Preparation method of anode material of lithium ion battery and preparation method of precursor of anode material

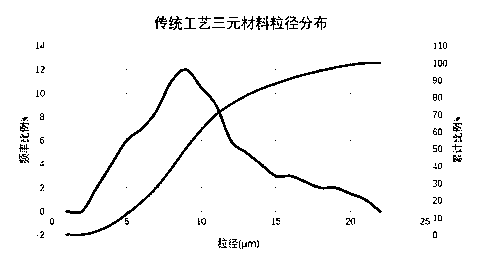

A lithium-ion battery, cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of difficult to control production conditions, poor uniformity, large particles, etc., to achieve good uniformity, full gram capacity, and operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

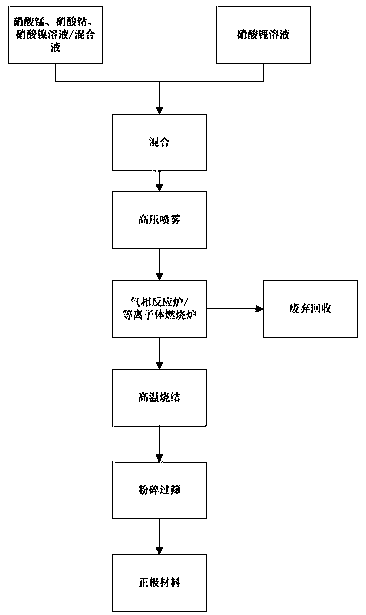

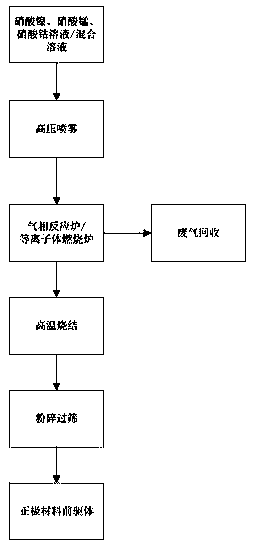

Method used

Image

Examples

example example 1

[0021] Example Case 1. According to Li[Ni 0.5 co 0.2 mn 0.3 ]O 2 For the stoichiometric ratio, take 58.69g foam nickel, 23.57g metal cobalt plate, and 32.96g manganese sheet and slowly add them to 200.0g, 80.0g, and 120.0g of concentrated nitric acid with a concentration of 65% to fully dissolve, and add a total of 400.0g , 160.0g, and 240.0g of high-purity water are diluted to prepare the corresponding nitrate aqueous solution.

[0022] The above dark green nickel nitrate solution, red cobalt nitrate solution and pink manganese nitrate solution were mixed and stirred, and 137.9g lithium nitrate and 200.0g high-purity water were added to fully mix and dissolve, and a light brown mixed solution was obtained after stirring evenly.

[0023] Set the pressure of the high-pressure sprayer to 50.0kg, spray the above light brown solution, and the size of the mist particles is 1-15 microns; set the temperature of the high-temperature gas phase reactor to 2000 degrees, so that the ...

example example 2

[0026] Example case 2, according to Li[Ni 0.8 co 0.1 mn 0.1 ]O 2 According to the stoichiometric ratio, 232.6g nickel nitrate hexahydrate, 29.1g cobalt nitrate hexahydrate, and 25.1g manganese nitrate tetrahydrate were dissolved in 400.0g, 50.0g, and 50.0g high-purity water respectively to obtain the corresponding nitrate aqueous solution.

[0027] Mix and stir the above-mentioned dark green nickel nitrate solution, red cobalt nitrate solution and pink manganese nitrate solution, add 68.9g of lithium nitrate and 100.0g of high-purity water to fully mix and dissolve, and obtain a gray-green mixed solution after stirring evenly.

[0028] Set the pressure of the high-pressure sprayer to 60kg, spray the above light brown solution, and the size of the mist particles is 1-15 microns; pass through the plasma combustion furnace (average temperature is about 3000 degrees), so that the mist particles can fully react with oxygen at high temperature , to obtain black powder.

[0029] ...

example example 3

[0031] Example Case 3, according to LiNi 0.5 mn 1.5 o 4 According to the stoichiometric ratio, 145.4g of nickel nitrate hexahydrate and 376.5g of manganese nitrate tetrahydrate were dissolved in 400g and 800g of high-purity water respectively to obtain the corresponding nitrate aqueous solution.

[0032] The above dark green nickel nitrate solution and pink manganese nitrate solution were mixed and stirred, and 68.9 g of lithium nitrate was added to fully mix and dissolve, and a light brown mixed solution was obtained after stirring evenly.

[0033] Set the pressure of the high-pressure sprayer to 40kg, spray the above light brown solution, and the size of the mist particles is 1-15 microns; set the temperature of the high-temperature gas phase reaction furnace to 1500 degrees, so that the mist particles and oxygen can fully react at high temperature, A black powder is obtained.

[0034] Pass the above black powder into a high-temperature sintering furnace with pure oxygen,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com