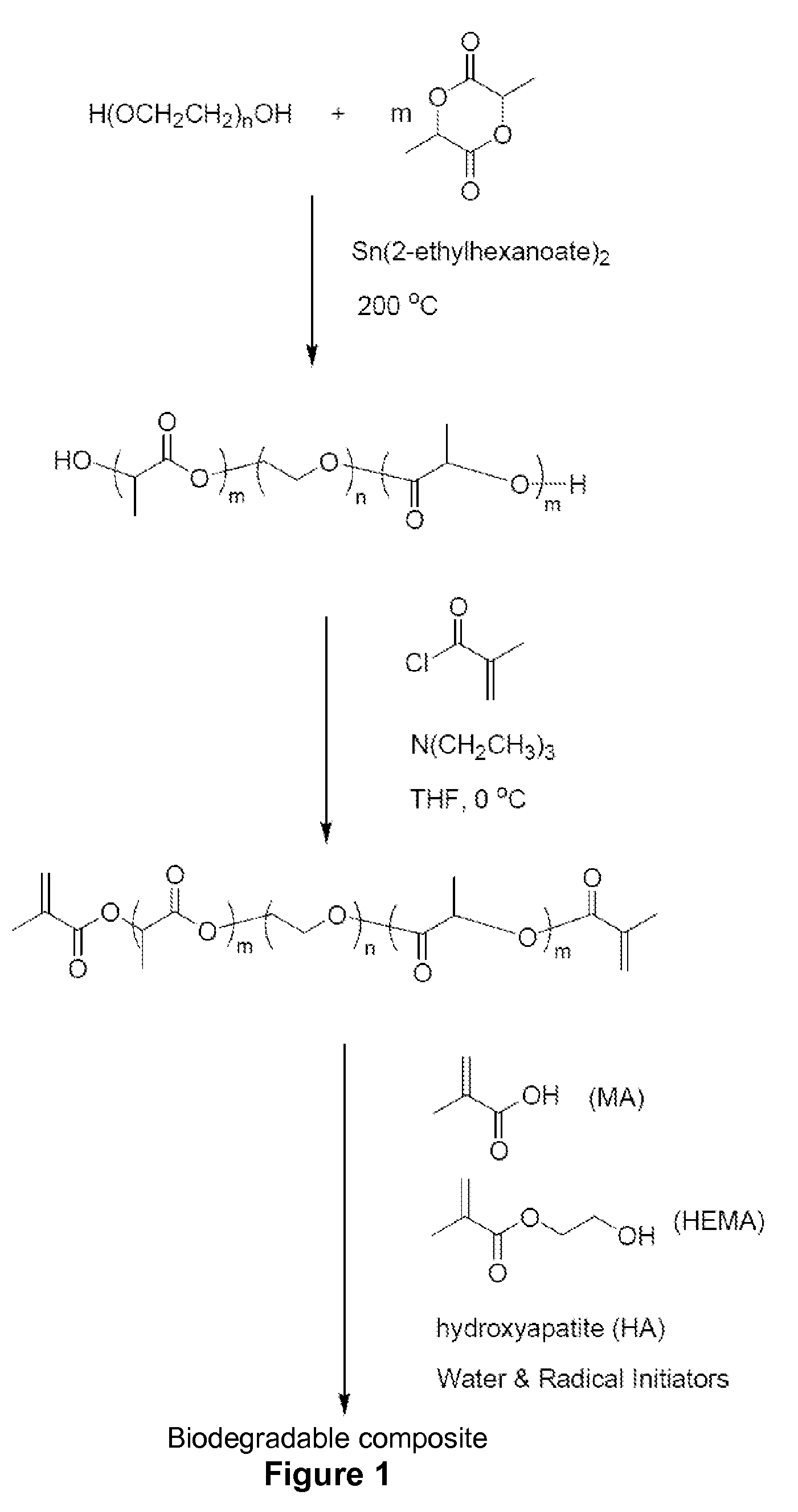

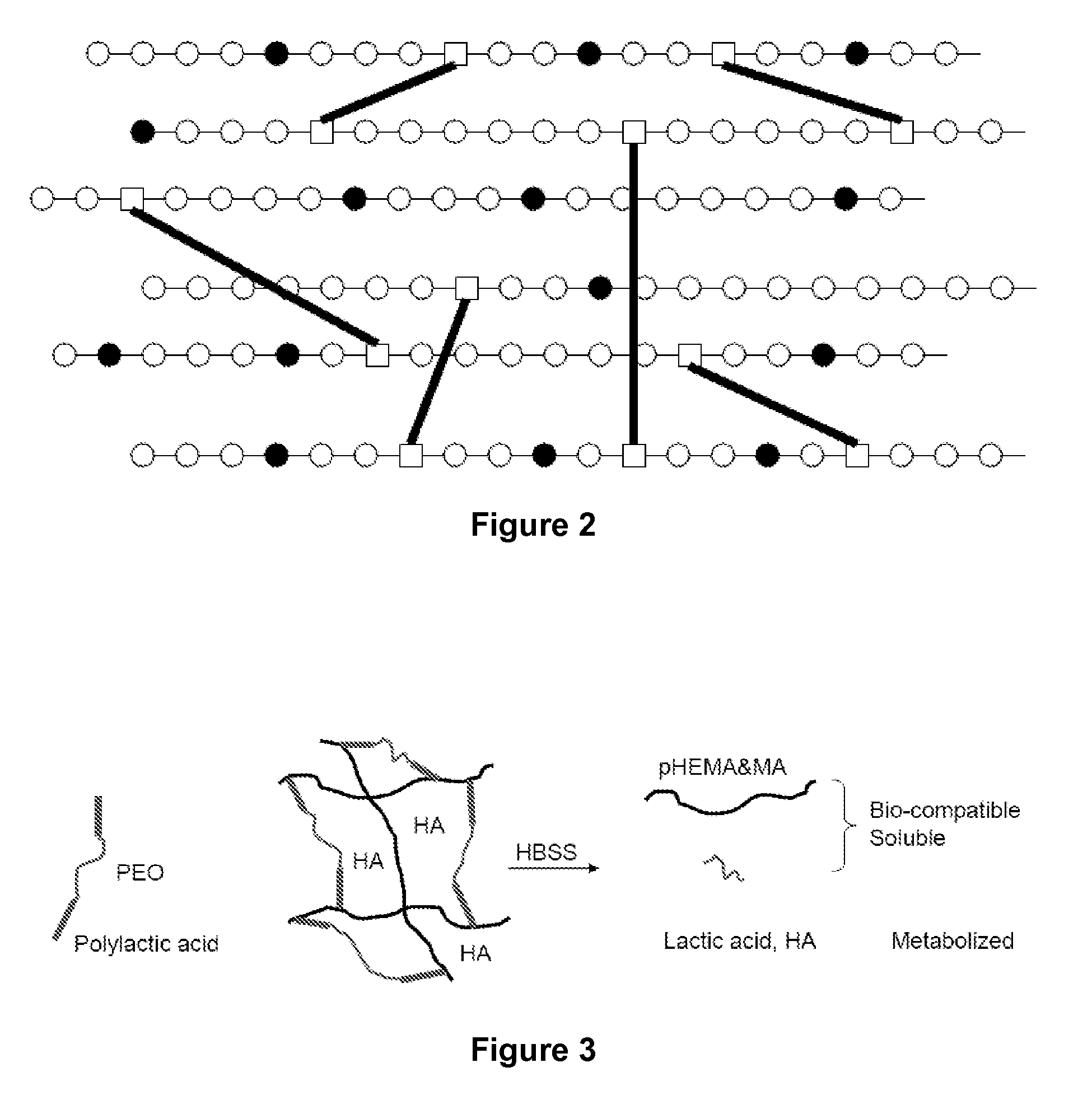

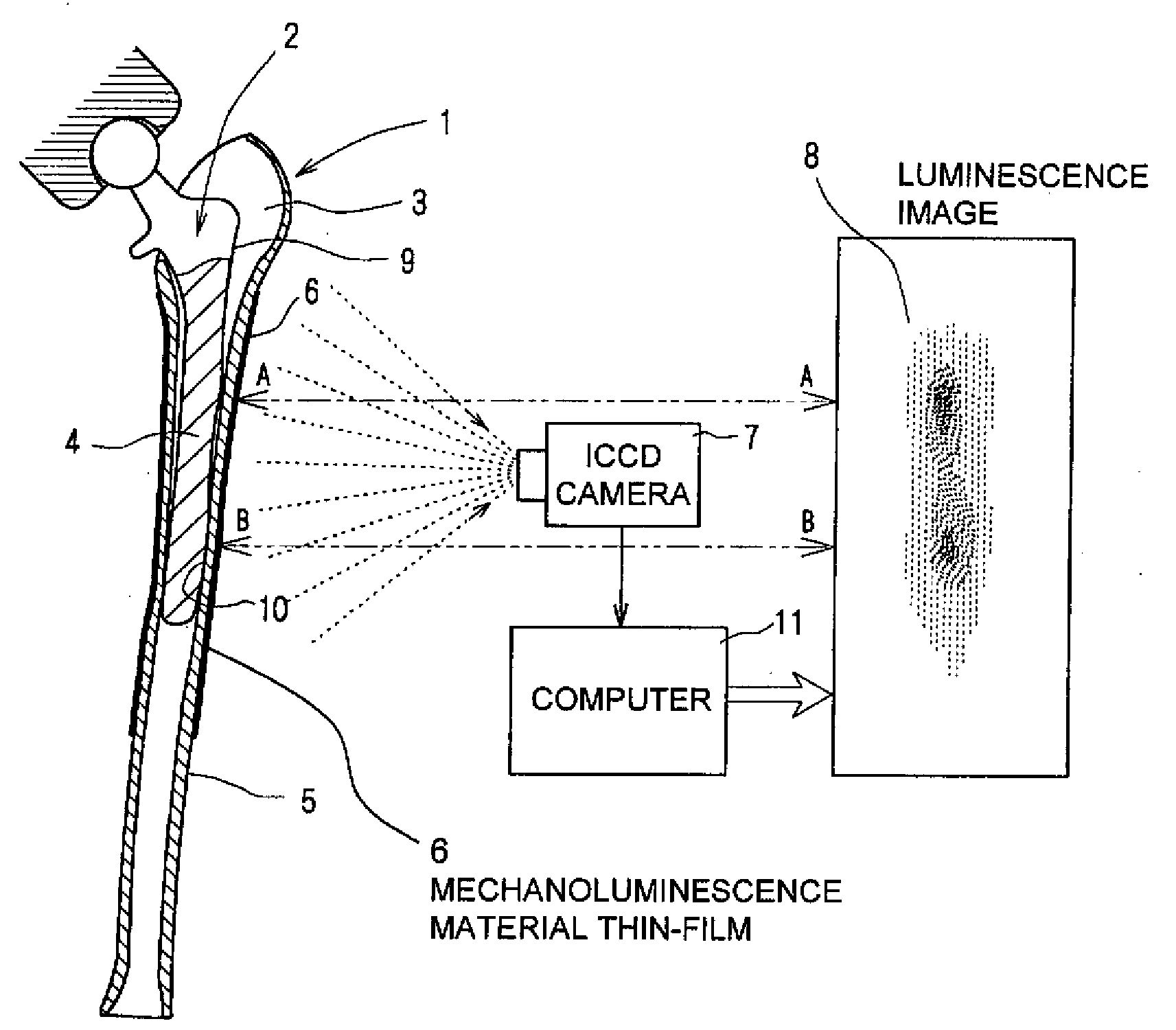

Biodegradable synthetic bone composites

Owner:RGT UNIV OF CALIFORNIA

