Prefabricated hollow slab

A hollow-core slab and hollow-core technology, which is applied to building components, buildings, building structures, etc., can solve problems such as low construction efficiency and difficulty in ensuring the quality of prefabricated hollow-core slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

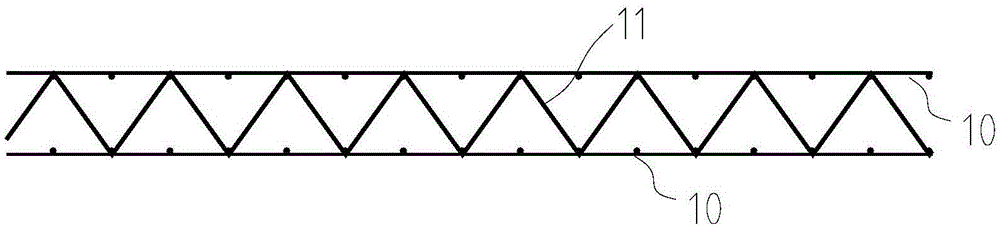

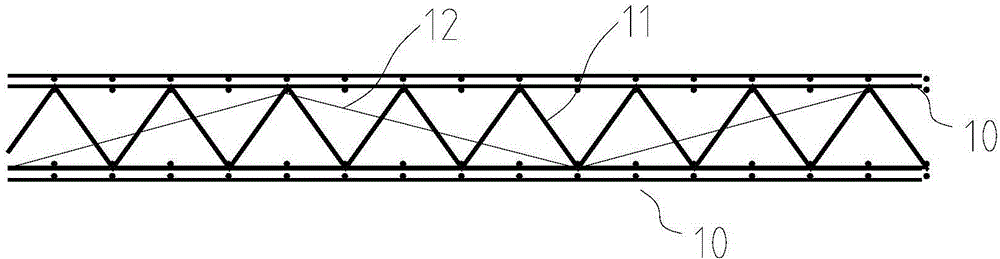

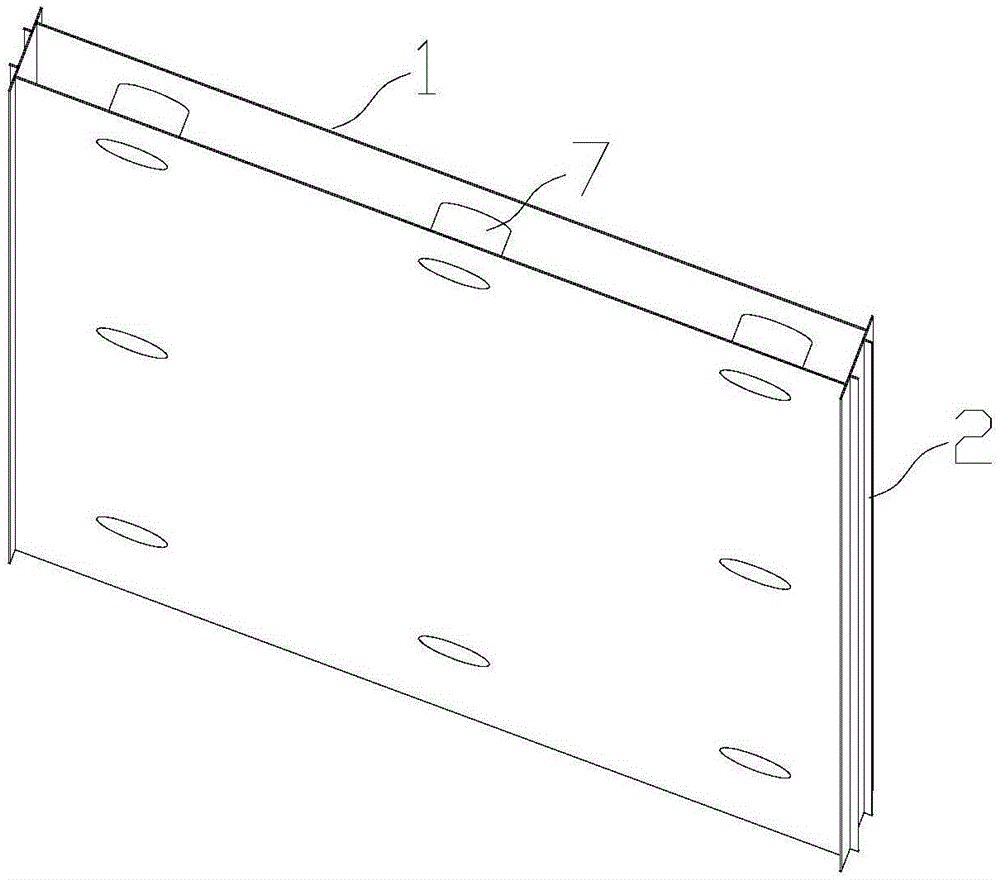

[0053] Embodiments of the present invention are as follows, see Figure 3 to Figure 14 , a prefabricated hollow slab, including a top layer 110 and a bottom layer 120, and a hollow device arranged between the top layer 110 and the bottom layer 120, the prefabricated hollow slab also includes a special network frame for the prefabricated hollow slab, and the special network frame for the prefabricated hollow slab It includes two meshes 10 arranged at intervals, at least one rib 11 perpendicular to the mesh is arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com