wind power equipment

A technology for wind power generation equipment and generators, which is applied to planetary gear transmissions and shafts of planetary gear transmissions. It is manufactured and used in the field of wind power generation equipment transmissions. It can solve problems such as denseness and cost, and avoid position loss and simplify Maintenance and time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

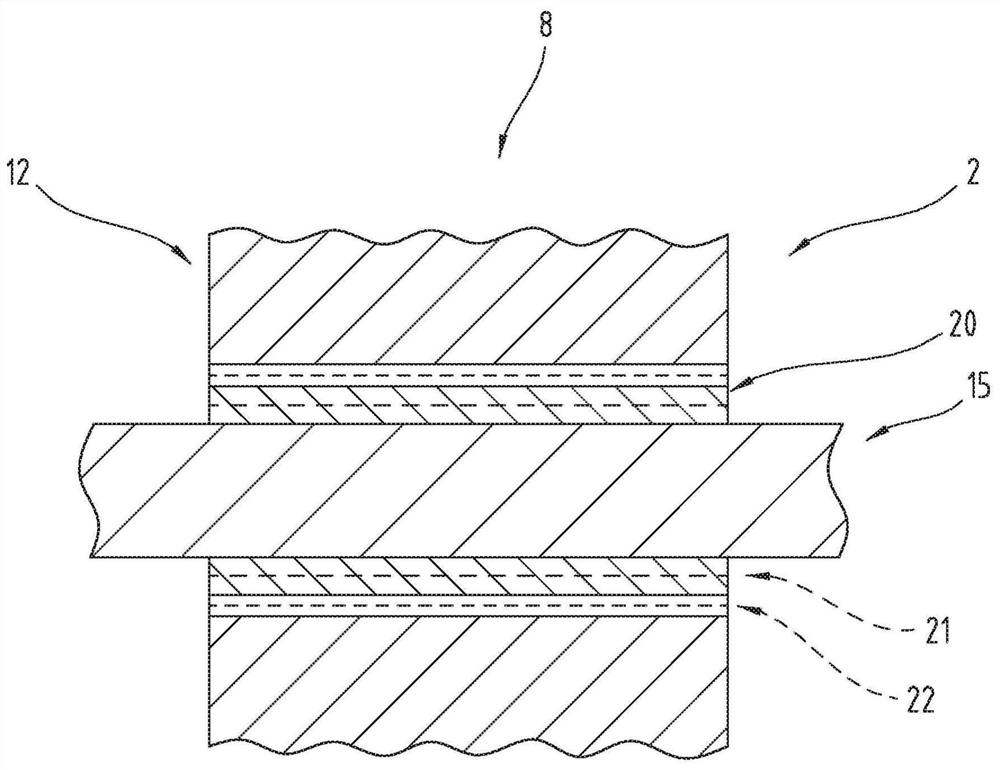

[0023] At the outset, it should be pointed out that the same reference numerals or the same component designations are used for the same components in different embodiments, wherein the disclosure content contained in the entire description can be referred to the components with the same reference numerals or the same component designations. Likewise, selected positions in the description such as above, below, side, etc. relate to the direct description and to the illustrated figures and, if the position is changed, are automatically transferred to the new position.

