A multi-channel parallel cross-cycle driven high-frequency micro-energy pulse power supply for electrical machining

A technology of pulse power supply and micro-energy electricity, which is applied in the direction of electric processing equipment, metal processing equipment, circuits, etc., can solve the problem of low discharge frequency of power supply, and achieve the effect of easy acquisition, easy control, and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments of the present invention will be described in detail below with reference to the drawings, but the scope of protection of the present invention is not limited to the following embodiments.

[0013] A specific embodiment of the present invention is used for the realization of the technical parameters of the high-frequency micro-energy electrical machining pulse power supply driven by multi-channel parallel cross cycle as follows:

[0014] The minimum pulse width can reach 60ns; the maximum pulse frequency can reach 3MHz;

[0015] According to the excellent performance of the high-frequency micro-energy pulse power supply device for electrical machining of the present invention in the pulse frequency, the duty ratio of the existing electrical machining narrow pulse is more than doubled from the common 1:10, reaching the domestic public report The highest frequency of micro-energy electromachining narrow pulse width.

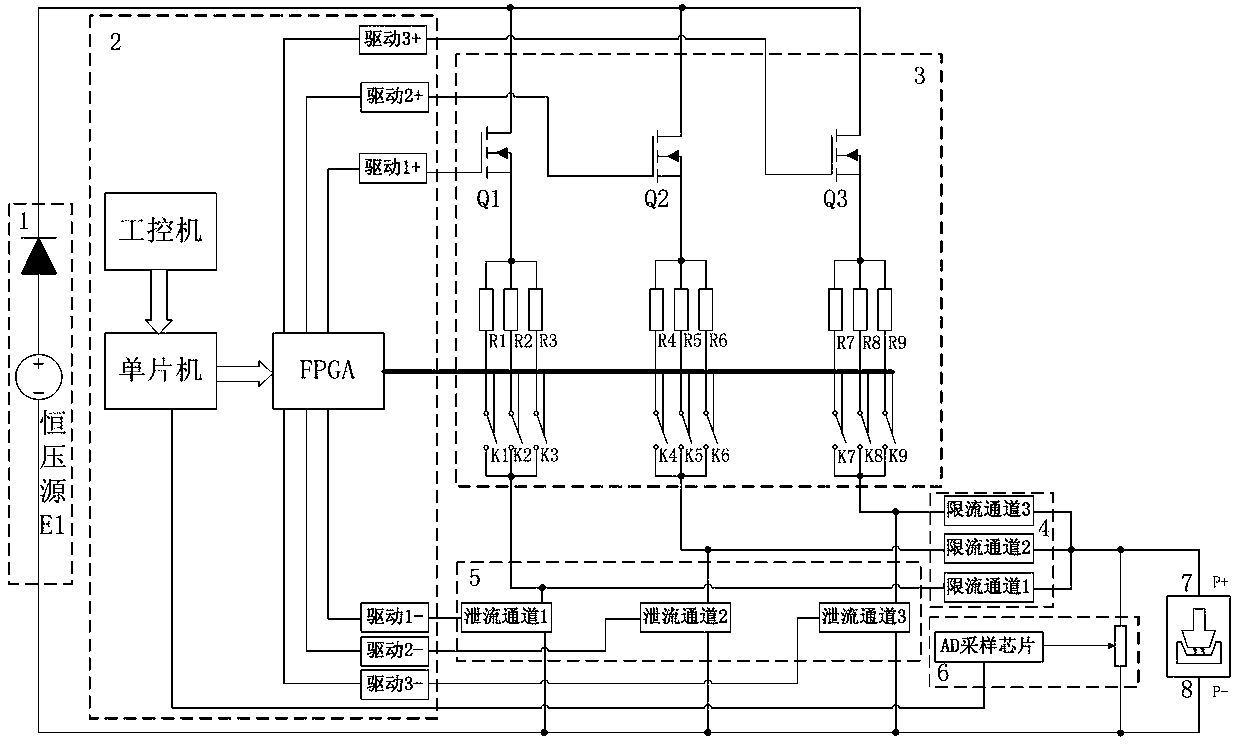

[0016] figure 1 It is the schematic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com