Method and device for purifying and activating industrial silicon microsilica fume

A technology of micro-silica fume and industrial silicon, applied in silicate, silicon oxide, silicon dioxide and other directions, can solve the problems of products with peculiar smell, difficult to filter, low concentration of water glass liquid, etc. Avoid the effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

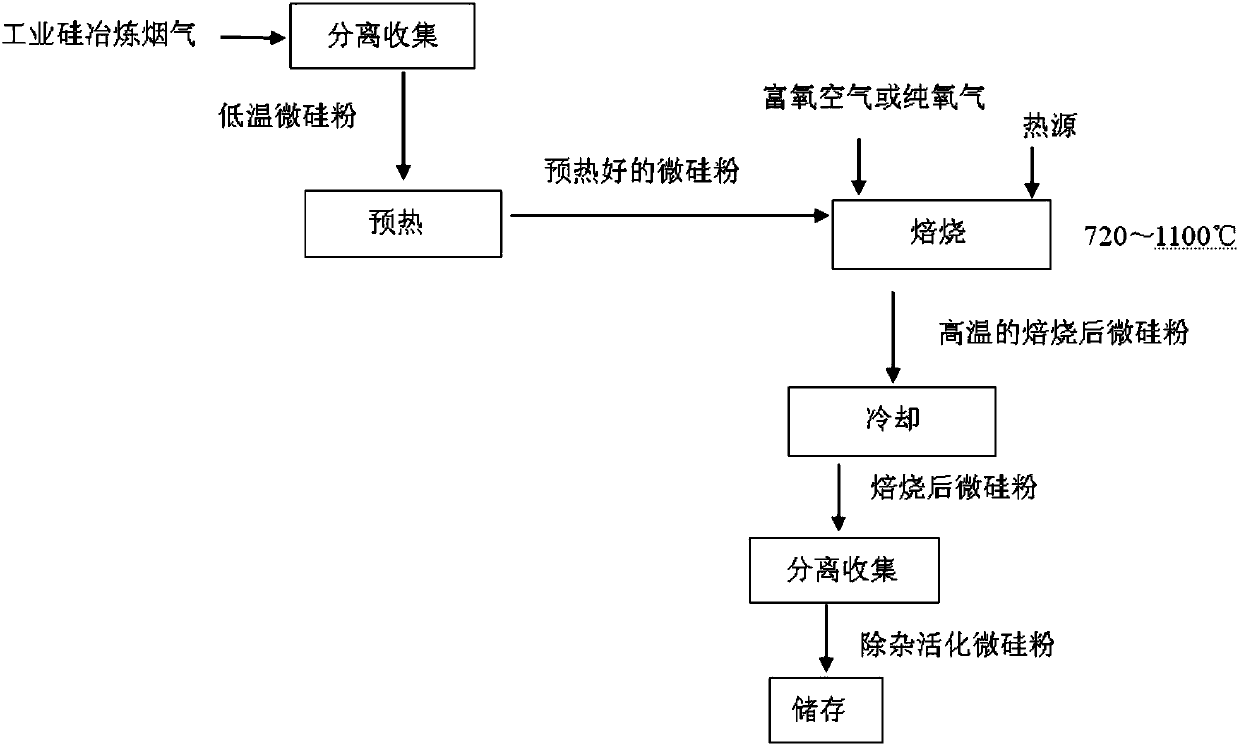

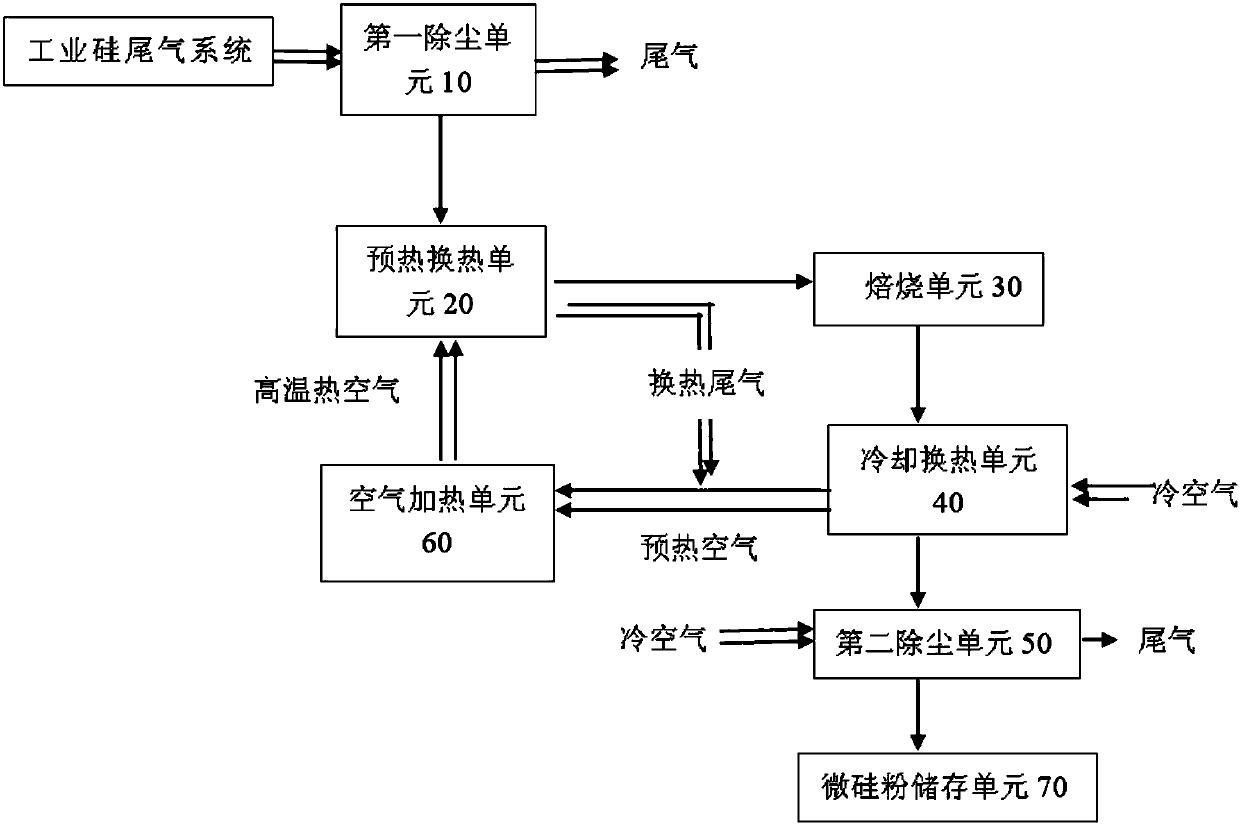

Method used

Image

Examples

Embodiment 1

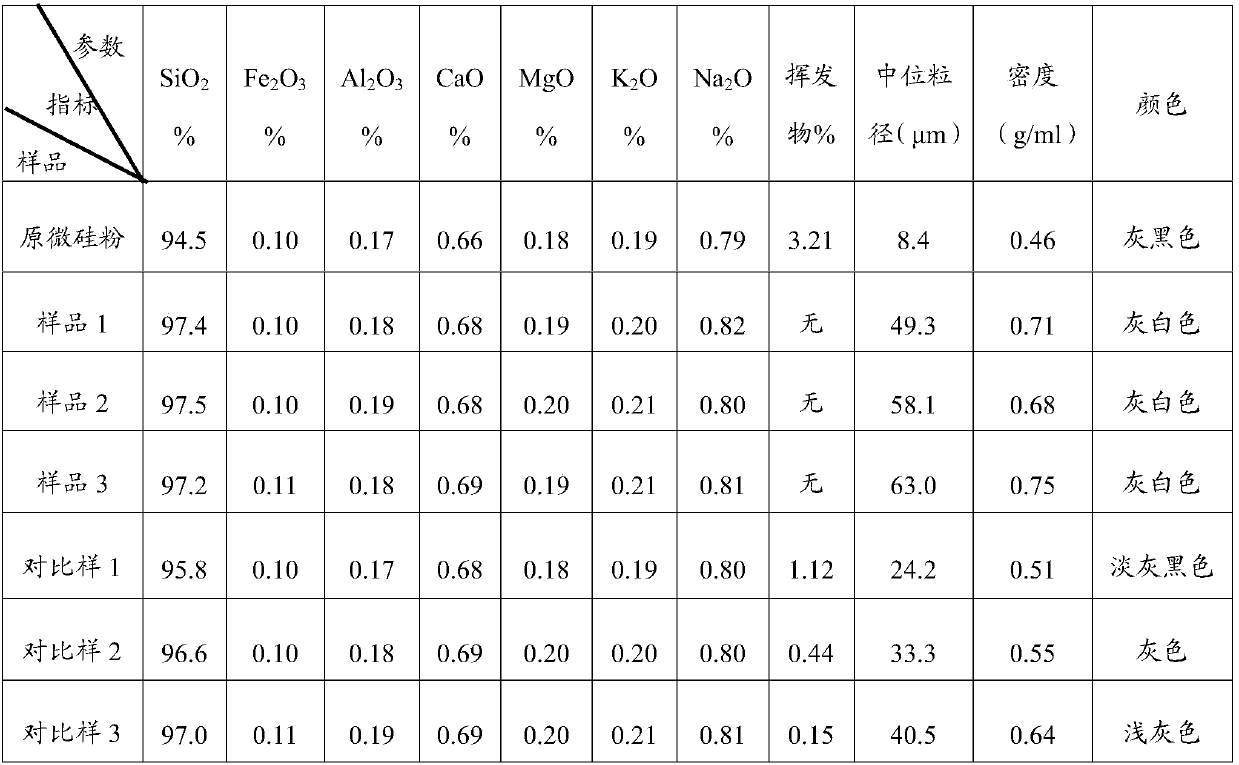

[0048] The gray-black micron-sized silicon powder (185°C) is separated and collected from the industrial silicon smelting flue gas by a bag filter; the micro silicon powder is preheated to 580°C by a heat pipe heat exchanger; then the preheated micro silicon The powder is sent to the electric heating high-temperature rotary roasting unit with three-stage temperature of 850℃, 880℃ and 920℃, and oxygen-enriched air is introduced. The number of revolutions of the rotary roaster and the length of the rotary roaster are adjusted to keep the micro silicon powder in the furnace. Mid-radial turning and axial movement to ensure that the