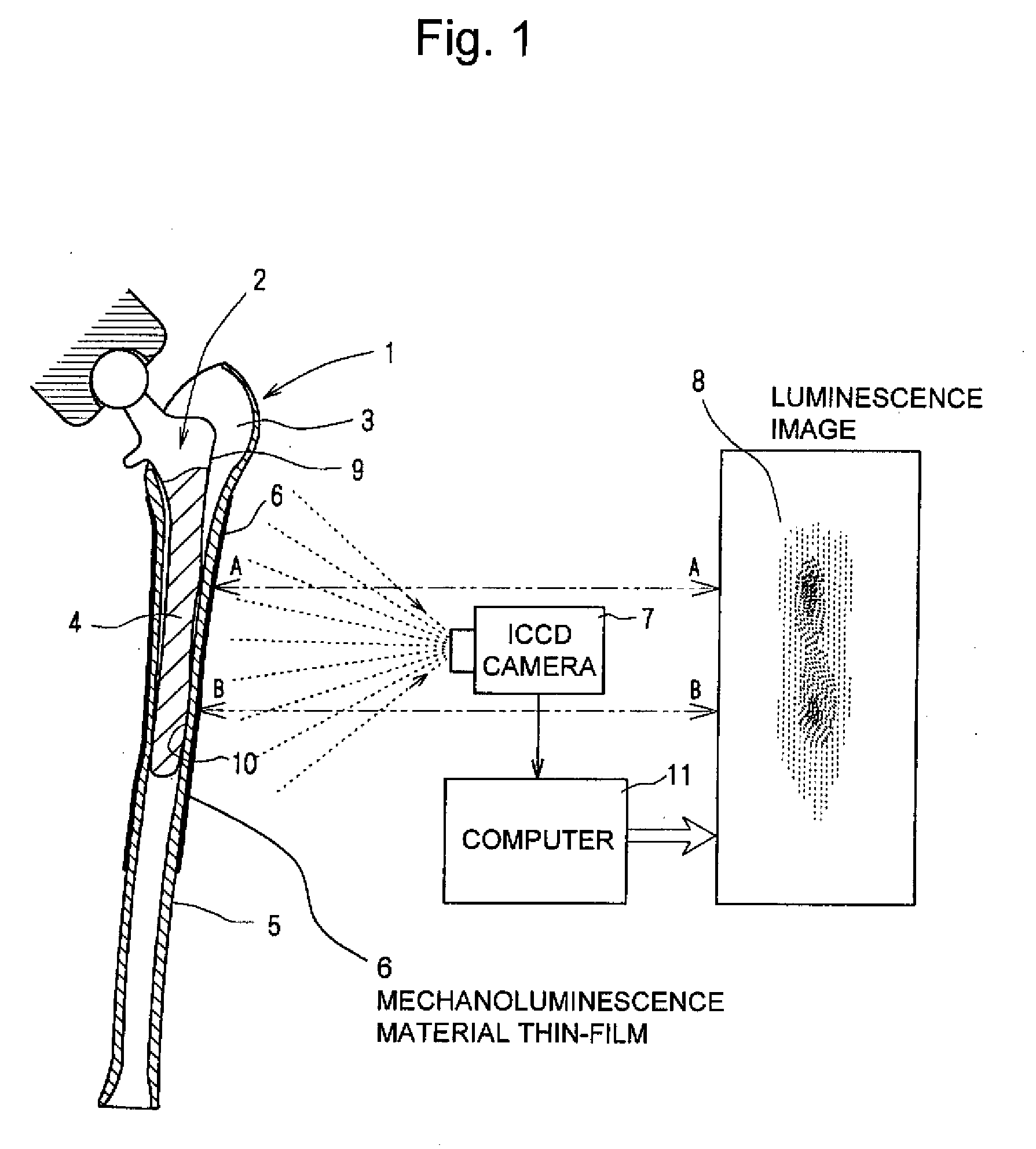

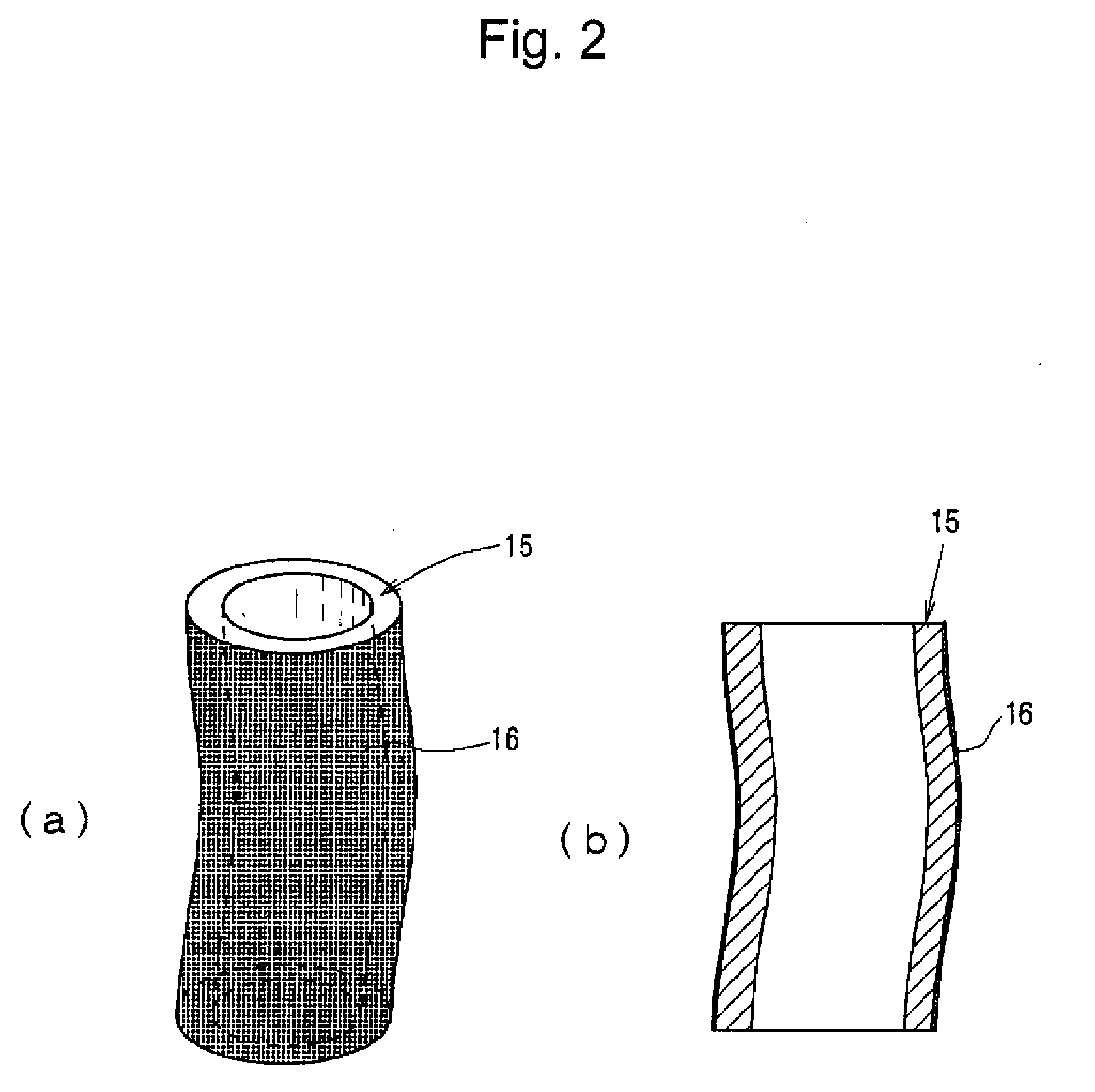

Method and member for measuring stress distribution of natural bone, synthetic bone, or member attached to them

