High-nickel positive electrode material with primary particles being directionally arranged, and preparation method for high-nickel positive electrode material

A positive electrode material and directional arrangement technology, applied in battery electrodes, secondary batteries, electrical components, etc., can solve the problems of poor cycle performance of secondary particles, achieve high electrolyte corrosion resistance, reduce cracking, and long cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

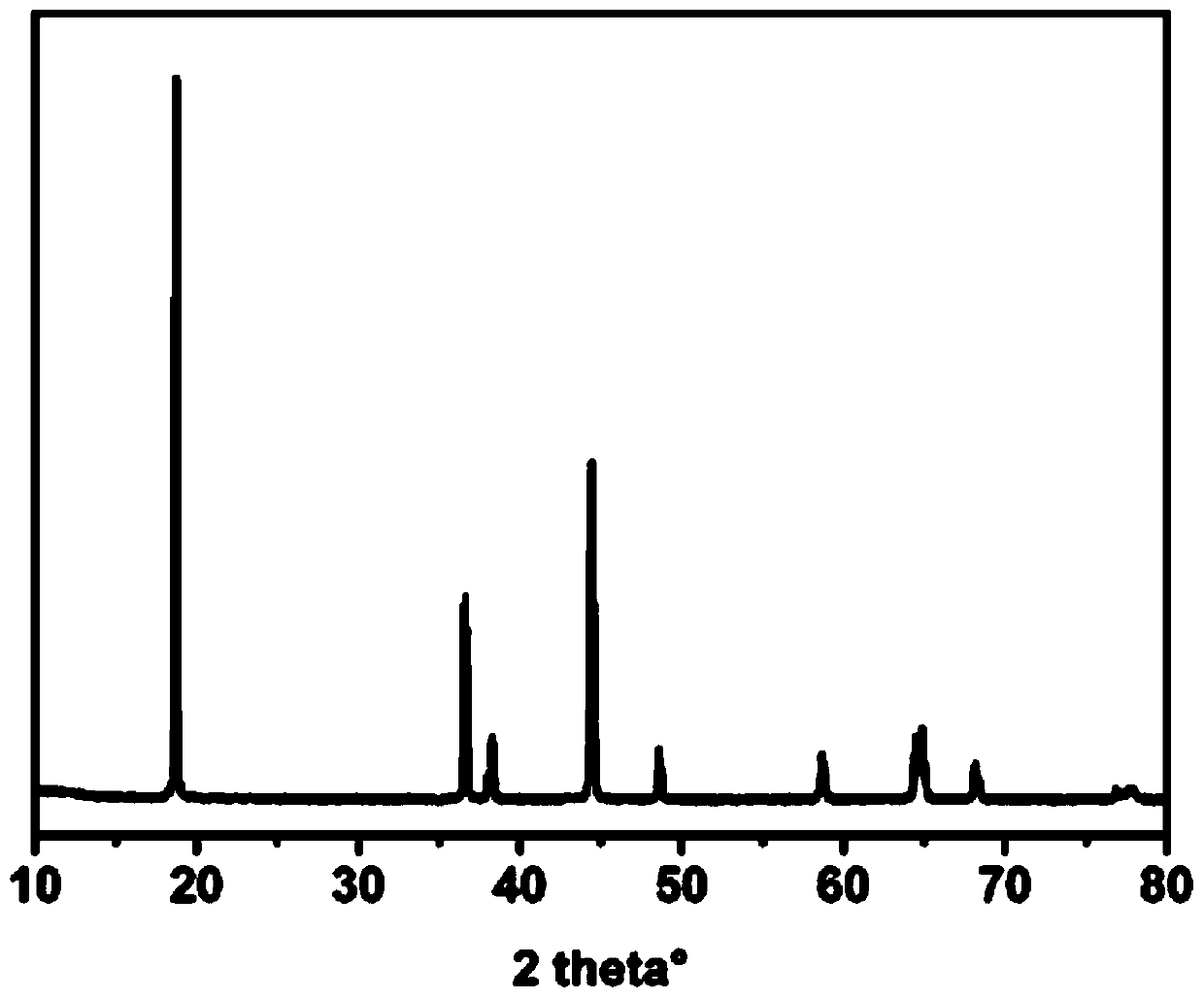

Embodiment 1

[0075] Add 1kg of the precursor Ni obtained by the co-precipitation method into the 50L reactor 0.88 Co 0.09 Mn 0.03 (OH) 2 , Add 476g lithium hydroxide monohydrate and 4.35g nano-magnesium oxide according to the molar ratio of lithiation coefficient 1:1.05, stir and mix for 20min, and wait until the materials are evenly mixed. Put it into a sagger, put in an oxygen atmosphere (oxygen concentration ≥80%), pre-sinter at 600°C, then heat up to 750°C for sintering, and cool to room temperature to obtain secondary particles in which the inner primary particles are radially oriented. Ultra-long cycle cathode material Li(Ni 0.88 Co 0.09 Mn 0.03 ) 0.99 Mg 0.01 O 2 .

Embodiment 2

[0077] Add 1kg of the precursor Ni obtained by the co-precipitation method into the 50L reactor 0.88 Co 0.09 Mn 0.03 (OH) 2 , Add 476g lithium hydroxide monohydrate and 3.76g nano diboron trioxide according to the molar ratio of lithiation coefficient 1:1.05, stir and mix for 20 minutes, and wait until the materials are evenly mixed. Put it into a sagger, put in an oxygen atmosphere (oxygen concentration ≥80%), perform pre-sintering at 600°C, then heat up to 760°C for sintering, and cool to room temperature to obtain secondary particles in which the inner primary particles are radially aligned. Ultra-long cycle cathode material Li(Ni 0.88 Co 0.09 Mn 0.03 ) 0.99 B 0.01 O 2 .

Embodiment 3

[0079] Add 1kg of the precursor Ni obtained by the co-precipitation method into the 50L reactor 0.60 Co 0.20 Mn 0.20 (OH) 2 , Add 835.28g of lithium carbonate and 15.65g of molybdenum oxide according to the molar ratio of lithiation coefficient of 1:1.04, stir and mix for 20 minutes, and wait until the materials are evenly mixed. Put it into a sagger, put in an oxygen atmosphere (oxygen concentration ≥80%), perform pre-sintering at 600°C, then heat to 800°C for sintering, and cool to room temperature to obtain secondary particles in which the inner primary particles are radially aligned. Ultra-long cycle cathode material Li(Ni 0.88 Co 0.09 Mn 0.03 ) 0.99 Mo 0.01 O 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com