Radial and axial rolling forming method for large-sized double-groove ring piece

An axial rolling, double groove technology, applied in metal rolling and other directions, can solve the problems of difficulty in guaranteeing quality and life, loss of cutting materials, large processing time consumption, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

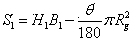

[0056] as figure 2 The large double-groove ring shown (referred to as the ring) is the specific implementation object, and the geometric dimensions of the ring are: outer radius 1050mm, inner radius 944, width 178mm, 40.25mm, 18.5mm, groove central angle for , groove arc radius 20mm, groove depth 17mm, groove width It is 39.5mm. The radial and axial rolling forming method is realized in the following steps:

[0057] 1) Billet making: evenly heat the bar section from room temperature to the hot forging deformation temperature, then upsetting, punching, and punching the hot section on a press to make a ring blank 4 for rolling. According to the 4 size design method of the ring blank, take the rolling ratio is 3.5, determine the size of the ring blank 4 as: outer radius 409.51mm, inner radius 162.87mm, width It is 251.63mm. ( image 3 shown).

[0058] 2) Rolling pass design: Take the rolling line speed is 1.2m / s, according to the rolling pass des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com