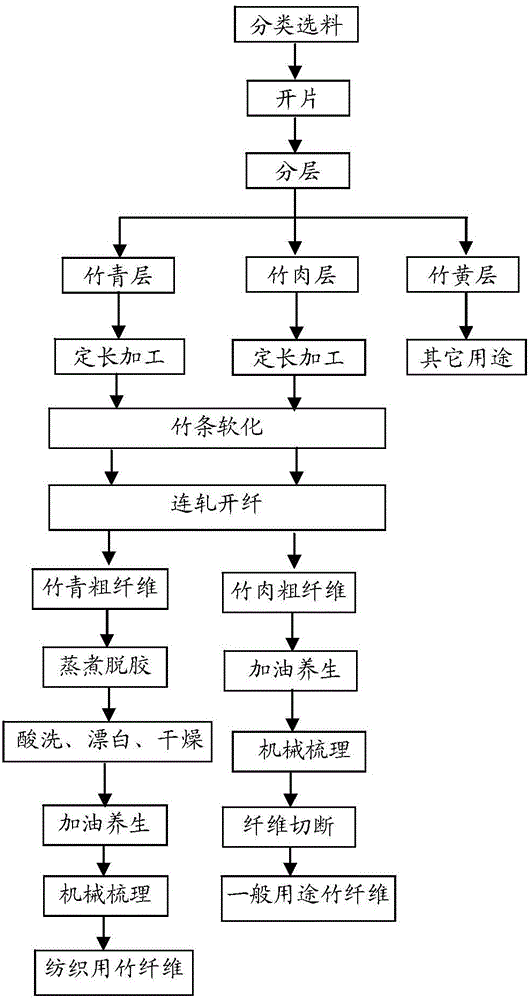

Method for extracting bamboo fibers from bamboo in layering mode

A bamboo fiber and bamboo technology, which is applied in the field of extracting bamboo fiber by layers of bamboo, can solve the problems of single quality of bamboo fiber, different quality of crude fiber, and not ideal enough, and achieve excellent strength and uniformity, low preparation time consumption, and improved The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Select the annual moso bamboo, Ci bamboo or green bamboo, cut off the tip and tail of the bamboo, and split the stem of the bamboo; the split bamboo is processed in layers, and the bamboo green layer bamboo strips and bamboo flesh are processed. Layer bamboo strips and bamboo yellow layer bamboo strips are removed from the bamboo yellow layer bamboo strips; the bamboo green layer bamboo strips and the bamboo flesh layer bamboo strips are respectively cut and processed into length-fixed bamboo strips of 50 cm to obtain the bamboo green layer fixed-length bamboo strips Bamboo strips and bamboo flesh layer fixed-length bamboo strips;

[0029] Put the fixed-length bamboo strips in the bamboo green layer and the fixed-length bamboo strips in the bamboo flesh layer in the softening tank for softening treatment; take them out after the fixed-length bamboo strips in the bamboo green layer change color, clean them with clean water, and dry them in the shade at room temperature un...

Embodiment 2

[0035] Choose one to two-year-old moso bamboo, Ci bamboo or green bamboo, cut off the tip and tail of the bamboo material, and split the stem of the bamboo material; the bamboo material after splitting is processed in layers to process bamboo strips with bamboo green layer, Bamboo flesh layer bamboo strips and bamboo yellow layer bamboo strips are removed from bamboo yellow layer bamboo strips; bamboo green layer bamboo strips and bamboo flesh layer bamboo strips are cut and processed into length-fixed bamboo strips of 70 cm respectively to obtain bamboo green layer fixed length bamboo strips. The long bamboo strips and the bamboo flesh layer are fixed-length bamboo strips;

[0036] Put the fixed-length bamboo strips in the bamboo green layer and the fixed-length bamboo strips in the bamboo flesh layer in the softening tank for softening treatment; take them out after the fixed-length bamboo strips in the bamboo green layer change color, clean them with clean water, and dry the...

Embodiment 3

[0042] Select two to three-year-old moso bamboo, Ci bamboo or green bamboo, cut off the tip and tail of the bamboo material, and split the stem of the bamboo material; the bamboo material after the division is layered and processed to process bamboo green layer bamboo strips , bamboo flesh layer bamboo strips and bamboo yellow layer bamboo strips, reject the bamboo yellow layer bamboo strips; the bamboo green layer bamboo strips, bamboo flesh layer bamboo strips are respectively cut and processed into length-fixed bamboo strips of 80cm, to obtain the bamboo green layer Fixed-length bamboo strips and bamboo flesh layer fixed-length bamboo strips;

[0043] Put the fixed-length bamboo strips in the bamboo green layer and the fixed-length bamboo strips in the bamboo flesh layer in the softening tank for softening treatment; take them out after the fixed-length bamboo strips in the bamboo green layer change color, clean them with clean water, and dry them in the shade at room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com