Novel long glass fiber-reinforced polyurethane technique capable of being produced into A-class surface product

A new process, polyurethane technology, applied in polyurea/polyurethane coatings, devices for coating liquid on the surface, special surfaces, etc., can solve problems such as uneven product surfaces, difficult to remove, and difficult to fill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

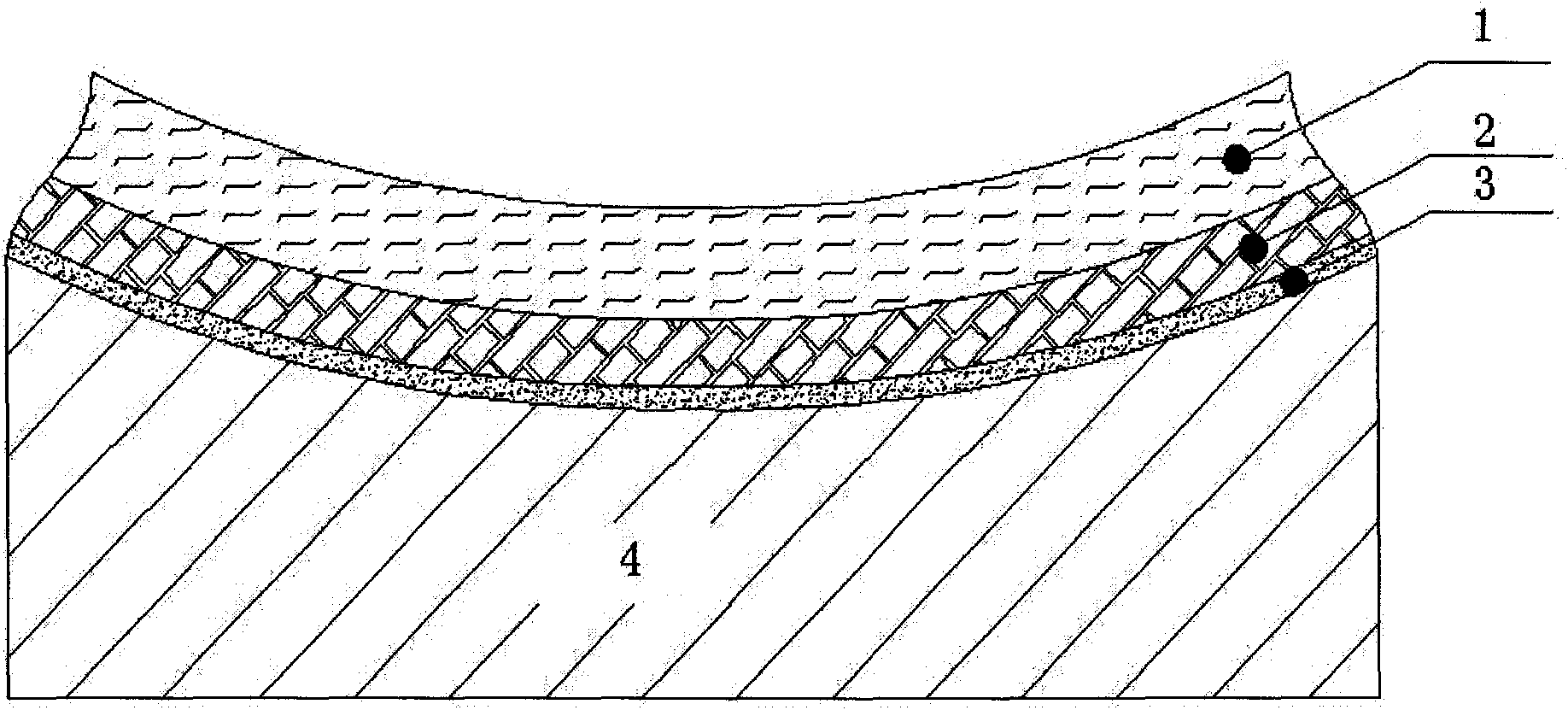

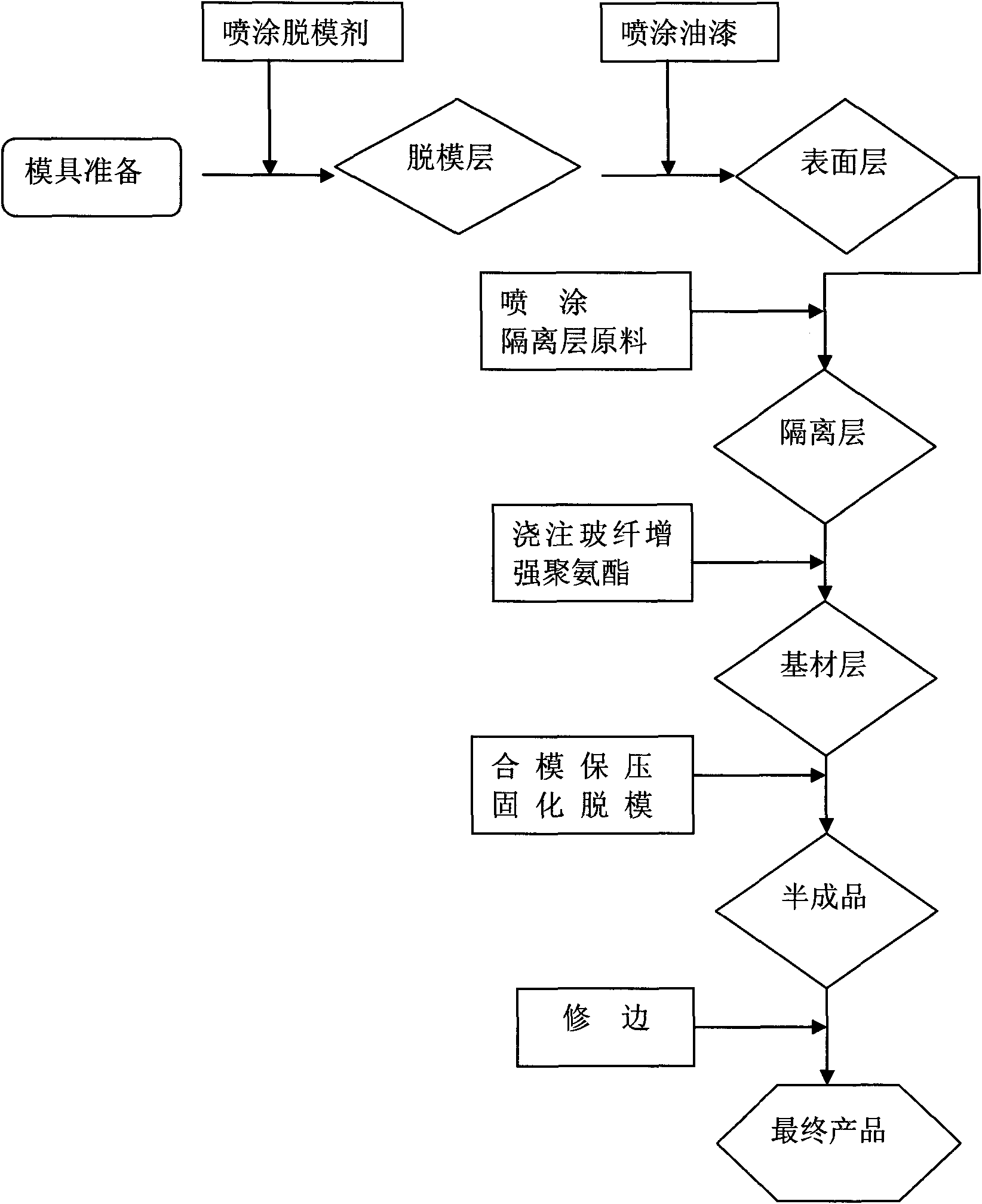

[0020] A. Control the mold temperature at 30-60°C, spray wax-based release agent inside 4, and after 8-10 minutes, wipe 4 with a dry cloth.

[0021] B. Spray the in-mold paint evenly on the surface of the mold to produce and form 3, but do not make the paint film produce orange peel phenomenon; wait for 30-60 seconds, after the paint film is dry, spray 0.5-1mm thick paint on the paint film The foamed polyurethane material is produced and formed 2. The spraying of this material mainly uses a polyurethane spray foaming machine. The flow rate of the mixing head of the foaming machine is controlled to maintain at 20-80g / s, and the atomization effect of the mixing head is uniform and good. The width of the atomized fan is 100-300mm; the temperature of the raw material is controlled at 40-60°C, and the viscosity of the raw material is controlled below 600mpa.s; the spraying amount should be uniform.

[0022] C. After spraying the isolation layer, during the semi-curing period of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com