Method for preparing electrical insulating papers containing broadleaf wood fibers

An electrical insulation and hardwood technology, applied in the field of electrical insulation paper, can solve problems such as unspecified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

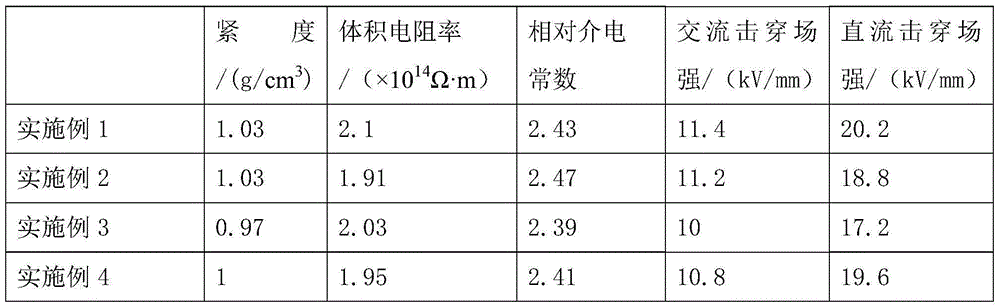

Examples

preparation example Construction

[0014] The preparation method of the electric insulating paper that the present invention proposes contains hardwood fiber, comprises the following steps:

[0015] (1) Under ambient temperature, submerge the softwood pulp dry board and the hardwood pulp dry board in deionized water for 12 hours, respectively, to obtain a softwood pulp wet board and a hardwood pulp wet board;

[0016] (2) Utilize beater, respectively or mix above-mentioned coniferous wood pulp wet pulp board and broad-leaved wood pulp wet pulp board to decompose, beating, beating concentration is 0.5%~2%, and beating time is 5 minutes~25 minutes, makes pulp The Schober beating degree of material is 10 ° SR~45 ° SR, obtains pulp suspension, the mass ratio in the suspension is, softwood pulp fiber: hardwood pulp fiber=1:(0.1~1);

[0017] (3) According to the quantitative size of the paper sheet, take the above-mentioned pulp suspension and put it into the paper sheet forming equipment for dehydration forming to o...

Embodiment 1

[0023] (1) Under ambient temperature, immerse softwood pulp dry pulp board in deionized water for 12 hours to obtain softwood pulp wet pulp board;

[0024] (2) Utilize beater, above-mentioned coniferous wood pulp wet pulp plate is loosened, beating, and beating concentration is 0.5%, and beating time is 25 minutes, and the Schober beating degree of slurry is 40 ° of SR;

[0025] (3) Paper weight 490g / m 2 , take 12L of the above pulp suspension, put it into the paper forming equipment for dehydration forming, and obtain the electrical insulating paper of the required specification;

[0026] (4) Carry out hot-pressing treatment to above-mentioned insulating wet paper, hot-pressing pressure is 500N / cm 2 , the hot-pressing temperature is 115° C., and the hot-pressing time is 5 minutes to obtain a finished product of electrical insulating paper after hot-pressing and drying.

[0027] (5) The finished electrical insulating paper prepared above is stored in a constant temperature a...

Embodiment 2

[0030] (1) Under ambient temperature, submerge the softwood pulp dry board and the hardwood pulp dry board in deionized water for 12 hours, respectively, to obtain a softwood pulp wet board and a hardwood pulp wet board;

[0031] (2) Utilize beater, carry out disentanglement, beating to above-mentioned coniferous wood pulp wet pulp board and hardwood pulp wet pulp board respectively, coniferous wood pulp beating concentration is 0.5%, and beating time is 25 minutes, and the Shober beating of slurry The beating degree of hardwood pulp is 40°SR; the beating concentration of hardwood pulp is 0.5%, the beating time is 21.5 minutes, and the Schober beating degree of pulp is 38°SR. Then softwood pulp beating liquid and hardwood pulp beating liquid are mixed, mixing mass ratio is: softwood pulp fiber: hardwood pulp fiber=1:0.11, stirs evenly, obtains pulp suspension;

[0032] (3) Paper weight 490g / m 2 , take 12L of the above pulp suspension, put it into the paper forming equipment f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com