Workpiece surface roughness control method and device and numerical control machining equipment

A technology of surface roughness and workpiece surface, which is applied in the field of workpiece surface roughness control and CNC machining equipment, can solve the problems such as the inability to accurately control the workpiece surface roughness, achieve precise control of the workpiece surface roughness, reduce labor time consumption, The effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

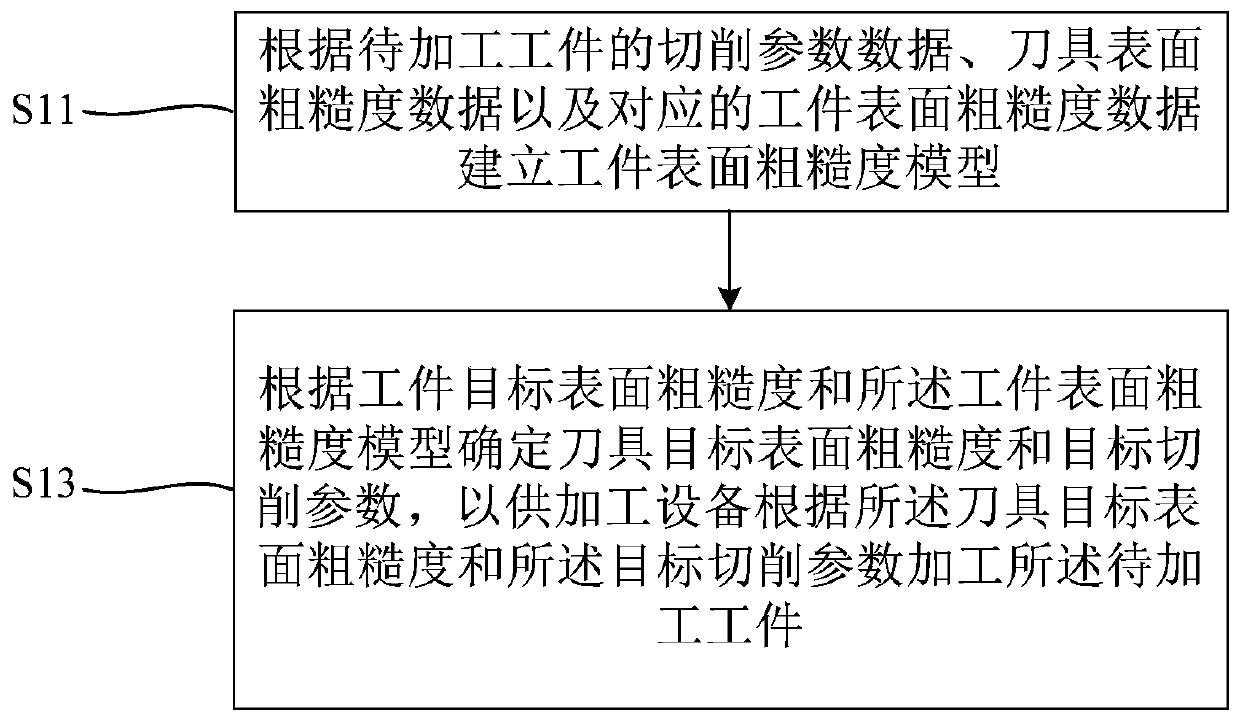

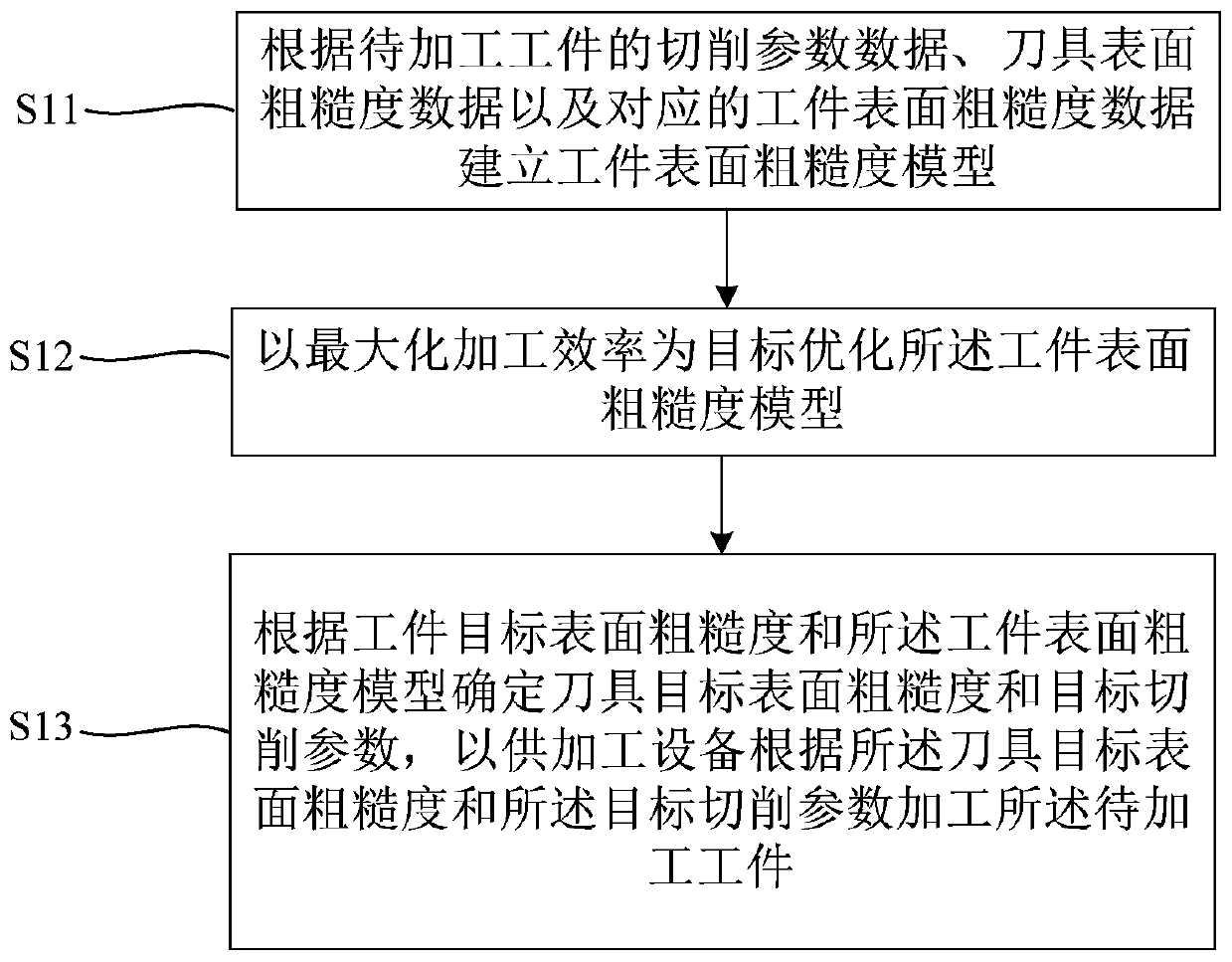

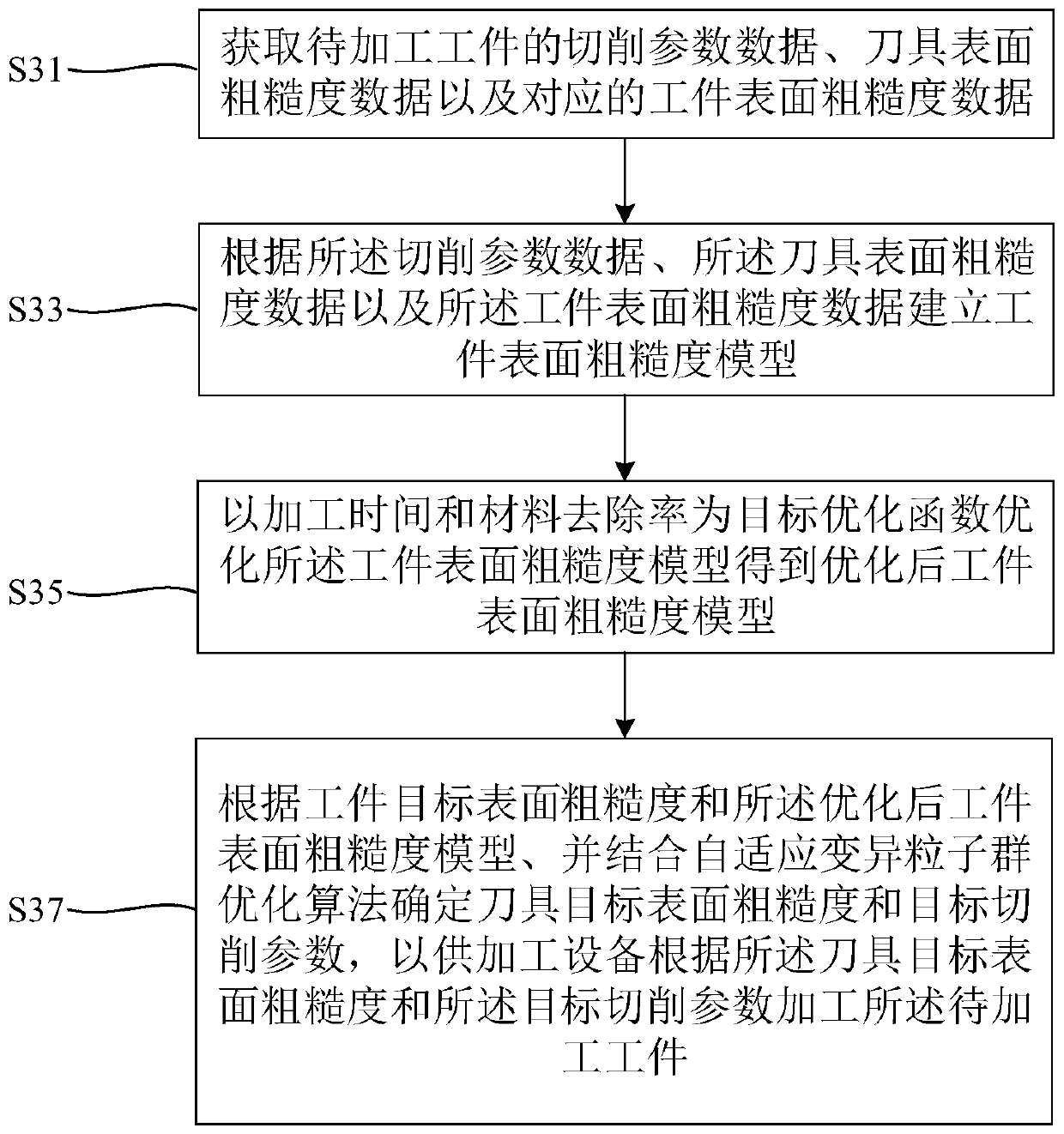

[0029] See Figure 1a , Which is a schematic flowchart of a method for controlling the surface roughness of a workpiece according to the first embodiment of the present invention. Such as Figure 1a As shown, the method for controlling the surface roughness of a workpiece provided by the embodiment of the present invention includes the steps:

[0030] S11: Establish a workpiece surface roughness model based on the cutting parameter data, tool surface roughness data and corresponding workpiece surface roughness data of the workpiece to be processed;

