Plain weave three-dimensional multilayer cylindrical or cylindrical special-shaped braided fabric

A three-dimensional multi-layer, woven fabric technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problems of inability to better adapt to high-pressure pipelines, uneven force, low production efficiency, etc., to achieve compact structure, weaving speed. Fast, strength-enhancing and stress-resistant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

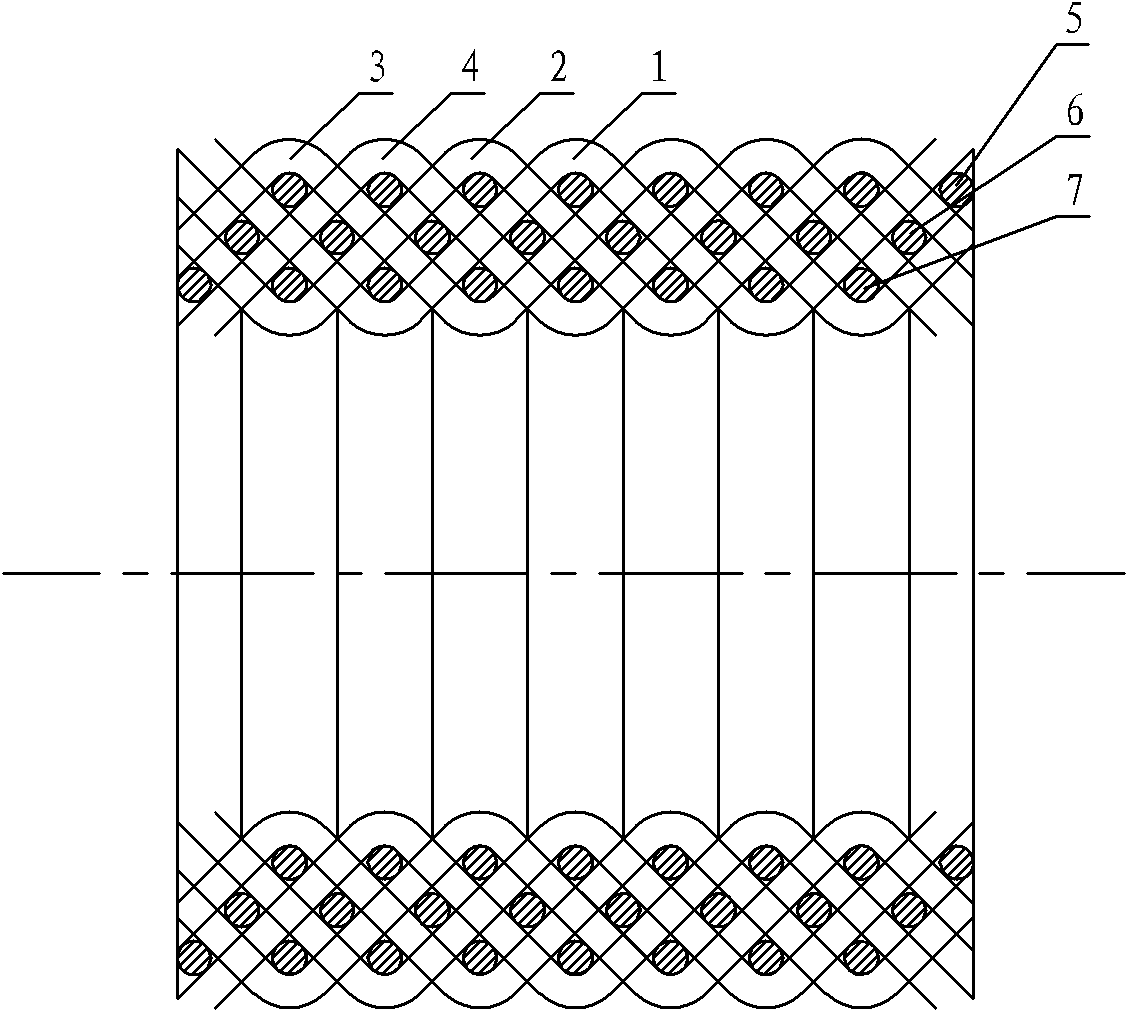

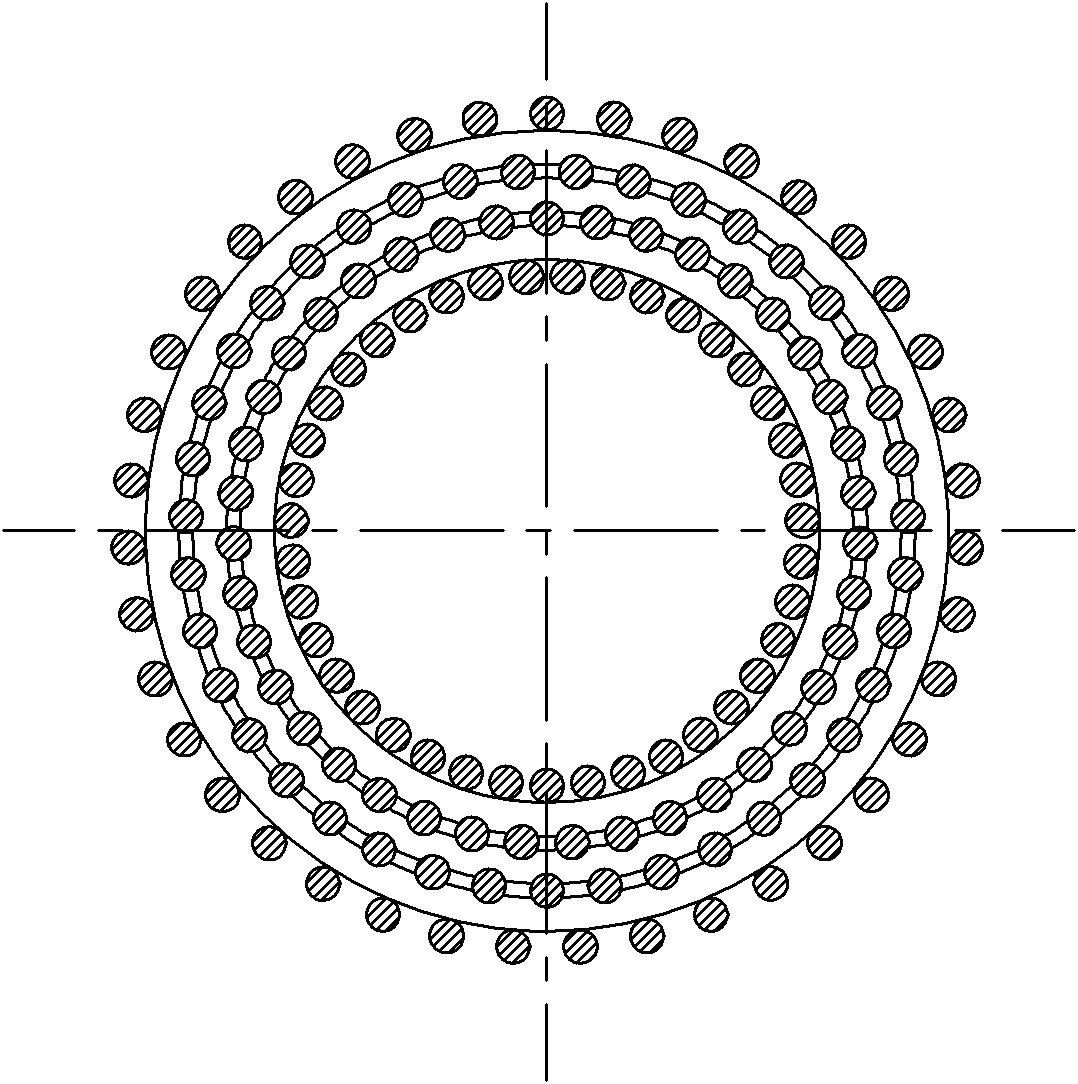