ActiveUS20090012431A1Accurate measurementInexpensive systemSurgeryForce measurement by measuring optical property variationStress distributionNatural bone

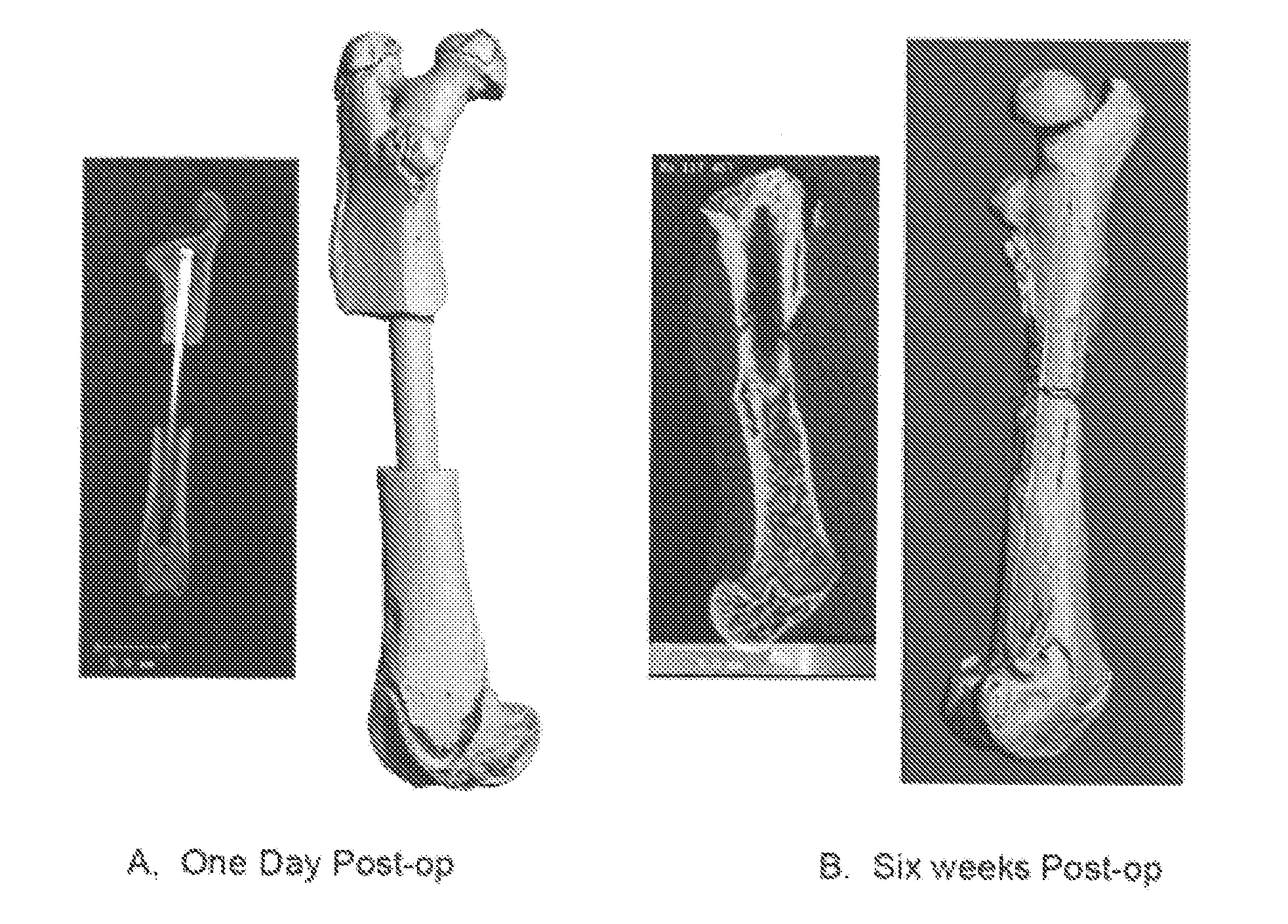

When visualizing the stress distribution of natural bone, synthetic bone, or a member attached to either thereof without omitted points, in order to measure accurately in a variety of modes using an inexpensive system, a mechanoluminescence material thin film 6 is formed in advance on a bone material peripheral surface 5 in an appropriate area thereof including the portion where an insertion support portion 4 of an artificial hip prosthesis 2 is inserted into a hollow inside 3 of a damaged femur 1 or a synthetic bone simulating the damaged femur. The mechanoluminescence material thin film 6 portion is photographed over its entire circumference with an IICCD camera 7 from the external peripheral side thereof as or after the artificial hip prosthesis 2 is inserted. The obtained image is fed to a computer 11 to obtain a luminescence image 8. The computer 11 outputs the intensities of the received light in the form of an image as is, so that the luminescence image 8 can be obtained easily. Particularly, the data about the intensities of the received light can be used as stress / strain data virtually as is. Such method is also suitable for dynamic analysis.

