Tight connecting device of glass tube and metal tube

A connection device and metal pipe technology, which is applied in the direction of pipeline connection arrangement, pipe/pipe joint/pipe fitting, heating device, etc., can solve the problems of complex production process of transition components, increased welding difficulty, poor corrosion resistance, etc., and can expand the working temperature. Scope and scope of use, improve heat collection efficiency and service life, and reduce the effect of production process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

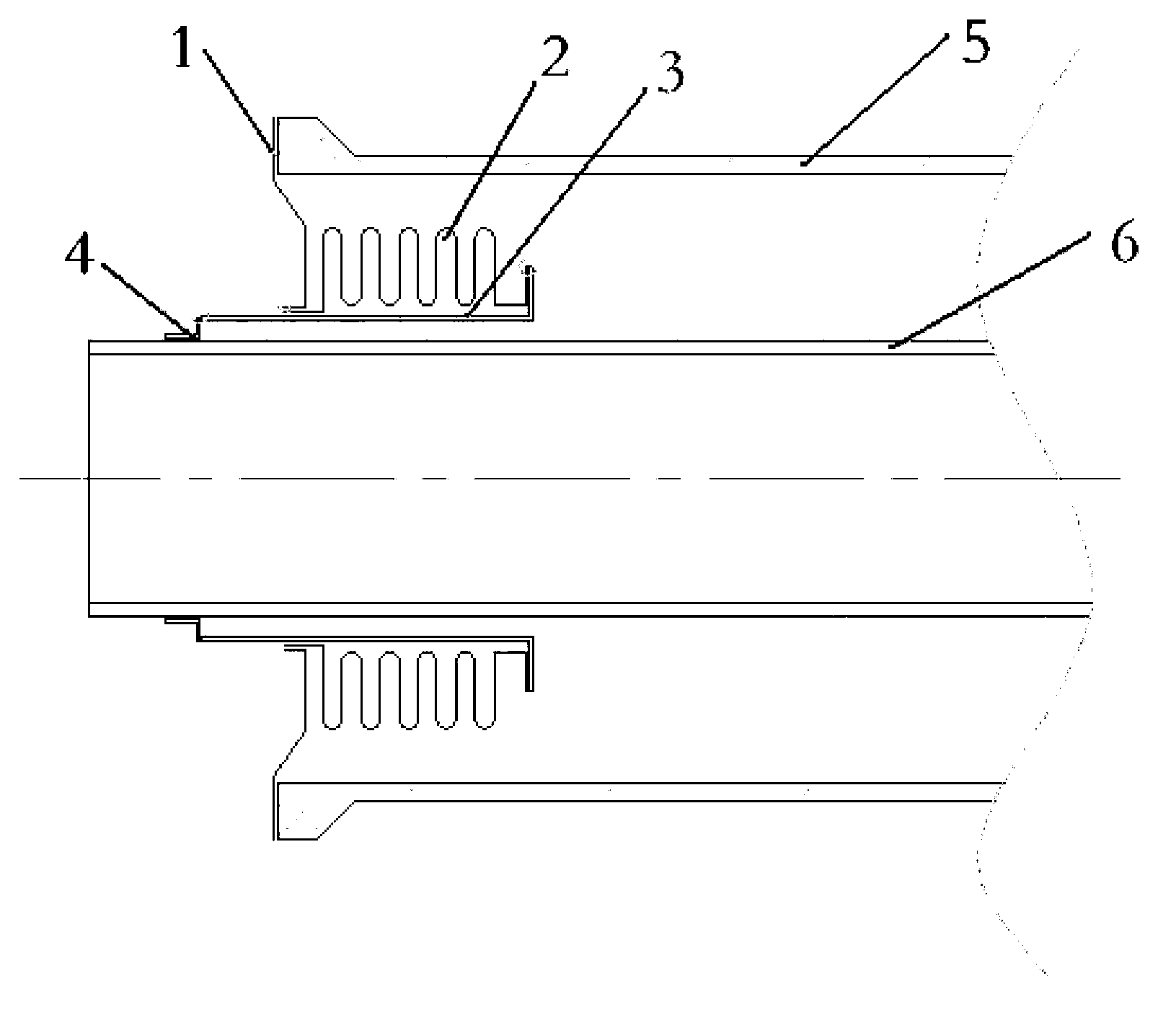

[0016] A glass tube and metal tube sealing connection device of the present invention, the metal tube 6 is sleeved in the glass tube 5, including the transition tube 3, the metal end cap 1 and the corrugated tube 2. The transition pipe 3 is sleeved outside the metal pipe 6 , one end of which is connected to the metal pipe 6 , and the other end is provided with an outer flange and extends into the glass pipe 5 . The metal end cap 1 is made of expanded alloy, which is set on the transition tube 3, and its outer peripheral edge is hot-press sealed to the nozzle end surface of the glass tube 5, and the inner peripheral edge of the metal end cap 1 is welded together with one end of the bellows. Polishing the metal end cap 1 can effectively improve the oxidation resistance, high temperature resistance and corrosion resistance of the end cap, and increase its service life.

[0017] The bellows 2 is set on the transition pipe 3 located inside the metal end cap 1, one end of which is w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com