Rotary tool for welding

A tooling and articulation technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high labor intensity and low welding efficiency, and achieve the effect of reducing labor intensity and improving welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

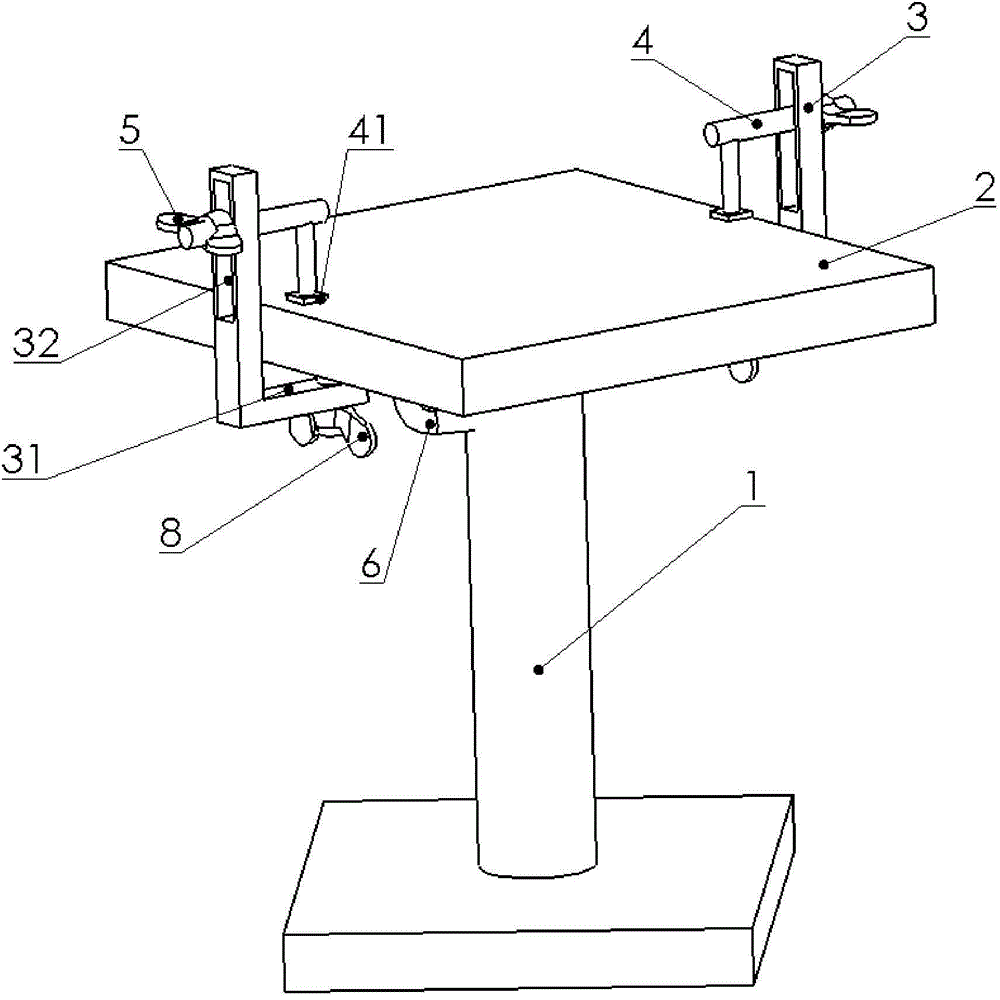

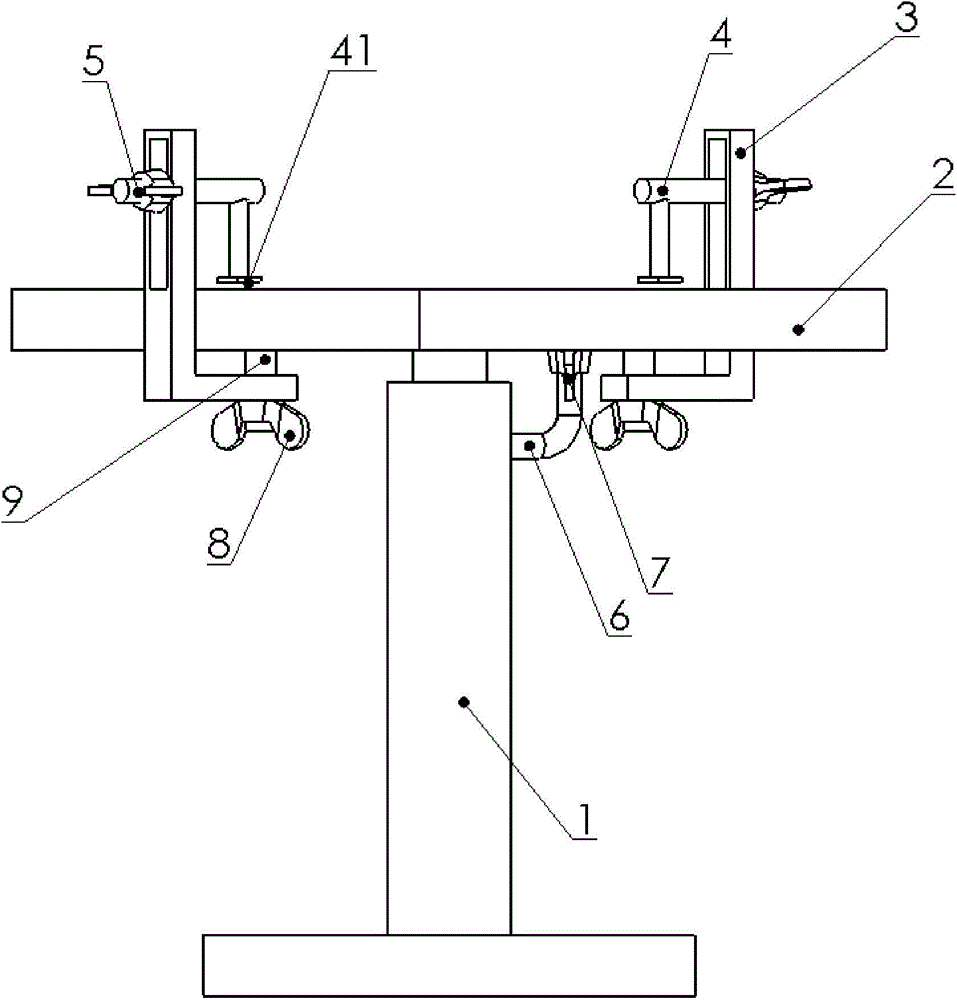

[0020] Now in conjunction with accompanying drawing, this welding overturning frock is described in further detail.

[0021] As shown in 1, 2, and 3, a rotary tooling for welding, including a support 1, an operating table 2, and a plurality of pressing units;

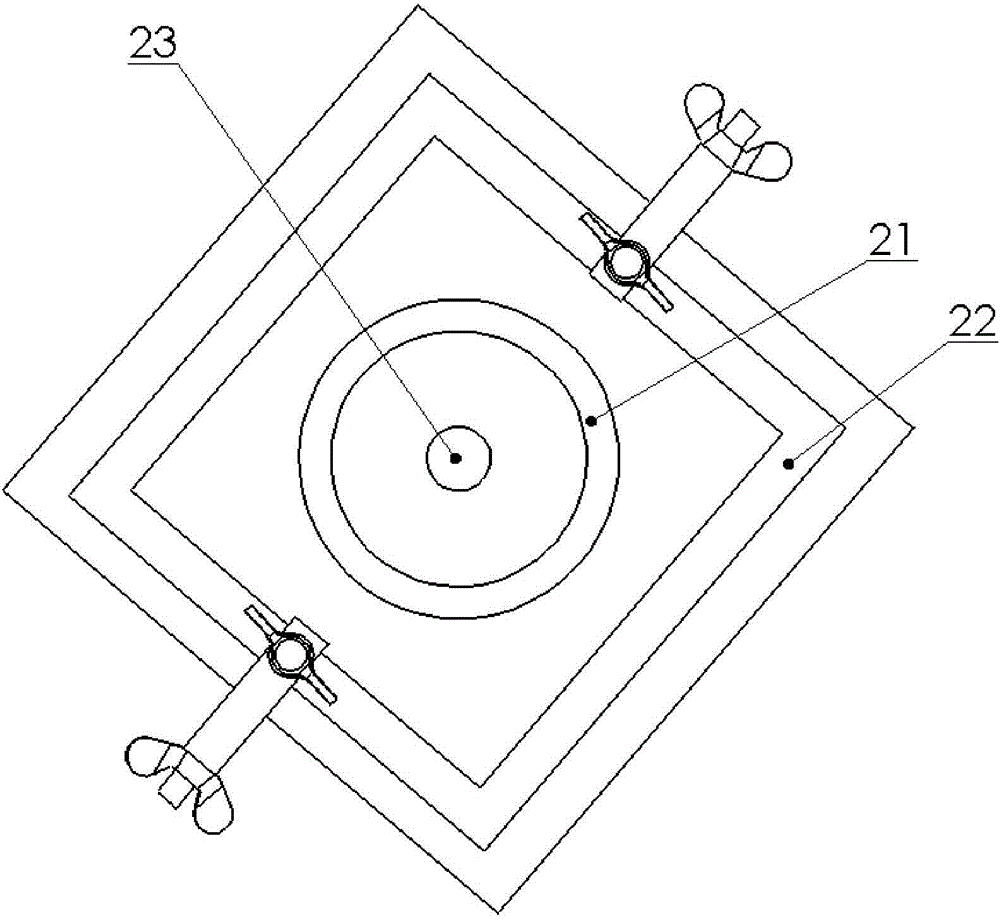

[0022] The middle part of the bottom surface of the console 2 is provided with a positioning groove 23, and the positioning groove 23 is hinged with the upper part of the support 1;

[0023] A positioning unit is provided at the hinged position between the console 2 and the support 1;

[0024] The plurality of pressing units are respectively slidingly connected to the operating platform 2 .

[0025] Such as figure 2 As shown, the positioning unit includes a positioning shaft 6, a positioning groove 21, and a second clamping element 7. The positioning shaft 6 is an inverted "L" shape, and its lower part is fixedly connected to the support 1. The positioning The groove 21 is located at the outer edge of the hinged pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com