Owner:NAT INST OF ADVANCED IND SCI & TECH

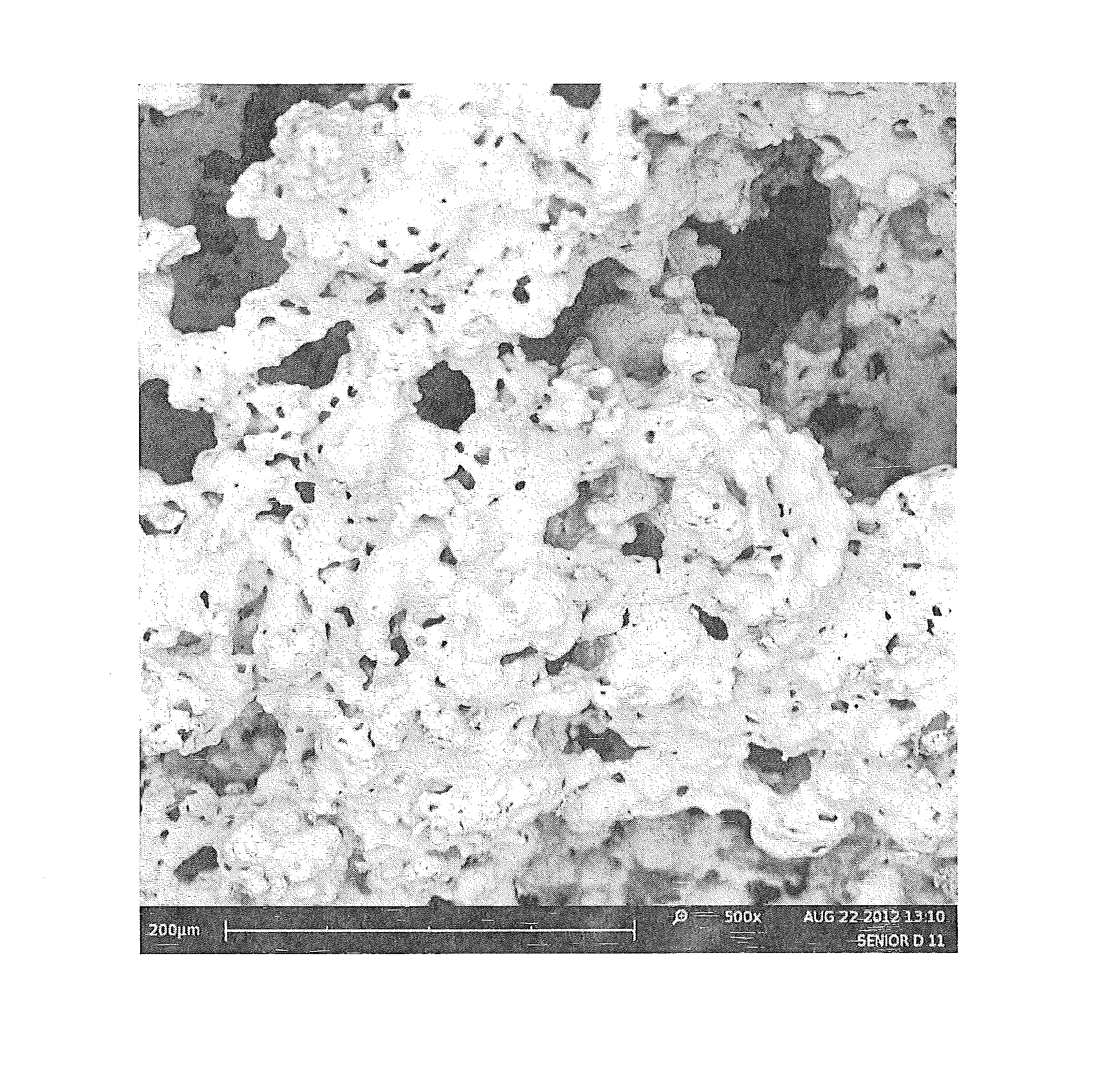

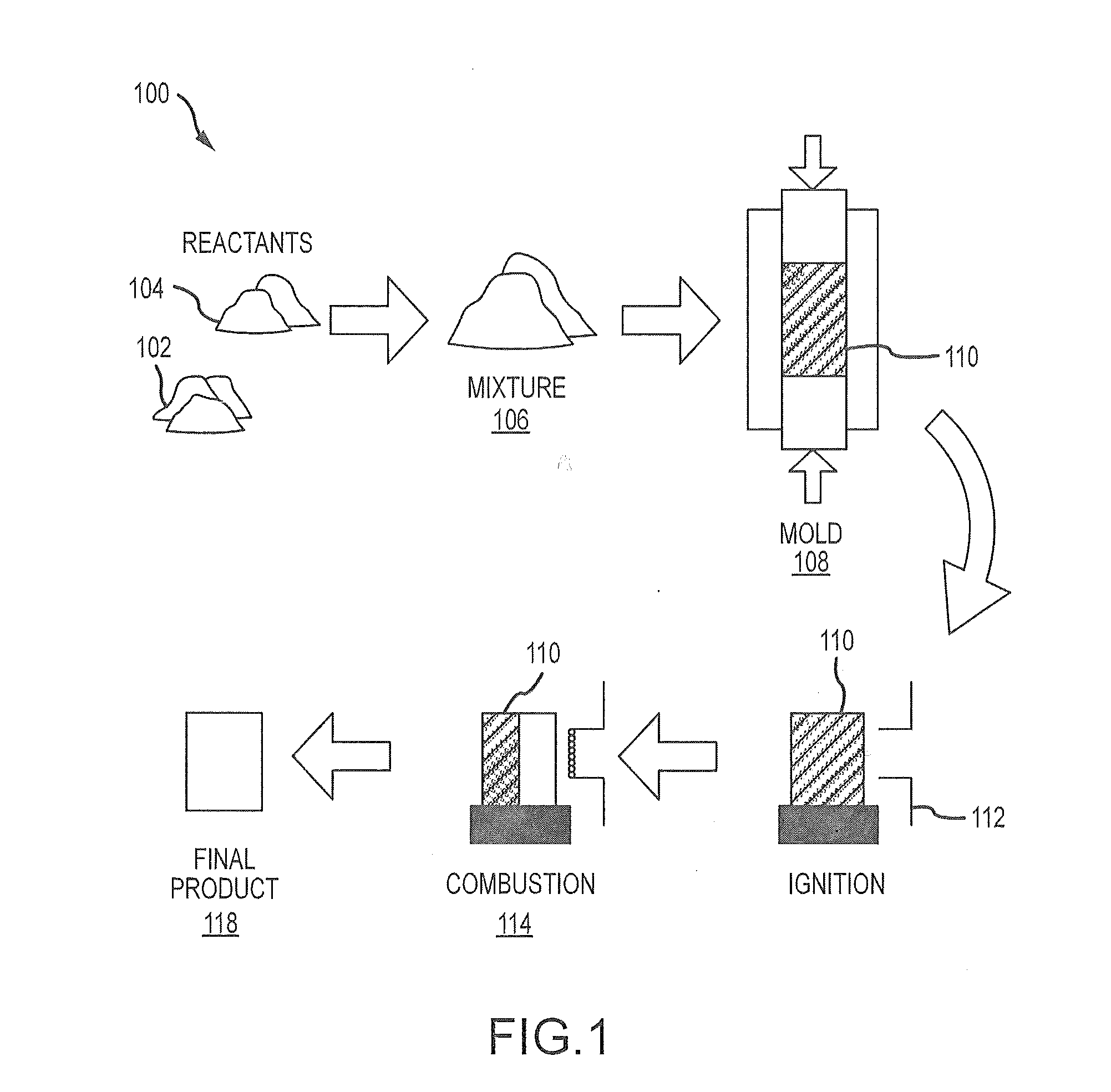

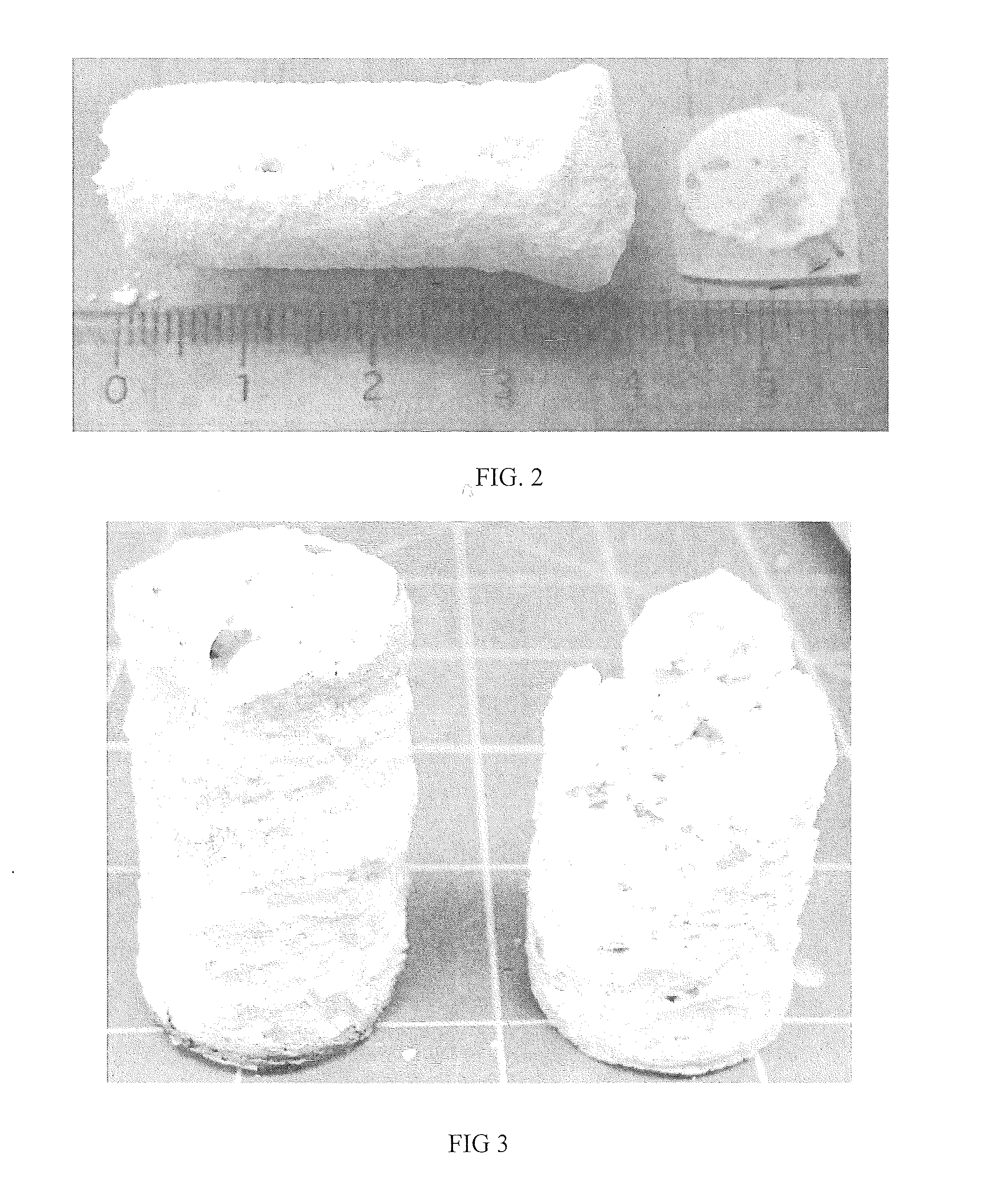

Combustion synthesis of calcium phosphate constructs and powders doped with atoms, molecules, ions, or compounds

The invention relates to a synthetic bone material and a process for making the same. The synthetic bone material may comprise multiple phases of calcium phosphate. Another aspect of the invention is a porous filter, and the method of making the same, and wherein the porous filter is substantially similar to the process for forming the synthetic bone material.

