Carpet weaving machine

A technology for weaving machines and carpets, applied in the field of weaving machines, can solve the problems of high labor intensity, low production efficiency, different product quality, etc., and achieve the effects of high degree of automation, high processing efficiency, and many tufting styles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

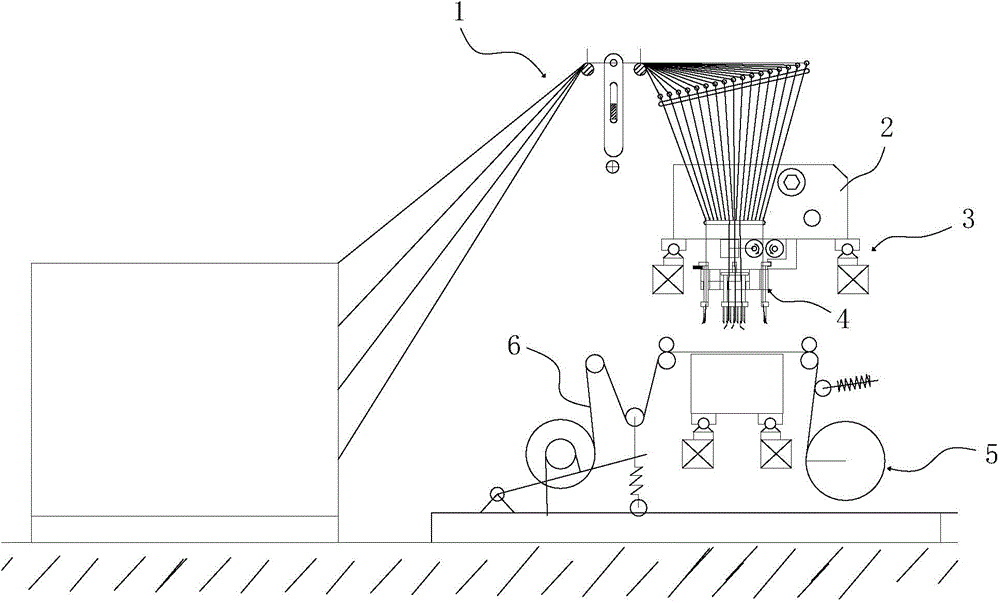

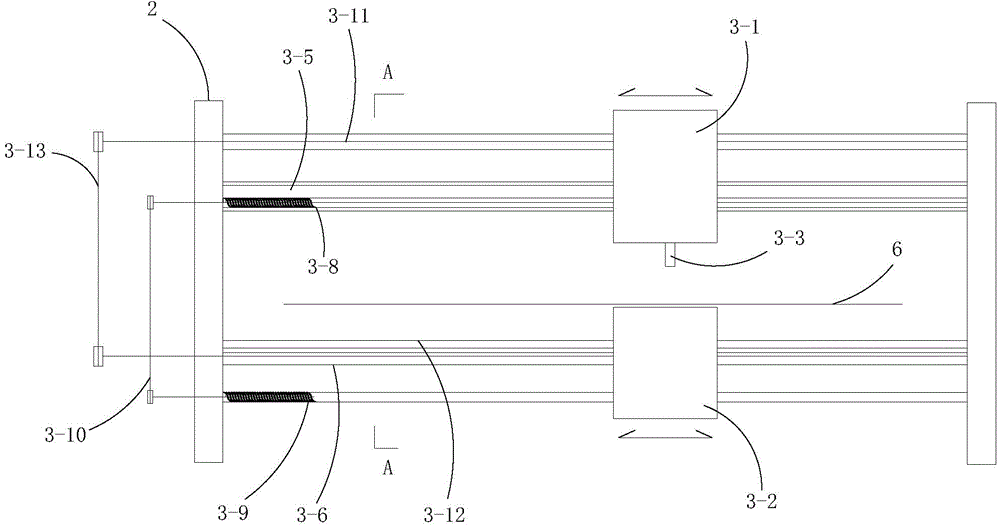

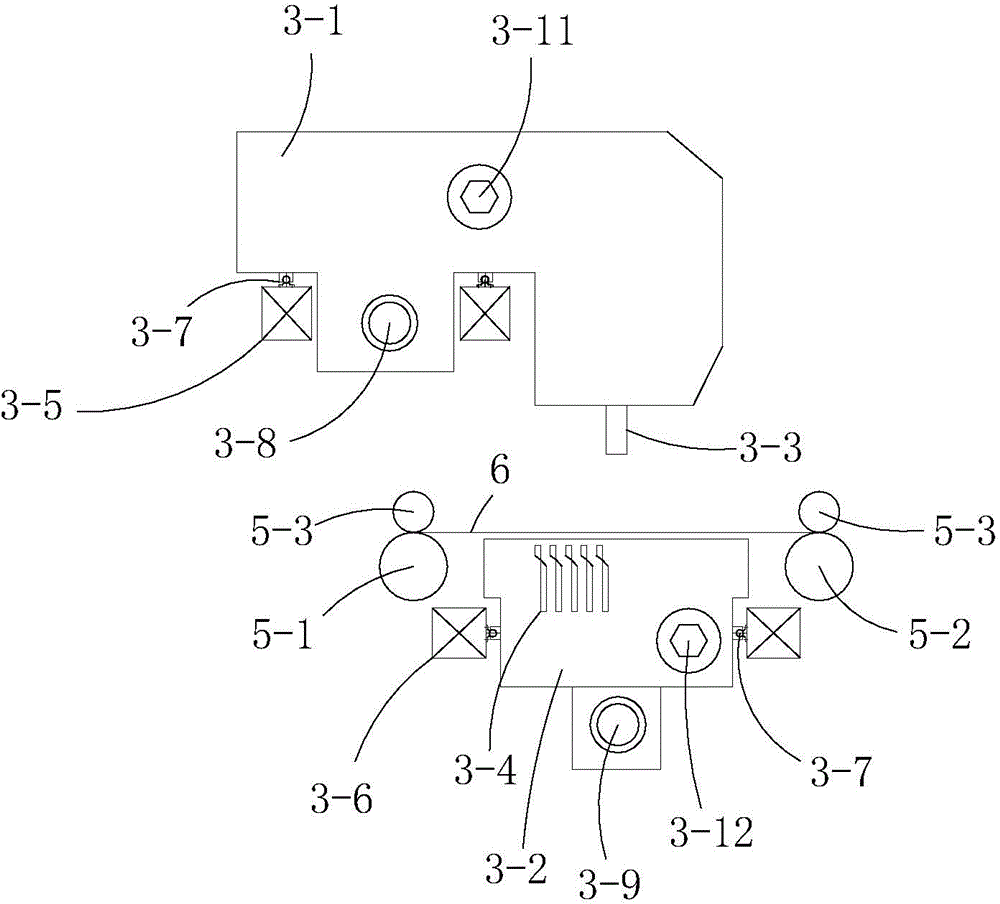

[0030] see figure 1 , a carpet weaving machine, including a yarn placement and synchronous conveying mechanism 1, an electrical control system, a frame 2, and also includes a head traverse mechanism 3, a yarn color selection mechanism 4 and a base cloth feeding mechanism 5. Among them, the yarn placement and synchronous conveying mechanism 1, the electrical control system, and the frame 2 are existing technologies in the textile field, and are well known by technical personnel, and their structures will not be repeated here. The yarn placement and synchronous conveying mechanism 1 is used to place the yarn and deliver the yarn to the upper machine head 3-1 of the machine head traversing mechanism 3; the electrical control system adopts PLC an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com