Automatic generation system of numerical control machine tool working diagram

An automatic generation, CNC machine tool technology, applied in the general control system, control/adjustment system, program control, etc., can solve the problems of human design errors in processing drawings, affecting the processing accuracy of CNC machine tools, low processing efficiency and processing accuracy, etc. , to achieve the effects of low cost, good use effect, high processing precision and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

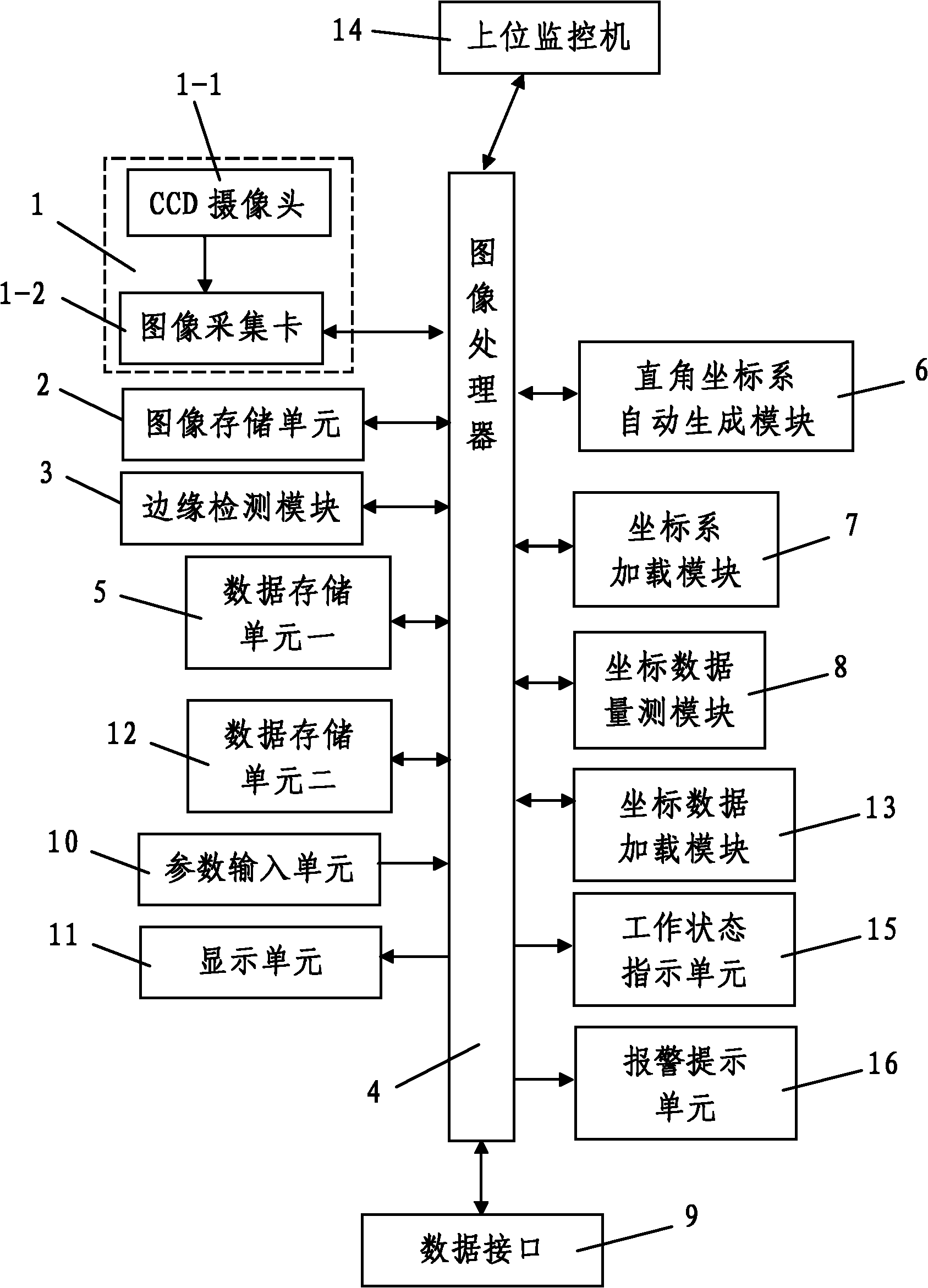

[0028] Such as figure 1 As shown, the present invention includes an image acquisition device 1 for capturing images of molded products, an image storage unit 2 for synchronously storing the images of molded products collected by the image acquisition device 1, and an edge detection unit for edge detection of the images of molded products Module 3, image processor 4 for extracting the outline of the molded product according to the detection result of the edge detection module 3, data storage unit 1 for synchronously storing the outline of the molded product extracted by the image processor 4, for automatically generating a plane The Cartesian coordinate system automatic generation module 6 of the Cartesian coordinate system, the Cartesian coordinate system generated by the Cartesian coordinate system automatic generation module 6 is loaded to the coordinate system loading module 7 on the contour line of the molded product, and the contour line of the molded product is loaded Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com