Bonding material shearing strength testing tool and bonding material shearing strength tester

A technology of shear strength and testing tooling, which is applied in the direction of applying stable shear force to test material strength, measuring devices, strength characteristics, etc., can solve the problems of low shear test efficiency, reduce man-hour consumption, test accuracy, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

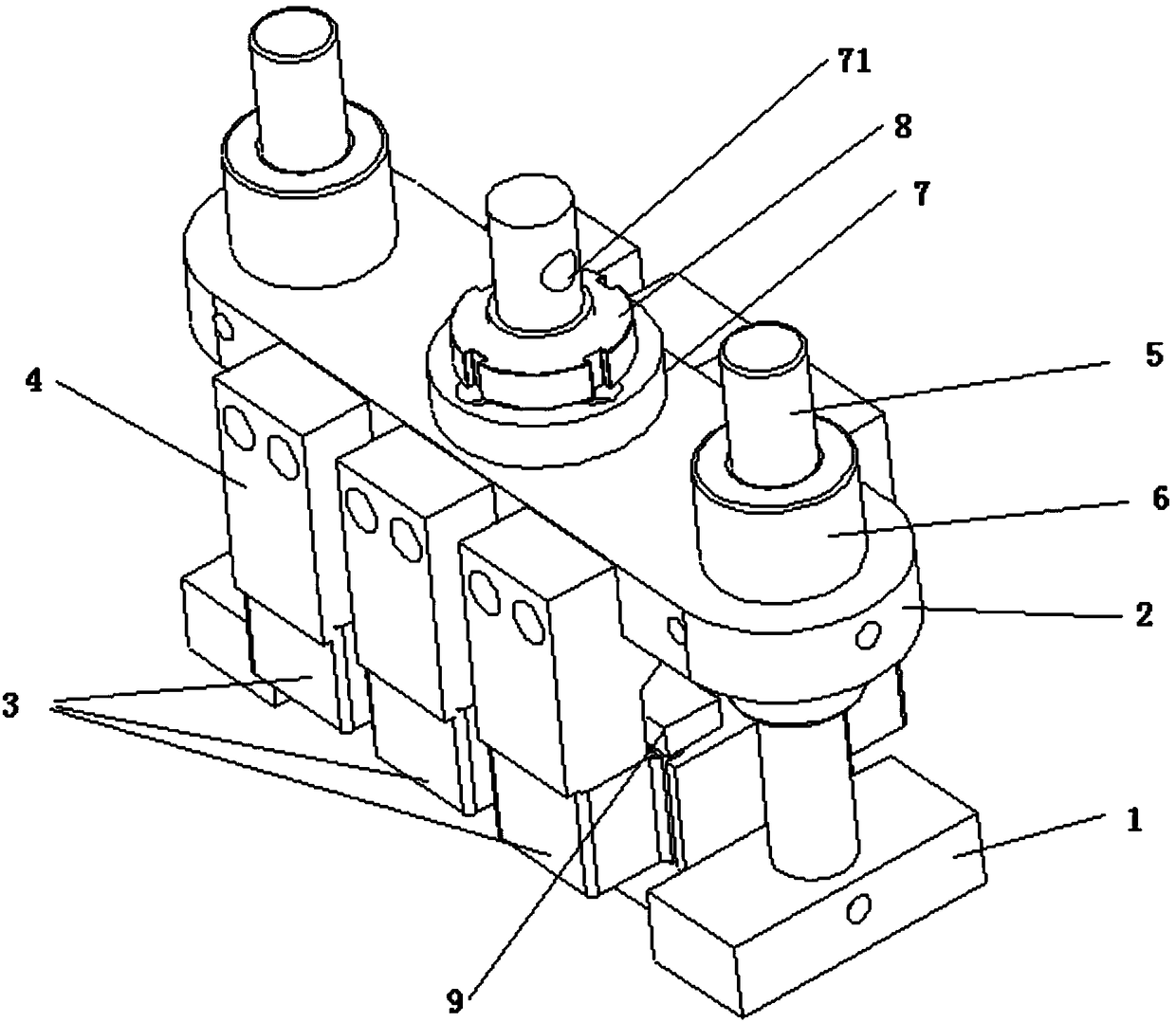

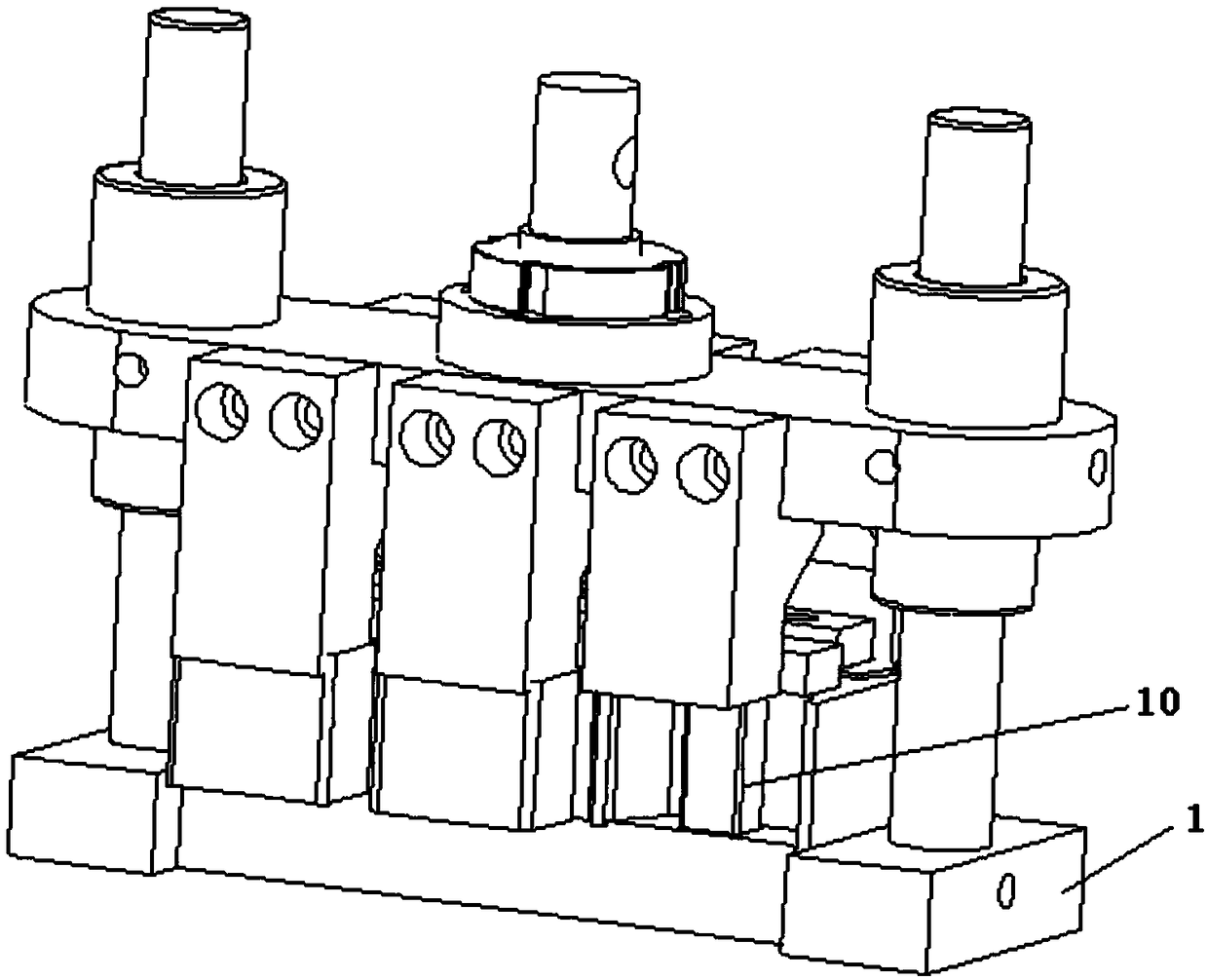

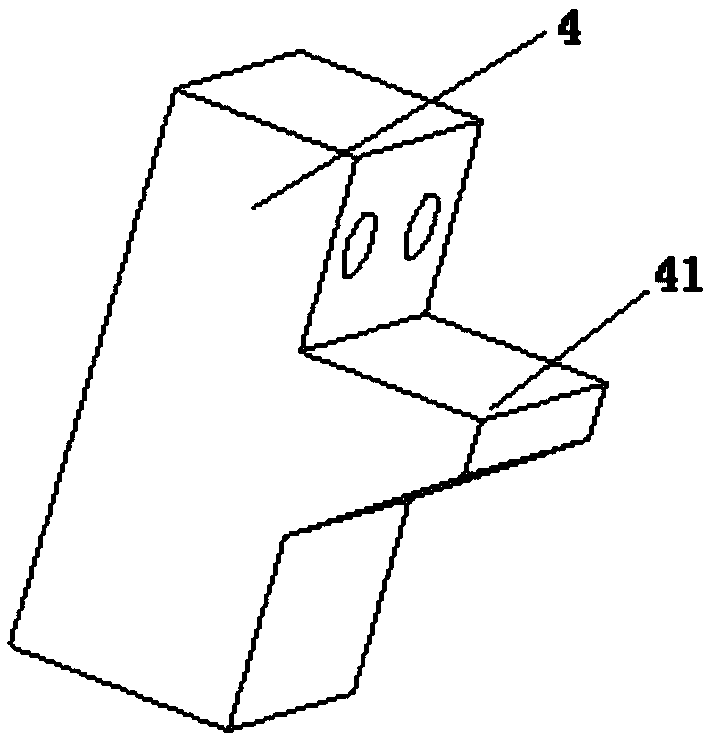

[0057] Such as Figure 1-3 Shown is a specific implementation of an adhesive shear strength tester that can perform a shear strength test on a carbon slide. The detection block 3 of the carbon slide includes a first structure that is an aluminum bracket and a carbon strip. A second structure body, a bonding surface is provided between the first structure body and the second structure body. The test tooling includes a base 1, the two ends of the base 1 along the length direction are evenly and symmetrically provided with a plurality of draw-in grooves, a columnar structure 10 is arranged in the draw-in groove, and the first structure body is provided with the The columnar structure 10 cooperates with the hole, and the columnar structure 10 cooperates with the hole to form a position-limiting structure that restricts the movement of the first structure inside the slot, so that the first structure is fixed in the slot , the columnar structure 10 is provided with a threaded hole,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com