Design method of reinforcement of fiber composite shell

A technology of fiber composite materials and design methods, applied in pattern design devices, fabrics, textiles, etc., can solve problems such as difficult operation, achieve good overall performance, excellent fatigue resistance, and short weaving cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

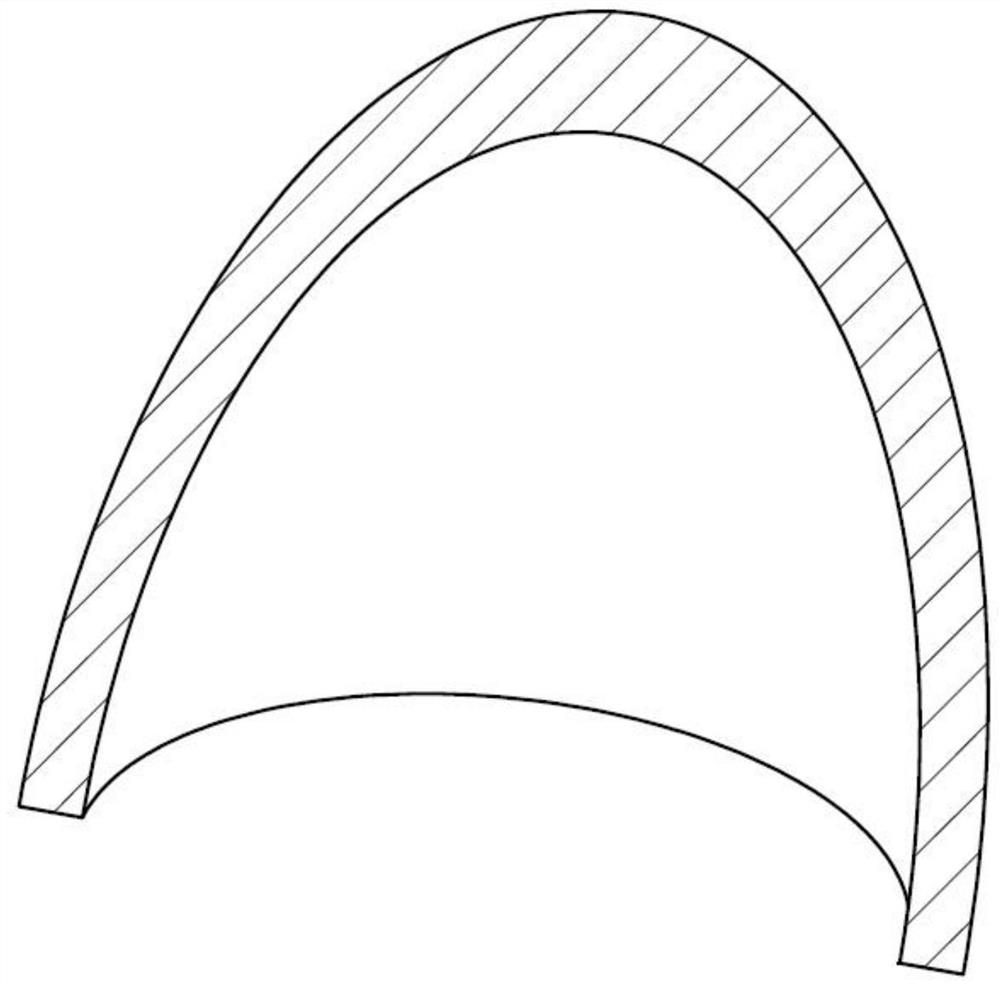

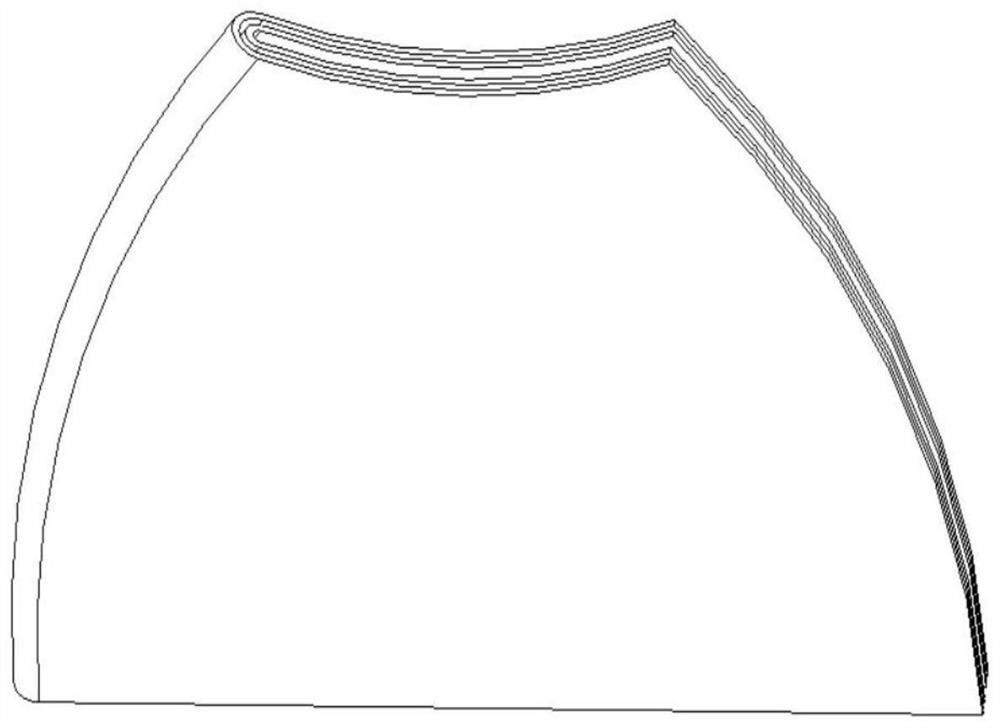

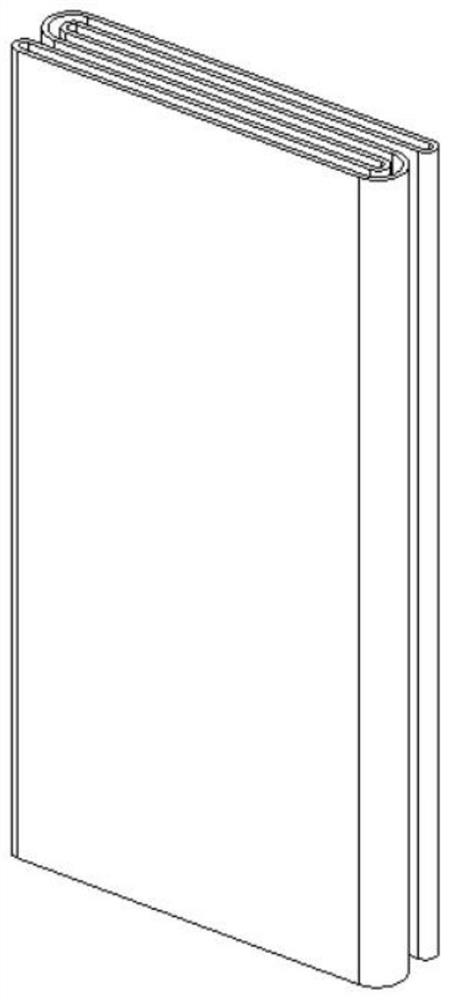

[0059] This embodiment is a regular shell reinforcement fabric, and its shape is as follows figure 1 As shown, the overall thickness is 4mm, as Figure 6 The thickness shown is the same, the diameter of the big end of the fabric is 200mm, the height is 500mm, the warp yarn is 66tex×1 strand of quartz glass fiber, the weft yarn is 66tex×1 strand of quartz glass fiber, the warp density is 16 threads / cm, and the weft density is 12 threads / cm cm for weaving. The design method is as follows: firstly, the overall thickness of the fabric is 4 mm, and the fiber composite shell reinforcement has low performance requirements between layers, so the total thickness is decomposed into 20 unit cone sleeves with a thickness of 0.2 mm; secondly, the fabric is The regular shell is designed by the two-piece method; the section is a regular circle, and the perimeter corresponding to different station heights is calculated by mathematical methods, and 1 / 4 of the perimeter is taken as the width o...

Embodiment 2

[0064] This embodiment is a regular shell reinforcement fabric, and its shape is as follows figure 1 As shown, the maximum overall thickness is 5mm, the minimum is 4mm, the thickness from the top of the shell to the bottom is 400mm, the thickness is 4mm, and the thickness is