Novel galvanometer for laser machining equipment

A new type of laser processing technology, which is applied in the field of laser marking machines, can solve the problems of difficult cost control, high cost of galvanometer production, and high price of galvanometers, and achieve the advantages of easy industrial production, low production process difficulty and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

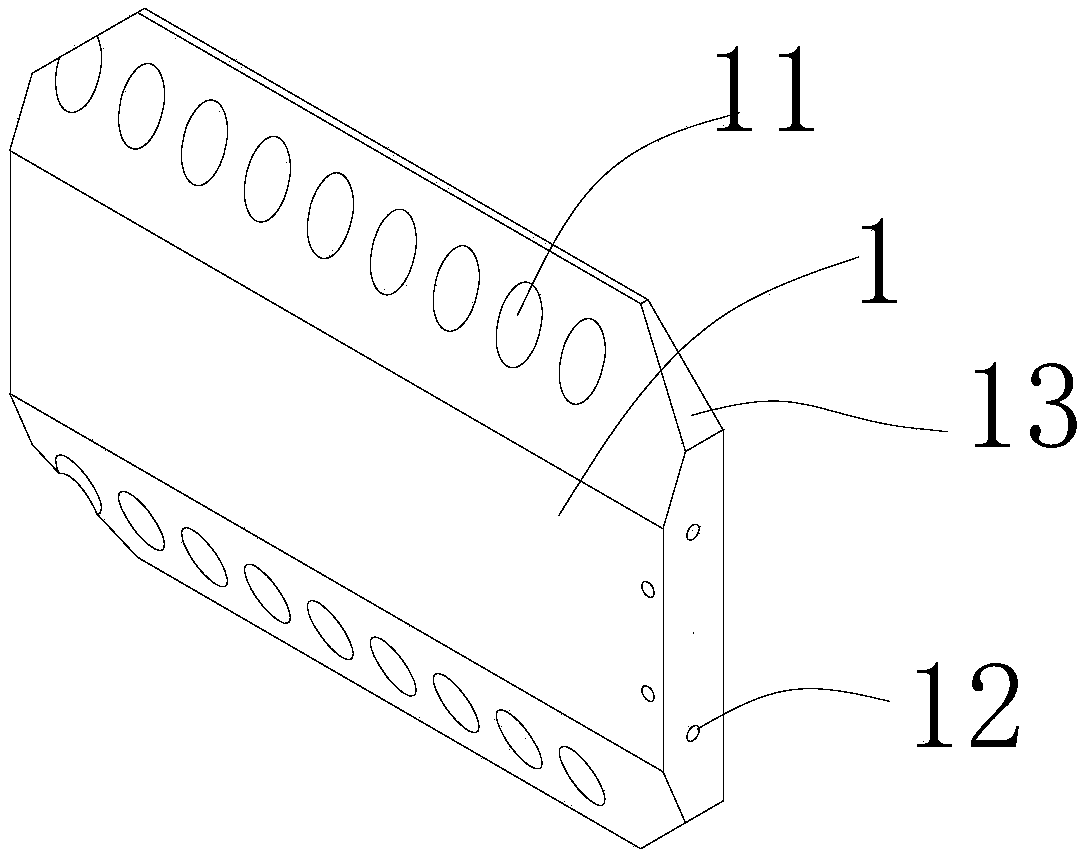

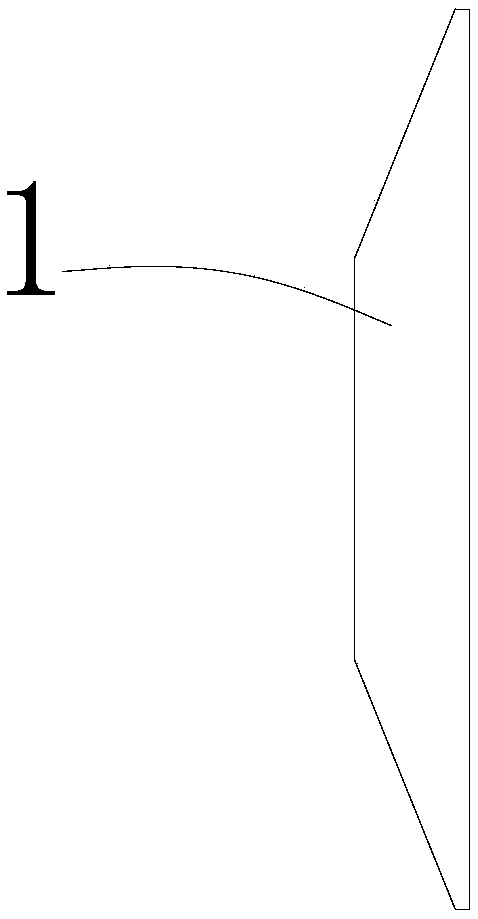

[0051] Such as figure 1 As shown, a new type of vibrating mirror used in laser processing equipment, the main body of the vibrating mirror is a symmetrical structure, and the main body of the vibrating mirror 1 is in the shape of a trapezoidal sheet, such as figure 2 As shown, its cross-sectional area is an isosceles trapezoid, and the four corners of the galvanometer main body are chamfered 13. The establishment of the chamfer is to reduce the weight of the main body of the galvanometer as much as possible, and the user can choose the weight of the main body of the galvanometer according to the speed requirement.

[0052] The thickness of the main body of the galvanometer with a trapezoidal cross-section is 1.2cm at the rotation axis, and the thickness of the corners gradually decreases to 0.2cm along the rotation axis to the left and right sides;

[0053] The main body of the vibrating mirror is a left-right symmetrical structure of the rotation axis, and the weight on the...

