Symmetric integrated crushing system

A crushing system, symmetrical technology, applied in the direction of grain processing, etc., can solve the problems of difficult to achieve fully enclosed environmental protection, large production line area, dust pollution, etc., to achieve compact structure design, reduce material transportation costs, and no dust pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

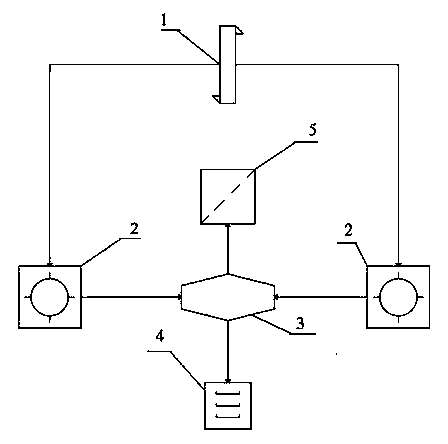

[0024] The invention as figure 1 As shown, the symmetrical integrated crushing system mainly includes a vertical elevator, a horizontal crusher, a central body, a negative pressure powder removal device and a grading vibrating screen.

[0025] The vertical hoist, horizontal crusher, central body, negative pressure powder removal device and grading vibrating screen are integrated on the same frame, in a three-dimensional arrangement structure, with the central body as the center, left and right on the horizontal axis line Two horizontal crushers are symmetrically arranged, and a negative pressure powder removal device, a vertical hoist and a vibrating screen are respectively arranged up and down on the longitudinal axis.

[0026] The outlets of the vertical hoist are respectively connected to two horizontal crushers symmetrically arranged left and right, the left and right inlets of the central body are respectively connected to the outlets of the two horizontal crushers, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com