Velveteen air jet loom

An air-jet loom and velveteen technology, which is applied in flannelette looms, looms, textiles, etc., can solve the problems of weaving quality decline, affecting tension control, and low production efficiency, and achieve stable velvet tension control, fast weaving speed, fully functional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with drawings and embodiments.

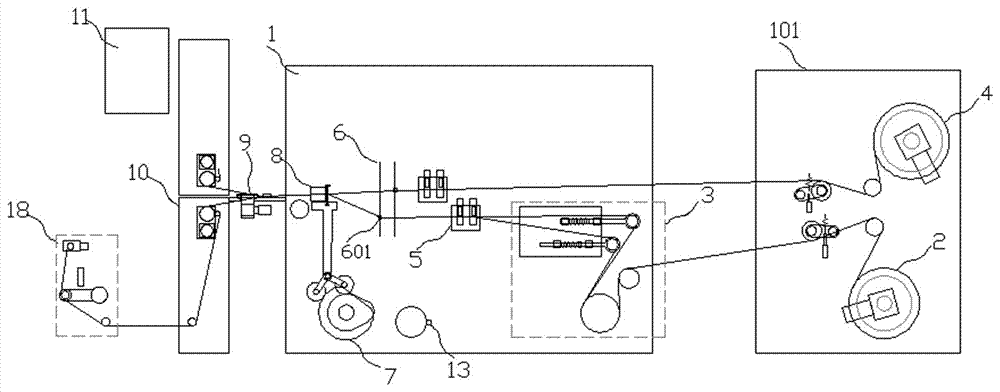

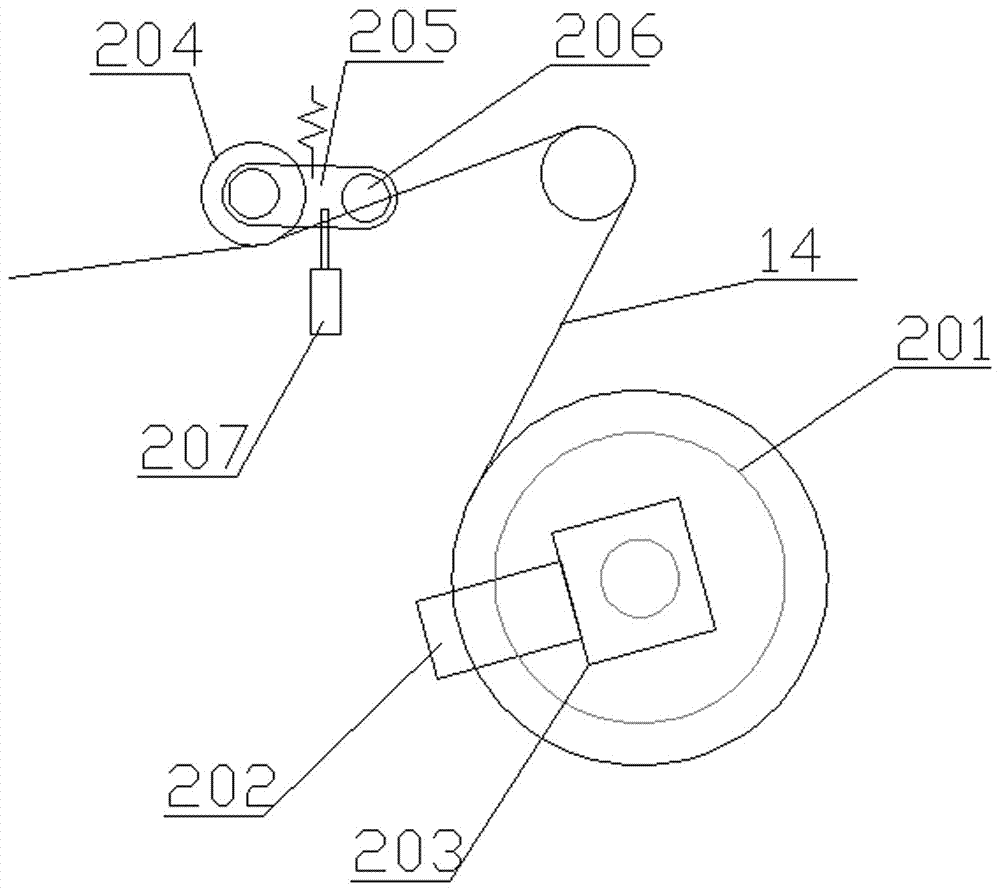

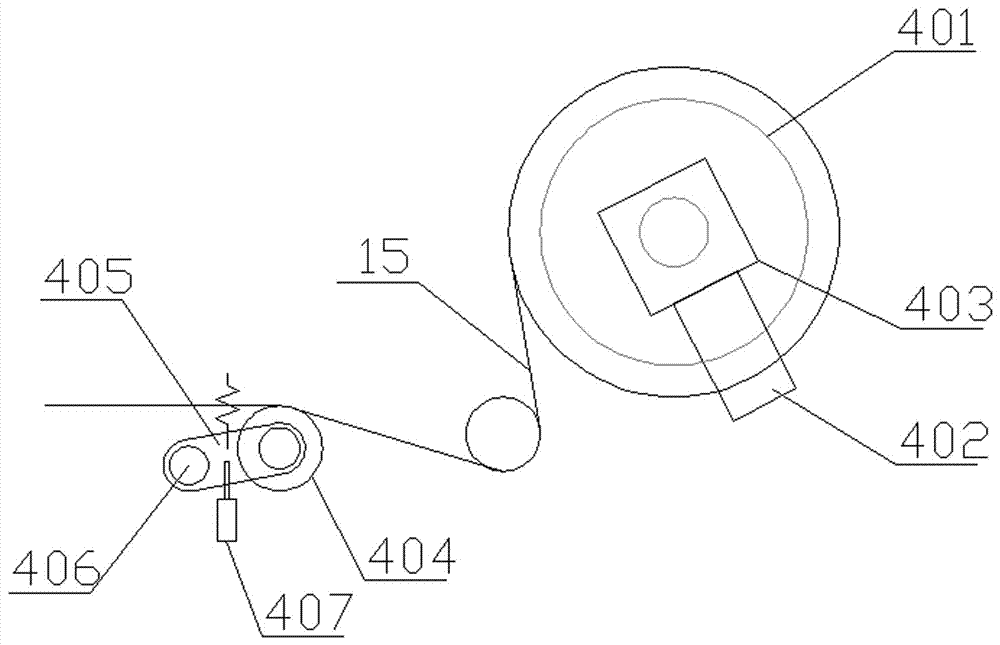

[0036] Figure 1-11 As shown: a velveteen air-jet loom includes a main frame 1, a warp let-off frame 101, a pile shaft warp let-off mechanism 2, a bottom shaft warp let-off mechanism 4, a numerically controlled cashmere feed mechanism 3, a warp stop mechanism 5, an opening mechanism 6, a Weft mechanism 7, air jet weft insertion mechanism 8, double-layer cutting mechanism 9, coiling mechanism 10, cloth rolling mechanism 18, weft finder 12 and electric control box 11. The encoder 13 is set on the main shaft of the loom or a shaft synchronous with the main shaft of the loom to rotate synchronously, and transmits electrical signals and pulse signals to the electric control box to feed back the angle of the main shaft of the loom and control the starting and ending angles of the action of each electrical part of the loom . The warp beam let-off mechanism 2 on the warp let-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com