Pressurized gas nitrocarburizing method

A technology of nitrocarburizing and pressurized gas, which is applied in the direction of coating, metal material coating process, solid diffusion coating, etc., can solve the problems of limitation, long co-infiltration holding time, influence of penetration depth, etc., and reduce production The effect of reducing cost, shortening the holding time, and increasing the penetration depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

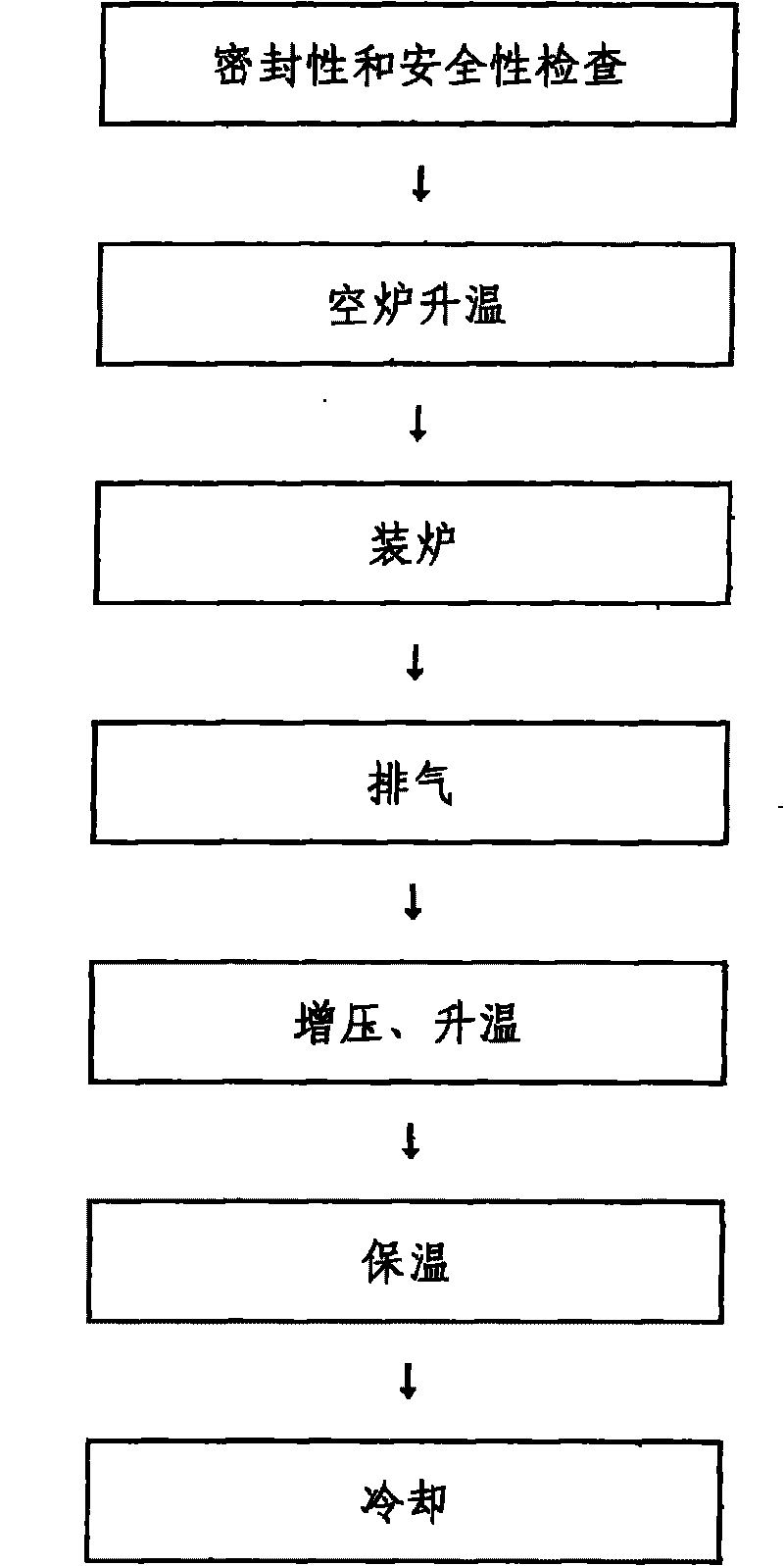

[0010] A pressurized gas nitrocarburizing method, the process of which is: sealing and safety inspection → empty furnace heating → furnace loading → exhaust → pressurization and heating → heat preservation → cooling, by controlling the pressure and temperature in the furnace, Speed up the nitrocarburizing speed and shorten the nitrocarburizing holding time.

