Workbench with gluing device

A workbench and glue-holding technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve problems affecting processing progress and efficiency, material stacking and collapse, etc., to improve processing progress and efficiency, high efficiency, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

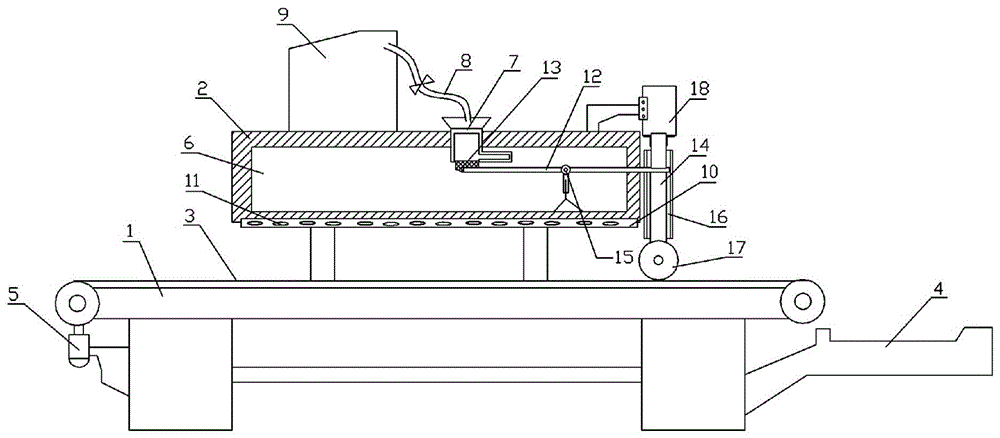

[0012] The reference signs in the drawings of the description include: base 1, horizontal box 2, transport platform 3, material receiving box 4, motor 5, glue chamber 6, feed port 7, rubber hose 8, material loading box 9, glue lowering Plate 10, drop hole 11, cantilever lever 12, sealing plug 13, strut 14, hinge fulcrum 15, chute 16, rolling roller 17, thrust cylinder 18.

[0013] The embodiment is basically as attached figure 1 Shown: a workbench with a gluing device, including a base 1 and a horizontal box 2 arranged on the base 1, a transport platform 3 is provided on the base 1, and a connecting box is provided under one side of the transport platform 3. Material box 4, transport platform 3 comprises belt transmission mechanism and the motor 5 that is connected with belt transmission mechanism, and horizontal box 2 is provided with the glue chamber 6, and the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com