Wear-resistant clamp for grinding optical fiber connector blanks

An optical fiber connector, wear-resistant technology, applied in the direction of the work carrier, etc., can solve the problems that the product quality cannot be fully guaranteed, easy to wear and deform, and the number of grinding is small, so that the clamping and operation process is simple and fast, not easy to wear and tear. Deformation, the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

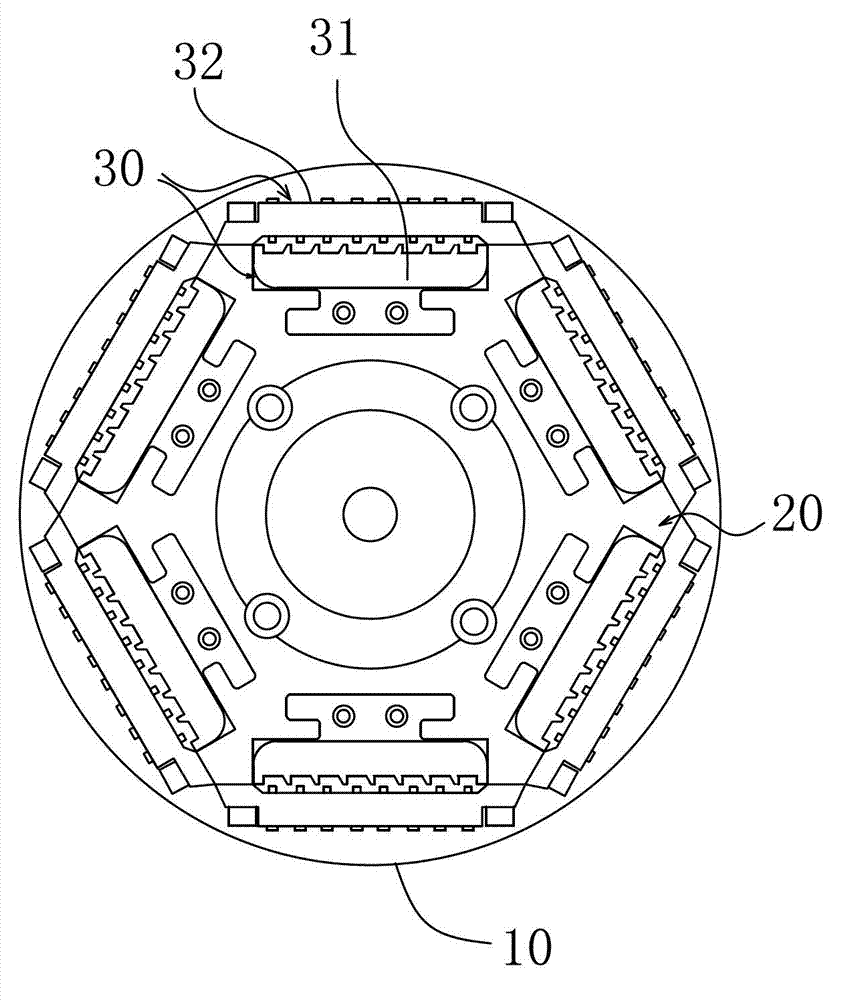

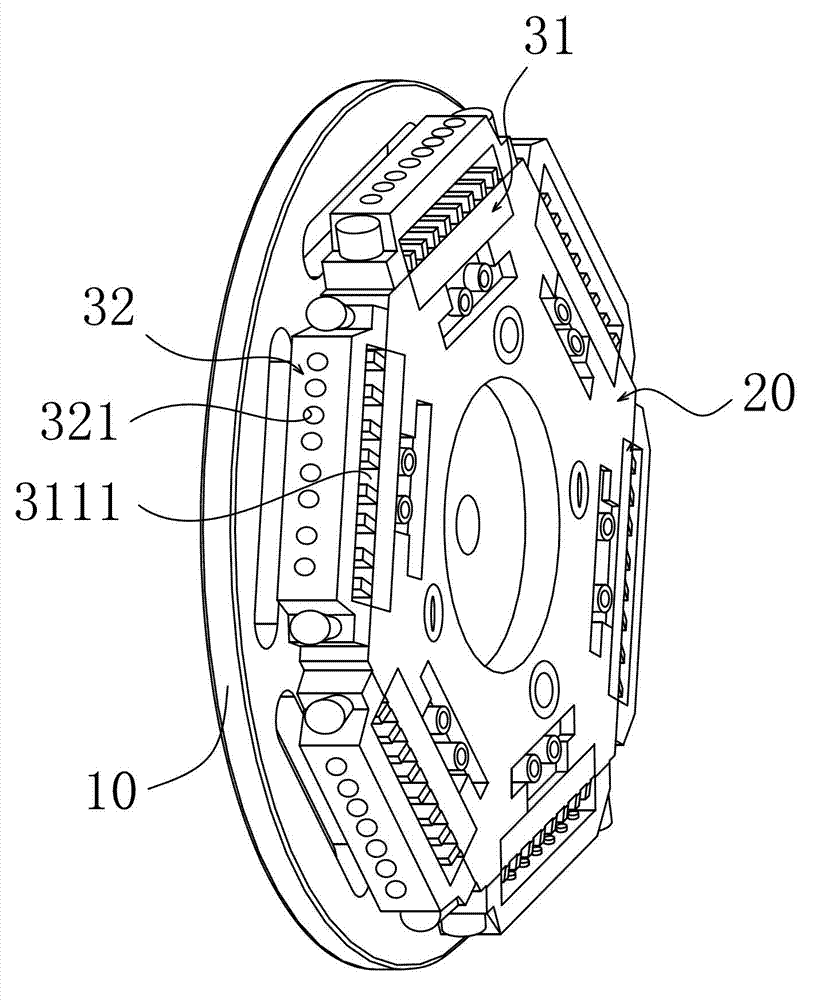

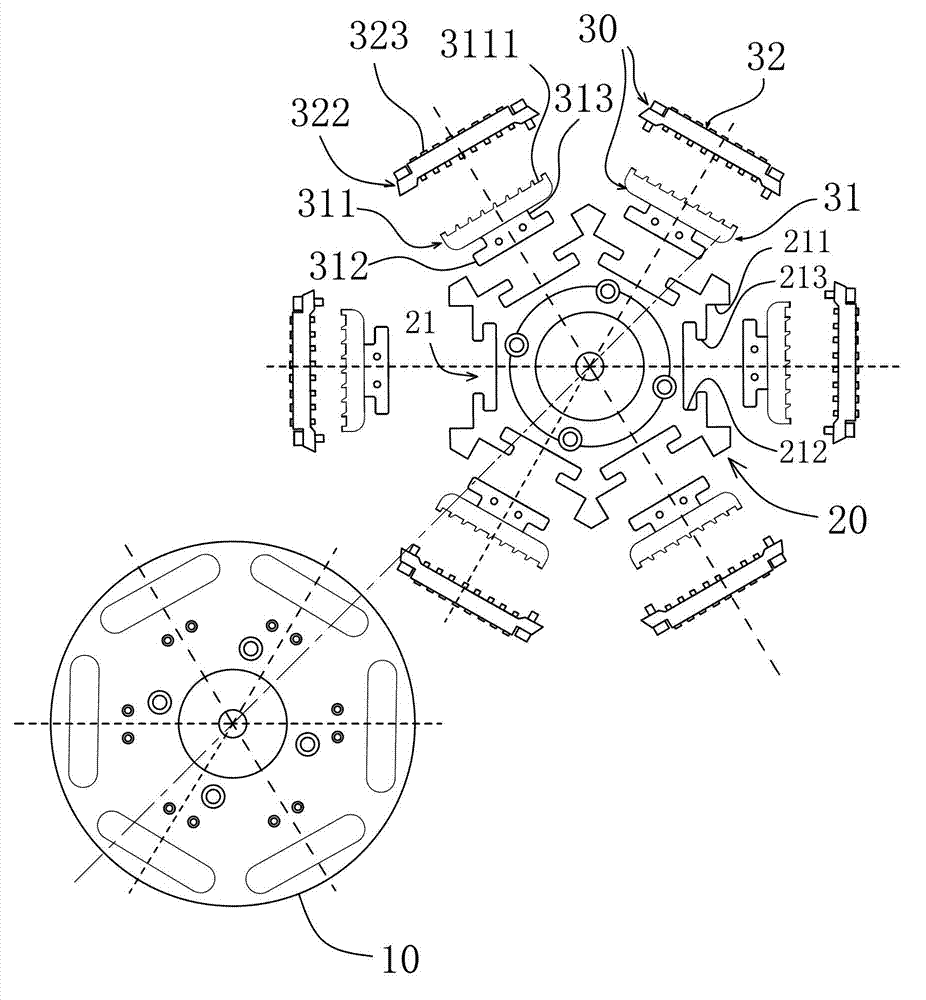

[0019] refer to Figure 1 ~ Figure 3 , the wear-resistant optical fiber connector blank grinding fixture of the present invention is a fixture for grinding an optical fiber connector blank cut from a quartz substrate, which includes a base 10, a polygonal clamp disc 20 and a plurality of unit clamps 30 .

[0020] Such as Figure 1 ~ Figure 3 , the fixture has a circular base 10, the base is a plate-shaped body made of stainless steel, the center of the base 10 is provided with a screw hole, and the base passes through the screw hole with a screw and the grinding machine frame (in the figure not shown) are connected. A polygonal fixture plate 20 is provided on the base 10 , and the polygonal fixture plate 20 is a polygonal plate-shaped body made of stainless steel, which is fixed to one side surface of the base 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com