Wire-releasing machine for manufacturing continuous carbon fibers

A wire-drawing machine and carbon fiber technology, which is applied to the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of unstable fiber tension and unreasonable arrangement of wire-drawing racks, etc., to achieve reasonable layout, ensure uniformity and stability , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

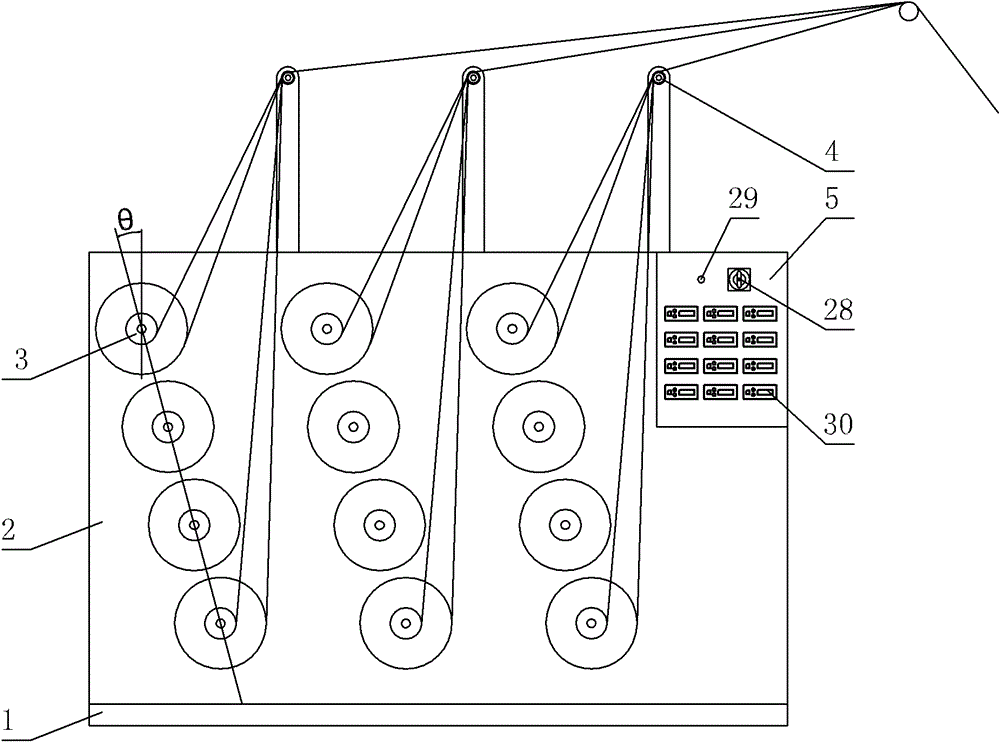

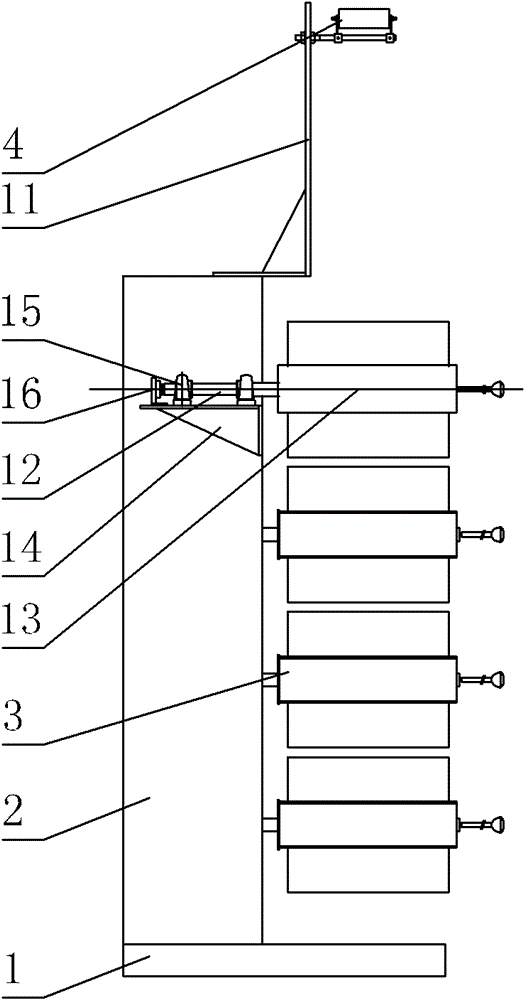

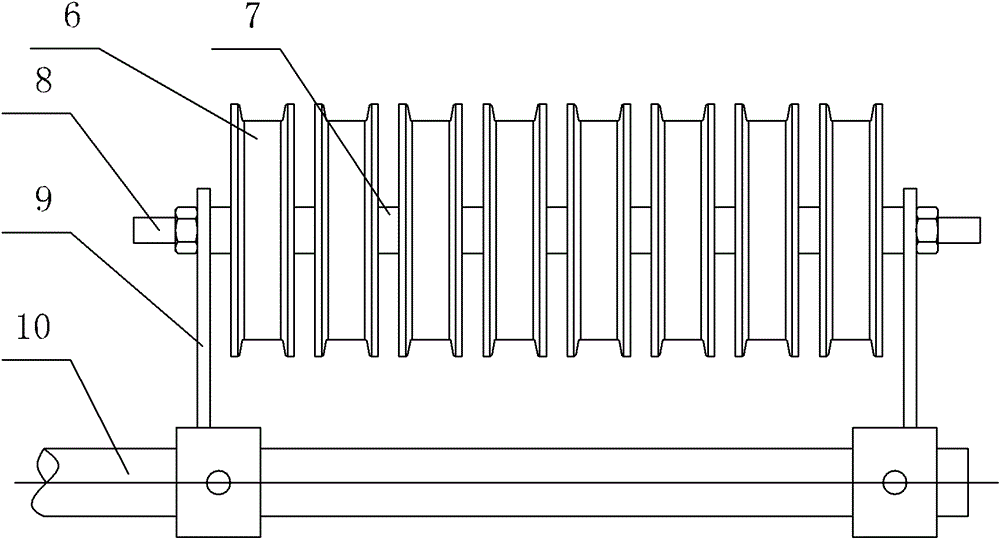

[0034] Such as Figure 1 to Figure 4 As shown, a wire-drawing machine for producing continuous carbon fibers includes a base 1, a box body 2, a plurality of wire-drawing racks 3 arranged on the side of the box body 2 in an "array" manner, and a mounting frame 11 arranged on the box body 2 multiple godet roller assemblies on the top 4, control box 5, the control box is set on the upper right side of the box body, the control box is composed of the wire unwinding machine power switch and its indicator light, the tension controller instrument system, the control instrument rough adjuster and The control instrument is composed of a fine tuner, and the control box is required to have an explosion-proof function. Each godet assembly 4 corresponds to a row of pay-off frames 3 .

[0035] The "array" arranged by the wire rack 3 satisfies the following parameters:

[0036] (1) Row spacing: A=Φout+(20~150)

[0037] (2) Column spacing: B=Φout+(m-1)Atanθ+ (20~200)(50~200)

[0038] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com