Embodiment 2

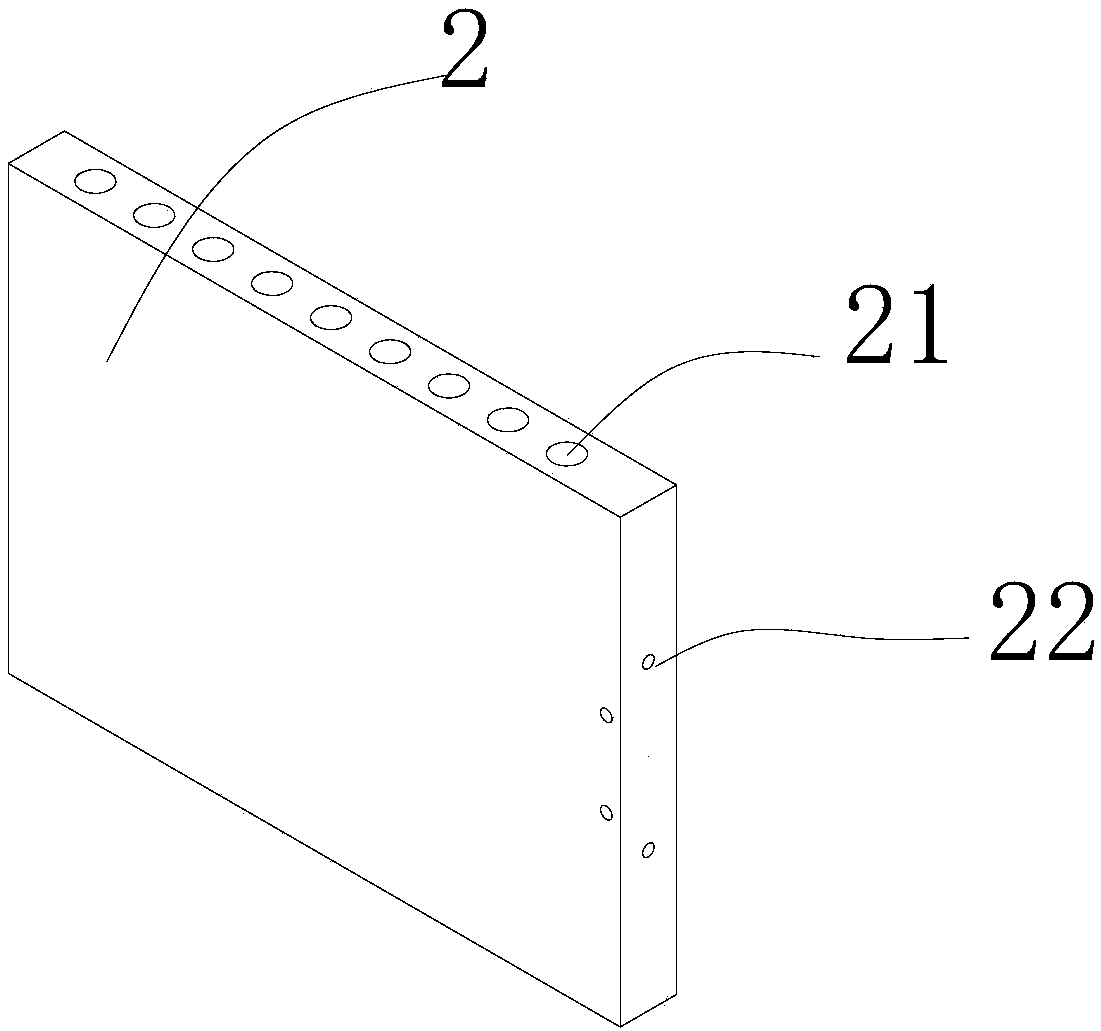

[0066] Such as image 3 As shown, a new type of vibrating mirror used in laser processing equipment, the main body of the vibrating mirror is a symmetrical structure, and the main body of the vibrating mirror 2 is in the shape of a rectangular sheet, such as Figure 4 As shown in , its cross-sectional area is rectangular, and the four corners of the main body of the vibrating mirror are all right angles.

[0067] The thickness of the main body of the galvanometer with a rectangular cross section is 1 cm;

[0068] The main body of the vibrating mirror is a left-right symmetrical structure of the rotation axis, and the weight on the left side is the same as that on the right side;

[0069] The vibrating mirror main body is provided with nine circular hollow holes 21, arranged in parallel from the left end of the vibrating mirror main body across the right end; the hollow holes are perpendicular to the axis of rotation;

[0070] The main body of the vibrating mirror is integral...

Embodiment 3

[0081] Such as Figure 5 As shown, a new type of vibrating mirror used in laser processing equipment, the main body of the vibrating mirror is a symmetrical structure, and the main body of the vibrating mirror 3 is in the shape of an arc sheet, such as Figure 6 As shown, its cross-sectional area is an arc surface, and the two corners on the main body of the galvanometer are chamfered 33 . The establishment of the chamfer is to reduce the weight of the main body of the galvanometer as much as possible, and the user can choose the weight of the main body of the galvanometer according to the speed requirement.

[0082] The thickness of the galvanometer body 3 with an arc-shaped cross section at the rotation axis is 1.2 cm, and the thickness of the corners gradually decreases to 0.2 cm along the rotation axis to the left and right sides;

[0083] The main body of the vibrating mirror is a left-right symmetrical structure of the rotation axis, and the weight on the left side is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com