Environment-friendly aggregate series mobile crushing station

A mobile, crushing station technology, applied in grain processing, etc., can solve the problems of single and unchangeable crushing scheme, occupying a large working space, fixed equipment layout and cannot be moved, etc., to achieve direct and effective logistics transfer, convenient and reasonable installation and maintenance, and excellent The effect of broken product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

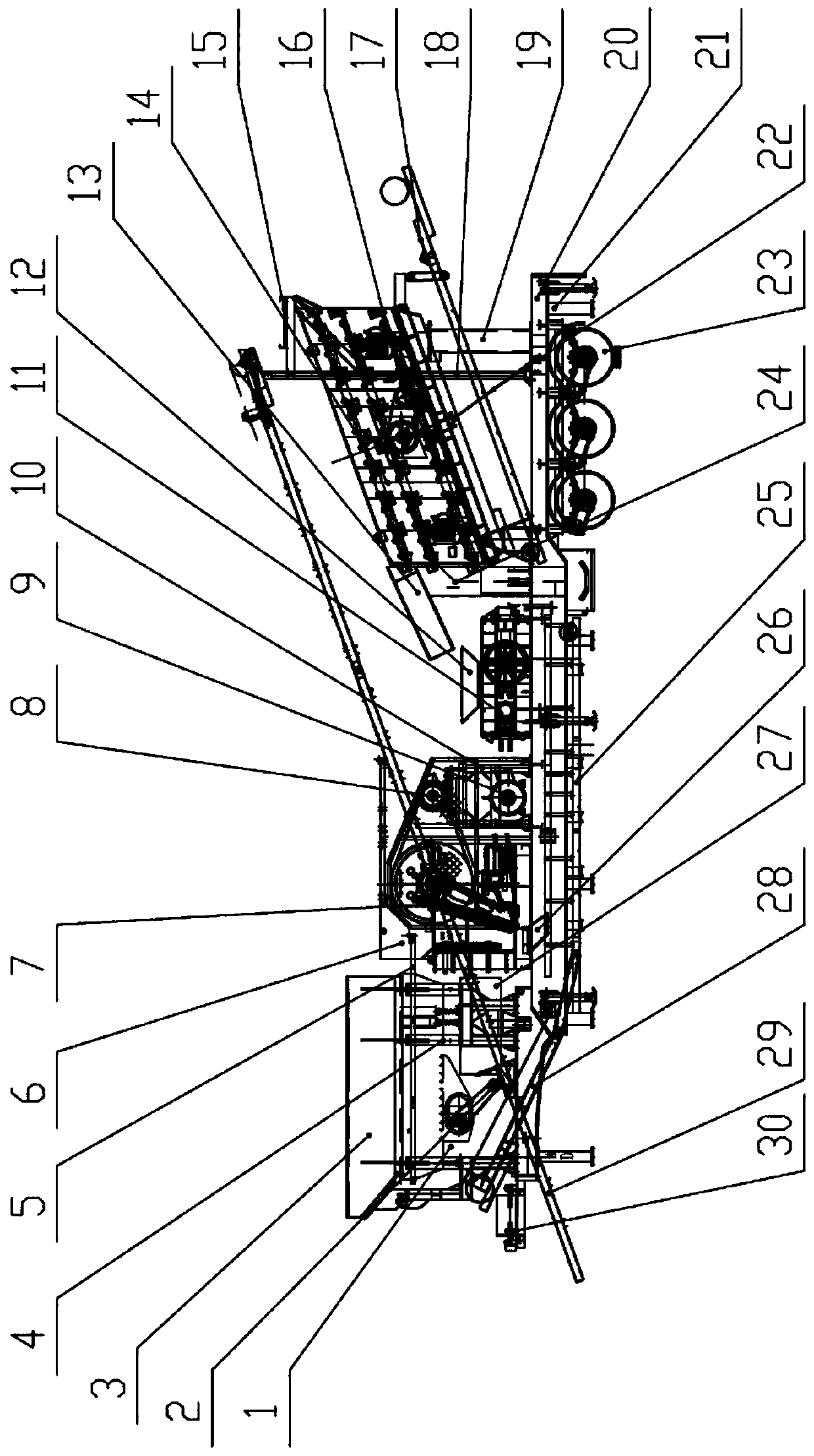

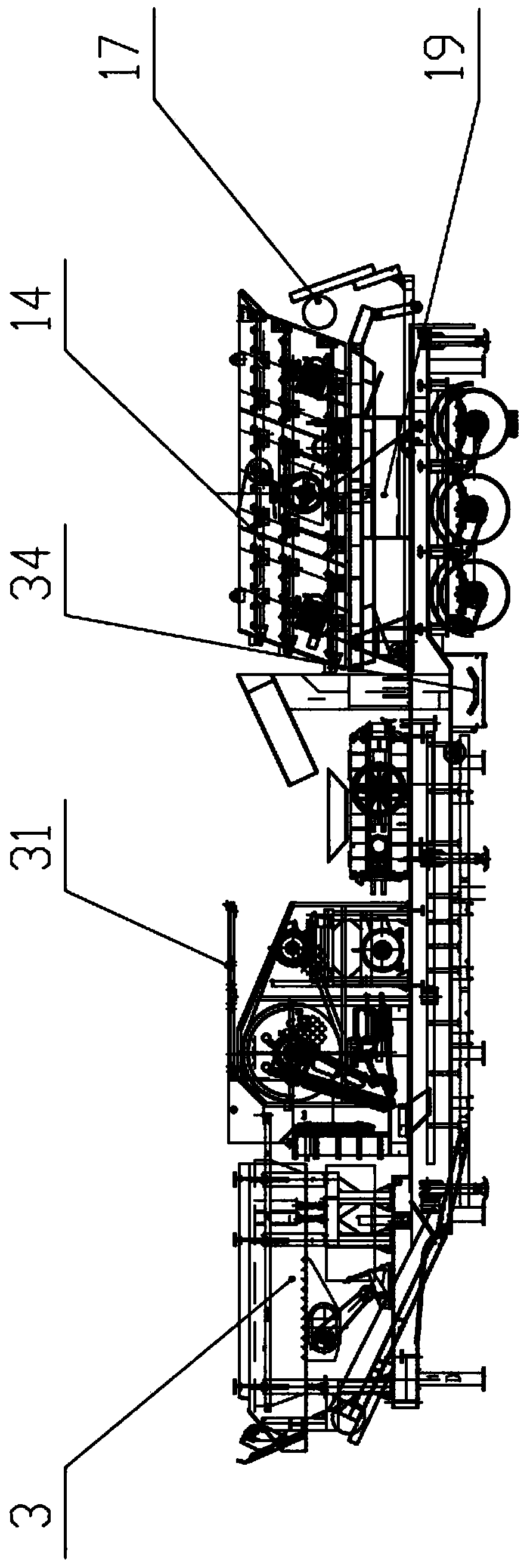

[0029] see figure 1 , the invention discloses a series of mobile crushing stations for environmental protection aggregates. As shown in the figure: it includes vibrating feeding equipment 1, primary crushing equipment 7, secondary crushing equipment 11 and vibrating screening equipment 14 arranged from front to back. The discharge port 5 of the vibrating feeding device 1 corresponds to the feed hopper 6 of the primary crushing device 7, and the non-finished product discharge hopper 13 of the vibrating screening device 14 corresponds to the feed hopper 12 of the secondary crushing device 11; the first The belt conveyor 25 is arranged through the outlet of the primary crushing equipment 7 and the outlet of the secondary crushing equipment 11, and the first belt conveyor 25 and the subsequent belt conveyors 28 and 29 connected thereto are further connected to the feed inlet of the vibrating screening equipment 14 ; The finished product outlet of the vibrating screening equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com