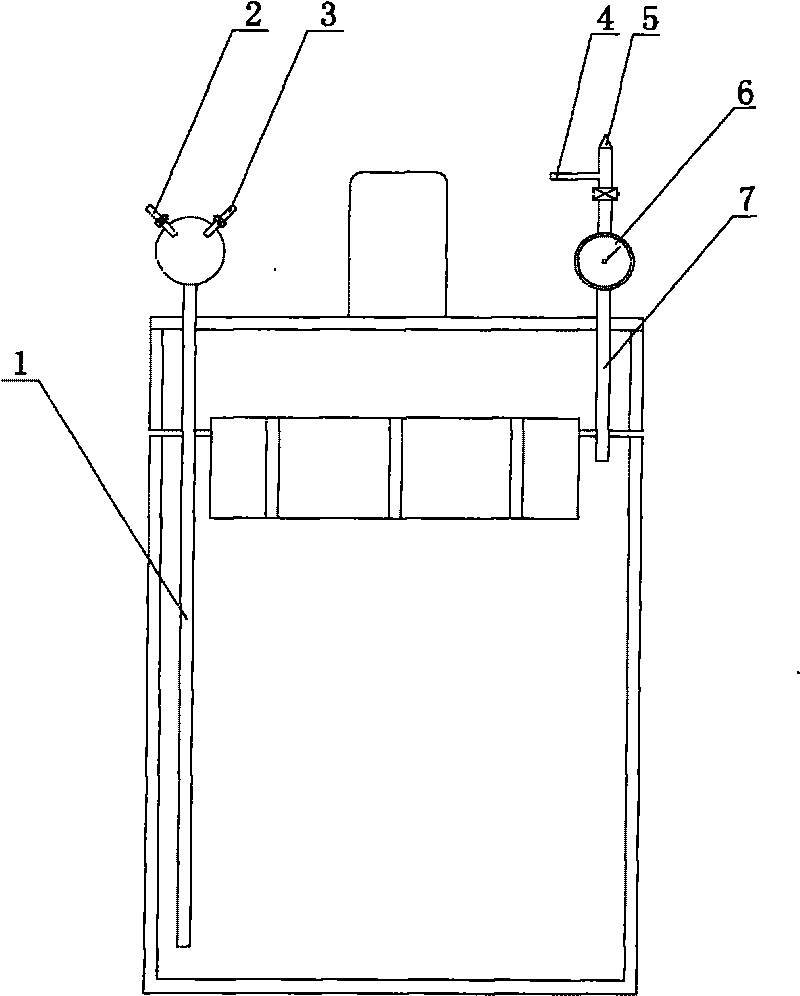

[0011] Referring to the accompanying drawings, first of all, the sealing and safety inspection of the nitrocarburizing furnace must be carried out to check whether the furnace tank is leaking, whether the pressure relief safety valve 6 is intact, etc., to ensure the safety of the nitrocarburizing process when the gas is pressurized.

[0012] Before the workpiece is put into the furnace, the temperature of the empty furnace is raised, the temperature in the furnace is controlled not to exceed 400°C to 500°C, and the temperature is kept for 0.5 to 1 hour to make the temperature in the furnace uniform.

[0013] When loadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com