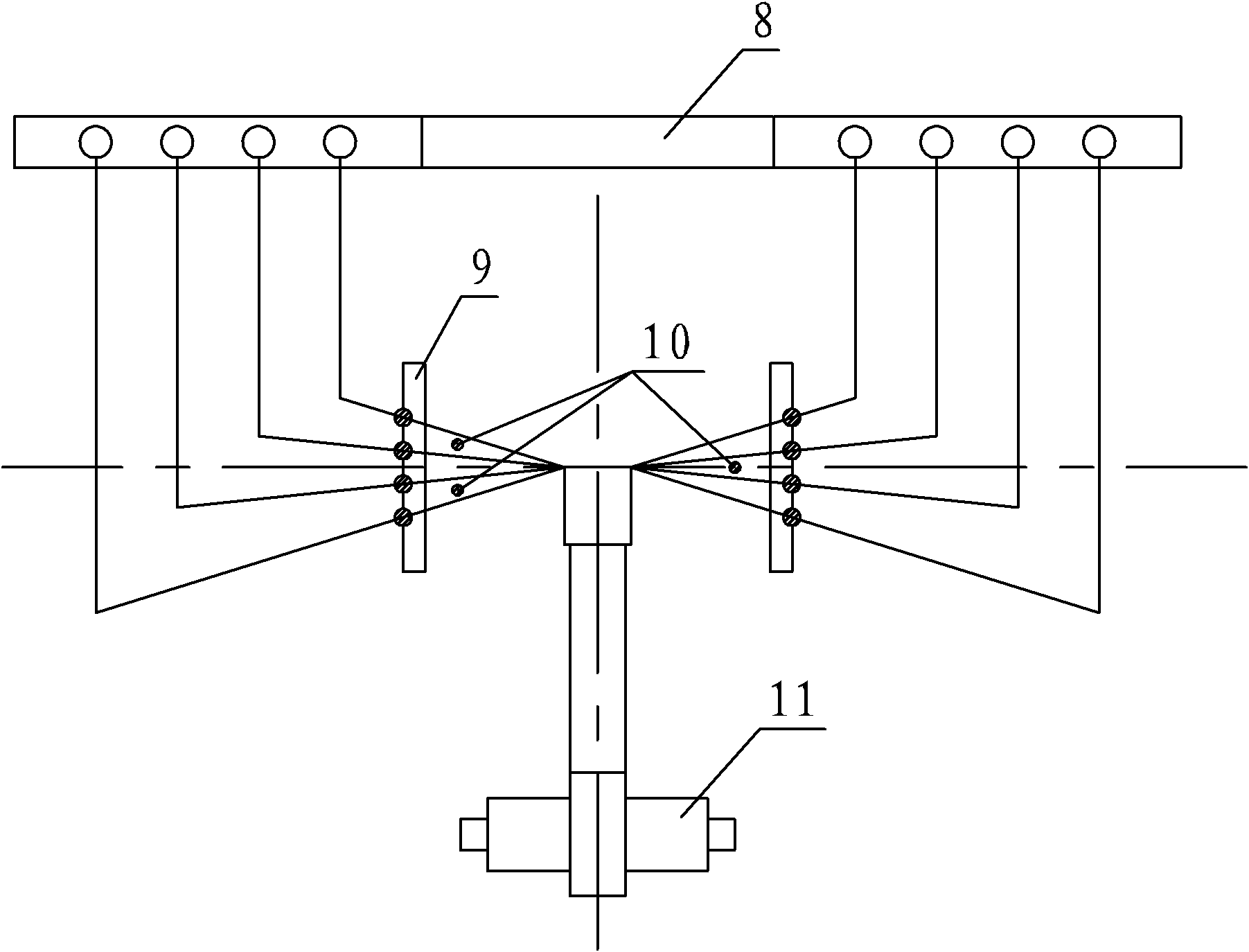

[0015] Such as figure 1 , figure 2 The plain weave three-dimensional multi-layer cylindrical or cylindrical special-shaped braided fabric has a total of 7 layers, and the braided fabric is composed of the first layer of warp yarn 1, the second layer of warp yarn 2, the third layer of warp yarn 3, and the third layer of warp yarn. Four layers of warp yarns 4 and the first layer of weft yarns 5, the second layer of weft yarns 6, and the third layer of weft yarns 7 are interwoven to form a three-dimensional continuous cylindrical braid, the first layer of warp yarns 1 or the second layer of warp yarns 2 or the third layer The warp yarn 3 or the fourth layer of warp yarn 4 all pass through other layers of warp yarn, and each layer of warp yarn and other layers of warp yarn are wound layer by layer to form a continuous cylinder. The first layer of weft yarn 5 or the second layer of weft yarn 6 or the third layer The weft yarn 7 is orthogonally embedded in each layer of warp yarn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com