Device used for plasma negative pressure electro discharge treatment of high concentration VOC industrial exhaust gas

An industrial waste gas, high-concentration technology, applied in the field of air purification, can solve the problems of unsatisfactory purification treatment effect, limited electron energy, low discharge efficiency, etc., achieve ideal purification treatment effect, increase energy utilization rate, and reduce environmental oxygen content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

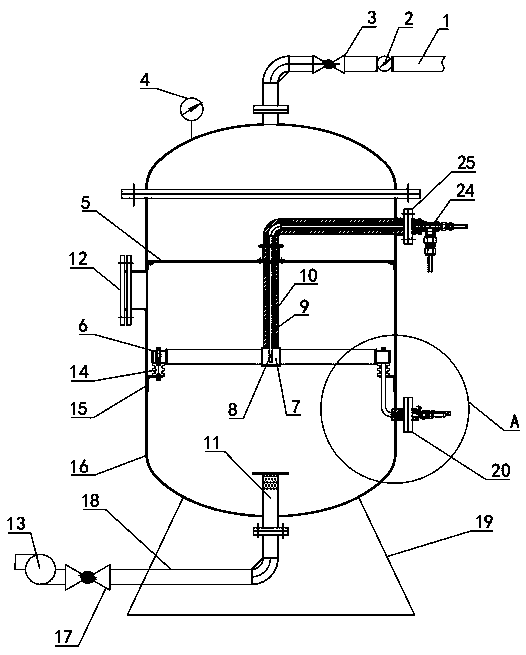

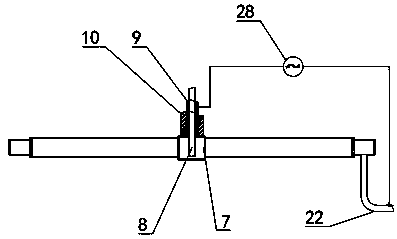

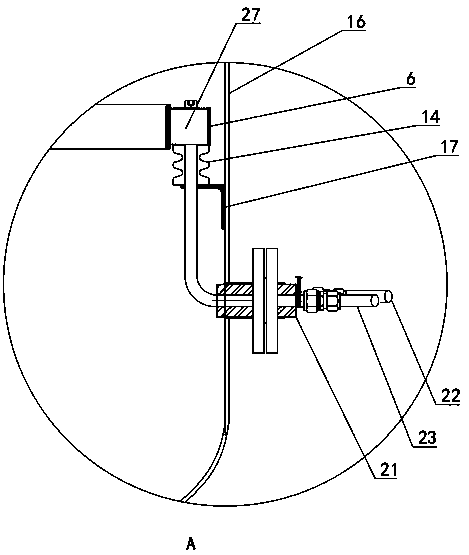

[0027] Figure 1~3 It is the best embodiment of the present invention, below in conjunction with the attached Figure 1~3 The present invention will be further described.

[0028] refer to Figure 1~2, Plasma negative pressure discharge treatment of high-concentration VOC industrial waste gas device, including a discharge chamber 16, a gas inlet is opened above the discharge chamber 16, the gas inlet is connected to an intake pipe 1, and a flow meter 2 and an intake valve 3 are arranged on the intake pipe 1 , to control and detect the amount of gas entering the discharge bin 16 . The gas outlet is provided with a riser pipe 11, and the riser pipe 11 is placed in the discharge chamber 16, and a plurality of through holes are arranged on the side wall of the upper part of the riser pipe 11, and the lower end of the riser pipe 11 is connected to an exhaust pipe 18, and the exhaust pipe 18 Exhaust valve 17 and vacuum pump 13 are arranged on it. The discharge chamber 16 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com