Owner:AYERS REED A +1

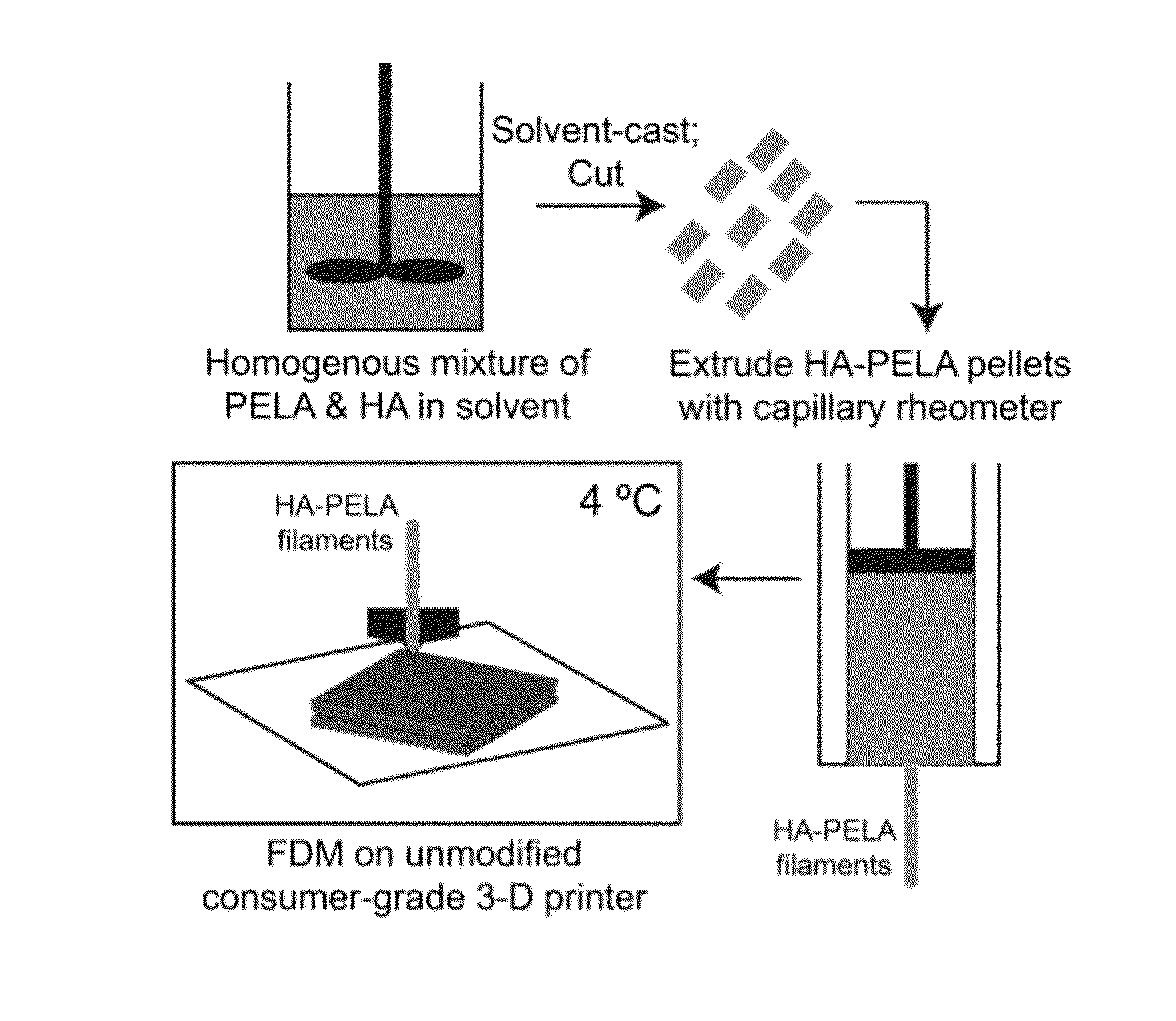

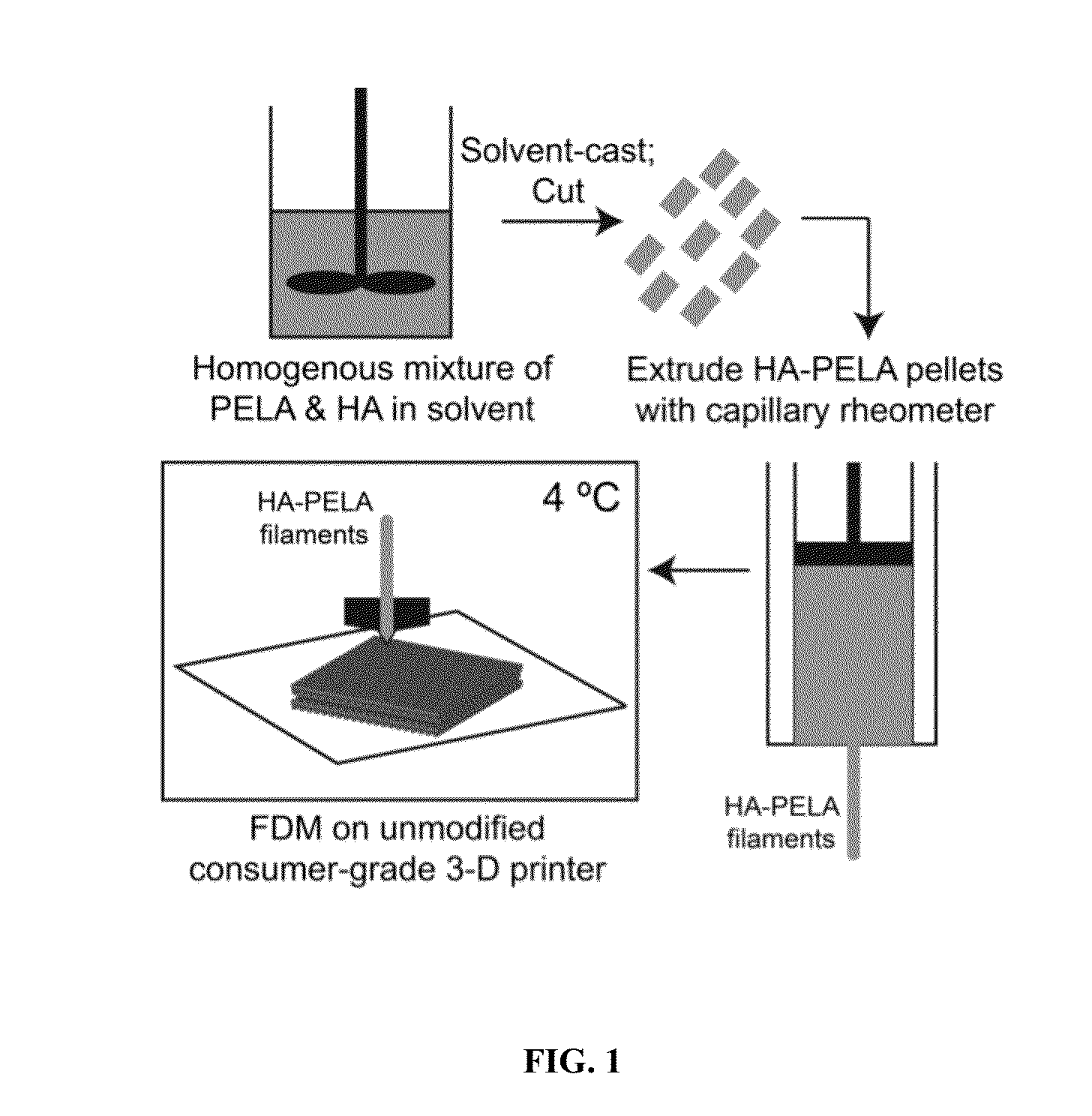

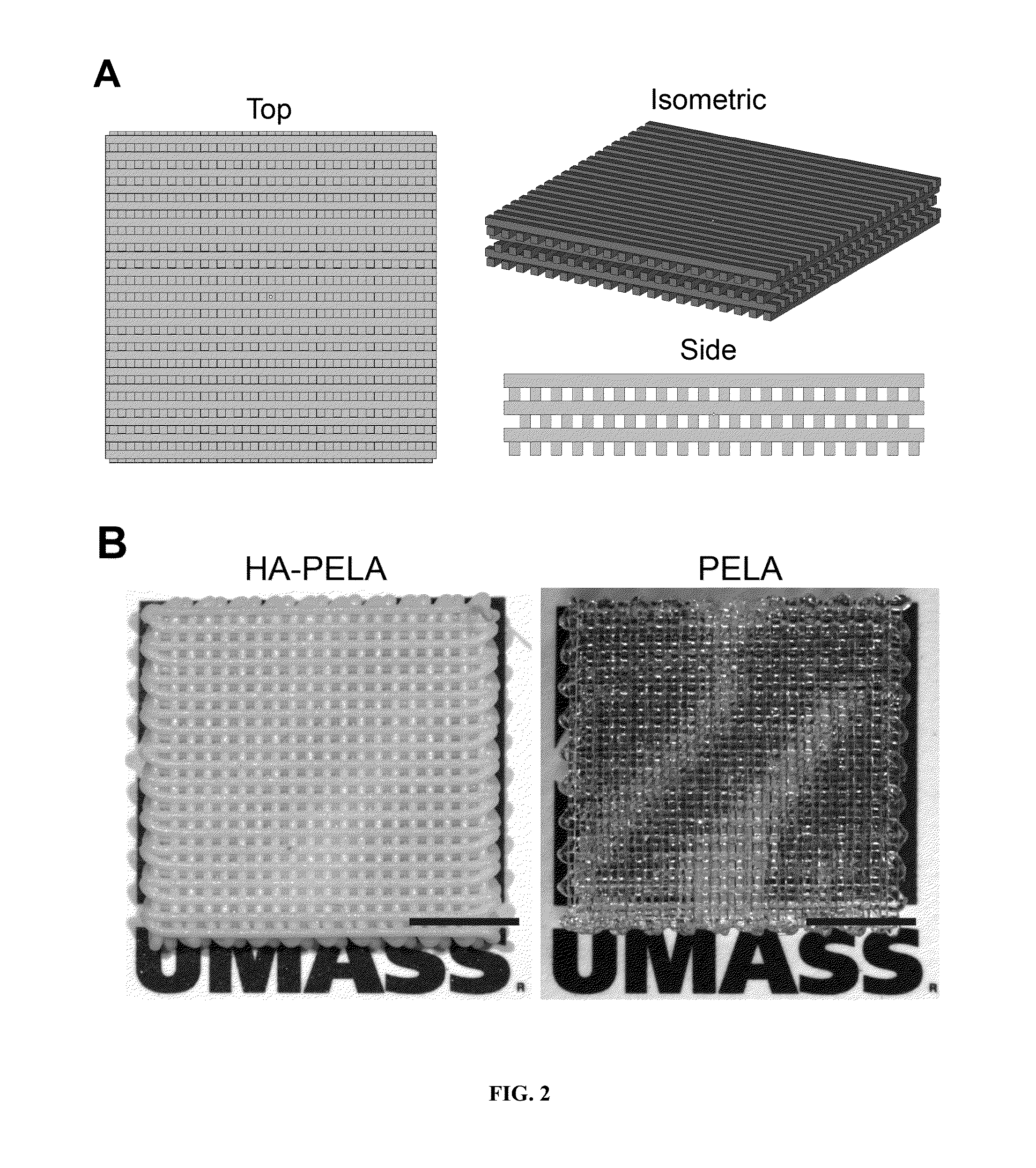

Elastomeric and degradable polymer scaffolds and high-mineral content polymer composites, and in vivo applications thereof

InactiveUS20160114077A1Inhibition of attachmentAdd supportImpression capsBone implantBiological propertySynthetic bone

This invention provides novel synthetic bone grafting materials or tissue engineering scaffolds with desired structural and biological properties (e.g., well-controlled macroporosities, spatially defined biological microenvironment, good handling characteristics, self-anchoring capabilities and shape memory properties) and methods of their applications in vivo.

Owner:UNIV OF MASSACHUSETTS MEDICAL SCHOOL

High strength synthetic bone for bone replacement for increasing ompressive strength and facilitating blood circulation, and manufacturing method therefor

InactiveUS20170065740A1Improve usabilityHigh compressive strengthSurgical adhesivesTissue regenerationSynthetic boneTri calcium phosphate

