Cold rolling forming method for automotive hub bearing ring part with L-shaped cross section

A technology for automobile hubs and rings, which is applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of wasting a lot of material processing time, high scrap rate of cold rolling, and inability to stabilize mass production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

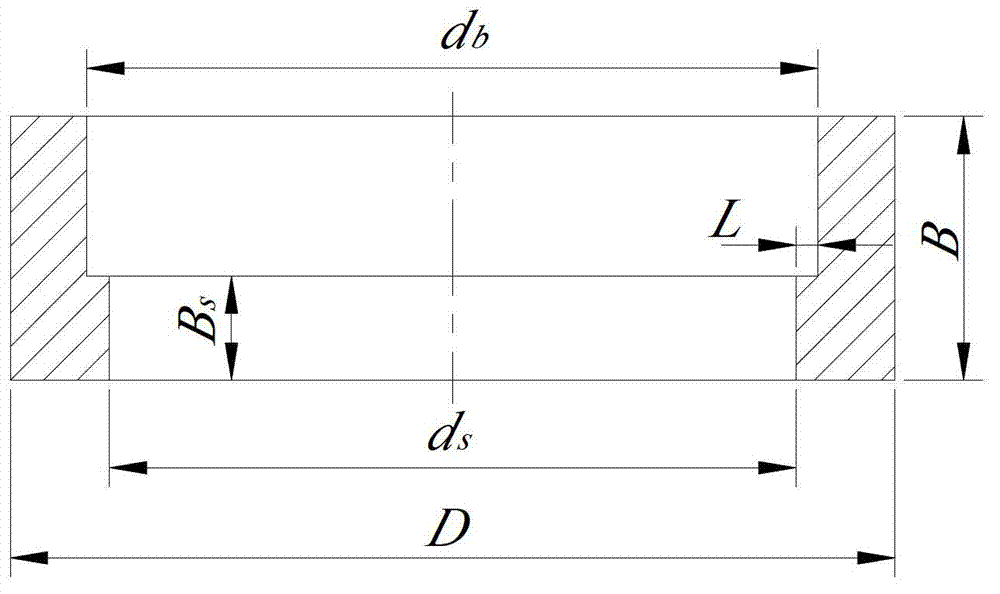

[0110] by figure 1 The shown L-shaped cross-section automobile hub bearing ring is a specific example, and the outer diameter of the cold-rolled ring is required to be D, and the inner diameter of the large-hole ring is d b , the inner diameter of the small orifice ring d s 59.3mm, 49mm and 46mm respectively, ring height B, inner step height B s 17.7mm and 7mm respectively, the cold rolling forming method includes the following steps:

[0111] (1) Ring blank design and processing

[0112] According to the ring blank size design method of the present invention, since the tower-shaped forging process is used to process the bearing inner ring and the outer ring at the same time, the rolling ratio λ is selected as 1.13, and the inner diameter d of the small hole ring of the ring blank is determined s0 is 40.8mm, take the ring blank height B 0 1.75mm, ring blank step height B s0 7mm, step length L 0 is 1.5mm, take the volume compensation coefficient K V is 1.00, and the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com