Horizontal knitting machine

A technology of flat knitting machine and head, applied in the direction of weft knitting, knitting, textile and paper making, etc., can solve the problems of high energy consumption, affecting the economic benefits of enterprises, and low transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention can be explained in more detail through the following embodiments:

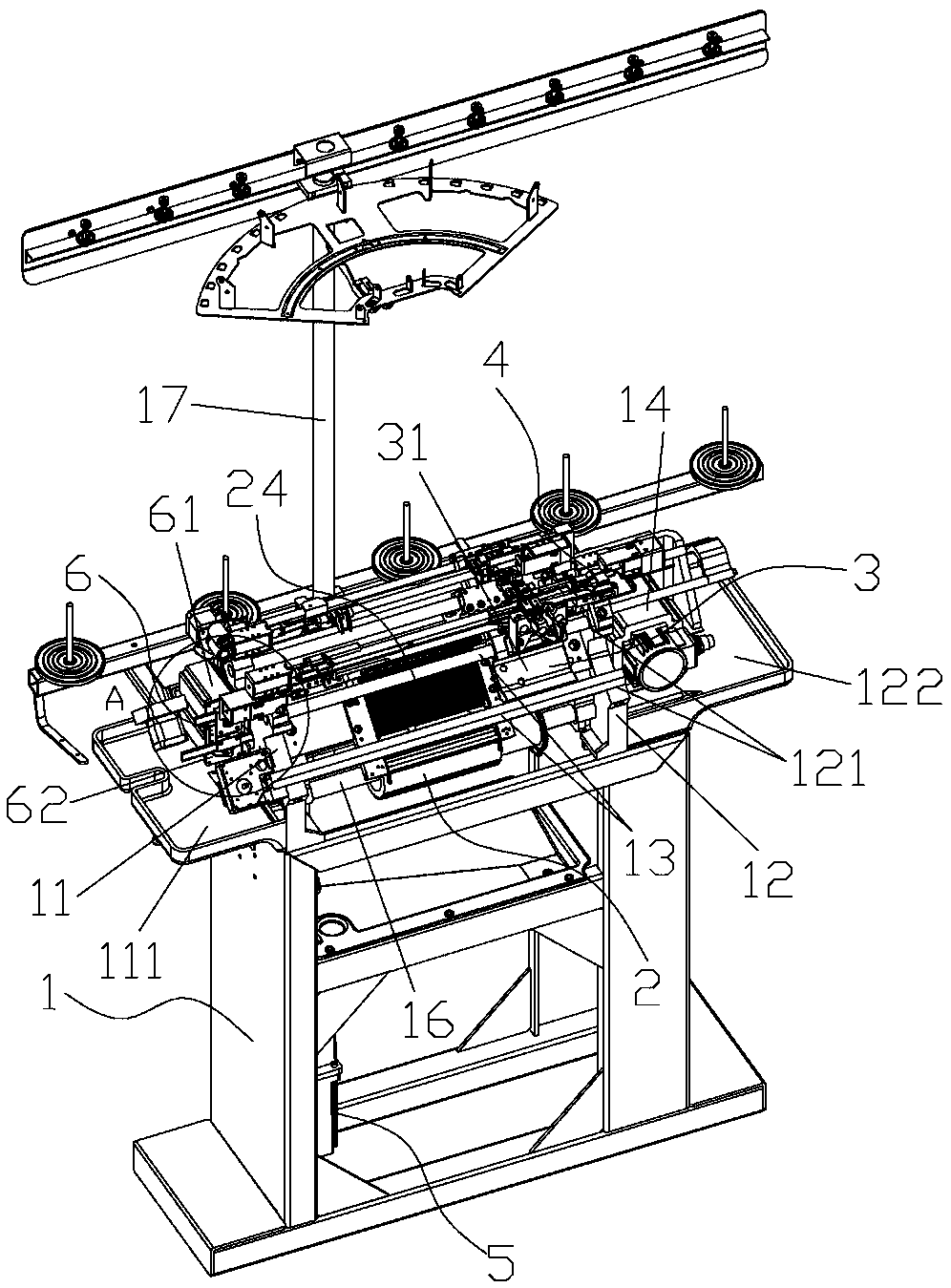

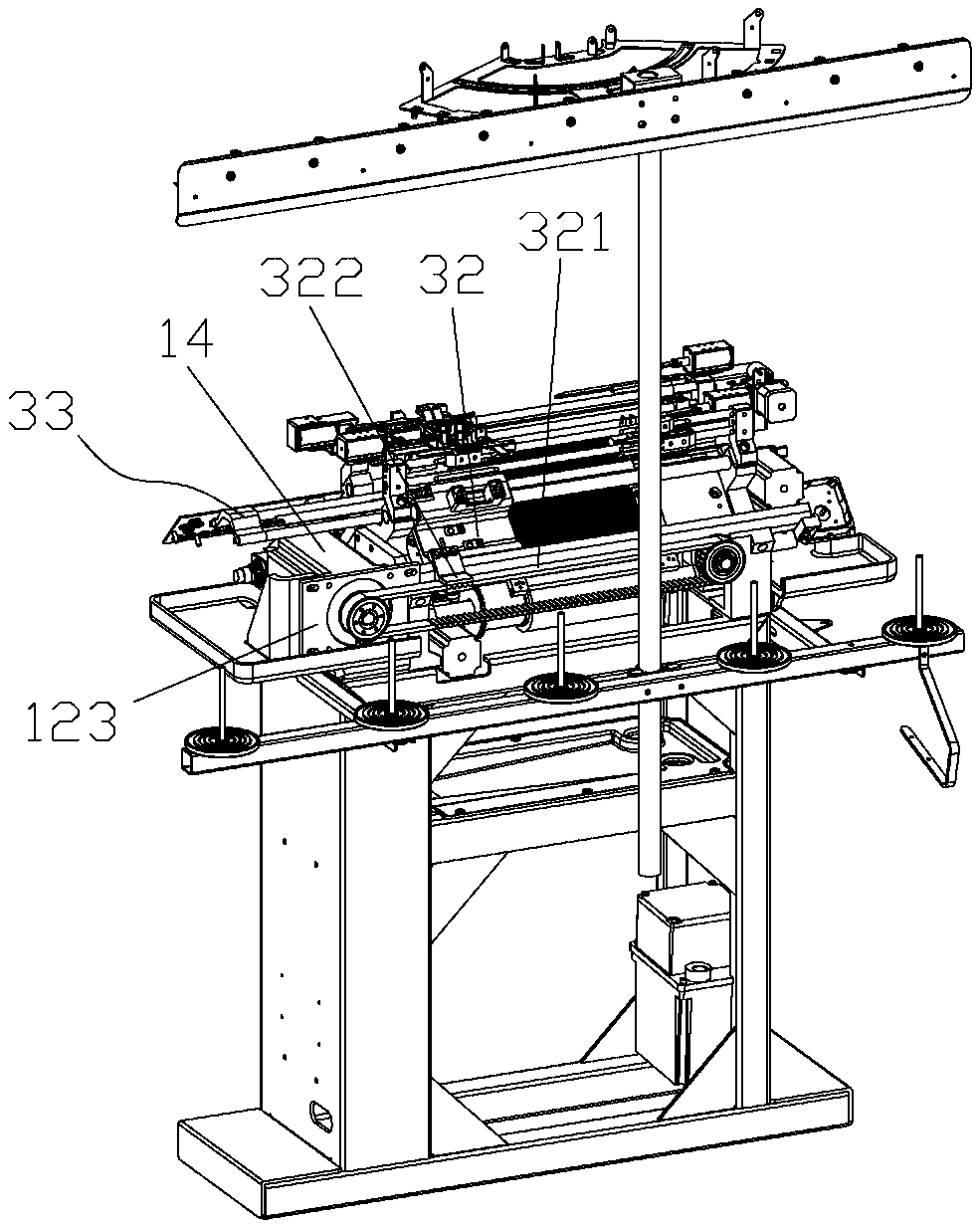

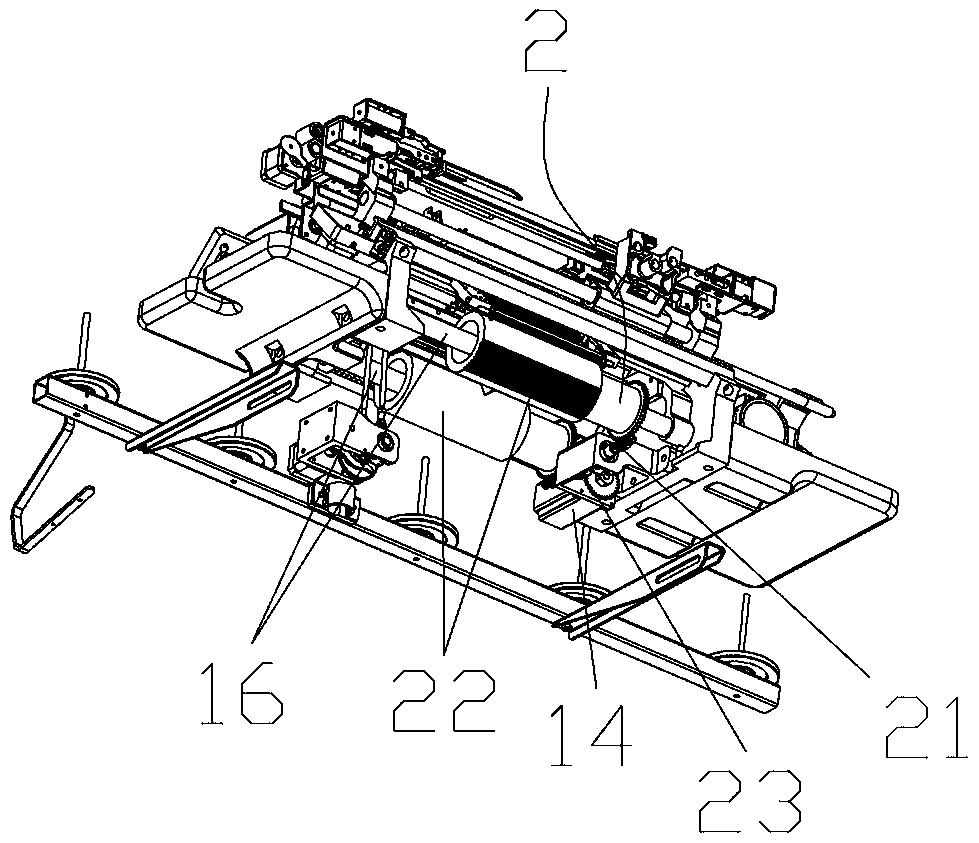

[0039] Such as figure 1 , 2 A flat knitting machine shown includes a main frame 1, a left base 11 and a right base 12 are arranged on the main frame 1, and a needle selection system 2 is arranged between the left base 11 and the right base 12. The top of the system 2 is provided with a slide rail assembly 13, the slide rail assembly 13 is installed on the left base 11 and the right base 12, the slide rail assembly 13 is provided with a machine head part 3, and the machine head part 3 includes a front machine head assembly 31 With the rear nose assembly 32, the front nose assembly 31 and the rear nose assembly 32 are arranged symmetrically or asymmetrically before and after, and the right side lower end of the right base 12 is provided with a motor seat 122, combining Figure 12 , the front side of the motor base 122 is provided with a control operation panel 124, the motor base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com