Cold rolling forming method for automotive hub bearing ring part with L-shaped cross section

A technology for automotive wheel hubs and rings, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve problems such as high scrap rate in cold rolling, butterfly shape, metal flow filling, and complex geometric motion changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

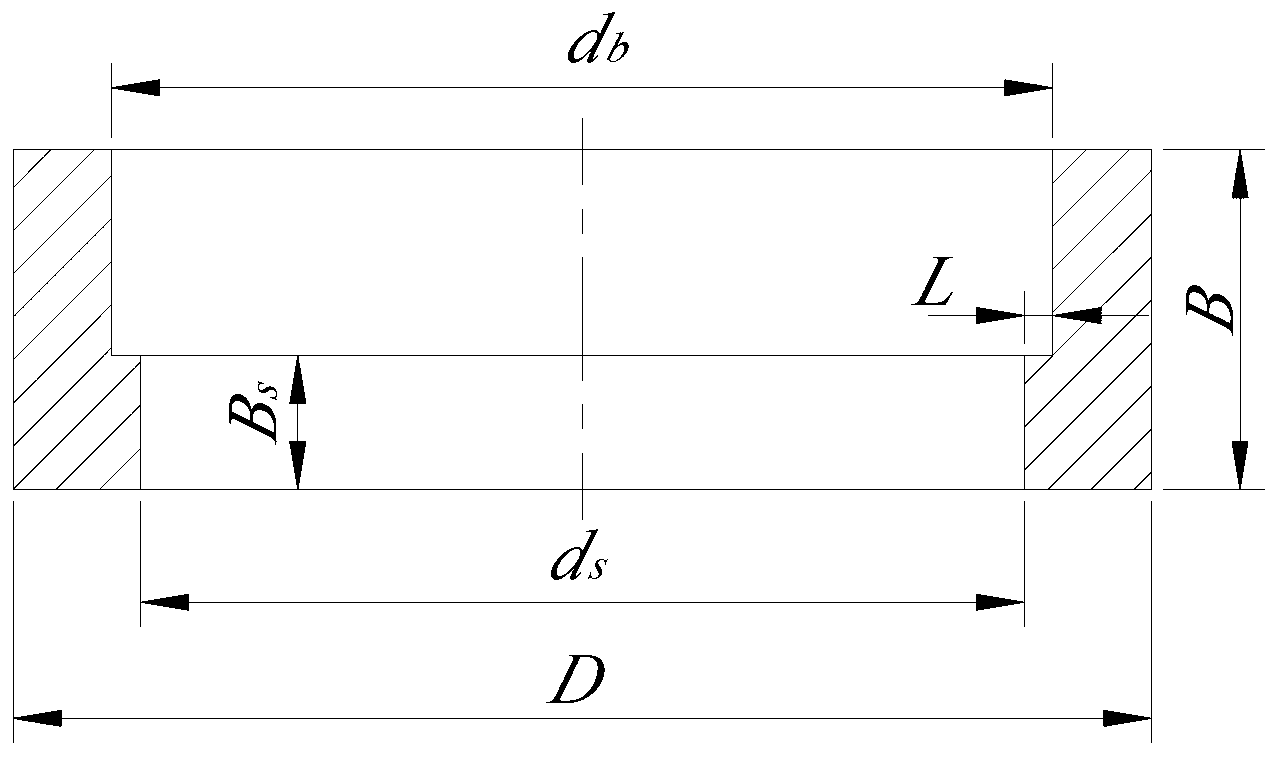

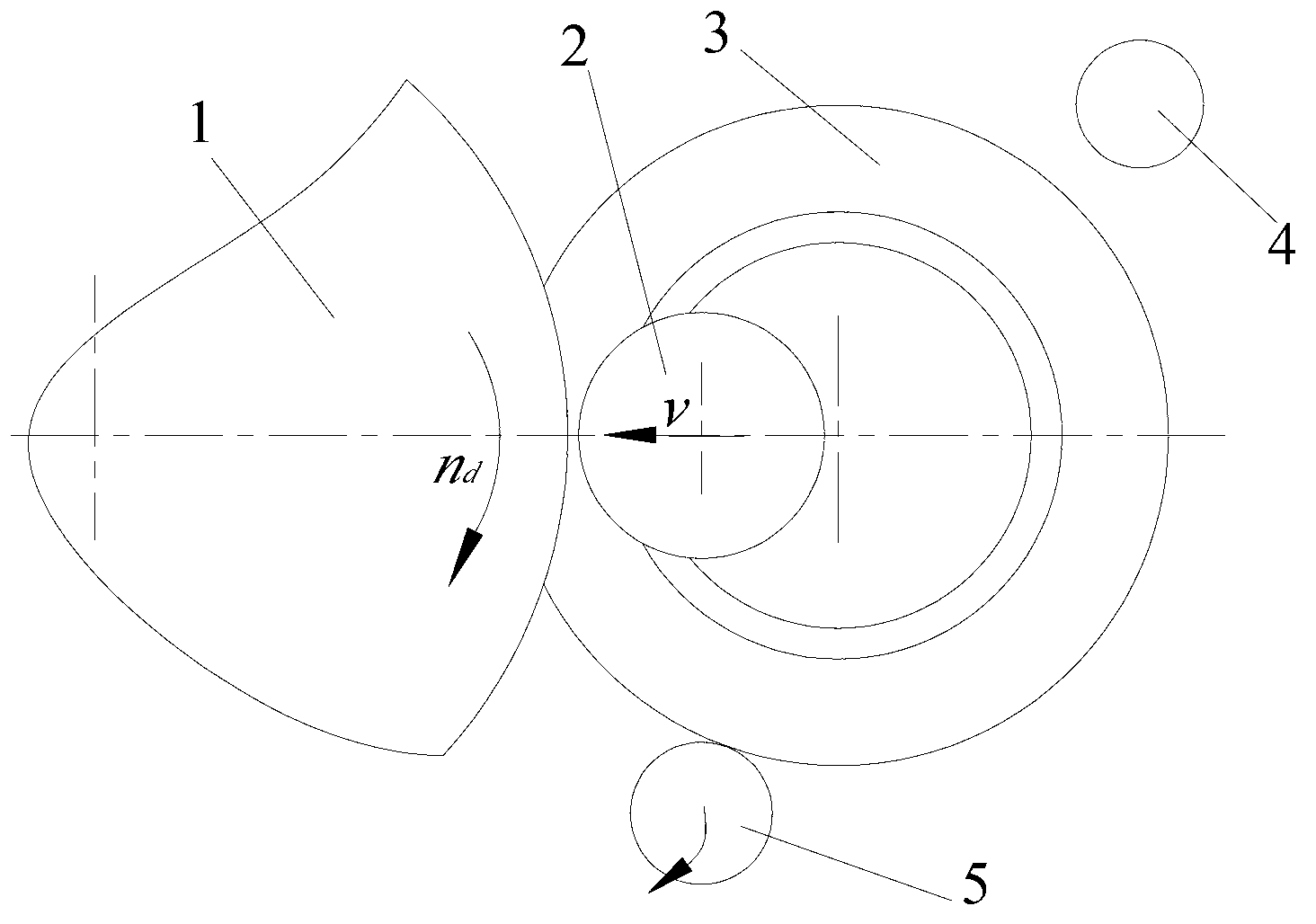

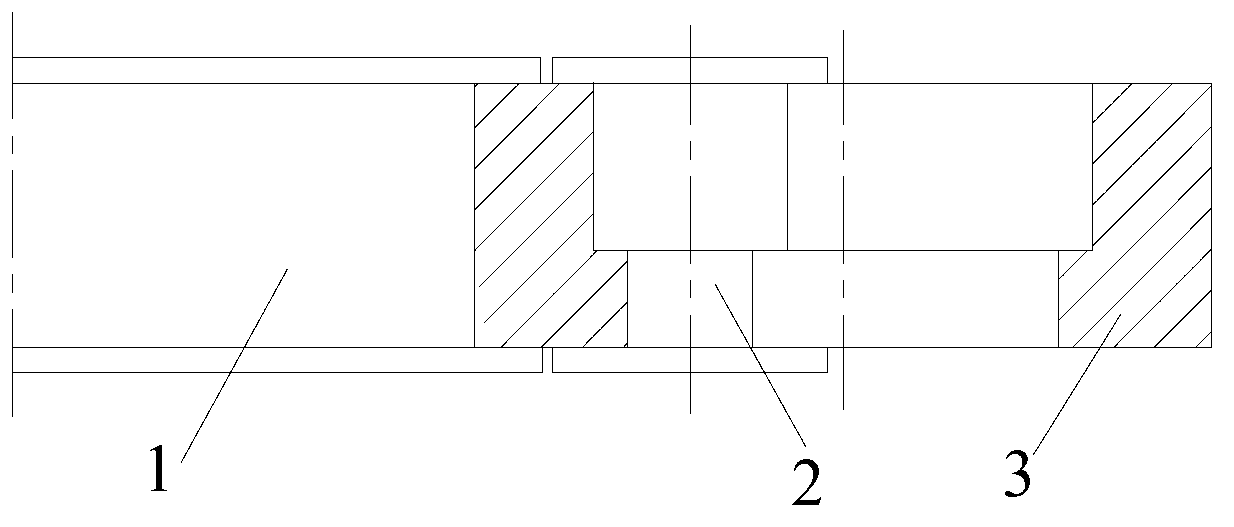

[0110] by figure 1 The shown L-shaped cross-section automobile hub bearing ring is a specific example, and the outer diameter of the cold-rolled ring is required to be D, and the inner diameter of the large-hole ring is d b , the inner diameter of the small orifice ring d s 59.3mm, 49mm and 46mm respectively, ring height B, inner step height B s 17.7mm and 7mm respectively, the cold rolling forming method includes the following steps:

[0111] (1) Ring blank design and processing

[0112] According to the dimension design method of the ring blank of the present invention, since the inner ring and the outer ring of the bearing are simultaneously processed by the tower-shaped forging process, the rolling ratio λ is selected as 1.13, and the inner diameter d of the small hole ring of the ring blank is determined s0 is 40.8mm, take the ring blank height B 0 1.75mm, ring blank step height B s0 7mm, step length L 0 is 1.5mm, take the volume compensation coefficient K V is 1.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com