Reducing furnace, and technology for directly reducing coal-containing pellets through preheating outside coal base

A reduction furnace and process technology, applied in the field of reduction furnace and coal-based external preheating coal-containing pellets direct reduction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

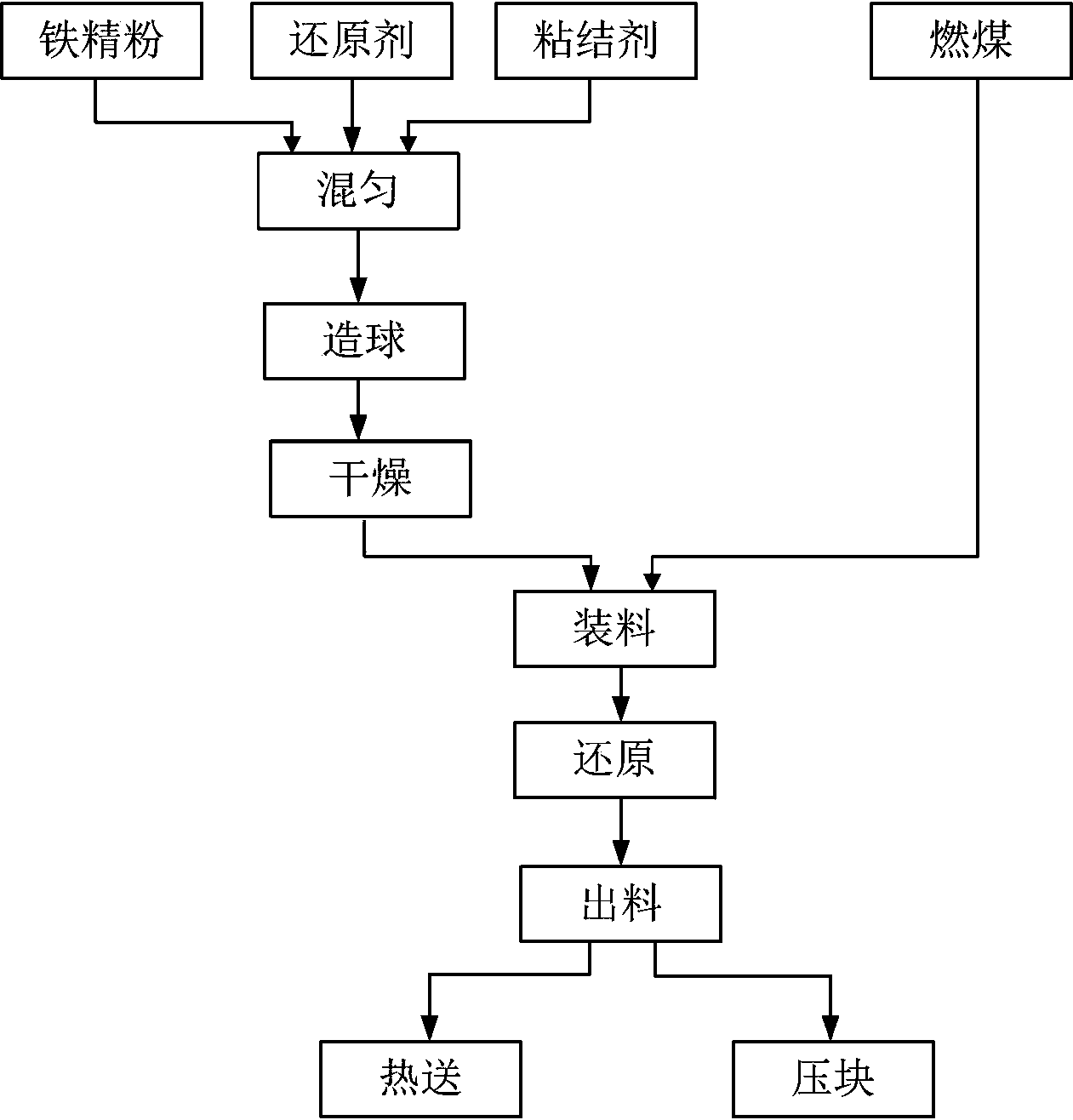

Method used

Image

Examples

Embodiment 1

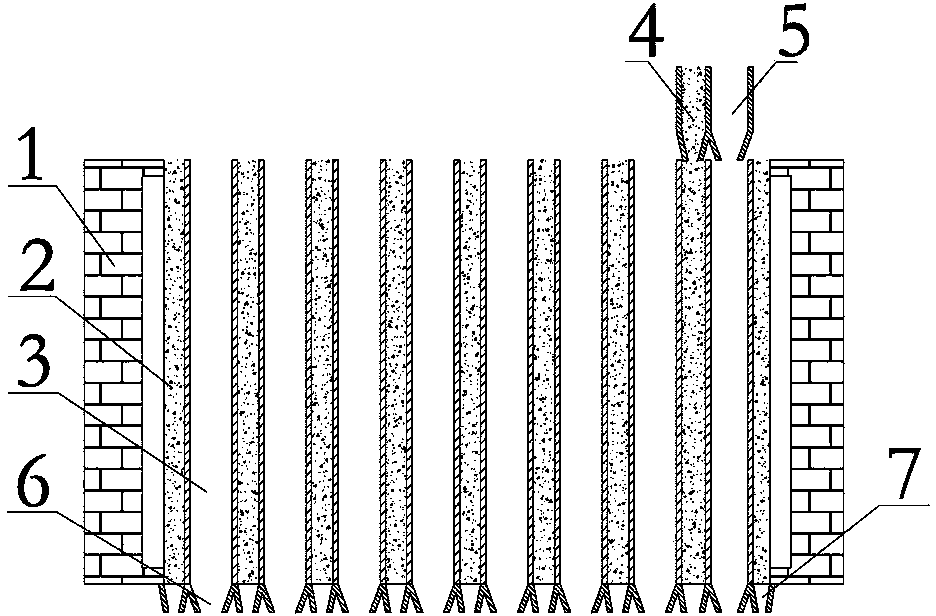

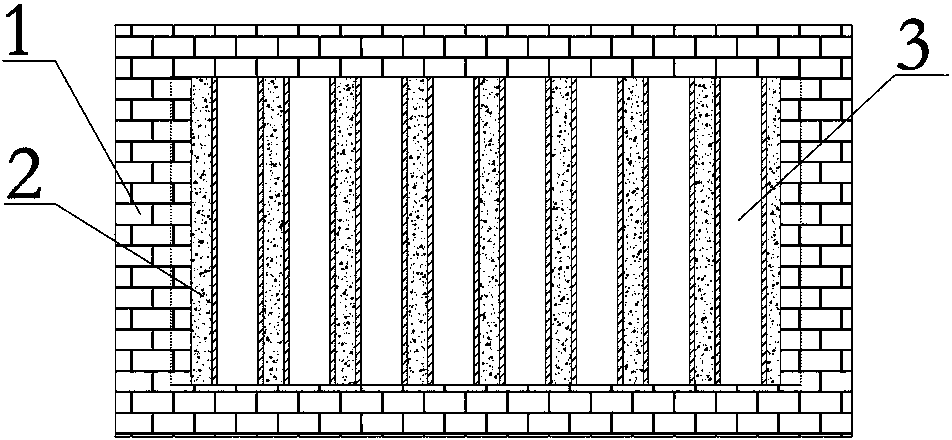

[0035] Such as Figure 1 to Figure 2 As shown, it is the reduction furnace provided by Embodiment 1 of the present invention, which includes a furnace wall 1 , a plurality of reduction tanks 3 , and a plurality of combustion tanks 2 . A plurality of reduction tanks 3 and a plurality of combustion tanks 2 are arranged alternately. The top end of each reduction tank 3 is connected with a raw material feeding device 5 , and the bottom end of each reduction tank 3 is provided with a discharge port 6 . The top of each combustion pot 2 is connected with a fuel feeding device 4 , and the bottom end of each combustion pot 2 is provided with an ash outlet 7 . The number of reduction tanks and combustion tanks can be set according to the annual production requirements.

[0036] In this embodiment, the cross-sections of each reduction tank 3 and each combustion tank 2 are quadrangular, and multiple reduction tanks 3 and multiple combustion tanks 2 are arranged alternately along the hor...

Embodiment 2

[0048] Such as Figure 4 with Figure 5 As shown, it is the reduction furnace provided in Embodiment 2 of the present invention, which is roughly the same as Embodiment 1, except that the cross sections of reduction tank 3 and combustion tank 2 are both ring-shaped, and multiple reduction tanks 3 and multiple combustion tanks Tanks 2 are concentrically arranged alternately. Feeding adopts the way of feeding tank and distribution chute, adding coal and pellets in batches.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com