micro-silica powder is in full contact with oxygen-enriched air, and control the time from entering the rotary roasting furnace to discharging the micro-silica powder to 23 minutes; after high-temperature roasting under dynamic conditions, the material is discharged and enters the air cooler Cooling; and then separated by bag filter to obtain sample 1 of ...

Embodiment 2

[0050] The gray-black micron-sized silicon powder (194℃) is separated and collected from the industrial silicon smelting flue gas by the bag filter; the micro silicon powder is preheated to 600℃ by the heat pipe heat exchanger; and then the preheated micro silicon The powder is fed into a natural gas-heated high-temperature rotary roaster at 880℃; pure oxygen is fed into the rotary roaster and the rotation of the rotary roaster is adjusted and the length of the rotary roaster is controlled to keep the micro-silica powder turning radially and moving axially in the furnace. Ensure that the micro-silica powder is in full contact with the oxygen-enriched air, and control the time from entering the rotary roasting furnace to discharging the micro-silica powder to 28 minutes; after being roasted at a dynamic high temperature, it is discharged and cooled in the air cooler; and then separated by a bag filter Removal of impurities and activated micro-silica fume sample 2. The entire pro...

Embodiment 3

[0052] The gray-black micron-size micro-silica powder (202℃) separated and collected from the industrial silicon smelting flue gas by a bag filter; preheat the micro-silica powder to 650℃ through a heat pipe heat exchanger; then the preheated micro-silicon The powder is fed into a natural gas-heated high-temperature rotary roasting furnace at 950℃; oxygen-enriched air is introduced, and by adjusting the number of revolutions of the rotary roasting unit and controlling the length of the rotary roasting furnace, the micro-silica powder is kept radially turned and axially turned in the furnace Move to ensure that the micro-silica powder is in full contact with oxygen-enriched air, and control the time from entering the rotary roasting furnace to discharging the micro-silica powder to be 20 minutes; after roasting under dynamic high temperature, it is discharged and enters the air cooler for cooling; and then passes through the bag filter Separate and obtain sample 3 of impurity rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com