Method and device of processing the contacting surface of the digital controlled lines

A technology of surface processing and digital control, applied in the direction of digital control, electric processing equipment, metal processing equipment, etc., can solve the problems of the same or similar reports or literatures that have not been found, and achieve the solution of processing efficiency and error control, less linkage The number of axes and the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

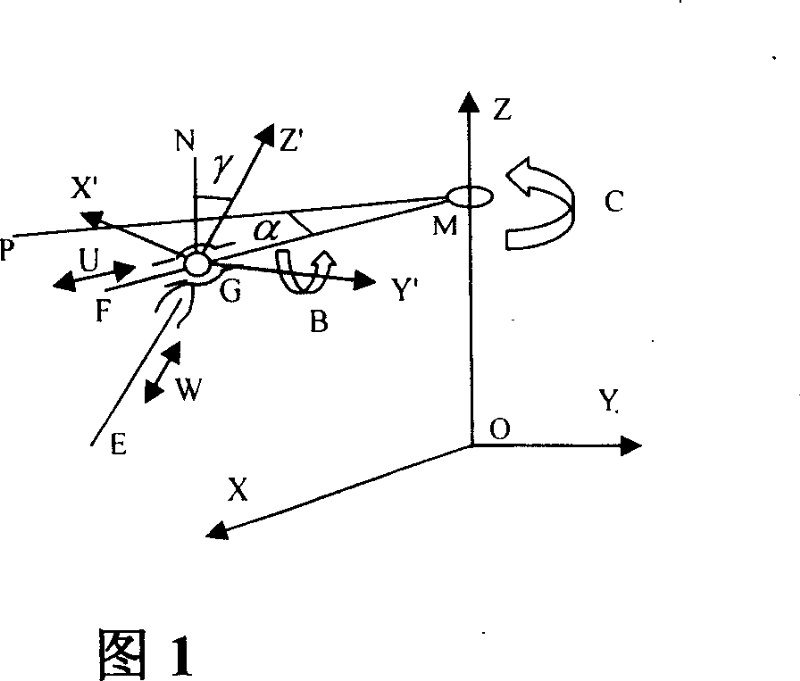

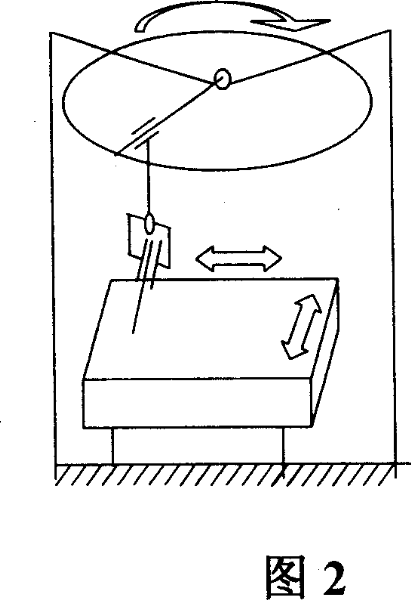

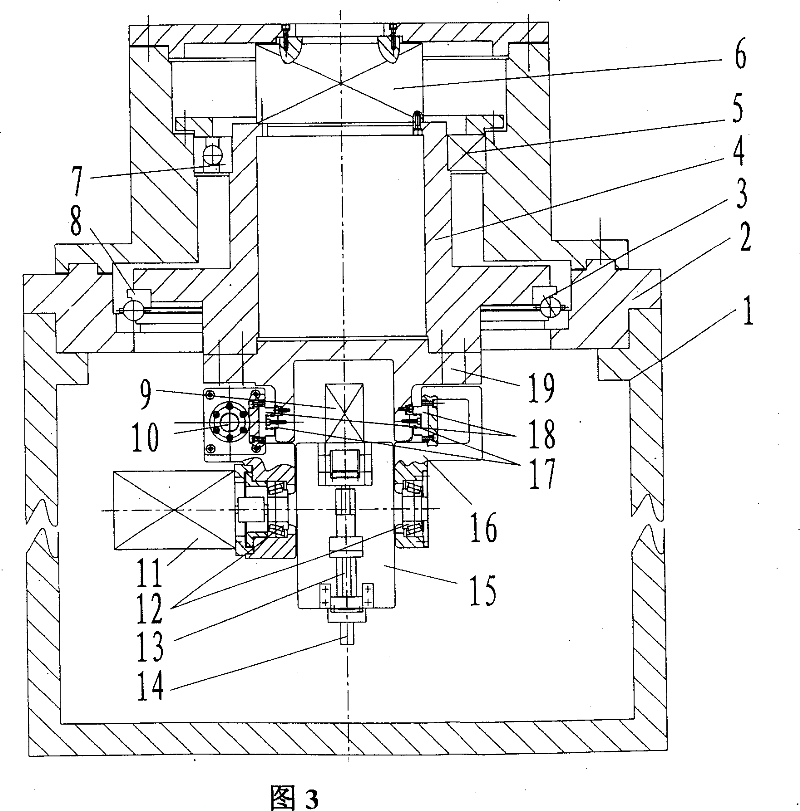

[0033]Referring to Fig. 3, the present invention, as a digital control line contact curved surface processing equipment, includes a digital control system, a power drive source, and a coordinate feed system with numerically controlled multi-axis motion. The key point is that it must also have a four-axis contact The curved surface processing device, the four-axis contact curved surface processing device is mainly composed of five parts: a rotary assembly, a translation assembly, a swing assembly, a telescopic assembly and a cutting assembly. The rotary body 4 and the upper bearing 5 are composed of two bearings 3 and 5 fixed on the support frame member 2, the rotary body 4 is statically connected with the upper bearing inner ring 7 and the lower bearing inner ring 8 respectively, and the rotary motor 6 is installed on the support frame On part 2, the shaft rotation of motor 6 drives the rotary body 4 and its extension 19 to form the feed axis of rotary motion, that is, the C ax...

Embodiment 2

[0037] The overall device is the same as in Embodiment 1, except that the rotating body 4 and its extension 19 are connectors, which are manufactured in parts and then installed. The support frame member 2 is also a combined member, consisting of upper and lower members and a cover, manufactured in parts and then installed, which is easy to process, easy to install, low in cost, and also conducive to improvement.

Embodiment 3

[0039] The overall device is the same as that of Embodiment 1, except that the lower bearing 3 and the upper bearing 5 in the rotary assembly are replaced by one bearing, which can simplify the structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com