Method for preparing graphene two-dimensional material through liquid-phase stripping

A liquid phase exfoliation, two-dimensional material technology, applied in graphene, chemical instruments and methods, inorganic chemistry and other directions, can solve the problems of low yield, large pollution, complex process, etc., to achieve high yield, low price, process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a liquid phase exfoliated graphene two-dimensional material, the method is implemented through the following steps:

[0031] (1) Mix 5g of graphite powder, 500mL of water, and 500mL of isopropanol in a beaker with a capacity of 2L, submerge the cutter head of the emulsification cutter under the liquid surface, and keep the cutter head at 8000rpm in a water bath at 40°C. The mixture was cut for 2h.

[0032] (2) Put the mixed solution after step (1) into a cell disruptor, and in a water bath at 40° C., maintain a power of 800 W, and sonicate the mixed solution for 30 minutes.

[0033] (3) The emulsification and cutting step described in step (1) and the ultrasonic step described in step (2) are alternately performed on the mixed solution for a total of 5 rounds of alternation.

[0034] (4), centrifuge the mixed solution of step (3) at a rotating speed of 3000rpm for 15min, and collect the supernatant, which is the graphene dispersion. The precipit...

Embodiment 2

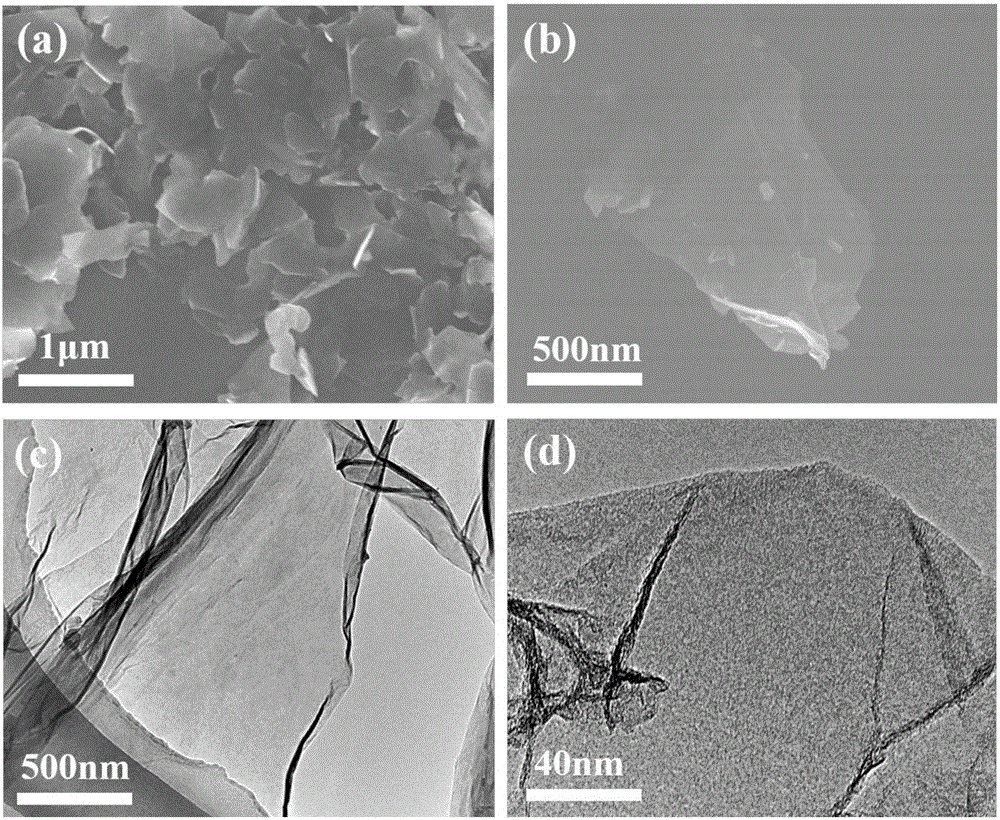

[0038] A kind of preparation method of the graphene two-dimensional material of liquid phase exfoliation, its method step is basically the same as embodiment 1, difference is, the ratio of feeding capacity of water and isopropanol is 3:7, the appearance of gained graphene is carried out Characterized, the average lateral dimension of graphene is between 0.1-3 μm, the thickness is between 1-20 nm, and the yield is 1%.

[0039] image 3 It is the characterization result of the liquid-phase exfoliated graphene in Example 2, which proves that the lateral dimension of the graphene is between 0.1 μm and 3 μm. image 3 (c) and (d) are transmission electron microscopy (TEM) images, which further confirm the above-mentioned lateral dimensions of graphene and its ultrathin characteristics.

Embodiment 3

[0041]A kind of preparation method of the graphene two-dimensional material of liquid phase exfoliation, its method step is basically the same as embodiment 1, and difference is that the ratio of water and isopropanol feed capacity is 7:3, and the morphology of gained graphene is carried out Characterized, the average lateral size of the graphene is between 0.1-3 μm, the thickness is between 1-20 nm, and the yield is 0.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com