Method for repairing cracks of circular saw blade through welding

A welding repair and circular saw blade technology is applied in the tool dressing, welding medium, welding equipment and other directions of the sawing machine device, which can solve the problem of poor weldability of carbon tool steel, alloy tool steel and spring steel, and inconvenience and troublesome repair of circular saw blades. , circular saw blade welding to repair cracks and other problems, to achieve the effect of low welding repair cost, saving welding material consumption, and reducing welding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

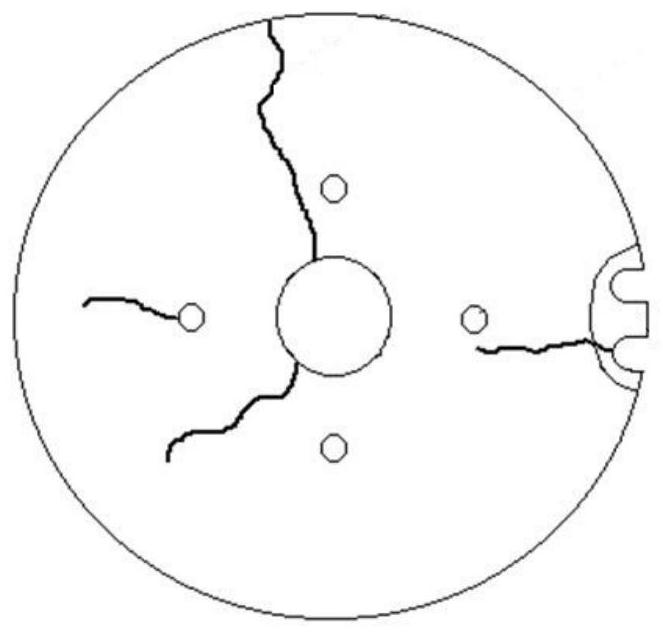

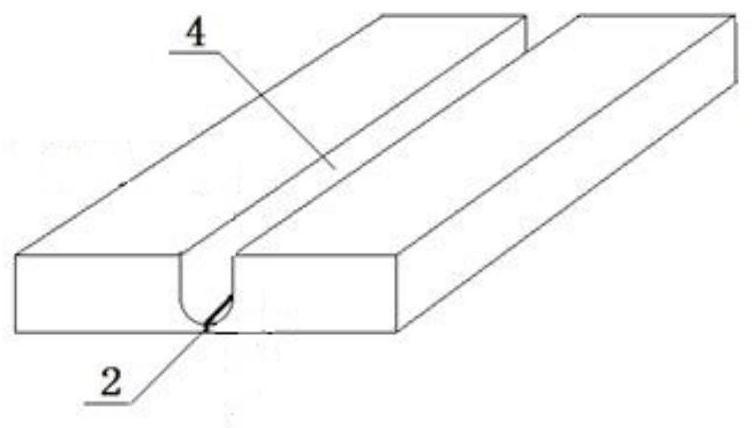

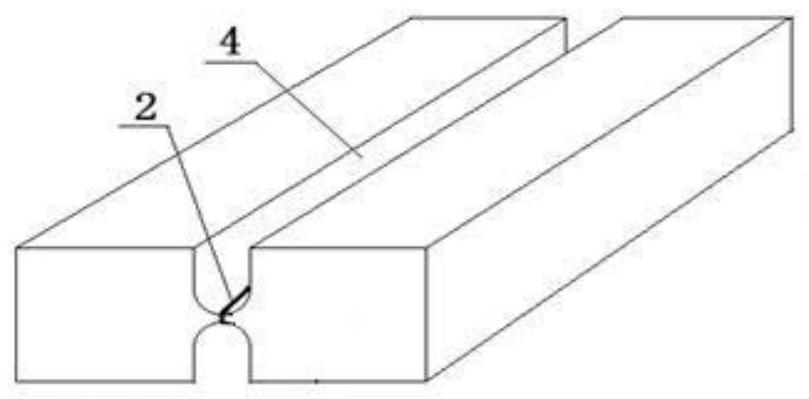

[0042]SeeFigures 2 to 11 In the present embodiment, the circular saw blade 1 thickness is 6 mm, the diameter φ2200 mm, the material is carbon tool steel, and the crack 2 shown is cracked during the graft of the circular saw blade, and the crack direction is irregular.

[0043]Welding repair method for circular saw cracks, according to the following steps:

[0044]Welding method: use DC welding machine to reverse the polarity manual arc welding.

[0045]Welding material: use the low hydrogen type of the weld metal and the saw blade metal, high toughness flat welding strip 10, the flat welding strip weld metal tensile strength 830 MPa, the electrode is 2mm × 4mm, the electrode has good Welding process performance and crack resistance, drying temperature 300 ° C before welding, heat insulation, then put it in the thermal insulation barrel.

[0046](1) Reprinches oil: Wire wire brush to clear the circular saw blade 1 to 100 mm in the range of 100 mm in the range of 100 mm, without rust, etc., the d...

Embodiment 2

[0062]SeeFigures 2 to 13In the present embodiment, the circular saw blade 1 thickness is 10 mm, the diameter φ3600mm, the material is alloying tool steel, and the crack 2 shown is cracked during the quenching process of the circular saw blade, and the crack direction is irregular.

[0063]Welding repair method for circular saw cracks, according to the following steps:

[0064]Welding method: use DC welding machine to reverse the polarity manual arc welding.

[0065]Welding material: use a low hydrogen type with a weld metal and a saw blade metal, a high toughness flat welding strip 10, a flat-shaped electric welding strip welded metal tensile strength of 850 MPa, the electrode specification is 2mm × 4 mm, which has good Welding process performance and crack resistance, drying temperature 300 ° C before welding, heat insulation, then put it in the thermal insulation barrel.

[0066](1) Reprinches oil: The steel wire brush is used to clean the circular saw 1 crack 2 peripheral to clean, and there...

Embodiment 3

[0084]In the present embodiment, the circular saw blade is 8mm, the diameter is φ3000mm, the material is spring steel, the groove opening width is 6mm, the thickness of the slope is 1.5 mm, and the tensile strength is 800MPa, the electrode is 2mm × 4 mm flat electric welding strip, according to the Example 2 Method was carried out by a circular saw crack, and it was qualified by the weld inspection.

[0085]In summary, the above process method has been used, and the welding repair of circular saw blades has been well used in production. Practice has proved that the welding repair is 100%, but sometimes it is 100% in accordance with the operation of this process. Since the welder will have a defect of welding bite, if it is discovered early, it can be soldered immediately to make up the error, and it will not affect the repair quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com