Topological optimization design method for compliant mechanism with specified real output displacement

A compliant mechanism and topology optimization technology, applied in the field of compliant mechanism topology optimization design and compliant mechanism optimization design, can solve problems such as virtual spring stiffness and not real output displacement, and achieve the effect of avoiding numerical instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055]A topology optimization design method for a compliant mechanism with a specified real output displacement, specifically comprising the following steps:

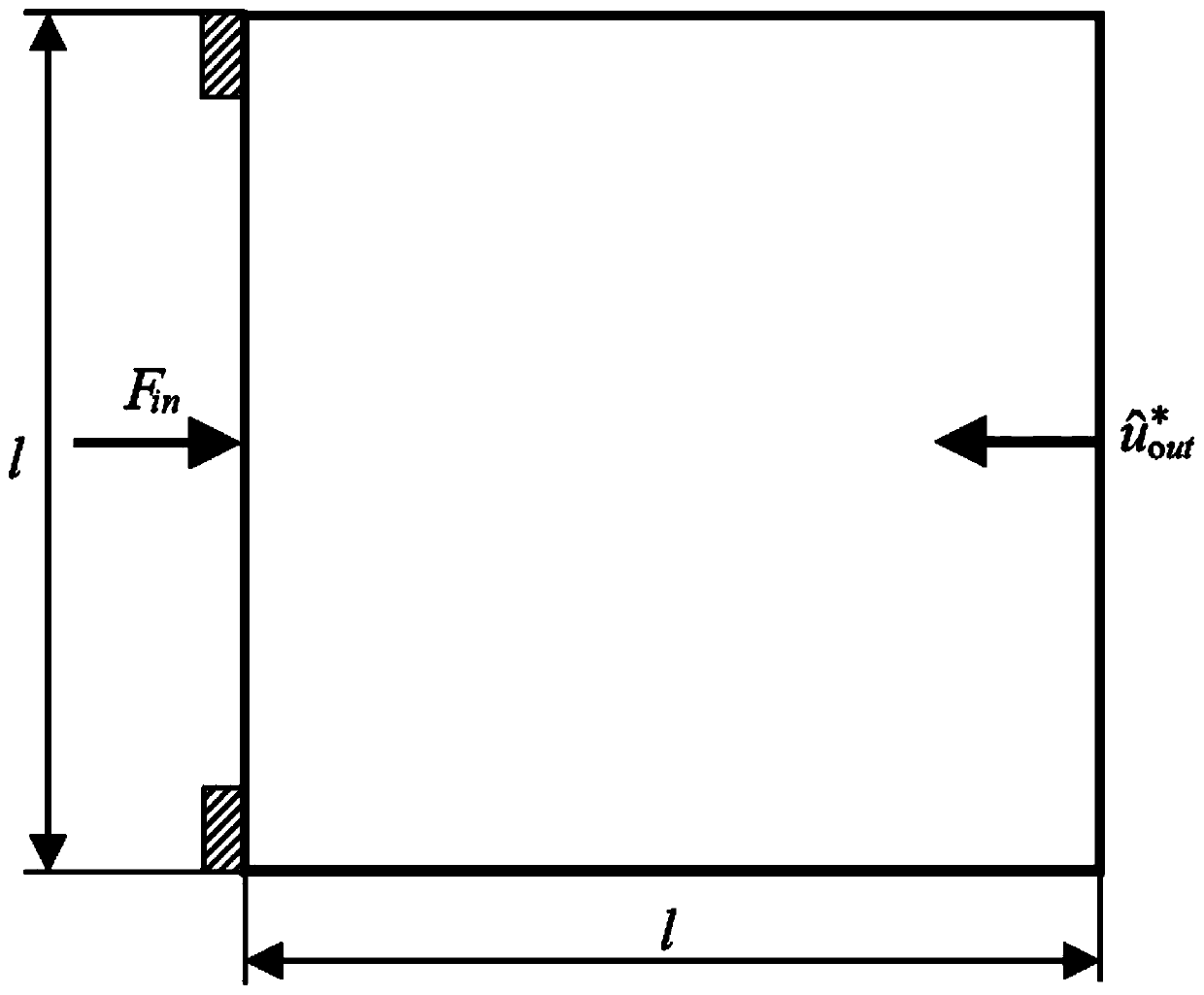

