Micro and fine high-frequency grouped pulse power supply

A kind of pulse power supply and micro-technology, which is applied in the direction of electric pulse generator circuit, energy storage components to generate pulses, electrical components, etc., can solve the problems of reduced surface roughness in processing efficiency, large discharge pulse interval coefficient, and low processing efficiency. Solve the effect of processing efficiency and surface roughness, increase discharge frequency, and reduce development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

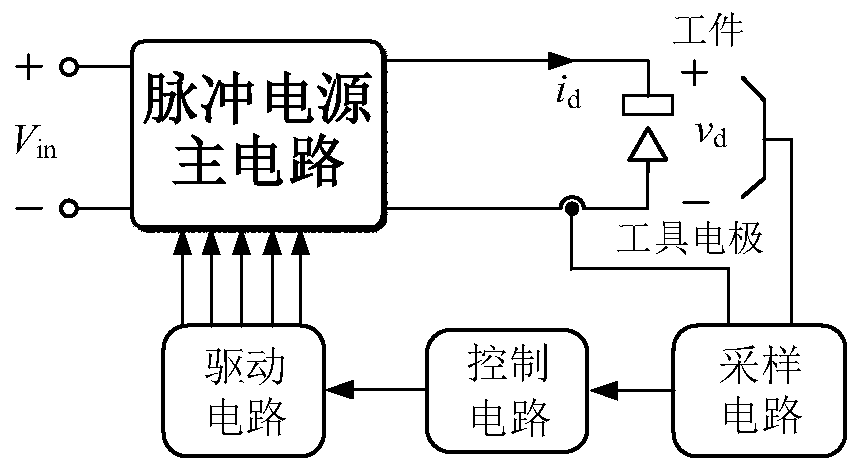

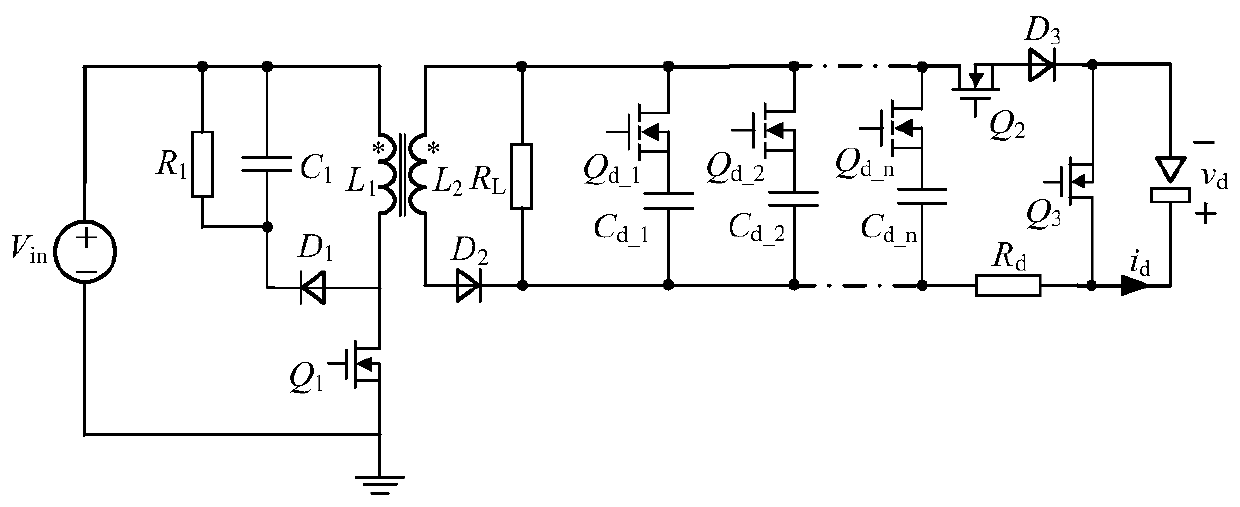

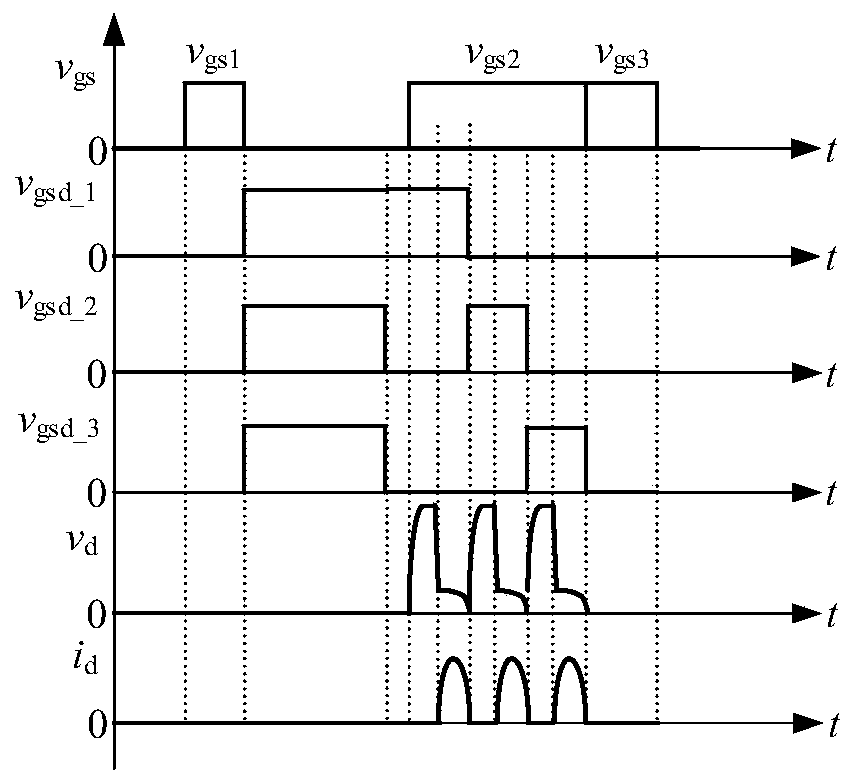

[0027] Such as figure 1 As shown, the micro-high-frequency group pulse power supply of the present invention includes a DC power supply, a pulse power supply main circuit, a gap voltage and current sampling circuit, an FPGA control circuit, and a drive circuit; The voltage and gap current are sampled, and the sampling signal is input to the FPGA control module, and the calculation is performed according to the processing requirements to generate a PWM signal, which is filtered and amplified by the drive circuit and then respectively driven to drive the primary switch tube Q in each circuit of the pulse power supply 1 , micro-discharge switch tube Q 2 , Disconnect switch tube Q 3 , the switching tube Q connected in series with the discharge capacitor d_1 to Q d_n , so as to realize high-frequency and adjustable pulse width EDM pulse wavefor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com