Automatic winding machine for spring wire

An automatic winding machine and spring wire technology, applied in the direction of non-rotational vibration suppression, etc., can solve the problems of difficult to ensure accuracy of spring wire, unstable tension control, high labor intensity, etc., to improve accuracy, improve versatility, and ensure consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

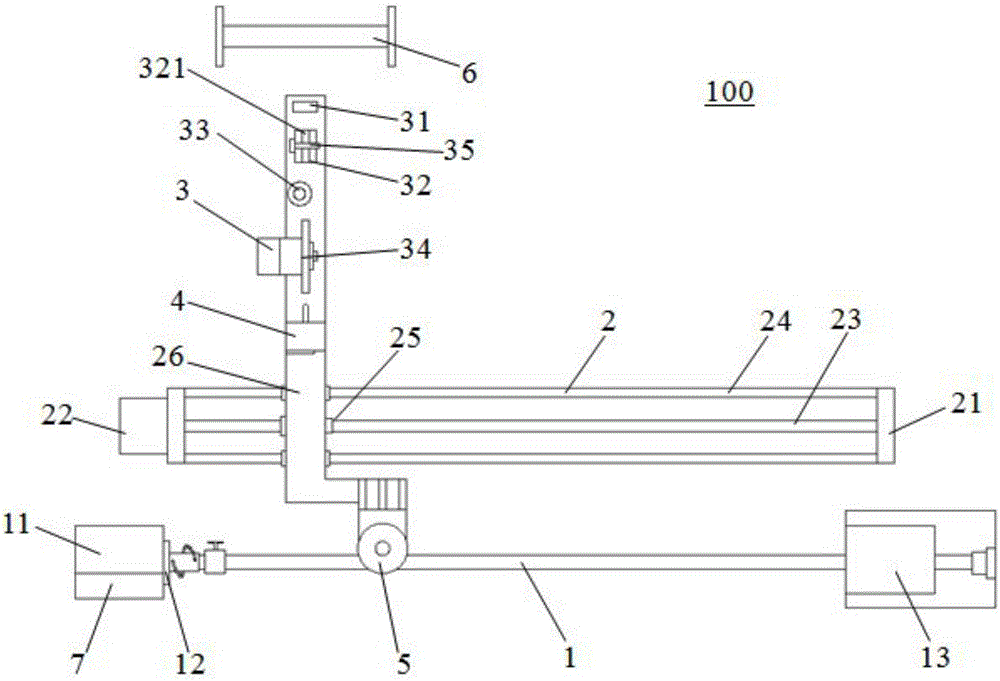

[0037] Please refer to Figure 1-Figure 5 , the present embodiment is an automatic winding machine 100 for spring wire, which includes a winding drive device 1, a transfer device 2 arranged horizontally with the winding drive device 1, and a cable guide device that moves on the transfer device 2 3. The cutting device 4 and the shock absorbing device 5 , the pay-off frame 6 and the control unit 7 for supporting the cable coil.

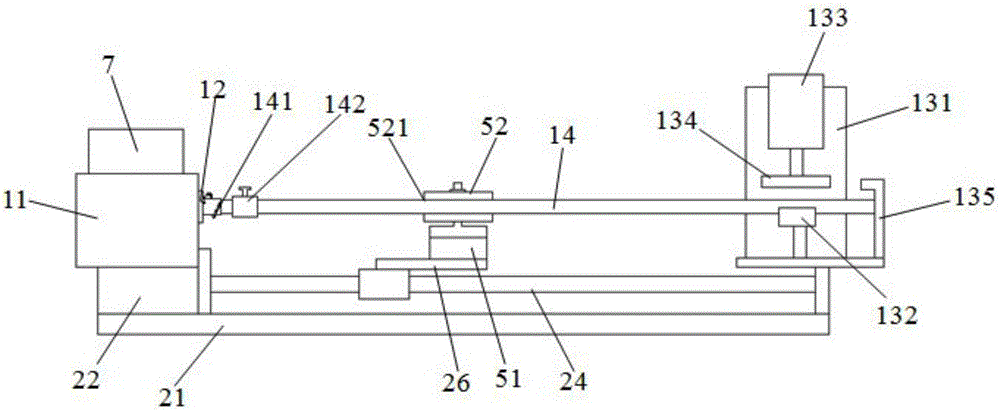

[0038] The winding driving device 1 includes a first driving device 11, a jaw 12 fixed on the rotating end of the first driving device 11 and adjustable in size, a supporting device 13 positioned at the tail of the winding driving device 1, one end fixed on the jaw 12 and The other end is fixed on the bobbin 14 on the supporting device 13 . The support device 13 includes a first support 131, a support roller 132 fixed on the first support 131 for supporting the bobbin 14, a first air cylinder 133 positioned above the support roller 132, a pressure cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com