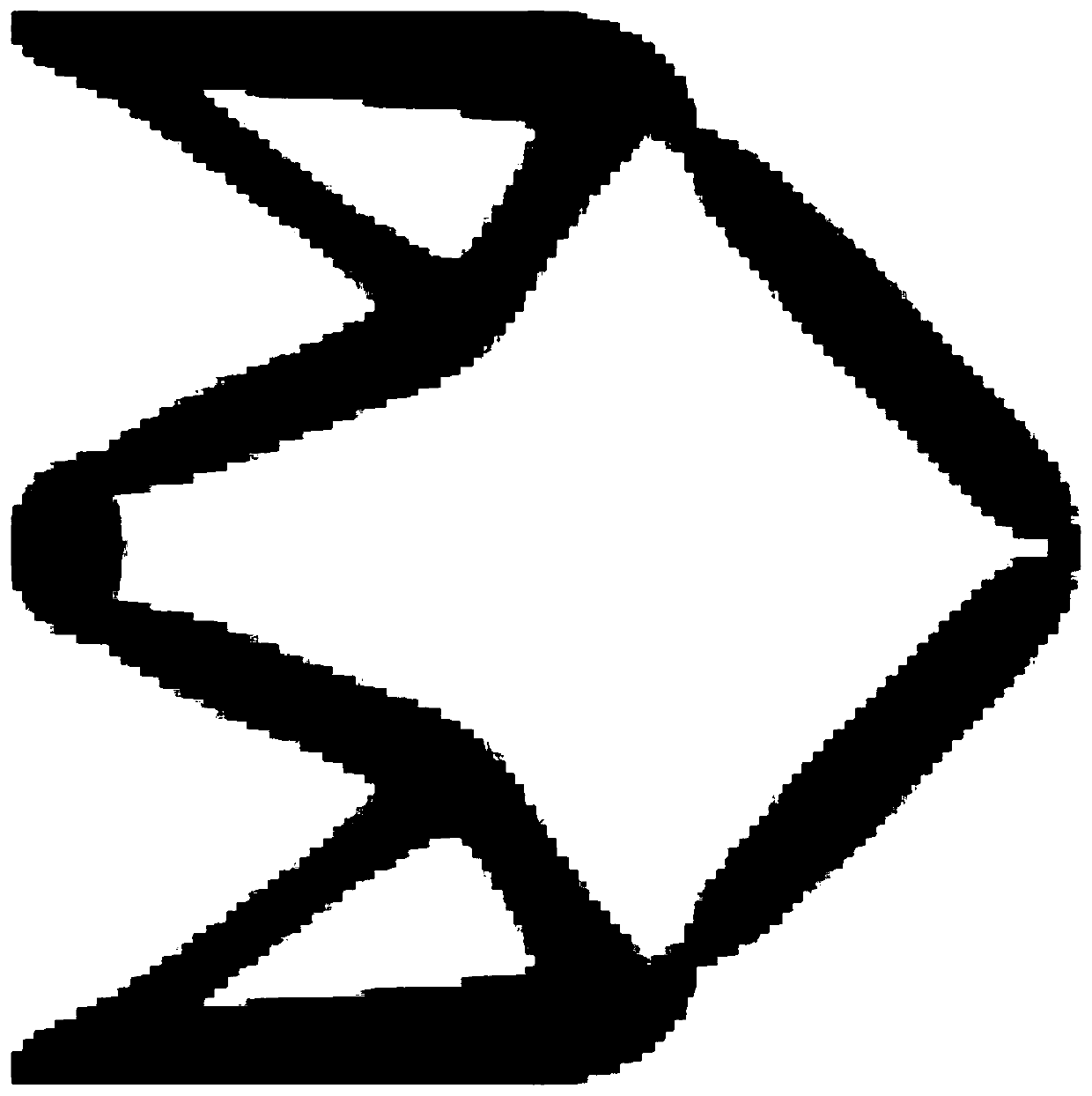

[0056] (a) the compliant mechanism is a compliant displacement reverse mechanism, figure 1 Shown is the design domain of the topology optimization of the compliant displacement inverse mechanism, the design domain is set as a square, the side length l is 100 mm, the upper left corner and the lower left corner are fixed, and the right direction is applied at the midpoint of the left boundary Input force F in For 10N, it is expected that the midpoint of the right boundary produces a displacement to the left with the specified true output The design domain is discretized into 100×100 square finite elements.