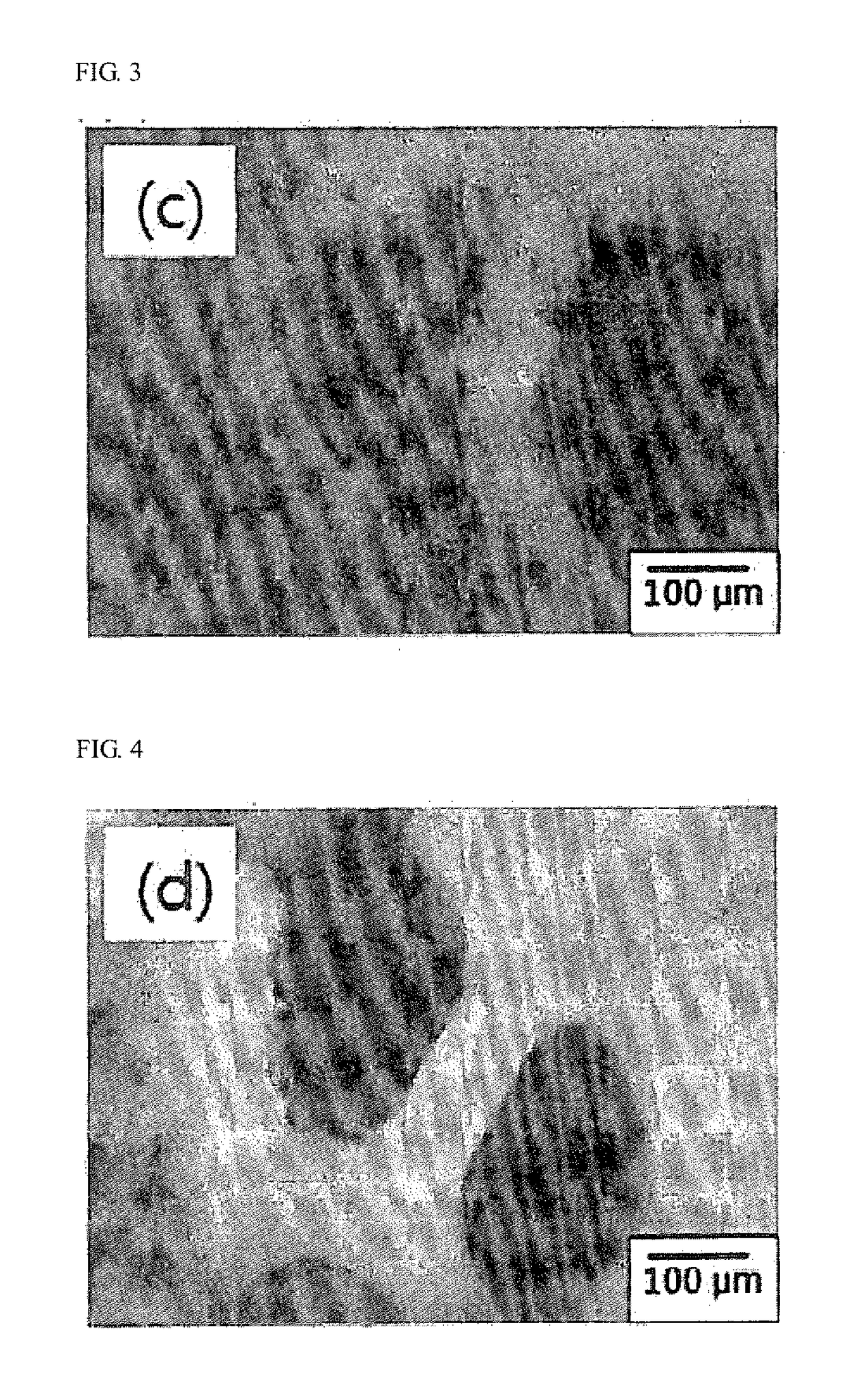

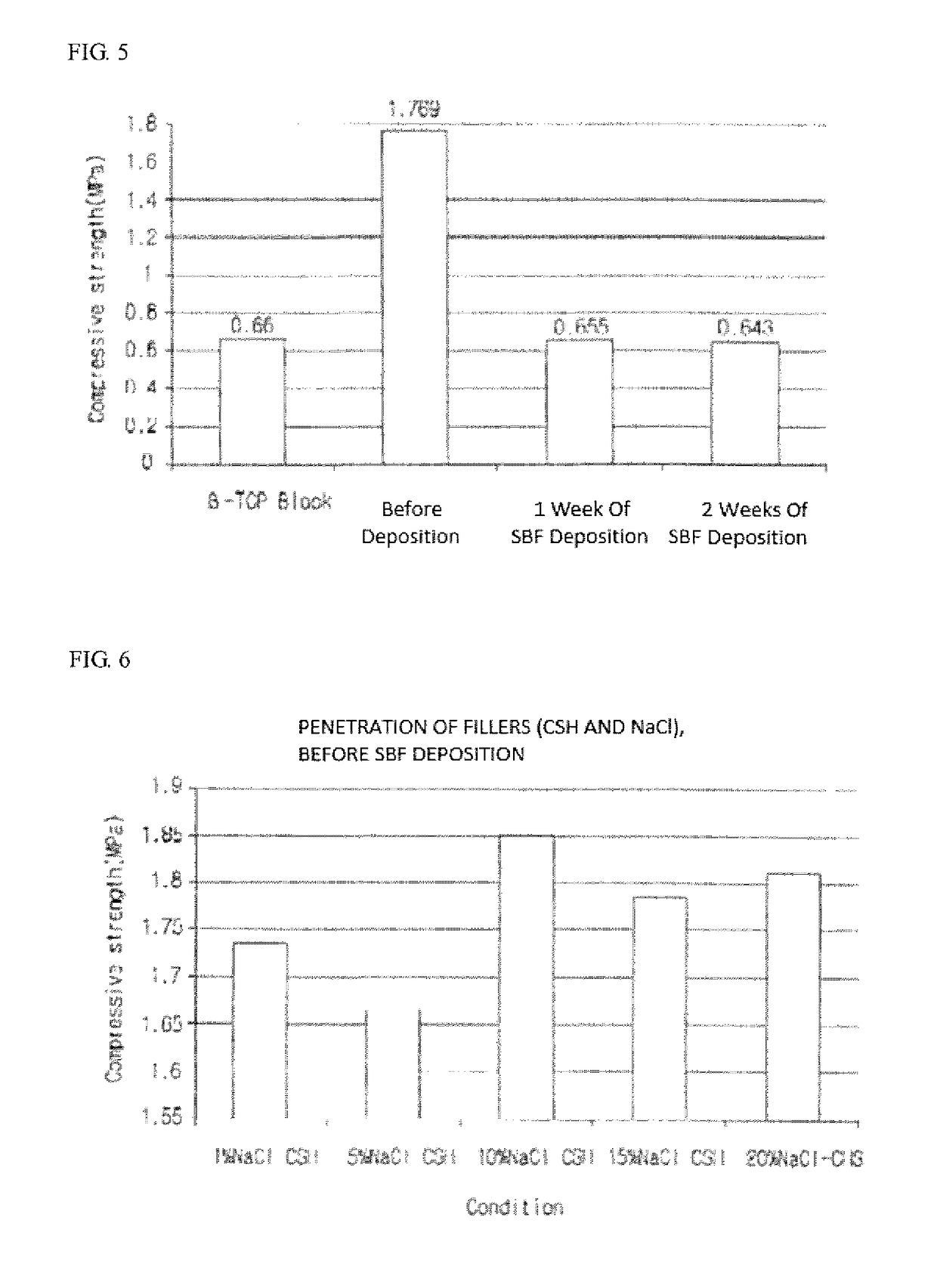

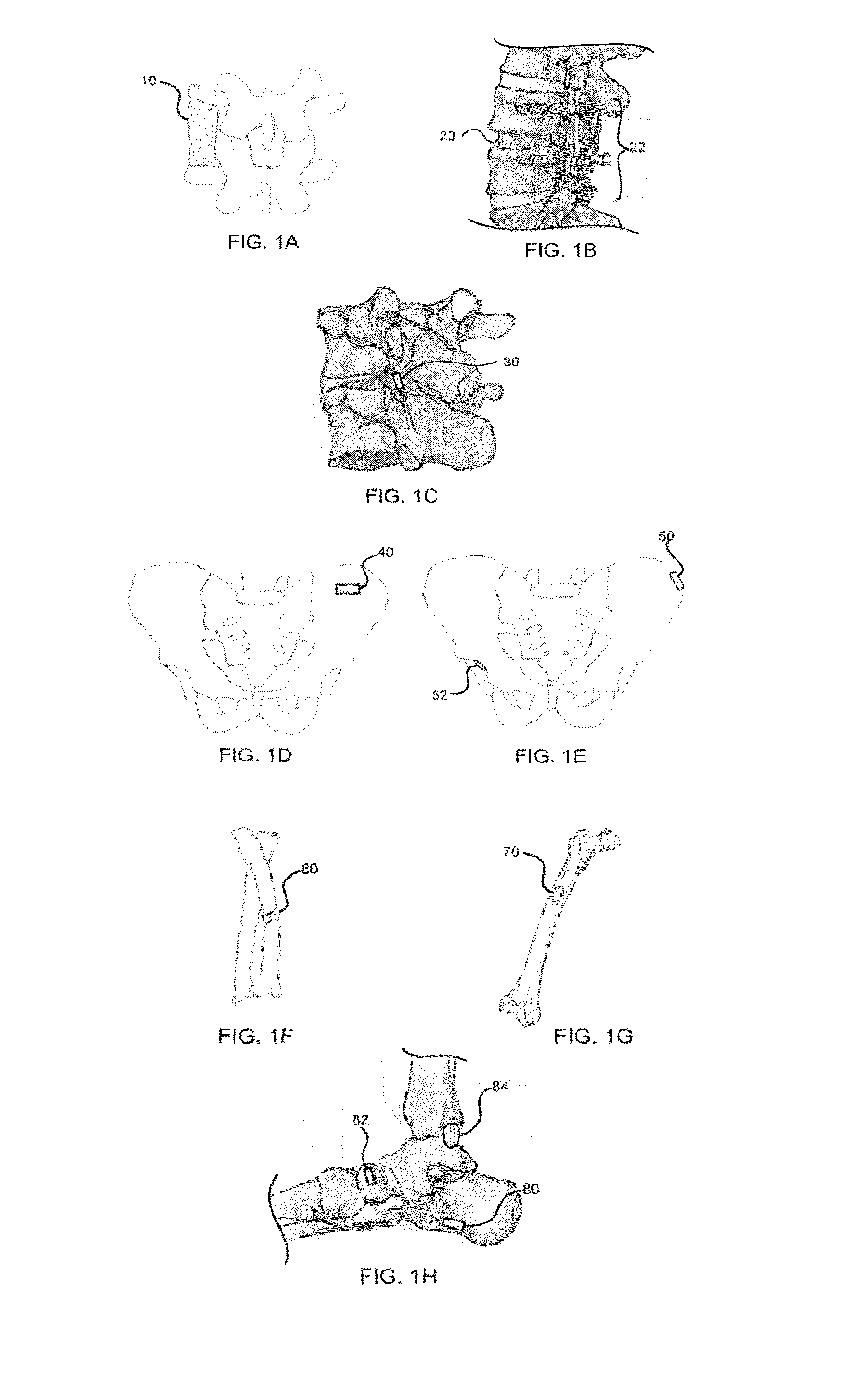

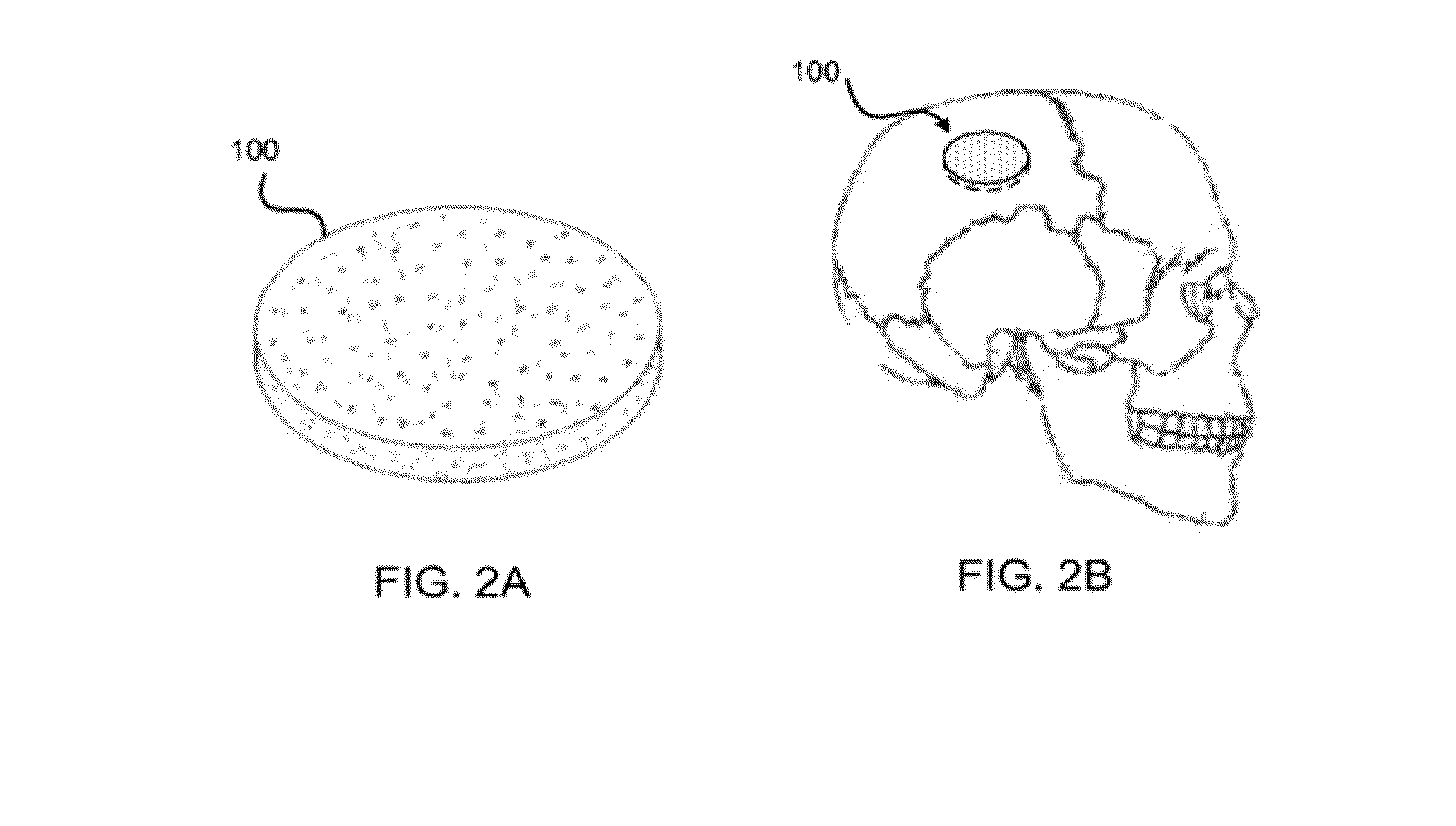

The present invention relates to a high strength synthetic bone for bone replacement for increasing compressive strength and facilitating blood circulation, and a manufacturing method therefor, and provides the high strength synthetic bone for bone replacement in which calcium sulfate hemihydrate (CSH) and NaCl, in a particle state, penetrate into the pores of a porous inorganic material such as β-tricalcium phosphate (β-TCP) and a wet treatment is performed on the same such that the CSH penetrated into the pores is combined with moisture so as to form a hydrated crystal of calcium sulfate dihydrate (CSD) to expand the volume thereof in the pores, thereby preventing the escape of a filler by physical force.