[0031] S13: Determine the target surface roughness and target cutting parameters of the tool according to the target surface roughness of the workpiece and the surface roughness model of the workpiece, so that the processing equipment can process the target surface roughness of the tool and the target cutting parameters. Workpiece to be processed.

[0032] In order to facilitate the understanding of the method for controlling the surfac...

no. 2 example

[0127] Such as Figure 6a As shown, the second embodiment of the present invention provides a device 100 for controlling the surface roughness of a workpiece. The workpiece surface roughness control device 100 includes, for example:

[0128] The roughness model establishment module 110 is used to establish a workpiece surface roughness model according to the cutting parameter data of the workpiece to be processed and the tool surface roughness data;

[0129] The target parameter determination module 130 is used to determine the target surface roughness and target cutting parameters of the tool according to the target surface roughness of the workpiece and the workpiece surface roughness model, so that the processing equipment can process the workpiece to be processed according to the target surface roughness of the tool and the target cutting parameters. A surface with target surface roughness. Specifically, the target parameter determination module determines the target surface r...

no. 3 example

[0133] Such as Figure 7 As shown, the third embodiment of the present invention provides a numerical control processing device 500. The numerical control processing equipment 500 is, for example, a five-axis linkage numerical control machine tool, and includes, for example, an equipment main body 510 and a controller 530.

[0134] The device main body 510 may include, for example, a main moving part, a feeding motion execution part, a bed, a column, and the like.

[0135] The controller 530 is installed on the device main body 510. The controller 530 is, for example, a DSP controller, a PLC controller or other control equipment with similar functions, and it is a core component of the numerical control processing equipment 500. The controller 530 is used for: establishing a workpiece surface roughness model according to the cutting parameter data, tool surface roughness data and corresponding workpiece surface roughness data of the workpiece to be processed, and determining the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com