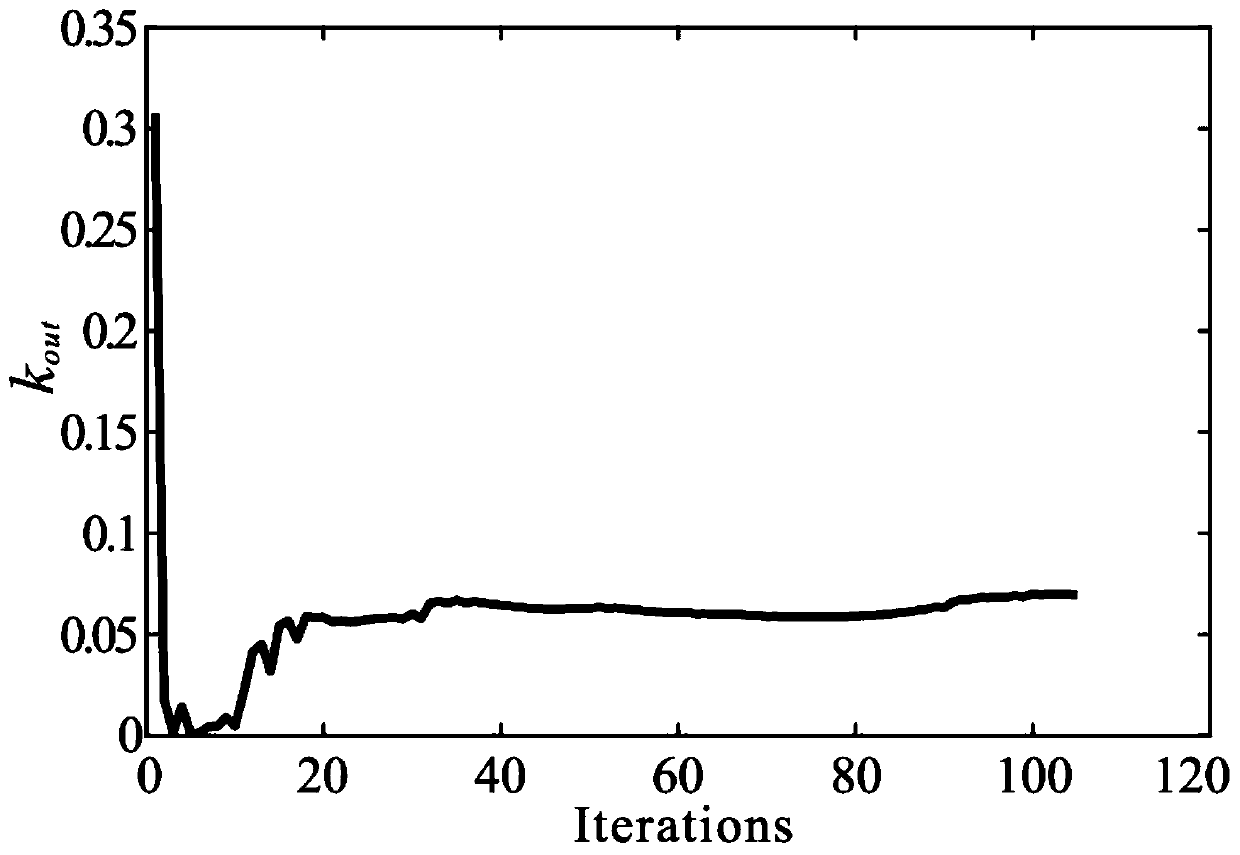

[0057] (b) The Young's modulus of the material in the design domain is set to 1GPa, the Young's modulus of the empty element is set to 0.001GPa, and Poisson's ratio is 0.3, and a virtual input spring is added at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com