gradually thickened from the position of 400mm to the top. 5mm, bottom 50mm length and thickness 5mm unchanged, the diameter of the big end of the fabric is 200mm, the height is 500mm, the warp yarn is 66tex×1 strand of quartz glass fiber, the weft yarn is 66tex×1 strand of quartz glass fiber, the warp density is 16 threads / cm, The weft density is 12 threads / cm for weaving. The design method is as follows: firstly, the maximum thickness of the fabric is 5mm, and the minimum thickness is 4mm. According to the minimum thickness, it is decomposed into 20 unit cone sleeves with a thickness of 0.2mm, and the maximum thickness is decomposed into 20 unit cone sleeves with a thickness of 0.2mm and 5 A truncated c...

Embodiment 3

[0066] This embodiment is a regular shell reinforcement fabric, and its shape is as follows figure 1 As shown, the maximum overall thickness is 5mm, the minimum is 4mm, the thickness of 4mm remains unchanged from the top of the shell to the bottom of 400mm, and the thickness gradually becomes thicker from the position of 400mm to the bottom, and the thickness range is 50mm. 5mm forms a variable thickness interval, the bottom is 50mm long and the thickness is 5mm unchanged. The diameter of the big end of the fabric is 200mm and the height is 500mm. The warp yarn is 66tex×1 strand of quartz glass fiber, the weft yarn is 66tex×1 strand and 66tex×2 strand of quartz Glass fiber is woven with a warp density of 16 threads / cm and a weft density of 12 threads / cm. The design method is as follows: firstly, the maximum thickness of the fabric is 5mm, the minimum thickness is 4mm, according to the minimum thickness, it is decomposed into 20 unit cone sleeves with a thickness of 0.2mm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com