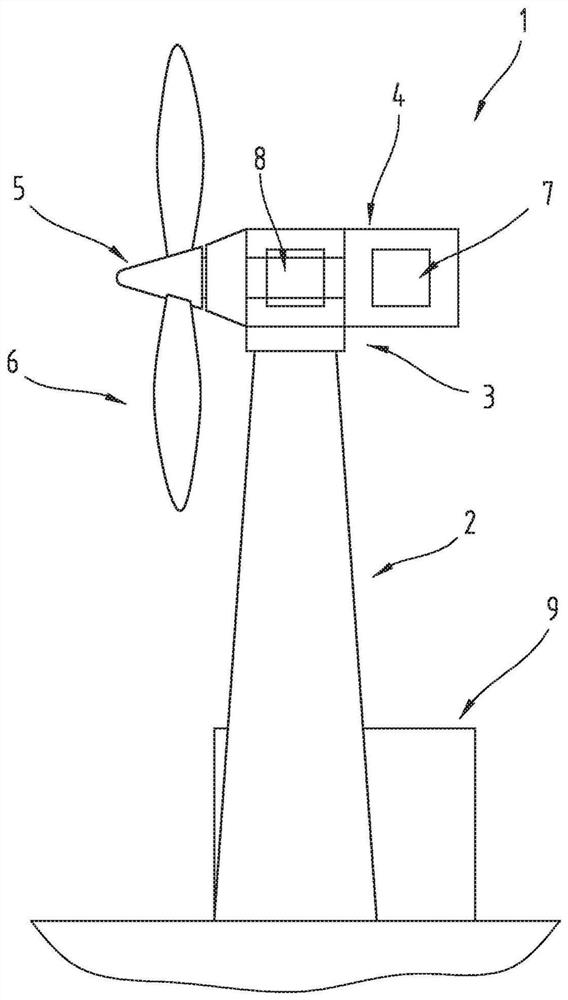

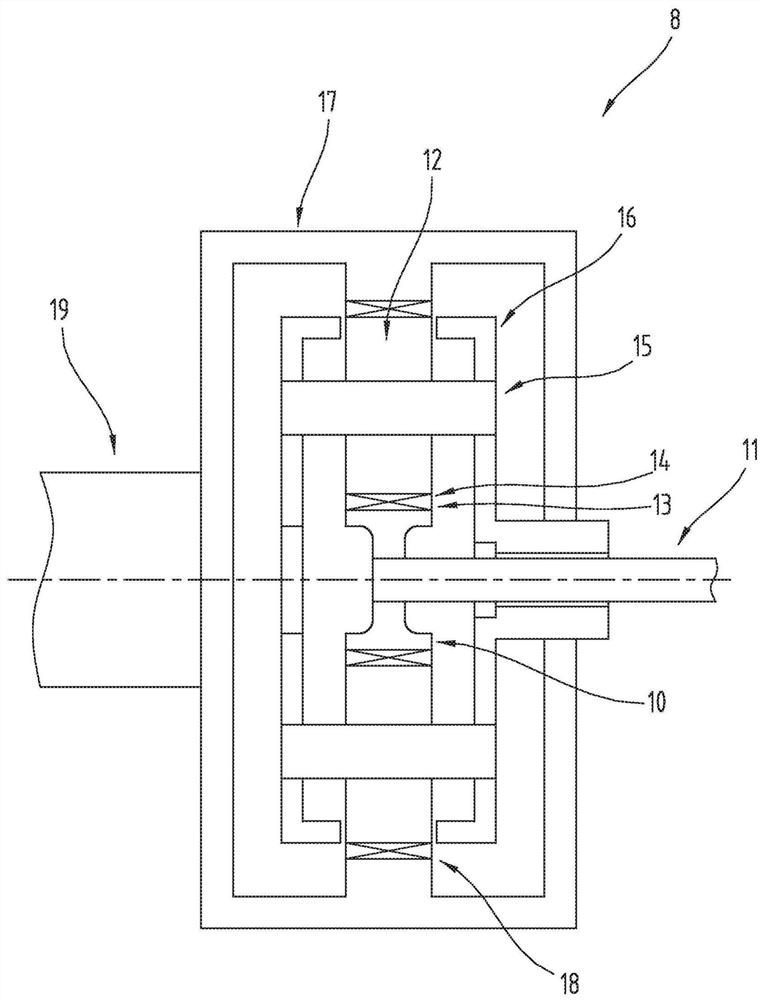

[0024] figure 1 A wind power plant 1 is shown. The wind power plant 1 corresponds in principle to the prior art, that is to say it comprises a tower 2 on which a nacelle 4 is arranged with a wind direction tracking device 3 connected in between, at the front of the nacelle a rotor with rotor blades 6 is arranged 5 and is provided with generator 7 at its rear end. Between the rotor 5 and the generator 7 , ie the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com