Method for controlling tension stability of wrap yarn during wrap feeding and rolling process of loom

A loom and warp technology, which is applied to program control and electrical program control in looms, sequence/logic controllers, etc., can solve problems such as poor flexibility, poor stability and anti-interference ability of single-chip microcomputers, poor flexibility, etc., to achieve Improve warp tension fluctuations, protect safe operation, and stabilize running performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] The object of the present invention is to provide an electronic warp let-off and take-up control system for weaving equipment to control the warp tension fluctuation of the loom during the weaving process in real time, so as to ensure that the warp tension of the loom is basically constant.

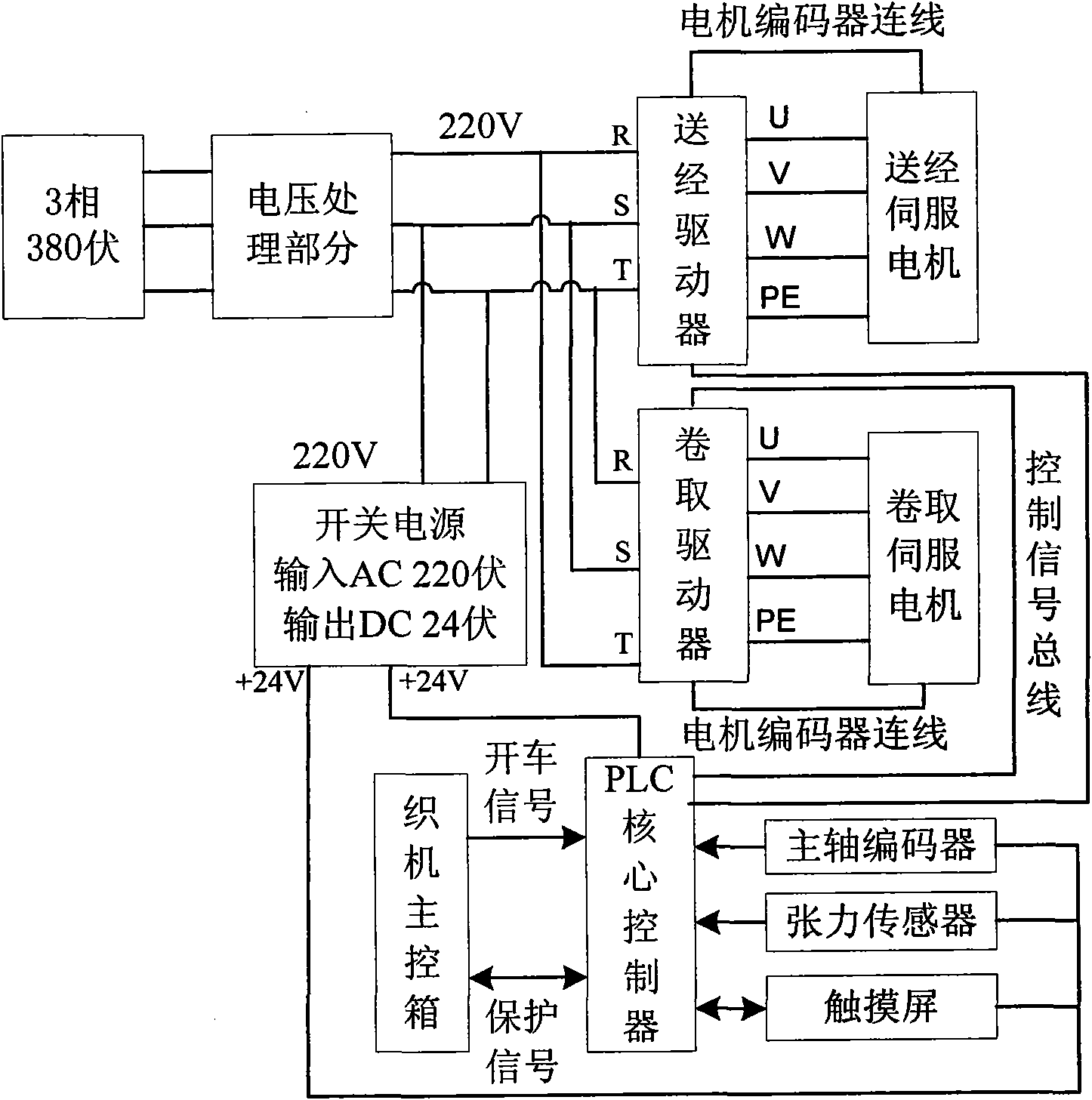

[0016] figure 1 It is the hardware circuit block diagram of the electronic let-off and take-up control system;

[0017] Among them, the voltage processing part includes: contactors, filters, transformers, circuit breakers and other components. The input power of the system is AC three-phase 380V. Firstly, the three-phase 380V voltage needs to be filtered and stepped down by the voltage processing part to make the output voltage be AC three-phase 220V. The AC three-phase 220V voltage provides source voltage for two parts, that is: one part is supplied to the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com