Owner:OSSEIN

Moldable bone graft compositions

ActiveUS20160136325A1Easy to carryStimulate proliferationBiocideInorganic phosphorous active ingredientsSynthetic bone graftBone transplantation

The present disclosure relates to compositions useful in synthetic bone graft applications. Particularly, the disclosure teaches moldable bone graft compositions, methods of making said compositions, and methods of utilizing the same.

Owner:BIOVENTUS

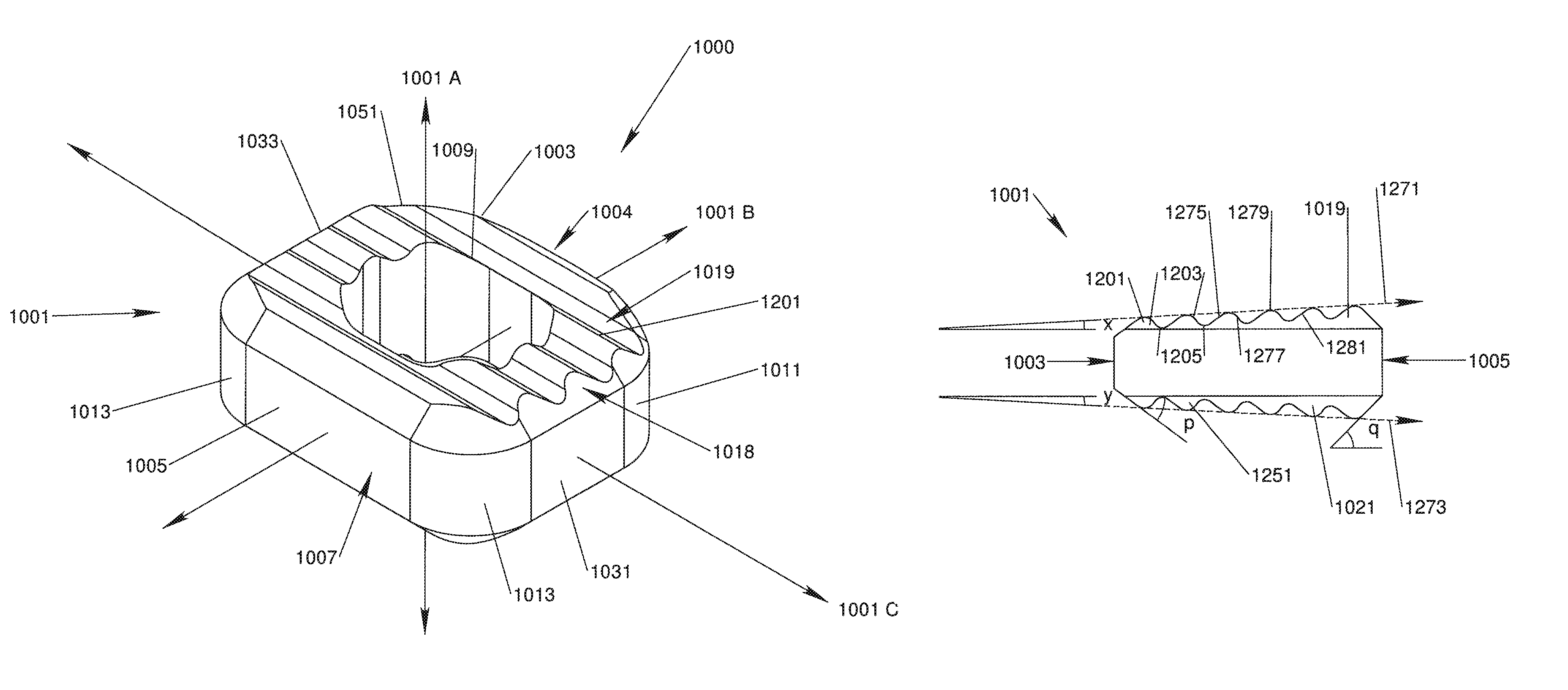

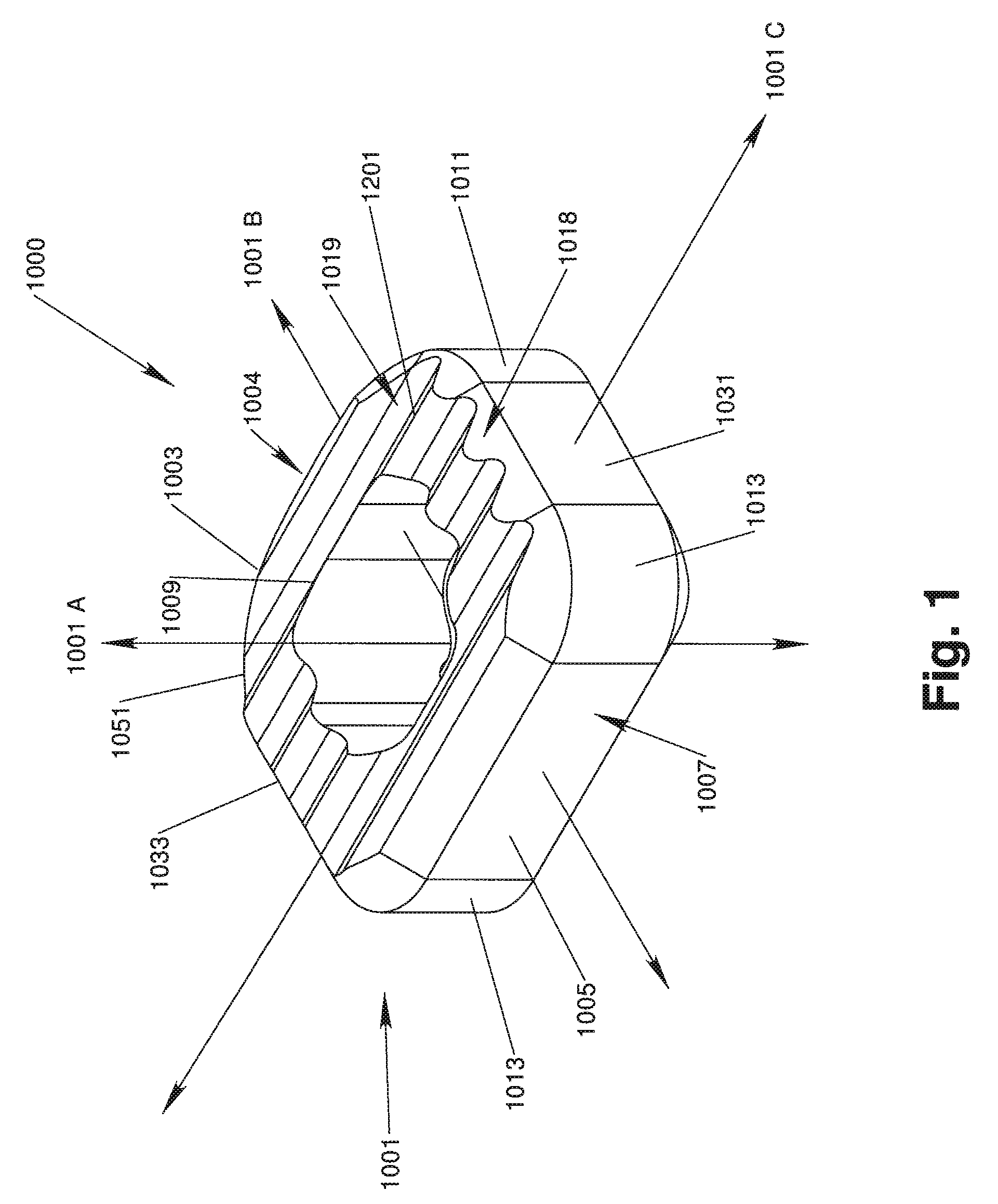

Intervertebral implant devices for supporting vertebrae and devices and methods for insertion thereof

InactiveUS8470040B2Less ductileImprove physical propertiesBone implantPharmaceutical delivery mechanismCalcium biphosphateStress concentration

Implant devices for implantation within an intervertebral space are provided, together with methods and tools for use therewith. Implant devices of the present invention include an implant body formed of a synthetic bone substitute material, such as a nanocrystalline calcium phosphate material. The implant body and the methods and tools used therewith are configured to optimize strength and stability of the implant, minimize areas of stress concentration in the implant body and promote bone growth through the implant body and fusion of the vertebra.

Owner:PIONEER SURGICAL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com