A high-stability composite screen making device

A technology of composite screen plate and production device, which is applied in printing plate preparation, printing and other directions, can solve the problems of easy breaking of the screen, moiré production efficiency, difficult control of tension uniformity, etc., and achieves short production time, high production efficiency, and tension. Controlling stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

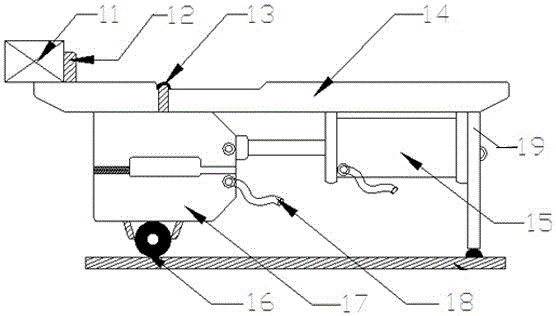

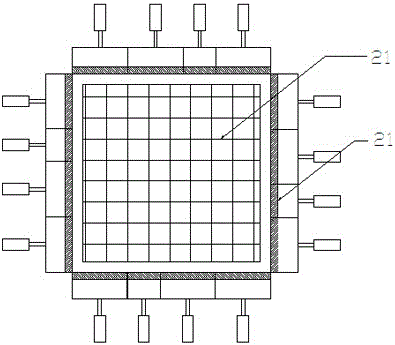

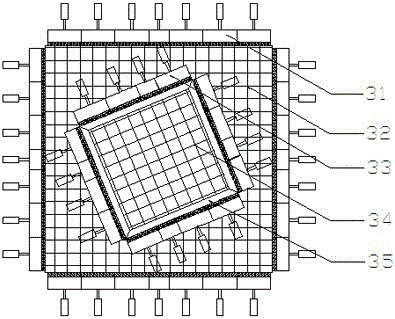

[0017] refer to Figure 1 to Figure 4 , the present invention relates to a high-stability composite screen making device, comprising a base 40, the base is provided with a support 49 driven by an oil cylinder or cylinder power 48, and the support is provided with a lifting platform 45, the The four sides of the lifting platform are respectively provided with a screen frame pre-stress device 42 and an operating table 47 positioned at the outside of the screen frame pre-stress device, and a polyester mesh 44 is arranged between the two screen frame pre-stress devices The screen frame 43 above the polyester mesh, and the polyester mesh can be used repeatedly, and a pneumatic or mechanical stretching machine 46 is respectively provided on the two operating tables, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com